Don’t Play the Universal Game

Lubricant issues are the number one cause of air conditioning compressor problems. Not enough, not the correct type, or inferior A/C lubricants are estimated to contribute to as much as one-third of all automotive compressor failures.

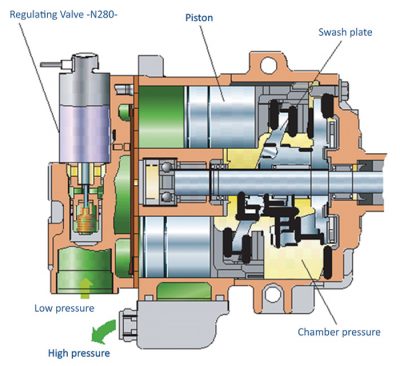

Lubricant transfers heat away from internal compressor surfaces, reduces friction, and help seal gaps between moving parts. If there is too little oil, the compressor will become noticeably noisy, overheat, and eventually fail.

Too much oil can cause slugging in the compressor, which can damage reed valves, piston rods, bearings, and other mechanical parts. Compressor discharge pressures will reach excessive levels and oil will coat condenser and evaporator walls, reducing heat transfer and passenger compartment cooling.

Today’s savvy tech always checks in ElsaPro for VW dealers and erWIN for everyone else. A reminder that every great tech knows… Refrigerants don’t mix (R-12 with R-134a) and neither do A/C Oils (Mineral with PAG) A/C repair and replacement procedures, torque specifications, oils and more can always be found Volkswagens 2 repair programs Elsa Pro and erWIN. Your parts person also has access to Volkswagens ETKA parts program that also lists A/C oils and more helpful info.

Different Types of A/C Lubricant

When vehicle manufacturers switched from R-12 to R134a refrigerant, they had to also switch from mineral oil, the lubricant used with R-12. Mineral oil is not miscible (does not mix) with R-134a, and so cannot be carried by the R134a refrigerant out of the evaporator. The resulting lack of oil in the compressor would lead to overheating, friction and wear, and eventually, compressor failure. The industry developed a synthetic oil — polyalkylene glycol (PAG), which offers the necessary lubricity (ability of the lubricant to reduce friction between rubbing surfaces), and mixes well with R134a.

Since the 1993 Volkswagen has used PAG oil in its A/C compressors and R143a refrigerants. If techs encounter Volkswagen vehicles with R-12 systems, then Mineral oil most likely will be the lubricant required.

A lower-cost alternative, polyol ester (POE), also works with R134a, but offers less lubricity, which translates to less wear protection. In high-temperature compressor operating conditions, POE tends to break down and form acids that are corrosive to A/C system surfaces.

Three Popular Viscosity Grades

PAG is available in a range of viscosities (a measure of a lubricant’s resistance to flow). The three most popular viscosity types are PAG 46 (thin), PAG 100 (medium thickness) and PAG 150 (high thickness). Viscosity Improver (VI) additives help each PAG grade to maintain anti-friction protection in an extreme-heat compressor operating situation, and at the same time offer excellent low-temperature flow capability.

Most Volkswagen models use PAG 46. Check the sticker under the hood for the A/C lubricant type and system capacity, or look it up on the VW ErWin or Elsa Pro, or other repair information database.

Don’t Mix Lubricants

Volkswagen uses several different brands and types of A/C compressors in its vehicles, and some may require different lubricant than others. Never mix different types of lubricant in the same A/C system. Use only the type of lubricant recommended for the component being installed. An incorrect lubricant may not mix well with the refrigerant, this may be incompatible with seals or other material in the system.

Even mixing two different viscosities of the same type of oil is not recommended. The factory-recommended viscosity is specified for a variety of performance-related reasons. An incorrect viscosity can lead to lack of lubricant flow to critical moving parts. This can cause startup and high-temperature protection issues, settling of oil in the condenser or evaporator, or other problems.

New Compressor? Time to Flush!

If you plan to install a different make or model compressor than was in the vehicle when it arrived at your shop, always flush the system first to remove the existing A/C lubricant. Check the installation instructions that come with the new compressor to see what type and amount of lubricant to add.

Volkswagen recommends flushing with compressed air and nitrogen if you need only to remove moisture from the A/C system. For systems that have suffered a component failure that left behind debris or other contaminants, Volkswagen recommends flushing with R134a refrigerant. Using R134a to flush the individual component that was compromised is more effective at removing debris and oil than using compressed air and nitrogen. Check ErWin, or your preferred repair information source for the Volkswagen advisory about proper flushing procedures. Check erWin and ElsaPro for proper flushing procedures.

