In this first article of a series designed to improve understanding of Nissan camshaft control systems, we’ll provide an overview of how two popular engines control the timing of their camshafts, including timing chains, tensioners, guides, and sprockets.

It’s no secret that today’s vehicles have become more complex with each coming model year. Computers and sensors now control everything that once was performed by mechanical devices. Fuel injection has replaced the carburetor. Modern, computer controlled, ignition systems have made distributors a thing of the past. While most of us are familiar with these common modern systems, we sometimes forget that every part of the vehicle has evolved along with them. One of the least understood systems is the camshaft control system. This article will address these systems and shed some light on an often overlooked, but crucially important part of the engine.

This is the first in a series of articles designed to bring greater understanding to what’s going on underneath that timing cover. We’ll identify and describe the many components that play a part in the system. After all, how can we hope to fix something if we don’t know how it works?

In later articles, we will look deeper into common failures, what causes them, and how to diagnose and fix them correctly the first time.

To make things easier to follow, we will focus on the 2013 Nissan Altima, the first model year of the fifth generation Altima. We will be using this particular vehicle because it employs two of Nissan’s most popular engines, the sturdy QR25DE 4-cylinder (182 hp, 180 lb∙ft) and the workhorse VQ35DE V6 (270 hp, 258 lb∙ft). These engines have some things in common, but also boast a few very interesting differences. Let’s take a look at how these engines control their camshafts.

Camshafts

Everything we will be covering in this article is designed to control the camshafts. It’s critical that they are clocked correctly with the crankshaft so they can open the valves right on time. Let’s quickly cover some of the terms important to camshafts:

- Camshaft lift height, measured in mm, is directly proportional to the height valves will open.

- Camshaft duration, measured in degrees of crankshaft rotation, is the amount of time that the valve will be open. One might think duration should be measured in a unit of time, but as the engine speeds up and slows down, the time a valve is open changes. What’s important is that the duration in degrees of crankshaft is the same at all engine speeds (assuming there is no CVTCS activity. We will discuss that later).

- Camshaft overlap, also measured in degrees of crankshaft rotation, is the duration of time that both valves are open.

Engines have always utilized a bit of valve overlap to create maximum power. By keeping both valves open for a short time, flow is improved, and the maximum intake charge can enter the cylinder. However, today’s engines can also use valve overlap to control emissions. Keeping some of the exhaust in the cylinder is a more efficient way to limit NOx emissions than a conventional EGR system, and you may notice that neither of these engines is equipped with an EGR system. Nissan employs variable valve timing, referred to as Continuously Variable Valve Timing Control System (CVTCS), which allows the engine to have small valve overlap when power is desired, and large valve overlap when cruising to minimize emissions.

Both engines in the 2013 Altima are equipped with CVCTS, but they work a bit differently. The QR25DE has control over both intake and exhaust timing, while the VQ35DE only has control over intake timing. Nissan also has a variable valve lift system, VVEL, but neither of these engines employ it. The QR25DE has slightly more lift (about .5mm) on the intake side; the VQ35DE has more lift (about 1.5mm) on the exhaust side, but neither is variable.

The QR25DE’s valve overlap, in degrees of crankshaft rotation. Notice that the total time either valve is open (a° and b°) are always the same, only their timing changes.

Camshaft Sprockets

There was a time when camshaft sprocket design was pretty straightforward. The timing chain drove the sprocket, which in turn drove the camshaft. Their main purpose was to spin the camshafts at half the speed of the crankshaft. This is achieved by simply making them twice as big as the crankshaft sprocket. Beyond this, the sprocket was just a basic chunk of metal. Tooth design and construction material have advanced over the years, but for a long time, the camshaft sprocket basically stayed the same.

Then variable camshaft timing came along. First introduced by Nissan as Variable Camshaft Timing, or VCT, it has evolved into the CVTCS used in Nissan engines today. The camshaft sprocket would never be considered simple again. Early, basic, valve timing sprockets used a solenoid to apply oil pressure to vanes in the sprocket, shifting its position relative to the crankshaft sprocket. These early systems were on/off type, either in normal position or full advance. While they improved upon performance, they were very limited.

