In spite of the wholesale O.E. switch to roller lifters that started a couple of decades ago, if you’ve got a vintage rod chances are it has flat tappets, and maybe you don’t want to go to the trouble and expense to retrofit to rollers. Plus, some racing venues only allow flat tappets. These operate at higher temperature and pressure levels at the lobe/lifter interface than rollers do, so require greater wear protection. The primary anti-wear additive for flat tappet camshafts and lifters is ZDDP (zinc dialkyl dithiophosphate), but that’s been phased out of ordinary motor oils mostly because of fears that it’ll foul the cat. Racing oil and additives provide zinc in adequate quantity to provide the protection you need to prevent catastrophic lobe and lifter wear.

Lubricant requirements of racing engines differ from those of street machines in many key ways. Compared to the latter, race engines operate at higher rpm and temperature levels, and have more aggressive cam grinds and higher-pressure valve springs, which necessitate more anti-wear additives. Also, race cars typically don’t have emissions controls, and they have far shorter oil drain intervals, so there is less need for detergents, dispersants, and acid neutralizers, which can sometimes conflict with wear protection and friction modifiers.

Flat tappet cams operate in a terrifically high-pressure environment where metal-to-metal contact is apt to occur. While we’re not going to try to make you a tribologist or lubrication engineer, there are some basics you should know. First, there’s hydrodynamic lubrication as you’d find in, say, a main bearing. During operation, the journal and the bearing surface are separated by an oil film, which is facilitated by a curved wedge-shaped “converging” gap between the two that produces something called hydrodynamic lift. Virtually no wear occurs.

Then there’s elastohydrodynamic lubrication (EHD), a much more subtle phenomenon in which the surfaces are separated by a very thin film of fluid. It seems that an oil’s viscosity responds to extreme pressure by becoming a semi-solid, so even a microscopic layer can support a load.

Mixed lubrication is where two surfaces are partly separated, but also partly in contact. The thickness of the fluid film is slightly greater than the surface roughness (the high points or peaks are called “asperities”), so there is little actual high point contact, and the asperities themselves can form miniature regions of EHD.

Out of bounds

Which brings us to boundary lubrication, the basic topic of this discussion. This occurs when the lubricating film is about the same thickness as the roughness of the two surfaces (RMS), so that the high points actually make contact. It should be obvious that this isn’t a good situation, but under the incredible pressures between a flat tappet and a cam lobe, it happens.

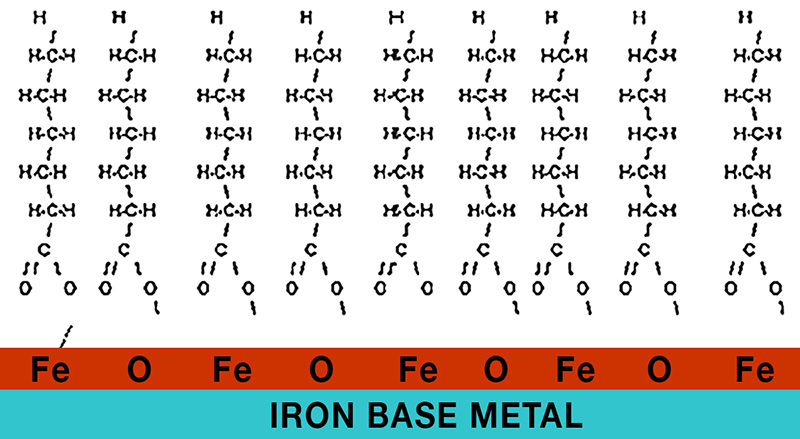

To avoid immediate mutual destruction, oil additives that provide a different form of lubrication have been developed. These have long polar molecules that attach to the wear surfaces — one expert describes them as a “molecular shag carpet.” This is what boundary lubrication is all about, and the only thing that ultimately protects cam lobe and lifter surfaces from scraping against each other and causing instant catastrophic wear. These molecules keep the metal surfaces apart. They rub against each other, and are considered sacrificial.

These helpful oil additives must bond to the metal and remain as a thin film if the oil is squeezed out under extreme pressure. This coating on each of the two metal surfaces then grinds against itself, acting as a shield for the moving parts.

Tougher at the Top

Under normal operating conditions, the bottom and sides of a flat tappet cam lobe are protected by a mixed film. Oil through the galleries, running down from the rockers, and just generally splashed around keep the lobes and lifters lubed. With stock cams and springs, the mixed film combo may remain intact.

As the lifter rises up the ramps and reaches the nose of the lobe, the force of the compressed valve spring pushes the lifter against the lobe at pressures that might sometimes be high enough to squeeze any oil out from between the two metal surfaces.

This creates a boundary lube condition in which there is no longer any actual liquid oil present to keep the lobe and lifter surfaces from scraping against each other as the cam rotates. The asperites tear into each other, break off, and presto – you’ve got wear. These metallic particles scratch the lobe and lifter surfaces, too, and circulate doing damage wherever they go.

