Editor’s Note: As an auto service professional, you’re obviously more than a little familiar with the subject of tools, and, for many of you, collecting them is almost a passion. Fine, but what you use in your day-to-day career, no matter how high-quality, is necessarily different from what you need for high-performance work, in this case engine building. The following will help acquaint you with the types of tools you’ll probably end up buying, as did Part 1in the October issue of HOT ROD Professional. To quote Greg from the introduction to that article, “. . . the more you learn about high-performance engine building, and the more you know how to do, the more tools you’ll need to support your activities. . . . you’ll have to allow for a savings and purchase model that will support your career trajectory.â€

by Greg McConiga

Skip to…

Valve Spring Height Micrometers

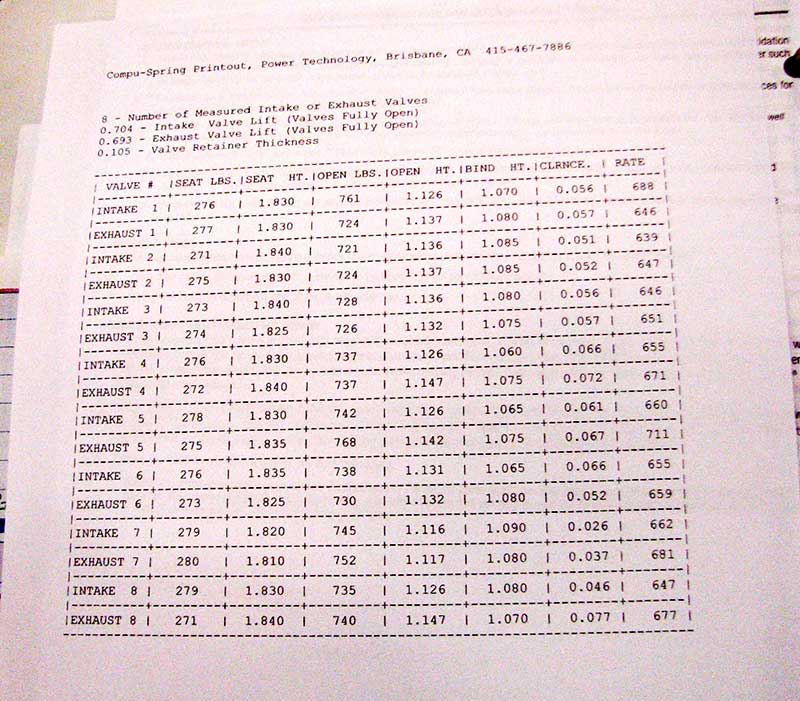

Your spring testers will give you spring tension at all heights on the spring along with the bind length. Use the height micrometer to set the installed height for the seat pressure that you need. Simply install them between the spring seat insert and the retainer, screw them tightly in place, and read the distance between seat and retainer. Shims can then be used to adjust the installed heights to your specification.

Cam Lobe Checking Tool

The plunger of this tool is reversible, as is the body. There is a flat tappet end and a roller end on the plunger, and the body fits common GM and Ford lifter bore diameters. If I run into an application that this won’t fit, I just use a lifter and a dial indicator to do the same job.

Combination Squares

These are must-have tools for layout, measurement, squaring things up, and setting ring depth while you’re grinding and fitting piston rings. There are so many uses I can’t even think of them all. I use them every day — can’t do without them.

Cast Iron and Aluminum Burrs

The narrow fluted burrs are for cast iron and the wide fluted burrs are for aluminum. In a pinch, you can spray the narrow fluted burrs with WD-40 and work slowly and they’ll do aluminum. Just remember to keep them lubed because once they load up with aluminum they are miserable to clean.

Header Spark Plug Tools

No explanation needed. If you’ve ever tried to get plugs in and out from around a set of large tube headers, you’ll know exactly what these are and why you need them.

Parts and Systems Trays

Cleanliness and organization. There’s nothing else to say. Available through CV Products, they are something you should not try to do without.