Today, the camshaft timing is continuously variable. The control solenoid can apply oil pressure to either side of the vanes in the camshaft sprockets, providing continuously variable control. The QR25DE’s intake valve can be made to open as early as 35° BTDC or as late as 5° ATDC. Its exhaust valve can be made to open as early as 41° BBDC or as late as 4° ABDC. That’s 40° of variability for the intake valve and 45° for the exhaust valve – quite a range of overlap.

Timing Chain

Nissan has always been partial to timing chains, as evident by use in the majority of their engines. So, the million dollar question is why a chain, and not a belt. Belts are a cheaper and simpler system to produce, but they aren’t as strong and require preventative maintenance that is costly to the customer. Chains cost more initially and are more complex, but they are stronger and under normal operating conditions they shouldn’t ever require service. Most importantly, timing belts wear out and can break. Timing chains do wear, but rarely, if ever, break. Both the QR25DE and the VQ35DE are interference engines, and a valve timing failure would cause catastrophic engine damage.

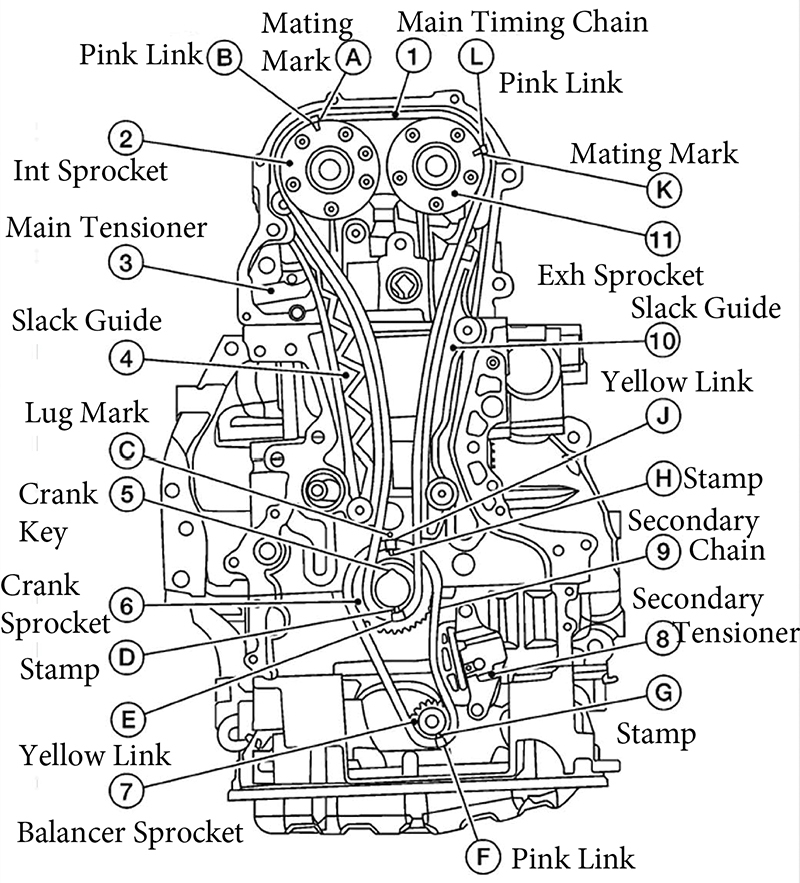

The QR25DE has two timing chains. The main timing chain that connects the crank pulley to the cam pulleys, and the balancer timing chain that connects the crank pulley to the balance shaft pulley. The sprockets have alignment marks and the chain also has colored links to ensure proper installation. The main chain has two pink links that line up with mating marks on the cam sprockets, and a yellow link that lines up with a mating mark on the crank sprocket. The balancer chain has a pink link for the balancer sprocket, and a yellow link for the crank sprocket.

