Nissan’s 2015 GT-R NISMO is a 600-horsepower, twin turbocharged feast for the senses. The low-gloss matte exterior and carbon fiber bumper fascia and accent body panels are a challenge for collision repair specialists, unless, of course, you pay attention to the step-by-step refinish instructions from Nissan and the manufacturers of the approved matte paint systems.

Since the mid-1980s, Nissan NISMO cars have torn up the tracks at the All Japan Sports Prototype Championship (JSPC), Japanese Touring Car Championship (JTTC), Formula Nippon, 24 Hours of Le Mans and 24 Hours of Daytona. In recent years NISMO cars have participated in the Super GT and FIA GT Championship, and in 2015 will compete at Le Mans with an all-new 3.0-liter, twin turbo, front-wheel-drive V6.

Their track record keeps NISMO cars in the top tier of supercar racing globally. The name NISMO comes from the first two syllables of the Nissan Motorsport division of parent Nissan Motor Company. The technology spin-off to Nissan’s consumer vehicles makes the 2015 GT-R NISMO a street-legal feast for the senses. The 600 horsepower, 3.8-liter, twin turbocharged V6 with NISMO-tuned suspension, dual clutch 6-speed transmission, and electronically-controlled all-wheel drive provide massive power, intelligently engineered for performance and confident control.

The 2015 GT-R NISMO is available in a low-gloss matte gray exterior paint finish that shimmers softly rather than shines. The understated elegance of the matte finish may make drivers feel they should wait for the paparazzi to arrive so they can be photographed making their grand exit from the vehicle.

The GT-R NISMO also features extensive use of carbon fiber from front to rear. Carbon fiber is five times as strong as steel, offers twice the stiffness, and yet weighs two-thirds less. Long used to build super strong yet lightweight bodies and safety cages for Formula One racecars, carbon fiber is now showing up on street machines to help meet fuel economy and emissions targets.

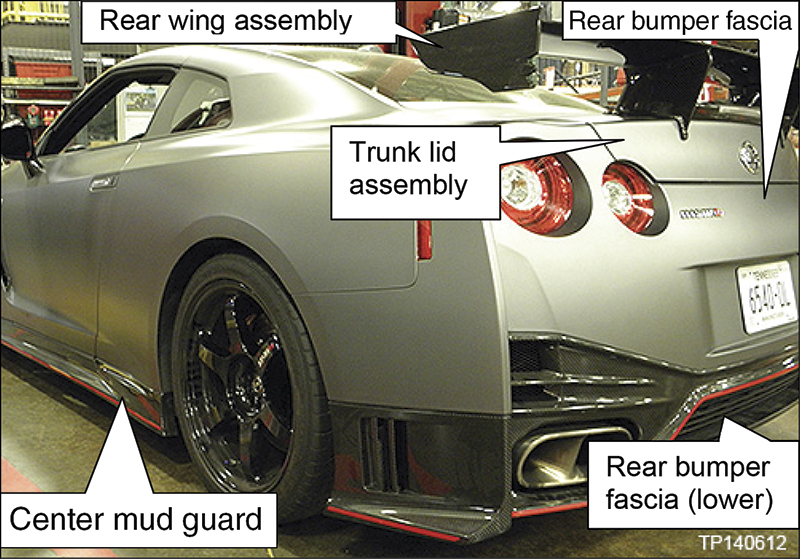

The GT-R NISMO boasts carbon fiber front and rear bumper fascia, rear trunk lid and side sills. There is also a lightweight carbon fiber rear spoiler that increases downforce by 220 pounds for road-hugging high speed performance.

The front bumper fascia and front part of the engine undercover on the 2015 GT-R NISMO are carbon fiber. Combined with the carbon fiber center mud guard, trunk lid, spoiler, and rear bumper fascia, these components not only look striking, they help reduce the total vehicle weight compared to steel.

The carbon fiber accents and matte finish offer all of the appeal of the newest clothing from a hot Italian fashion design studio, so you can expect the GT-R NISMO to eventually show up in your collision shop. Here are a few things you’ll need to know when it does.

The carbon fiber accents and matte finish may inspire oohs and ahhs, but they also require that collision technicians plan repairs and handle color and gloss matching using different procedures than those of the typical metal repair and clear coat refinish job.

Surface Texture and Reflected Light

Almost the entire rear end of the 2015 GT-R NISMO is carbon fiber, including the spoiler, trunk lid, rear bumper fascia (on which the license plate mounts), and the lower bumper fascia. You can see (and feel) the carbon fiber texture in the surface of the wraparound dark lower bumper fascia. The light components (trunk lid, rear bumper fascia) receive primer, a color base coat and a standard clear. The color is part of the carbon fiber material in the dark components (spoiler, lower bumper fascia), so they receive only clear coat.

