Learning these basics can save your life – what not to touch or do, and when to refer customers to a dealer

The high-voltage battery management system on the Mercedes-Benz S500 hybrid controls temperature, state-of-charge, and performs cell balancing for each individual cell to extend battery life. We’ve heard no complaints about Mercedes-Benz HV battery life, but if it does fail, the HV battery is unlikely to respond to further cell balancing attempts in the field, and should be replaced.

By now you’ve likely heard that there is enough electricity under the hood of a hybrid vehicle to kill you. There are many new safety protocols you’ll need to follow. Read on to learn more about ways to reduce your risk when a hybrid vehicle pulls into your bay.

Kill er Formula Ohm’s Law says that current equals volts divided by ohms. From a safety perspective for the repair technician, current (amps) is what fibrillates the heart and freezes muscles, resistance (ohms) is represented by your skin as the body’s wall attempting to keep current out, and voltage is the pressure that pushes amps through that defense. Hybrid vehicles dramatically increase the voltage, from the traditional 12 to a range from 350 up to 500 volts, depending on the vehicle model. So, even though resistance uses the old divide-and-conquer trick against volts, hybrids have enough voltage to easily overwhelm the body’s defense.

A Little Dab Will Do You

| Amps | Effect on the Body |

| 1.0 |

|

| 0.2 | DEATH |

| 0.1 | |

| 0.01 |

|

| 0.001 |

|

If you’re old enough to remember Brylcreme, you know that a little dab made your hair look good enough to win the girl of your dreams. Electric current (amps) is different. A little can kill you. The amount of current a person can accept and still retain control of his or her muscles can be less than 10 milliamps. A milliamp is 1/1,000th of an amp, so 10 milliamps is 0.01 amp.

The chart shows that death is most likely to occur in the middle of a range of electrical exposure from one milliamp up to as little as one amp. Why the middle? If a person is exposed to a low of onethousandth of an amp up to just under one-tenth, bodily reaction ranges from mild sensation to extreme breathing difficulties. In the middle, from 100 and 200 milliamps (0.1 to 0.2 amps), ventricular fibrillation (violent, abnormal contractions of the heart muscle) occurs, weakens the heart beyond repair, and death is almost inevitable. If more than two-tenths of an amp of current enters the body, the muscular contractions are so severe that the heart immediately shuts down. That immediate clamping force on the heart minimizes the development of destructive ventricular fibrillation. Lest you think that if you had to be exposed to electric current, you’d prefer it be on the higher end, remember that your heart has now stopped. It could be revived using artificial respiration or CPR, but only if there is someone nearby with the equipment or skills to begin resuscitation immediately.

No Room for Error

The battery-powered 1906 Mercedes-Benz “Electrique†was an electric vehicle leader almost 110 years ago.

The technician’s only defense is to never touch any live high voltage (HV) power circuit. You can minimize your risk. First, always put on HV gloves before starting any hybrid vehicle diagnosis or repair. High-voltage gloves are heavy rubber and Class O-rated to resist up to 1,000 volts. Do not substitute regular latex or neoprene shop gloves, as they are not insulated as well as Class O high-voltage gloves. Put a second pair of leather gloves over the high voltage rubber gloves to help protect against accidental cuts and abrasions while you work. A tiny puncture could allow current to seep in. Do not use leather gloves that have been previously used for a repair in which they may have picked up metal shavings, glass shards, or other materials with sharp edges. If a sharp object punctures the rubber glove, it creates a path that current can flow through and harm you.

Heavy-duty rubber insulating gloves are certified and date-stamped at the time of manufacture. Because rubber deteriorates over time, OSHA requires re-testing and re-certification of gloves that are more than a year old, to verify that they still offer the required protective benefit. Since the industrial and auto repair shop environments in which these insulating gloves are used is so rough, Class O gloves are also required to be re-certified or replaced after no more than six months of use. The cost of new gloves may be close to that of re-certification, making replacement the cost-effective option based on time savings. Contact your vendor for information on where Class O gloves can be re-certified.

Also, test your gloves before you put them on. Close the open end to keep the air inside, then roll the glove up to above the thumb. The fingers should balloon up. Inspect them to see if there are any pinhole openings, cracks, tears or splits. If any air escapes, discard the gloves and use a new pair. Remember, there is no room for error with the highvoltage circuits on a hybrid vehicle.

Take off jewelry, watches, and rings before putting on the gloves. Rogue electrons want to jump the gap between you and the component on which you are working, and a nearby metal conductor is strong temptation. One last thought about gloves – keep them dry. Some gloves are sold with a little talcum powder for this purpose. Humidity in the glove, like water on the floor or work surface, is a very good conductor. HV safety gloves are also coded with an expiration date. They need to be recertified after this date.