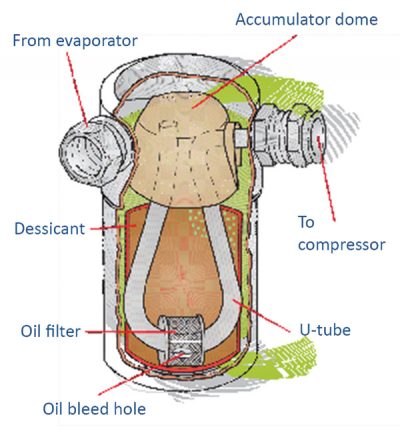

Inspect what flushes out to see if there is metallic debris, corrosion, dessicant bits, or other contaminants in the system. If the previous compressor imploded or threw off contaminants, it is a good idea to replace not only the compressor, but most other system components as well. Accumulators, receiver/driers, and orifice tubes or thermal expansion valves (TXV) cannot be flushed, and should be replaced. Also, modern parallel flow and flat tube serpentine condensers have tubing that is narrower than the lead in a pencil, and are not responsive to flushing.

Balancing Act

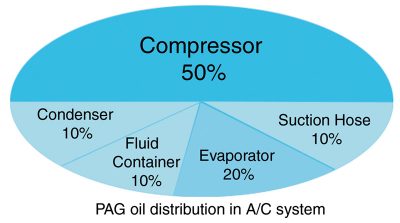

Back in the days when you added three or four pounds of R-12 during a compressor replacement, the amount of oil you put in could be a loose estimate. In today’s A/C systems that use less than one pound of refrigerant, the amount of oil you add is critical. Too much, and some oil will settle in the condenser and obstruct refrigerant flow, causing a loss of cooling. Too little oil and you increase the risk of compressor failure due to lack of lubrication.

If you’re replacing a compressor, the traditional means of determining how much oil you should put in the new unit is to drain it into a measuring cup. You will need to be patient, and you should rotate the compressor shaft frequently during the process. Of course, you’ll never get it all out. So, err on the generous side, but only slightly. Never overfill.

Fortunately, Volkswagen-approved replacement compressors ship with the proper ready-to-use lubricant so that you do not have to remove and replace oil during installation. If you are replacing only the compressor you should not have to pour in additional lubricant beyond what is in the replacement unit.

If, however, the A/C system was leaking, or other system components are being replaced at the same time, you may need to flush all oil from the system and start over. Check the installation instructions for the compressor or other component to confirm the amount of oil to add to the individual component. Add back the specified amount for each unit, then calculate how much, if any, you’ll need to add to bring the system up to the recommended overall oil quantity.

After adding oil to the compressor, it is a good idea to rotate the clutch manually a few times before installation. Rotating the clutch lubricates the bearings and reduces the potential for a dry start, which can damage the compressor.

Oil and Water

Moisture contributes to aging of refrigerant oil, altering its viscosity and causing it to become corrosive towards metals in the A/C system. PAG, POE, and other refrigerant oils are hygroscopic, meaning they can absorb moisture from the atmosphere. PAG oil that has absorbed too much moisture will become viscous (thicker than intended) and darken in color.

Moisture enters the A/C system when service valves are opened, and if bottles are left open too long before pouring lubricant into the system. Older hoses are also a culprit. As hoses age, they allow moisture to permeate through the hose material and into the A/C system. Newer barrier-type hoses reduce the potential for moisture to enter. New style service valves have been upgraded to contain a better O-ring seal, and to fit tighter onto the Schrader valve.

Volkswagen recommends several actions to minimize moisture contamination in your A/C repair process. Replace the cap immediately after pouring refrigerant oil out of its container. Do not re-use refrigerant oil that has been removed from a damaged or open A/C system. Remove as much moisture as possible from the A/C system by pulling a vacuum to 29.9 inches of mercury for at least 30 minutes before charging with new refrigerant.

Double End-capped PAG Oil

There are two types of chemical structures for PAG oil as it relates to moisture. One type of PAG is formulated with one end of its molecular chain capped. The other end remains open, and can react chemically with nearby molecules. In the presence of high heat and moisture, an inferior grade of this single end-capped PAG can break down and contribute to the formation of acids that are harmful to the A/C system.

A second, double end-capped type has both ends of its molecular chain capped, or sealed in a manner that makes it non-reactive with other molecules. While all PAG oils are hygroscopic and absorb moisture, double end-capped PAG is chemically stable and will not react to moisture, even at high temperatures, to form harmful acids.

The bottom line is, provide your VW dealership parts counterman with the VIN number of the car you’re working on. You can be assured of getting exactly the right lubricant for the car you’re servicing, rather than a “universal†lubricant that may not perform like the real McCoy.

0 Comments