First, we got anti-lock brakes, controlling wheel speed while decelerating. This evolved into traction control, controlling wheel speed under acceleration. Now we have advanced versions of Dynamic Stability Control. BMW drivers are safer than ever before, but how do we keep this winning streak going?

When drivers enter a BMW vehicle, they have a certain expectations. They expect lively acceleration along with a smooth idle. They expect a taut suspension, but not one so stiff it’s jarring. They expect the car to “ride on rails†through a corner even with road irregularities. Over the years, BMW has built its sporty reputation on engine performance and precise handling.

When replacing a wheel speed sensor, it is important to route the wiring as you found it in its various holding clips on the strut and in the connector housing. You don’t want the sensor wiring tugging on the sensor or the connector because eventually it will fail.

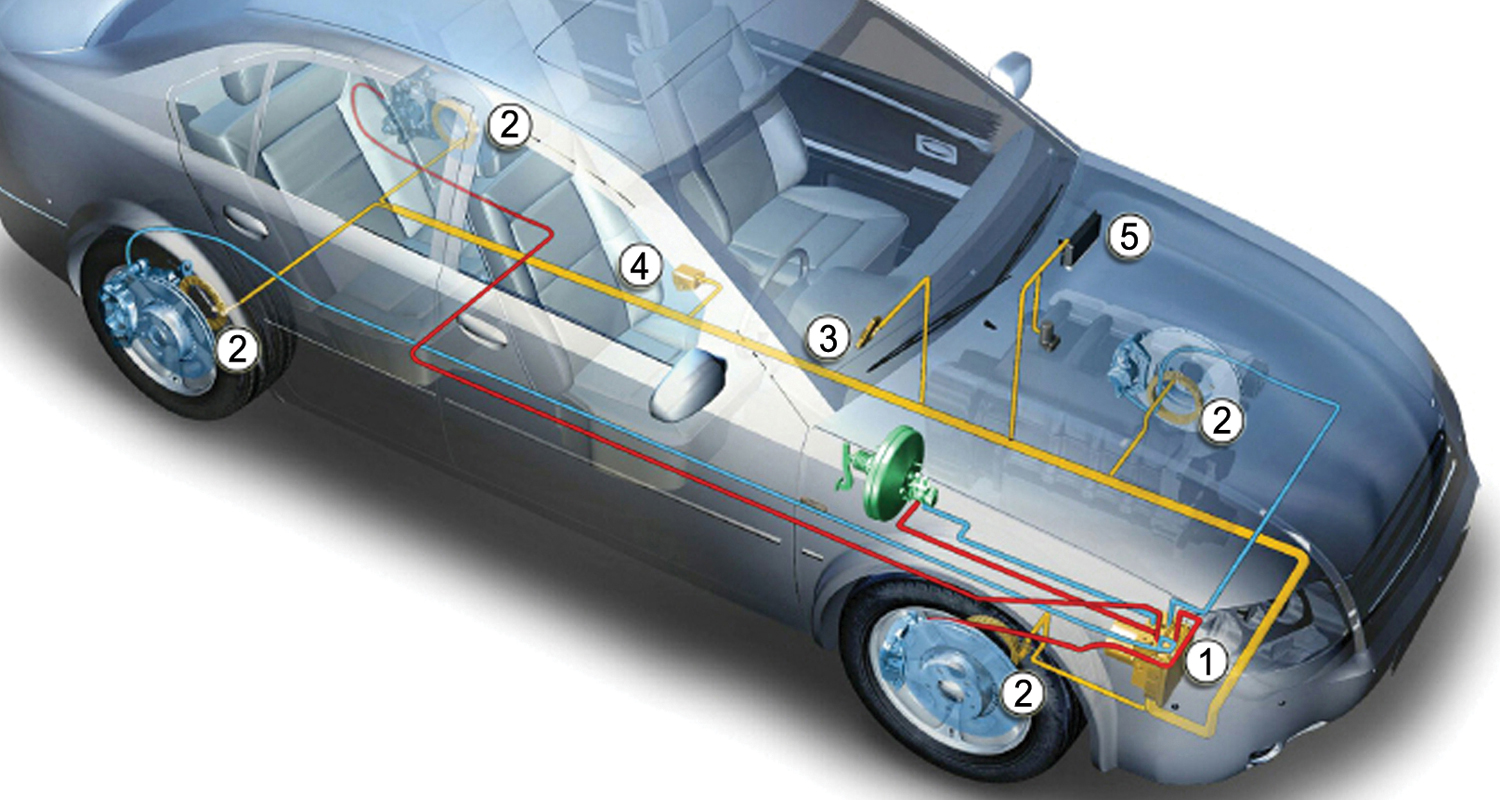

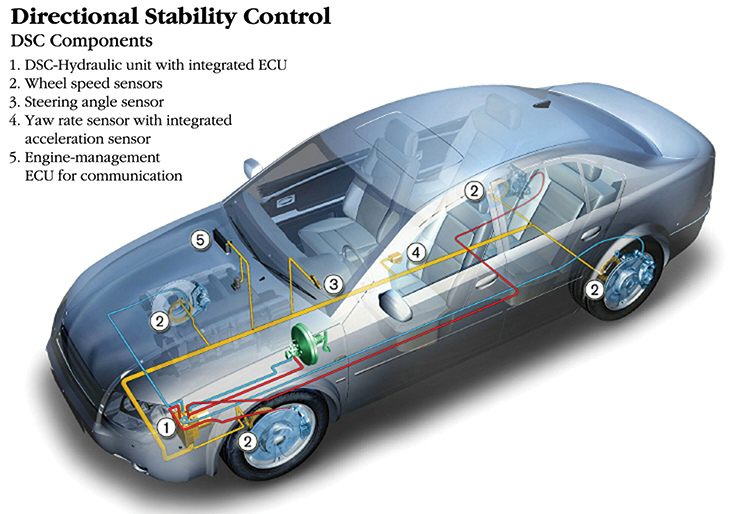

Later model BMW suspension systems are integrated with anti-lock brake and traction control systems to form Dynamic Stability Control (DSC). The electronic control units involved share information about the car’s rate of acceleration or deceleration, body roll in a corner, and individual wheel speeds. Although DSC has been with us for a while now, many technicians do not realize the extensive developments that have occurred on the software side of DSC. These features help reduce braking distances by anticipating the driver’s needs and taking into account environmental conditions from information on the CAN. Also, most drivers do not realize everything that is involved — they only notice when it does not work.

Most complaints will have to do with a DCS warning light, although some customers may notice that they no longer have a speedometer reading, or that the vehicle isn’t shifting properly. You may not think of querying the DSC unit right away unless you already know that it acts as the vehicle speed sensor for the entire car. The signal is picked up by the wheel speed sensors and passed on through the CAN. For example, on the E46 chassis with DSC III the left rear speed sensor signal is processed and transferred on the CAN bus to the MK III (navigation) and IKE (instrument cluster) systems. The navigation system compares GPS location to vehicle mileage and comes up with a more accurate reading of location. The instrument cluster uses this data to operate the speedometer. The right rear speed sensor signal is process and passed on to the DME (Digital Motor Electronics) and is shared by the AGS (Automatic Gearbox System) to control shifting.