Is This Thing On?

Second, make sure the high voltage system is shut down before you touch any hybrid system component. If it is not already off, shut down the ignition. Make sure the Ready light in the dash is not on. Move the key fob at least six feet away from the vehicle.

You can use the Mercedes-Benz XENTRY system to disable the high voltage circuit on the vehicle. XENTRY is diagnostic software and hardware that helps technicians identify the vehicle and its equipment, communicate with it, and diagnose its systems and performance. Contact your equipment vendor or mbdiagnosis@mbusa.com for more information about XENTRY.

Mercedes-Benz wisely includes what the company calls an “interlock circuit†to easily disable high-voltage circuits on hybrid vehicles. Key HV components include a removable plug that when detached, interrupts the flow of power to the circuit. Monitoring software in the battery management system control unit receives the interrupt signal. On some models, HV power will be lost while driving if the interlock is opened, others will continue to work until you stop moving, and still others will keep moving, but then will not restart after key cycle if the interlock is opened. This applies to not only the originating component, but also every other part of the HV circuit. This includes the electric motor, the power electronics controller, the electric-driven A/C compressor, and other HV components. Lock the plug in your toolbox, so no “helpful†co-worker can reinstall it without your knowledge while you are still working on the HV circuit.

Wait five minutes before attempting any further repair steps. This allows any high voltage remaining in the capacitors to dissipate. Test the HV circuit with a Cat III multi-meter to ensure that it is completely drained. Cat III rating ensures that your multi-meter can handle up to 1,000 volts. Traditional multi-meters are not HV rated. They do not include an ohmmeter that can push enough voltage to test for leaks through the insulation on HV cables, and cannot conduct hybrid insulation resistance tests.

Orange Juice

All high voltage electrical lines on Mercedes-Benz hybrid and other HV vehicles are marked with a bright orange color outer sheathing. All component hardware in the high voltage on-board electrical system has a yellow adhesive warning label that shows the symbol for high voltage.

Before attempting to remove or install an HV component, even on a hybrid or electric vehicle that has already been de-energized or disabled, the technician must have at minimum received High Voltage Awareness training (only offered to Dealer technicians). This training alerts employees to the need for caution around circuits carrying more than 60 DC or 25 AC volts.