Traditional clear coats are smooth and even, allowing light to bounce off of the surface in an equal and opposite angle from the source. When every ray of light from a source bounces off of a reflective surface at an equal angle, the surface appears bright and shiny due to the large amount of light being pushed in the same direction. The equal angle also allows an accurate reproduction of the image of the source on the first thing it meets – a wall, your eye, other surfaces. This is how we see our face reflected in a mirror, or in the shiny surface of a new car.

The surface of a matte topcoat is rough and uneven compared to that of a typical gloss clear coat. Microscopic pits and bumps in the surface scatter light randomly, which significantly reduces the brightness and shine of the surface, and causes any reflections to appear weak or blurry.

No Buffing!

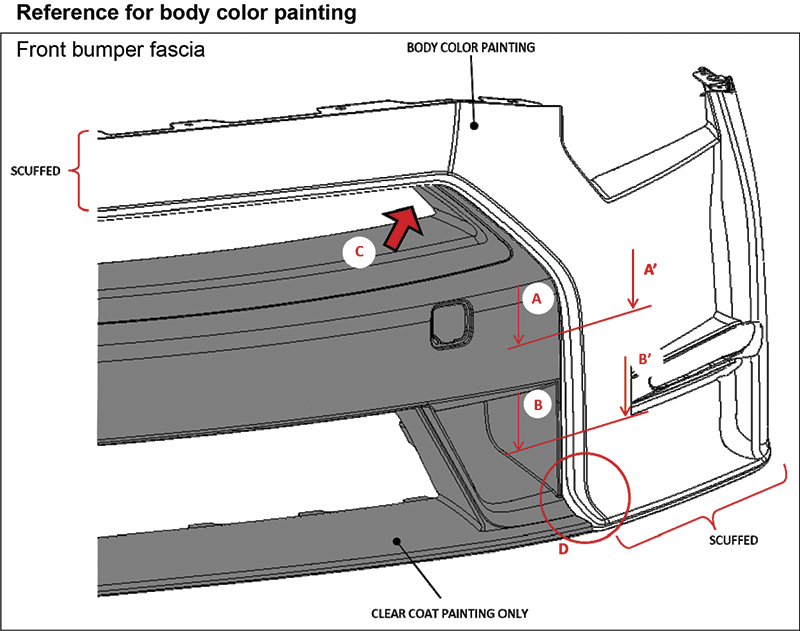

Refer to Nissan technical information for instructions on application of a scuffing treatment to the front bumper fascia.

Any errors in application of the matte clear coat cannot be buffed out. Buffing or polishing flattens the topcoat pits and bumps, resulting in significant differences in sheen compared to non-polished areas. Dirt in the application of the clear coat, mottling or striping due to improper spray technique, variations in film thickness and other visible defects require complete repainting of the final topcoat.

To minimize the need for buffing out imperfections, clean the vehicle before beginning to paint, and check for dust and other contaminants after applying the primer and basecoat layers. Also, use spray-out test cards to check for color and gloss match before painting the vehicle.

Experience Counts

The factory Gray Metallic matte finish on the GT-R NIMO consists of two top layers – a normal color base coat (color code: KAD) and a low gloss matte clear coat (color code: KBL). If you’ve had good experience with pearlized, metallic, and other premium automotive paints, you already have the skills to mix and apply matte paints properly, and to match color and gloss level.

| SUPPLIER | BRAND | SOLVENT BASE | WATER BASE |

| BASF | Glasurit / RM | Available | Available |

| PPG | (1) | Available | Available |

| AKZO Nobel | Sikkens | Available | Available |

| Sherwin Williams | (1) | Available | Â Available |

| Axalta (ex DuPont) |

Standox Spies Hecker Cromax |

Available | Available |

| Kansai Paint | RETAN PG ECO | Available | Available |

| Nippon Paint | (1) | Available | (1) |

| (1) Contact manufacturer for the brand name of the product that will work with the GT-R paint system for your region. | |||

The Art of the Mix

Regular gloss paint reflects approximately 90% of light, while matte finishes reflect only 20% of the light that hits them. The low reflectivity is a result of the use of different hardeners, reducers, application methods and drying options.

It is important to use Nissan-approved paints and follow the paint manufacturer’s recommended mixing formulas and application procedures. Minor deviations from the recommended ratio of hardener and reducer to the clear coat paint itself will result in significant changes in the gloss level.