Where Do I Start?

The DSC control unit is serviceable separately from the hydraulic unit. The new one will be in “factory†mode for shipment. You will need to use your iComm/ISTA/P to code it to the specific car. With a paid subscription to www.bmwtechinfo.com, you can access this software and program the module.

When you have to diagnose a problem, BMW strongly recommends you perform a “short test†with your iComm/ISTA scan tool or equivalent. A short test has the iComm go into each control unit and look for diagnostic trouble codes. This is important because the systems are integrated. This means they share and exchange information on their CAN and rely on information from one another. You may not see a code in the DSC system, but you may get a code in the DME informing you that the wheel speed sensor signal is missing. Now this could be the fault of the sensor itself, the DSC control unit, or a software mismatch. BMW also recommends you check the software levels on each control unit and update them all to the latest software to remove any glitches. Once you have identified the problem, you should back up your diagnostic procedure with electrical testing at the actual component.

The DSC through DSC8+ control unit has discreet inputs. In other words, they go directly into the DSC control unit. The data from switches and sensors tell the control unit what the chassis is doing dynamically as the car is driven down the road. On earlier systems, the control unit used to sit and wait for a situation that required its control. The brakes would be applied suddenly, say, and the wheels would start to lock up. If the control unit determined that the rotational speed of one wheel was not the same as that of the other wheels as reported by the speed sensors, it would reduce brake hydraulic pressure to the slower wheel. When that tire regained traction, brake pressure would be applied again. This process would alternate back and forth until the car came to a safe, controlled stop. The driver could still change steering inputs while the DSC control unit took care of braking. The modern DSC8+ control is not so passive when it comes to braking.