Go to the Experts

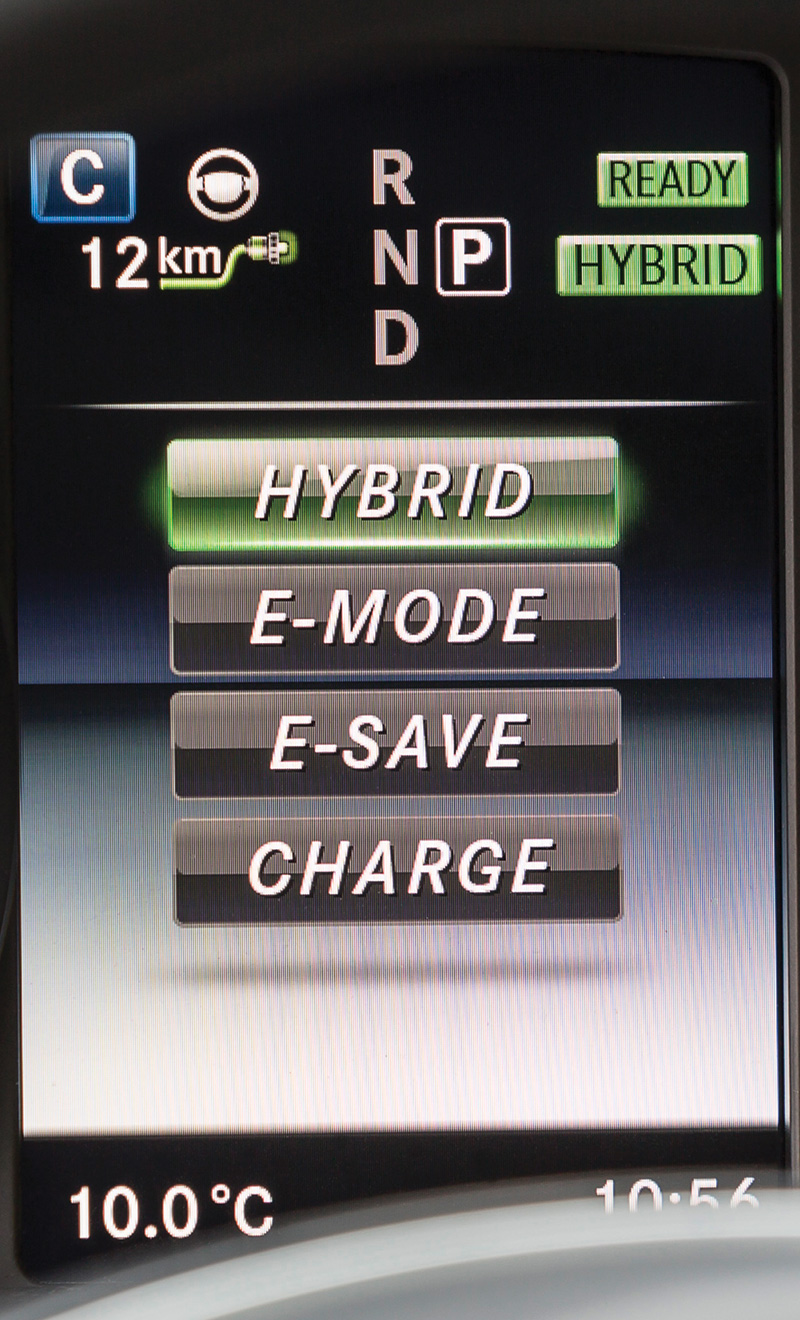

The Mercedes-Benz 2016 C350 Plug-In Hybrid features four operating modes, including allelectric (E-SAVE), all-ICE (E-MODE), hybrid combined electric and ICE, and charging through an external power supply, the on-board electric motor, or regenerative braking.

A technician involved in diagnosis-based de-energizing or disabling of HV systems, and testing, removal and replacement of the battery or other high-voltage components, must be an expert at working on that particular high-voltage vehicle model. Even within the Mercedes-Benz family of vehicles, certification for a specific model does not automatically translate to other models.

For high-voltage system diagnosis and repair, have the vehicle looked at by a Mercedes-Benz dealer. The Mercedes-Benz technician has completed product training and in-person (live, not online) skills assessment for the specific model.

If damaged, the battery, electrical lines and other HV components in a high-voltage vehicle should not be repaired. To ensure the safe future operation of the vehicle, damaged HV components must be replaced.

Drivability, Performance and Emissions

Mercedes-Benz E400 hybrid vehicles can use any of three different propulsion modes: conventional driving with the internal combustion engine (ICE) only, operation with the electric motor only, or hybrid driving with both the electric motor and the ICE. The ICE operates primarily when the driving load fits in its ideal torque range. The electric motor kicks into boost mode when extra acceleration or cruising power is needed. When the ICE needs no boost, the electric motor functions as an alternator, sending its power to be stored in the HV battery pack.

It’s Complicated

The PSC-700 battery charger from Midtronics is approved by Mercedes-Benz and provides 70 amps of current to recharge the high-voltage battery pack in the S400 Hybrid.

Software algorithms in the ME-SFI control unit (for a gasoline ICE), or (for diesel) the CDI controller determine the mix of propulsion modes to balance drivability, performance, and emissions. The software decides, for example, when the ICE should be used, how much the electric-only mode should be used to reduce emissions and enhance fuel economy, and if full-hybrid mode will give the best performance for current driving conditions. Additionally, it maintains the HV and 12-volt battery state-of-charge (SOC) using inputs from the electric motor, the ICE, or regenerative braking.

The ME-SFI controller reviews sensors for wheel speed, engine load, acceleration, torque requests, braking, and other driving inputs, the SOC and temperature of the HV battery pack, the rotational speed, torque and power feed status of the electric motor, the clutch and gear range condition of the transmission, plus sensor inputs from DISTRONIC PLUS, Active Blind Spot, and Lane Keeping Assist. In full-hybrid mode, it propels the wheels using the ICE and the electric motor simultaneously, depending on the driving load. If the vehicle is coasting but not braking or accelerating, the controller switches to regeneration mode and feeds a low level of charge back to the HV battery pack.

A DC/DC converter built into the power electronics module functions as a bidirectional generator of high and low DC voltage. It provides DC power to either the HV (boost mode), or the 12-volt onboard electrical system (Buck mode) on an as-needed basis. When both electrical systems and batteries are fully charged, the DC/DC converter goes into standby mode. The multiple electronic control units, interaction among numerous components in the HV system, multi-directional flow of energy, and real-time information exchange among various network bus systems requires extremely sophisticated tools. Voltage is a measure of flow, and is orders of magnitude faster in the electric motors and controllers than in the devices they replaced, or in components of the 12-volt system. Traditional millisecond I/O sampling rates won’t cut it for measuring HV current flow, pulse width modulation signals, and other HV sensor inputs.

Additionally, the hardware, software, and system management algorithms may differ significantly from one vehicle manufacturer to another. Technicians need training not only in the general sense for the new high-voltage technologies on hybrid vehicles, but also need factory diagnostic and repair information and training for specific Mercedes-Benz hybrid models and components.Â

0 Comments