More aggressive cam profiles and higher spring pressures in high-performance and race engines make the load at the top of the cam lobe even more potentially-damaging. To prevent wear as the lobe raises the lifter to its maximum height, engine oil has historically been formulated with zinc and molybdenum additives that form the needed protective film coating — the boundary lubrication.

This worked well for many decades, but flat tappet cam wear problems increased dramatically in the 1990s. Technicians originally blamed the higher incidence of wear on “soft†cam lobes and poor lifter quality.

Substandard lifters may indeed have been part of the problem as a result of a rise in imports from manufacturers with lower quality control requirements than those of traditional “Made in U.S.A.” companies. Although the quality of some imported lifters has improved, the old adage “You get what you pay for†applies here, so be careful not to choose lifters based on price alone.

Finding Out the Hard Way

Meanwhile, research proved cam lobes had not become softer. Instead, flat tappet cam failures increased due to the Environmental Protection Agency-mandated reduction of ZDDP in engine oils, the increase in detergent and dispersant additives, and the shift to lower viscosity motor oils.

Reducing the amount of zinc and phosphate in oil helps prevent plugged catalytic converters. Higher detergent and dispersant levels keep exhaust gas recirculation (EGR) and other emissions-reduction technologies functioning properly. Lower viscosity oil helps meet tougher fuel economy standards.

The new regulations were not usually a problem for street-only vehicles. Most manufacturers had already switched to roller lifters, which create much less friction and don’t need the high level of anti-wear protection provided by ZDDP.

For race applications and classic cars, however, it’s a different story. To keep racing from becoming a game in which only the deepest pockets reach the winner’s circle, NASCAR and many dirt track, circle track, and drag race classes prohibit the use of roller cams and other more expensive engine technologies. Racers cannot easily convert to technologies that work well with low-ZDDP oils.

ZDDP carries both phosphorus and zinc. Lower ZDDP limits mean less protection for engines with flat tappets. We just had to find out the hard way.

Trust, but Verify

Some lubricant manufacturers claim that their oils meet current reduced ZDDP specifications without risking harm to flat tappet cam systems. Check for verification of these claims.

Some are based on tests of systems with mild cam profiles and low spring rates. Even an entry-level “tweaked” engine may require higher wear protection than afforded by these low-ZDDP oils. The good guys publish their levels of ZDDP and other wear additives. Check their websites, or ask to see the tech sheet from your supplier.

ZDDP additive packs are available everywhere, but be careful. Oil is a complex mix of basestock and additives, many of which have conflicting effects.

Engineers include additives in the exact amounts and formulating methods (blending order and temperature, etc.) that extensive testing has determined provide the desired protection for a given application. Off-the-shelf additives that are not recommended by your camshaft manufacturer may alter the balance in ways that negatively affect lubricant performance.

ZDDP is a “smart” molecule

The long polar molecules of this boundary lubricant sacrifice themselves to shield the parts (courtesy STLE).

Zinc is not really a lubricant until activated by high heat and heavy load. Once activated, the zinc in ZDDP creates the protective film that prevents damaging metal-to-metal contact between the cam lobes and lifters. It works because ZDDP is a friction modifier — a polar molecule that is attracted to ferrous metals. The polar end “stands†the molecule up on the metal surface to which it adheres.

How quickly the film forms and how long it protects varies depending on the level of ZDDP and other additives, and the amount of pressure and friction between the surfaces. Some zinc additives require higher heat and load to activate the chemical reactions that cause film formation. Break-in oil should have a rapid zinc activation rate, so it can form the protective film as quickly as possible upon initial startup of a new or rebuilt engine.

Even when most or all of the oil is squeezed out from between the cam lobe and lifter as they slide against each other, the zinc film remains. The film becomes a sacrificial surface layer that minimizes direct contact between the lobe and flat tappet surfaces.

A Little Wear Is a Good Thing (Really)

New flat tappet cam and lifter pairs have to seat to each other during the initial break-in period in order to ensure smooth operation. This is accomplished by using break-in oil for initial startup. The special additive package in break-in oil provides extra anti-wear protection for the cam and lifter surfaces, while at the same time allowing just enough wear at the piston rings to properly seat them.

Don’t think because synthetic oil is great stuff that you should automatically use it as a break-in lubricant for a new or rebuilt engine. While a super-slippery synthetic can protect the cam and lifters, it may not allow the slight amount of wear required for rapid seating of the piston rings.

Many manufacturers combine a mineral oil base with friction modifiers and other additives to create a high-quality break-in lubricant.

Additionally, the traditional seal materials in many pre-1992 engines are not compatible with synthetic lubricants. The free-flowing nature of a low-viscosity synthetic makes it more likely to find a leak path.

Today, every NASCAR team uses flat tappet cams and lubricates its engines with synthetic oils. However, the synthetics are special formulations with a higher proportion of ZDDP than in API-certified street-use oils.