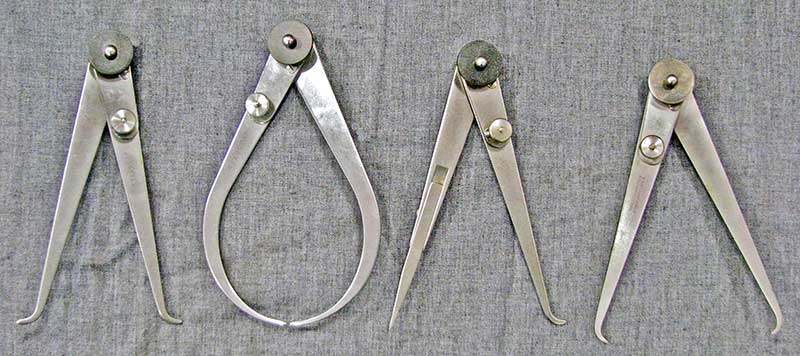

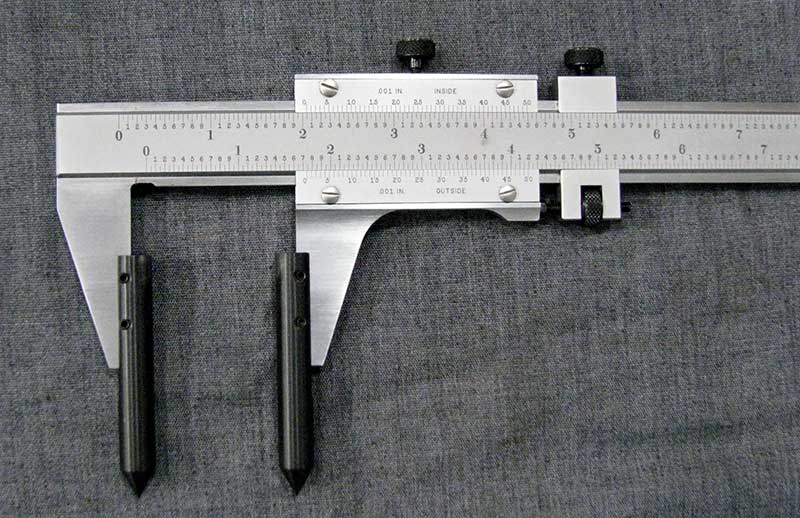

Plain Calipers

Useful for transferring measurements or roughing in a piece on the mill or lathe, they are also good for checking material thickness. Pictured are outside wide clearance calipers, hermaphrodite calipers, inside calipers, and narrow clearance outside calipers. These Starret calipers have a very nice feature in that you can lock the reading and then release one leg so you can remove them and close them back to the exact opening and read the measurement. That’s what that extra nut is for on the leg of the caliper. It releases one leg without changing the measurement.

2-6 inch bore gauge Bore Gauges |

|

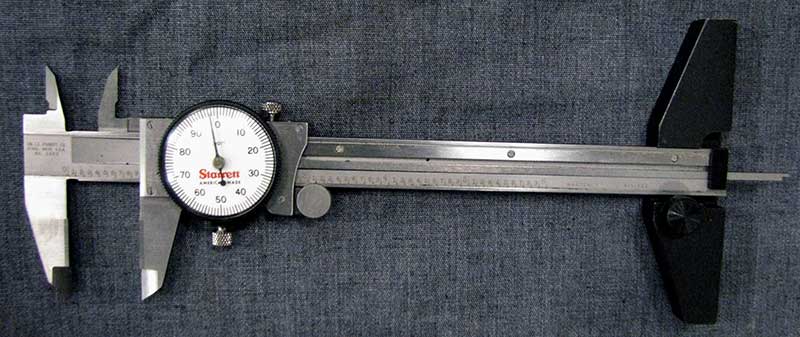

Dial, Vernier, and Digital Calipers Calipers come in three major configurations: dial, vernier, and digital. I’ve pictured just a few of the accessories that are available — there are others. The dial type reads out each .100 directly and the body of the caliper shows the inch and tenth of an inch divisions. The digital versions are nice because they read out directly. The vernier scale reads like any other vernier in that the marks that line up represent the reading. In this case, 1.742 lines up best on the outside (lower) scale. Make sure you check the accuracy of your calipers periodically by using your gauge blocks as a standard. You can stack gauge blocks to get a longer calibration length. |