Of course, sometimes matching the color of the base coat and gloss level of the clear to those of the vehicle may necessitate mixture or application process revisions. For example, the ambient temperature in your shop can affect your choice of whether to use slow or fast-acting hardeners and reducers, a relatively dry or wet spray technique, the length of flash-off time, and other factors that impact gloss level. Different combinations of these factors can alter gloss level by up to 20%.

Additionally, film buildup due to painting over the original factory clear coat can cause a color shift, or the gloss level of the vehicle may have changed due to its age and cleaning frequency. This may necessitate painting the entire side of the vehicle instead of just the damaged panel, in order to match the gloss level on that side.

When properly mixed and applied, the finish provides the same protection against stone chipping, corrosion, bird droppings, tree sap and other contaminants as non-matte coatings.

Test and Test Again

There are so many factors that can affect your ability to match the vehicle that you must create spray-out test cards before applying both the color and gloss coat. After looking up the color formula recommended by the matte paint manufacturer, spray at least three test cards with different ratios of matting agent (flattener) and clear coat. Colors will appear significantly darker when dry, so after drying, compare each test card to the vehicle. Evaluate both the color and gloss level. Check in natural daylight. Hold the card against the vehicle surface to ensure that your viewing angle and light source are the same for the area being repaired.

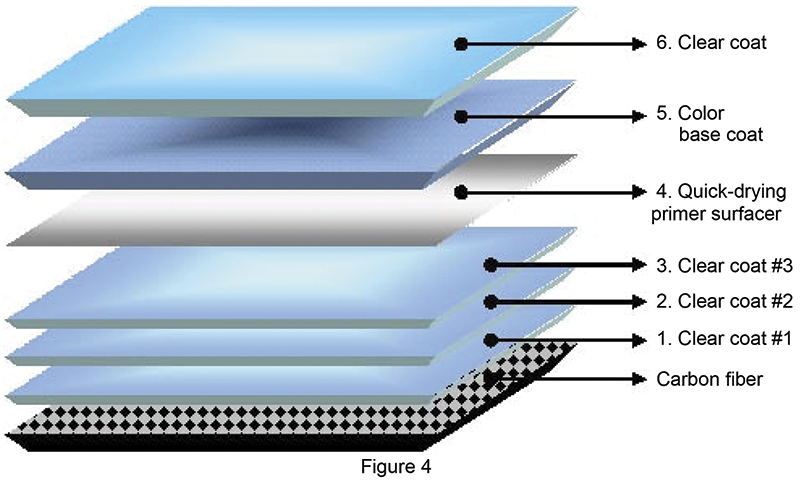

The light-colored body panels (trunk lid and front and rear bumper fascia) receive layers 4, 5 and 6 in the coating steps diagram, while the darker components receive only the clear (steps 1, 2 and 3).

Spray Expert

“Mottled†describes a finish that is streaked, spotty, or striped. It is the result of an unbalanced spray pattern, or of not observing the proper flash time between base coat and clear coat. If one spray pass is heavier than the others, that area may appear glossier after curing. Try to spray so that you maintain a wet edge, but no one pass is heavier than the others.

Changing the angle of the spray gun between strokes can result in uneven film thickness and stripes in the work. For example, if you paint while too tired, you may inadvertently allow your arm to drop while spraying. This tilts the spray up, resulting in more paint placed on the bottom portion of the pass than the top, and bingo, you’ve created a horizontal stripe in your finish.

Experiment with overlap. If a 50% overlap leaves light streaks, try 75%. Just be sure to maintain consistency with each pass.

To further reduce the appearance of striping, spray in different directions in the same coat. After covering the panel with horizontal passes, cover again while the coat is still wet, but use vertical strokes.

Two Different Coating Treatments for Carbon Fiber

The trunk lid and front and rear bumper fascia each receive only three coating layers – a primer, color base coat, and a standard clear coat. The engine undercover (front part), center mud guard, rear bumper fascia (lower part) and rear wing assembly (spoiler) get clear coat (three layers) and no primer or color coats, as the color is already built into the carbon fiber material.

If any damage exposes the actual carbon fiber, do not attempt to repair that part. The quality and adhesion of the coatings on any component with exposed carbon fibers cannot be guaranteed. Replace that part.

There are special steps required to “scuff†the front and rear bumper fascia and the outer side of the trunk lid. Refer to www.nissan-techinfo.com for further details.

Cleaning the Matte FinishDamage that results from failure to follow proper matte paint care instructions is not covered under Nissan’s new vehicle warranty. Matte finish care differences include: Preparation

Washing the Matte Paint

Cleaning the Wheels

|

0 Comments