How Do You Anticipate Braking?

If for whatever reason you cannot communicate with the DSC control unit, all you really need to do is verify that the control unit has the proper voltage supply and ground, and scope the CAN HI and CAN LOW lines at the connector to verify that the wiring is not damaged. If you have CAN data on your pattern, you should have communication.

Teves, Bosch, and BMW engineers have modified the software to read the inputs and anticipate braking maneuvers. An early example is EBV (Electronic Brake Force Distribution). This basically uses the ABS system to replace the proportioning valve. More brake pressure is applied to the front brake as the weight of the car is transferred forward. BMW uses rear disc brakes that help reduce stopping distances, but excessive brake pressure to rear wheels will allow them to lock up easier while weight is transferred away from the rear of the car. CBC (Cornering Brake Control) keeps the ABS working even at extreme turning angles by monitoring the steering angle sensor. DBC (Dynamic Brake Control) applies additional brake pressure when the brake pedal is not applied hard enough. Dry Braking intermittently applies the brakes when the wiper switch is on to keep the rotors free of water. Brake Standby starts to apply the brakes when the throttle is released suddenly to reduce the time it takes the brake pads to contact the rotor.

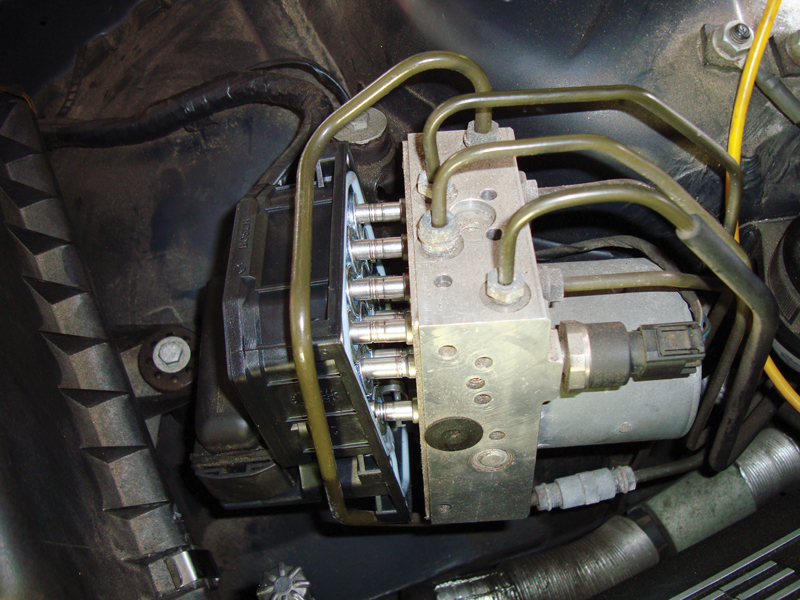

There are many more software programs that assist the driver during braking, acceleration, and cornering, but you really can’t fix these problems beyond programming the control units to the latest possible software. What you can diagnose and repair are the sensor inputs and the solenoid outputs of the DSC system. As far as the solenoids are concerned, there is also not much you can do. Both the control unit (that bolts directly to the hydraulic unit) and the hydraulic unit are available separately. It is your job to determine if the control unit is capable of operating the solenoids through activations with your iComm scan tool or equivalent. It is possible to scope the amp draw with an inductive amp clamp on the power feed wire of a solenoid while activating it. You can compare the amp draw of like solenoids to one another. The bulk of your diagnostics are going to be on the sensor inputs to the DSC module.

How Do You Anticipate A Diagnosis?