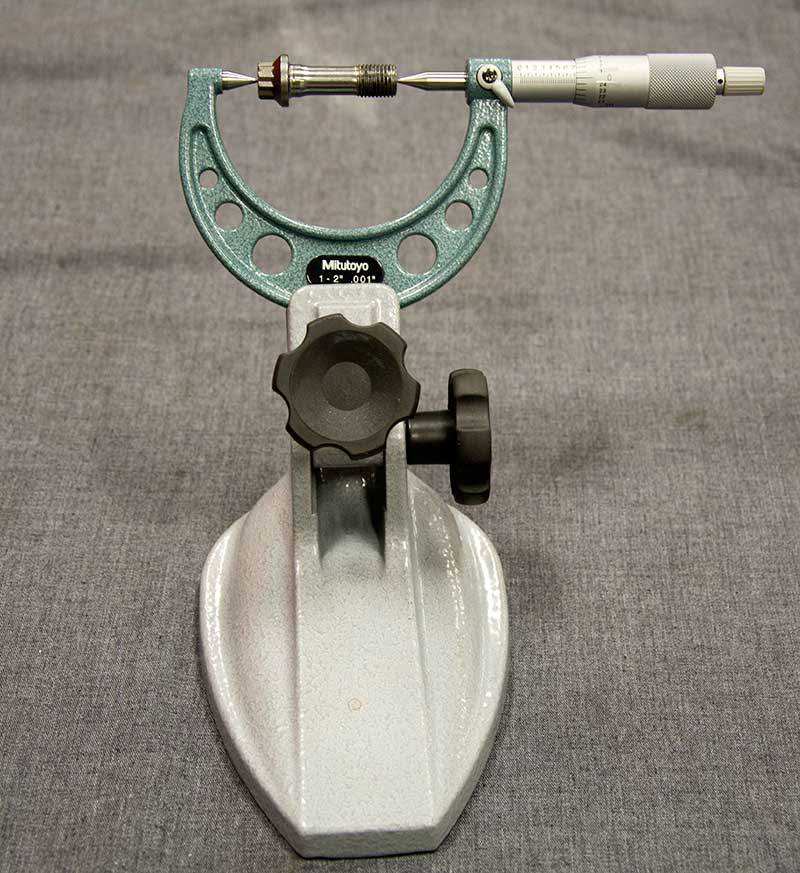

Micrometer Stand

Another must-have. It keeps your body heat from affecting the accuracy of the micrometer and it’s invaluable for setting up your dial bore gauges. It’s a third hand that makes your life a lot easier.

Thread Micrometer

I mark each rod bolt with its location, measure each using this Mitutoyo thread micrometer, then record the overall length of each bolt prior to assembly. The pointed ends of the micrometer fit into the stretch measuring dimples of the bolt. If a bolt remains stretched after removal it’s discarded. Rod bolts, valve springs, rings, bearings, spark plugs, engine oil, oil filters, gaskets, and seals are all consumable parts of a race engine.

Reading Tenths

The marks on the thimble and the barrel are the standard graduations you see on every micrometer. The additional lines that run lengthwise along the barrel make up a vernier scale that reads out in ten-thousandths of an inch. Carbide faces are the only way to go for long tool life.