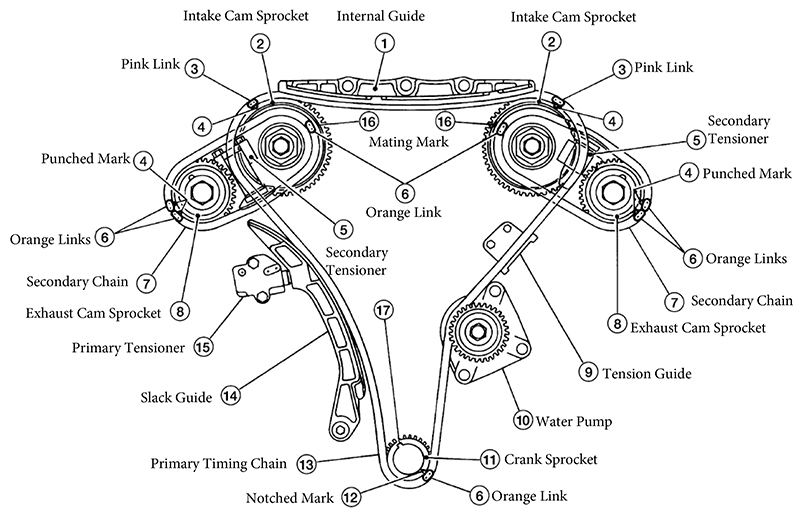

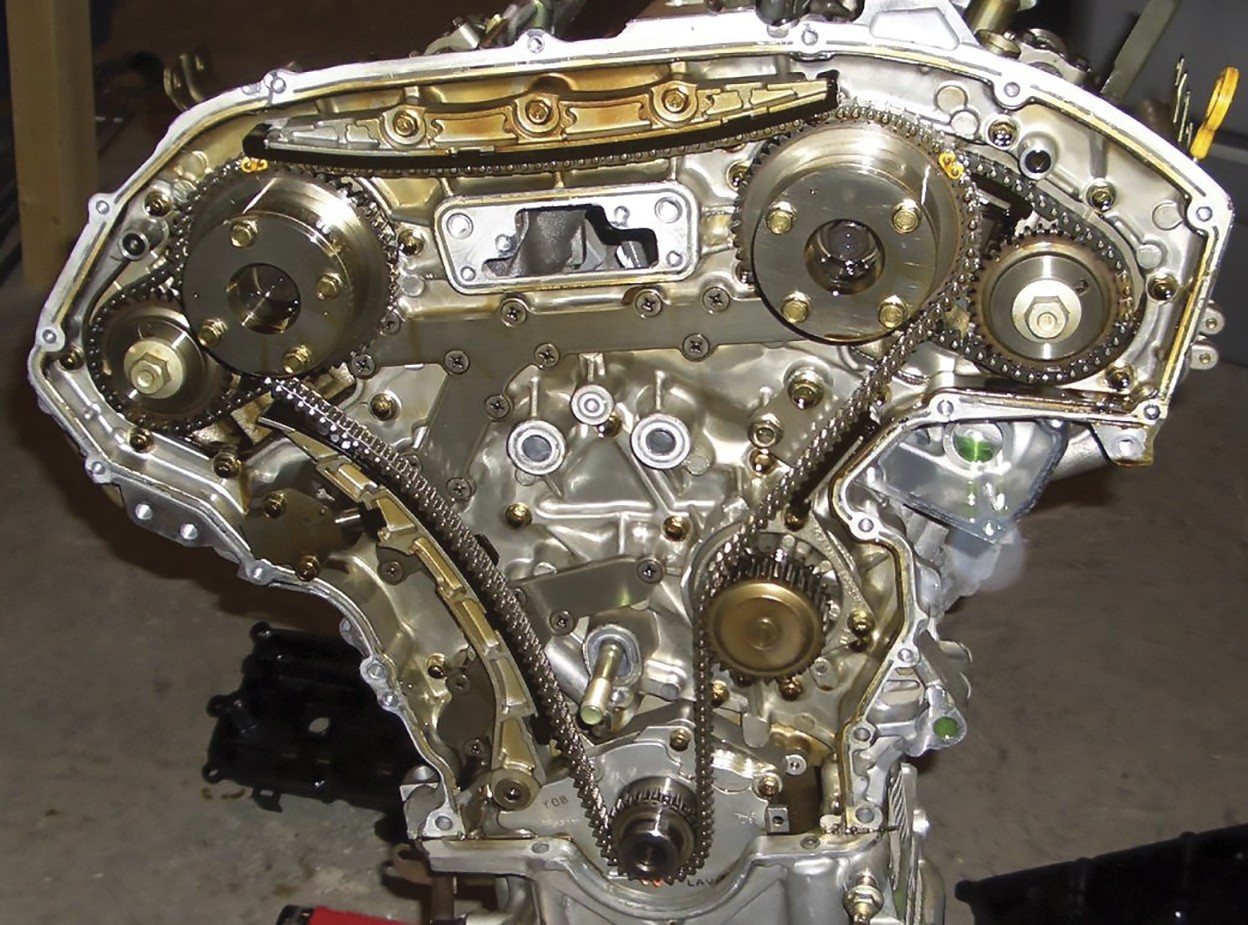

The VQ35 has three timing chains. The primary timing chain which connects the intake cam sprockets (one for each bank) to the crank sprocket, and two secondary chains that connect each banks intake cam sprocket to its exhaust cam sprocket. The primary timing chain also drives the water pump, as opposed to the QR25DE which drives the water pump with the serpentine belt. Along with the sprocket alignment marks, these chains also have colored links to ensure proper installation. The primary chain has pink links for the intake cam sprockets and an orange link for the crank sprocket. The secondary chains have double orange links for the exhaust cam sprocket and single orange links for the intake cam sprocket.

The VQ35DE timing chain schematic. Notice the water pump takes up most of the space that a longer tension guide would occupy.

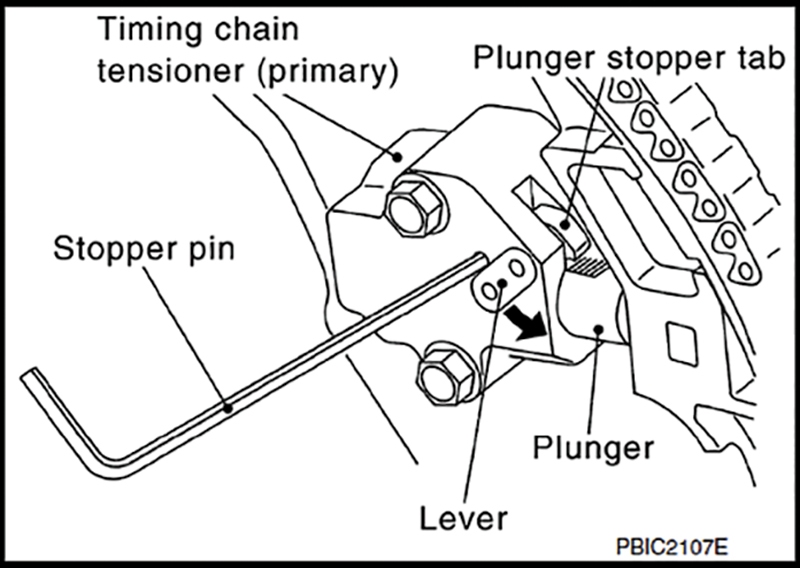

The main timing chain tensioners for both of these engines work in the same way. Move the lever down to release the ratchet, depress plunger, then move lever back up to lock plunger in place.

Tensioners & Guides

Both engines keep their primary timing chain taut with oil pressure regulated tensioners that are identical in operation. Both are located under the upper left hand side of the timing cover. While there are no springs in the primary tensioners, the ratcheting mechanism (referred to as “coaxial structure with leverâ€) must be released before the tensioner can be retracted and locked in.