Detergents and Dispersants Don’t Like Zinc

Like zinc, detergent and dispersants are polar molecules, so they compete with ZDDP for ferrous surface area to which they can adhere. They’re great for cleaning sludge and varnish, but detergents and dispersants can also clean away zinc.

Unfortunately, oils that meet current API certification for street use contain higher levels of detergent and dispersant to help keep the EGR system, the oil rings, and tiny passages elsewhere in the engine from clogging.

Historically, high-performance engine builders used non-detergent oils for break-in, thus eliminating a potential barrier to activation of the zinc additive in the oil. Today, look for break-in oil that offers anti-wear additives and detergent and dispersant in a balanced formula that won’t prevent zinc-film formation.

Diesel Oil Is Not What It Used To Be

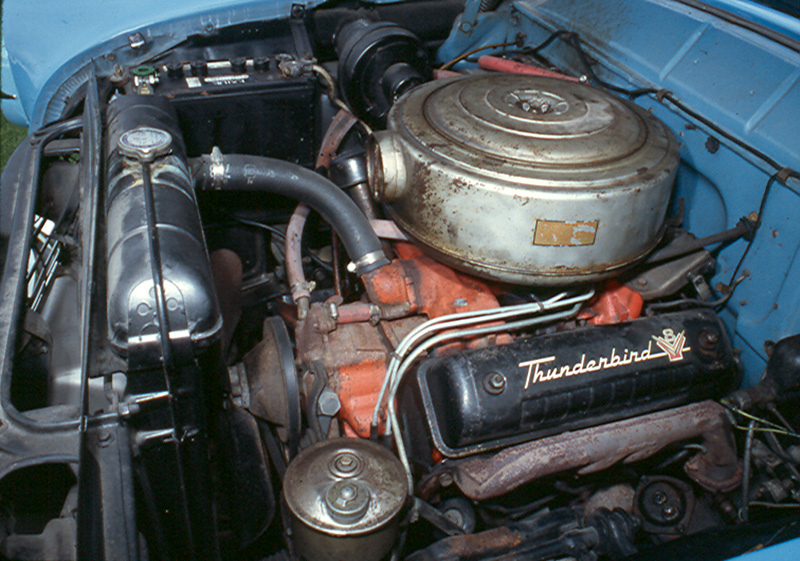

When you lose boundary lubrication with an aggressive cam grind and strong springs, you’ll get this…

While gasoline-engine lubricant standards were reducing ZDDP beginning as early as the 1990s, oil for diesel applications retained a higher content until 2007 when API reduced the ZDDP level for diesel from 1,500 to 1,200 ppm. For over a decade, some high-performance engine owners swore by diesel as the savior of their cam lobes and flat tappets. Although still higher than the current 800 ppm for passenger cars and light trucks, the lower ZDDP and higher detergent levels have made heavy-duty diesel oils no longer an attractive alternative for use with flat tappet cam systems.

Building Tips

What this all boils down to is to go with a brand of high-performance oil you can trust for your application. Read the lit.

Keep the following suggestions in mind during an engine build:

- Measure clearances between the lifter body and lifter bore, the camshaft and its bearings, and the engine main and rod bearings. If you hone or otherwise refinish surfaces in used engines, you may open things up enough to reduce hot oil pressure.

- Inspect the camshaft side of the lifter opening in the block. Look for egg-shaped wear on the opening. This allows the lifter bottom to shift off center as it contacts the camshaft lobe. An off-center lifter can scrape or push the oil film out from between the lifter and lobe, causing metal-to-metal contact and premature wear.

- Use a special break-in lubricant for the first startup of the engine after rebuild. Flat tappets rotate in their bores to spread the load around the entire bottom, and help extend the life of the lifter. Designers include a slight crown or convex surface on the lifter foot and a small taper angle on the cam lobe. This crown may measure only in the ten thousandths of an inch, but it is necessary to force the lifter to rotate as the lobe pushes against it. The break-in period helps wear-mate the lifters to their respective cam lobes.

- Pay attention to any lubricant recommendations provided by the manufacturer of your cam and lifters. Use oil designed for your engine type (air-cooled, or water-cooled).

- Don’t substitute thicker oil because your uncle told you it worked in the car he took to the dirt track as a teenager. The oil passages in some late-model high-performance engines don’t allow the proper flow with thicker oils.

- Don’t use lower viscosity oil than recommended in an attempt to lower friction. More often than not, reducing viscosity will increase friction due to higher load at the cam lobe crown causing boundary lube conditions in that area.

- We’ll conclude with an interesting note we just got about high-performance engine building from HRP’s exec tech editor, Greg McConiga: There is a ton of work going on with micropolishing and high-tech surface preparation systems that reduce the RMS to near zero, which acts to delay boundary lubrication because the peaks are much smaller and therefore less likely to collide under extreme pressure. Surface preparation is one way to reduce extreme wear.

Â

0 Comments