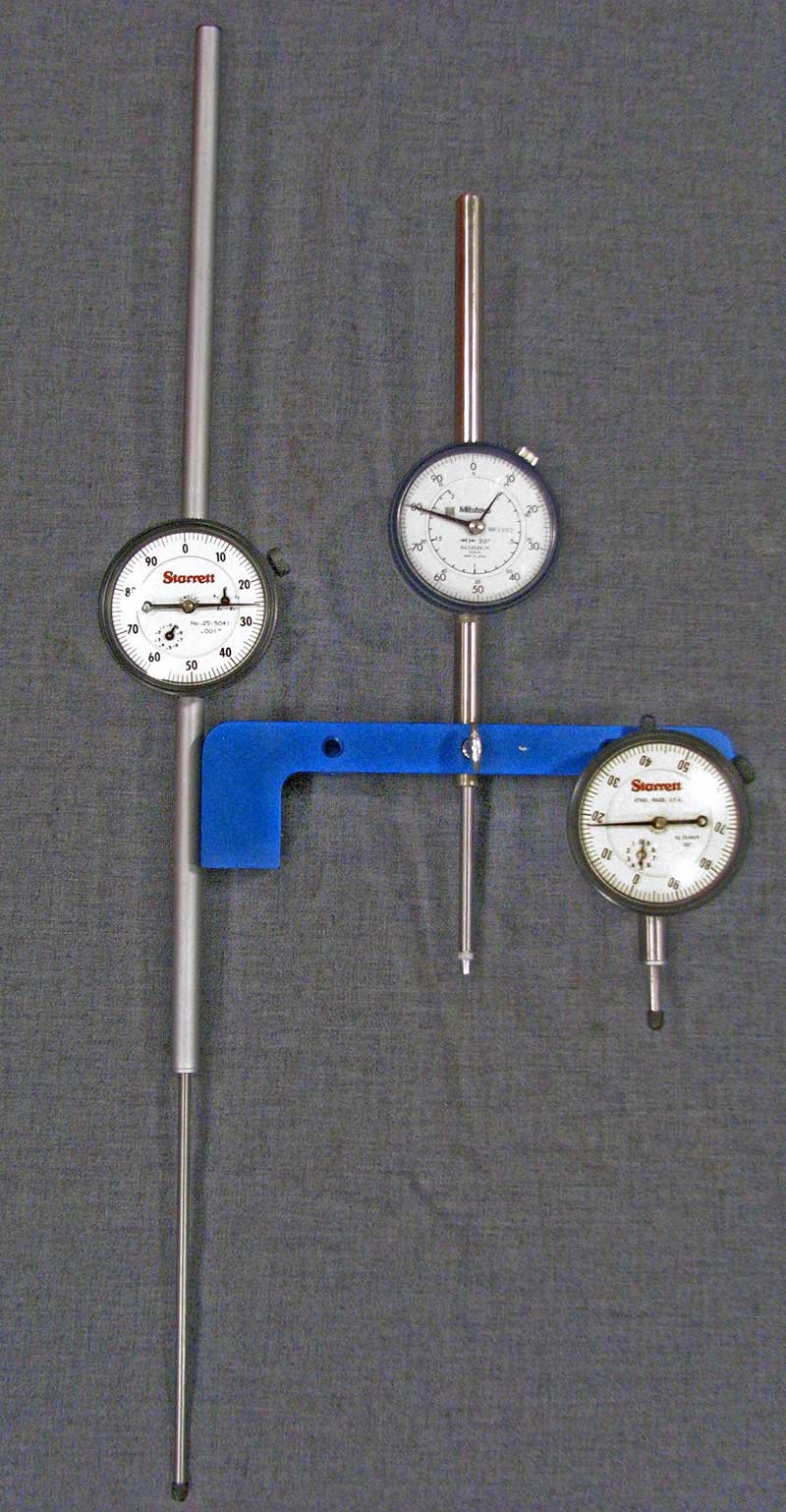

Dial Indicators

Indicators come in a lot of types. There are lug back, direct, and indirect reading and a lot of face sizes to choose from. The two inch is mounted in the bridge flanked with a one inch and a six inch. If you’ve got a good eye, you can interpolate between the tics and come up with readings within a few ten thousandths of an inch.

Spring Cup and Washer Pickup Tools

Ever try to recover those washers or valve spring cups from an oily engine? The oil sticks the washer down as if it were glue. Rare earth magnets embedded in an aluminum handle make short work of it.

Piston Stuffers

These aren’t a lot of money individually, but at about $50 each they add up when you have to buy one for each engine bore size that you work on. They are the only way to load pistons and rings into a block.