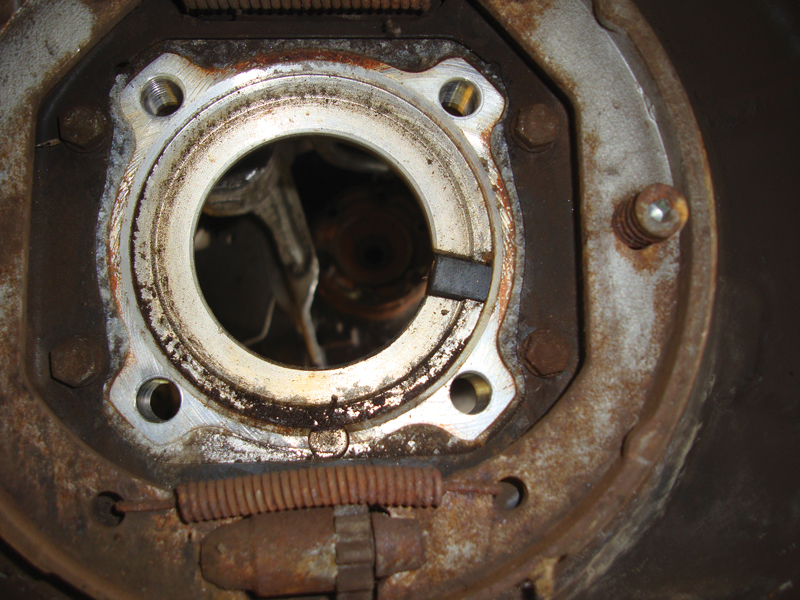

This is the rear spindle with the bearing removed. You can see the wheel speed sensor at approximately the three o’clock position (the black tab). If the correct bearing is bolted in properly, the alternating magnetic tone wheel will pass by the sensor and read wheel speed. Since BMW uses four different speed sensors, it is important for you to rely on your local BMW dealer’s parts department to make sure you get the correct sensor for your repair.

Obviously, wheel speed sensor signals are critical inputs to the DSC control unit. Here, BMW has developed a few different types to fit the needs of the system. BMW has used four different types of wheel speed sensors over the past 10 years. Early ABS, ASC, and ASC+T systems used AC pulse generators that developed a sine wave pattern as a tone wheel passes by the sensor winding. The signal increases in amplitude as vehicle speed increases. This means the amplitude also decreases in size with deceleration. So, it is possible the ABS may activate simply because one of the signals is too weak compared to the others even though the wheels are actually all traveling at the same speed. BMW also uses a Hall effect type of sensor. This requires a power supply of approximately 8V from the control unit, but the signal will not get stronger or weak with road speed. It generates a square wave signal, not a sine wave.

The next two sensors are considered active sensors. The third type of sensor BMW uses is of the magneto-resistive type, which also requires a power supply. These are fitted to cars with Teves DSC systems. The module puts out a 12V power supply to the sensor. As the tone wheel passes by the sensor element, the magnetic field changes. There is an evaluation element in the body of the sensor that can detect the small changes and pulls the reference voltage to a lower level. This sensor also generates a square-wave pattern that is interpreted by the DSC control unit. It can detect closer to zero vehicle speed and will not be affected by a worn-out wheel bearing. The most sophisticated sensors are found on the DCS8+ system. They have three Hall-effect sensing elements that can detect if the vehicle is stopped, moving at extremely low speeds, and its direction. This allows for DSC function in reverse as well as forward.

What Makes Them Different?

If you look closely at the wheel bearing seal, you will see the detents from the alternating magnetic tone wheel built into it. This is how the wheel speed sensor picks up the rotational speed. An aftermarket wheel bearing may not match this design and you will have to do the job over again.

These active wheel speed sensors require a power supply from the control unit, but do not put out a simple sine wave or square wave. They have logic circuits in them that transmit the data through a pulse-width-modulated (PWM) signal. A small PWM square wave sends something more like a communication signal by varying the pulse width of the signal depending on standstill, acceleration/deceleration, direction of wheel travel, and even variations in air gap from a worn bearing. This signal is sent every approximately every .7 of a second. You can scope the communication signal, but don’t expect to see a significant change with wheel speed increase or decrease. You will only notice the change in the pulse width — the sensor does read the wheel speed. What is unique is that the bearing seal houses the alternating pole magnets that make up the tone wheel. This means it is very important that you purchase your parts from your BMW dealer’s parts department. They must contain the alternating magnetic ring in the seal of the wheel bearing and you must replace the bad wheel speed sensor with the correct one. Your BMW parts person will ask you for the last seven digits of the VIN to properly identify the type of replacement wheel speed sensor you need.

This system has many more inputs, both discreet and shared from the CAN. We will go over these additional inputs in our second installment of Does this Stop the Car? in a future issue of the bimmer pub. To accurately diagnose and repair BMW vehicles you need to have an understanding of the different systems the company has used and the variations or options. Consider your BMW parts department as your partner in achieving these goals, and who could have a better partner than that?

0 Comments