The VQ35DE has a pair of secondary timing chain tensioners, one for each bank. The left bank tensioner faces down, and the right bank tensioner faces up. Both are also operated with oil pressure. They do not have the ratcheting mechanism, but when removing tension from them Nissan recommends not only holding them with a pin, but also with a thin plate to avoid the plunger falling out during disassembly.

The QR25DE’s secondary chain, which runs the balance shaft, is the only tensioner that does not operate by oil pressure. It is spring loaded and has a stopper tab that must be released before tension can be removed.

The primary timing chains for both engines run along a series of guides to keep them in place. None of the secondary chains have guides, because they are much shorter and do not require guides.

The QR25DE has a pair of guides that span most of the distance between crank and cam pulleys. The slack guide runs along the left side and is acted upon by the main timing chain tensioner. The tension guide runs along the right side. This is a bit confusing, because one would think the tensioner should act upon the tension guide. But that is not the case. The engine spins clockwise, so the crank sprocket is pulling the timing chain from the right side. Thus the right side of the timing chain is the tension side.

The VQ35DE requires three guides, due to the greater distance between the cam pulleys. Like the QR25DE, the slack guide runs along the left side and is acted upon by the main tensioner. The tension guide runs along the right side of the engine, like the QR25DE’s, but it is much shorter. The reason for this is the water pump. It’s mounted on the right side below the tension guide, taking up most of the space that a longer guide would occupy. The third guide is called the internal chain guide, and it spans the entire length between the intake cams of bank 1 and bank 2.