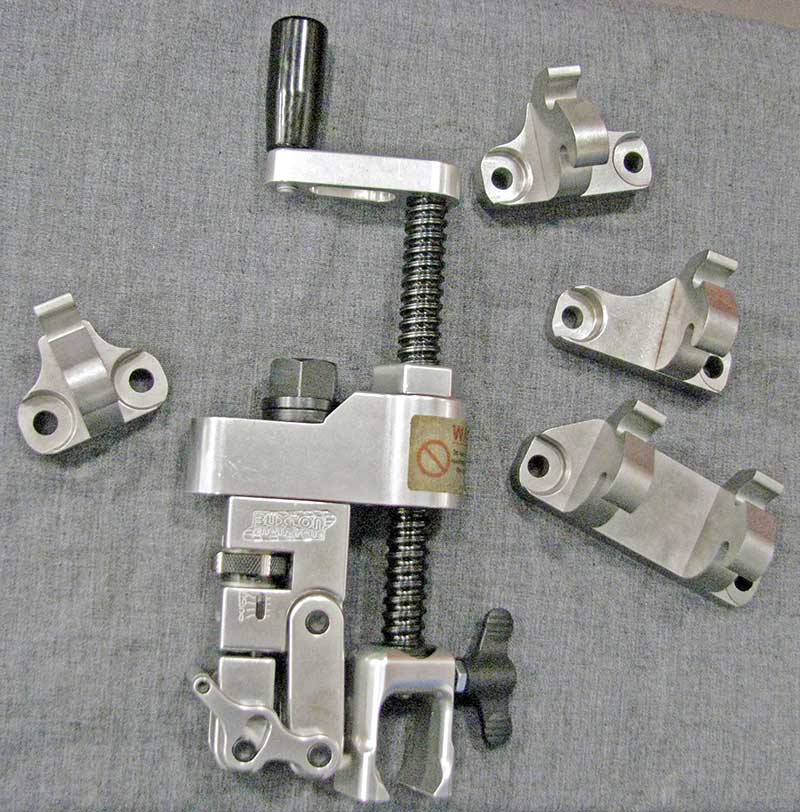

High-Pressure Valve Spring Compressor

Another great tool by Buxton Engineering. This is without a doubt the best tool I’ve ever used for removing racing valve springs, and there is a bunch of adapters to fit nearly any application. Even valve springs that measure 450-500 lbs. seat pressure are easily removed. Yet another must-have.

High-Tech Compression Gauge

Compression gauges are another one of those tools that I’ve had several of over the years and accuracy has always been a question. This is a homemade unit, using bits from Snap-on and an Ashcroft 500 pound ¼ percent of scale accuracy gauge. Make sure if you try to replicate this that you spec the gauge correctly. It has to be tolerant of some pretty serious transient pressure surges. I was on a quest to verify my dynamic compression ratio software accuracy when I built this. The software is dead-on, by the way. That will become more important to you later when you’re trying to build performance pump-gas engines and you’re trying to find the upper compression limits you can run.

SPi Squares

There will be a number of times during a build that you’ll need to confirm that parts are aligned or square with one another. A small machinist’s square set like this is just the ticket.

|

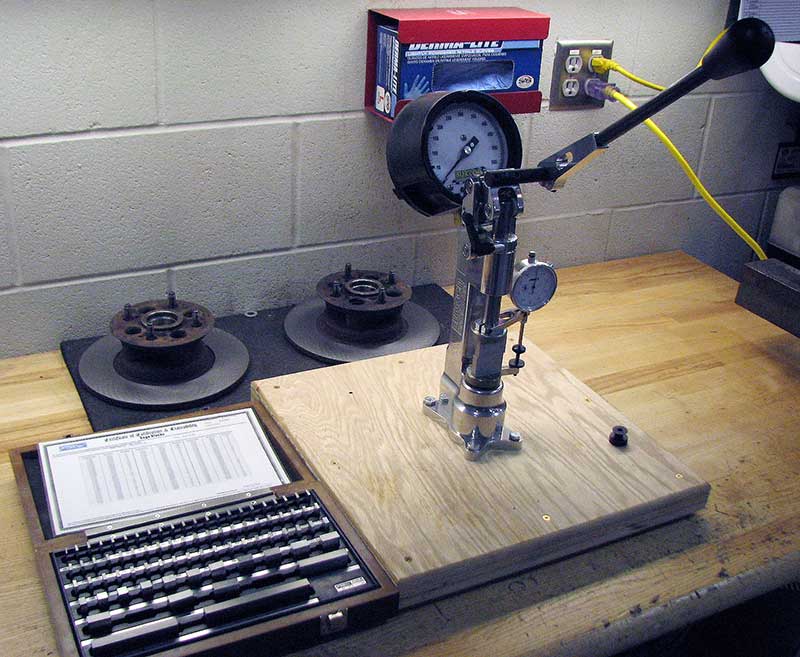

Testing Valve Springs |

Modified ARP Bolt Stretch Gauge

Never torque rod bolts, always stretch them whenever you can. I have run into manufacturers who want you to torque their bolts, but in my mind that sounds like a no-confidence vote for their own product. Stretch must be accomplished in one pull — never pull, measure, pull, measure, and so on as you’ll only ruin the bolt. Don’t forget to re-apply lube on the threads and under the bolt head before the next tightening attempt.

|

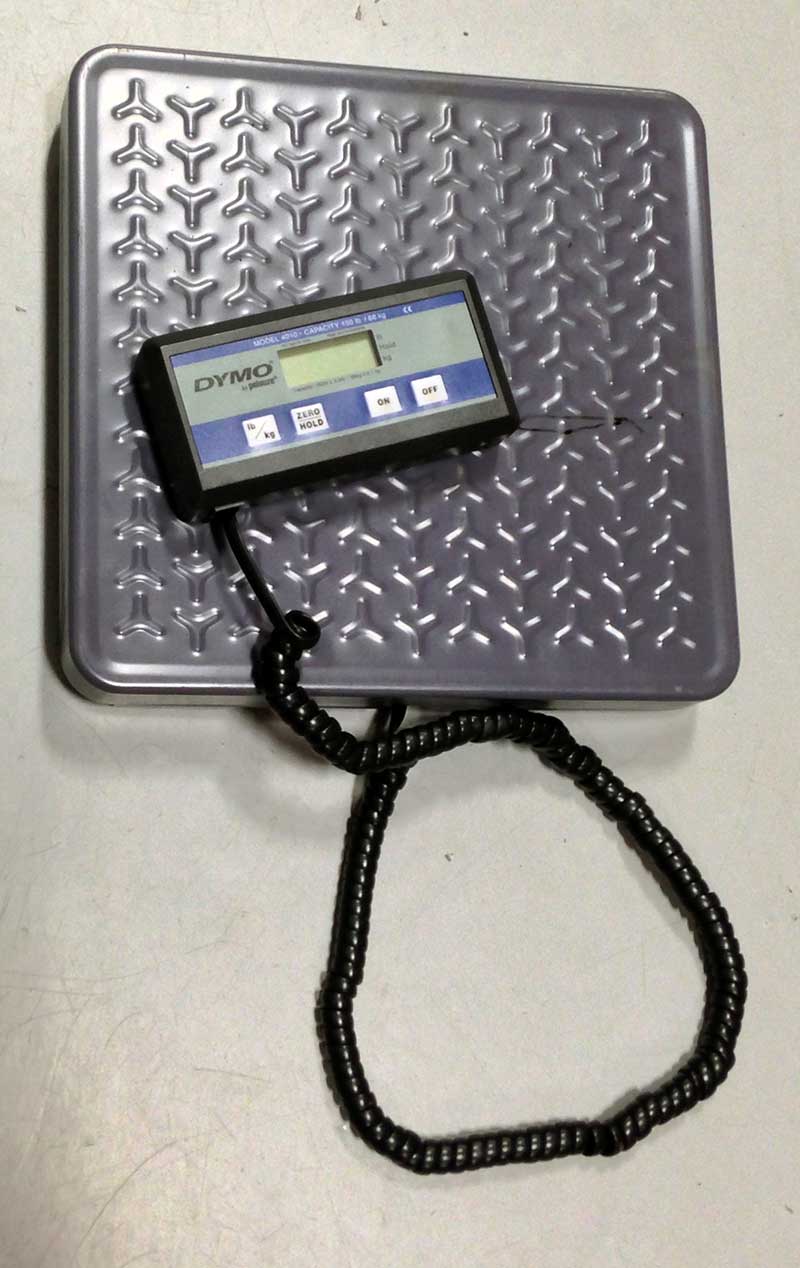

Scales |

LMS Valve Adjuster Tool

Makes adjusting the valves a snap. It’s a calibrated clicker-style torque wrench that snaps over at twenty pounds-feet.

Ring Grinder and Switch Box

This variable speed unit uses a diamond grinding wheel and a flat turntable to mount the ring perfectly perpendicular to the grinding wheel. A dial indicator tells you exactly how much material you’ve got left to remove. I didn’t like snapping the little toggle switch on this unit on and off, so I built a switch box to put in series with the grinder. If my switchbox fails, new parts are as close as the nearest big box hardware retailer.

Degree Wheel

A degree wheel and a good pointer is essential to finding TDC and degreeing in the cam. Every racing engine builder has one. The larger the diameter of the degree wheel the more accurate it is.

Thread Chaser Kit

Every hole, every bolt, every threaded fastener must be checked. New block, old block, new part, or old part — check them all. I promise you it’ll save your hindparts one day.

0 Comments