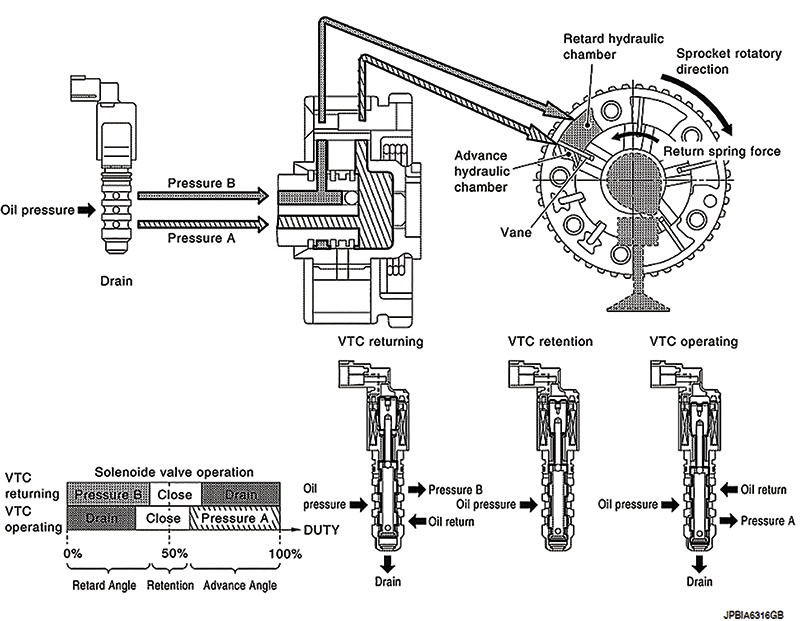

Valve Timing Control

The Valve Timing Control Cover, located in front of the cam sprockets, houses the CVCTS solenoids. The QR25DE has one housing that contains three solenoids, and the VQ35DE has two housings that contain one solenoid each. The VQ35DE’s only solenoid is called the Intake Valve Timing Control Solenoid Valve, and it does just that. The ECM controls this solenoid by varying its duty cycle. The solenoid has two oil passages that lead to either the Advance Hydraulic Chamber, or the Retard Hydraulic Chamber, both located inside the intake camshaft sprocket. When oil pressure is directed to one of these chambers, it is simultaneously drained from the other chamber. The solenoid can also be closed to both passages to maintain constant timing.

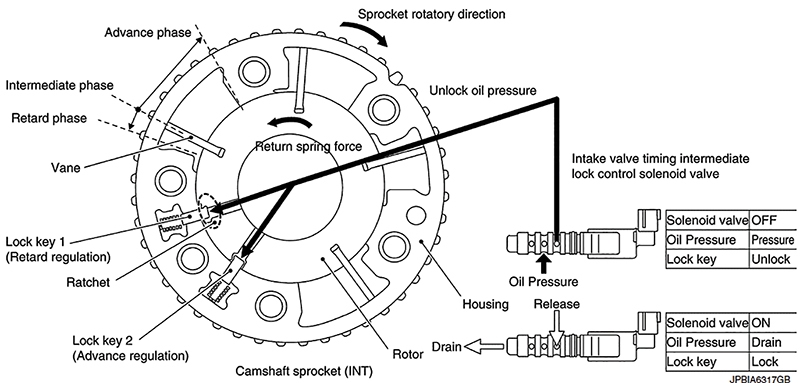

The QR25DE has an Intake Valve Timing Control Solenoid and an Exhaust Valve Timing Control Solenoid that work in the same way. The third solenoid is the Intake Valve Intermediate Lock Control Solenoid Valve. It locks the intake camshaft into what is called Intermediate Lock, where the intake valve opens 5° BTDC (25% advanced from its position at idle). This improves the cleaning ability of exhaust gasses at cold start.

When in the ON position, the solenoid drains oil pressure from the two lock keys in the camshaft sprocket. The lock keys are spring loaded, so without oil pressure to hold them open, they are forced closed and lock the camshaft sprocket in a fixed position. When the engine reaches 140°F (60°C), the solenoid is commanded OFF by the ECM. When OFF, the solenoid closes and oil pressure builds to overcome the spring force on the lock keys and intake valve timing becomes continuously variable.

As you can see, camshaft timing systems are anything but simple in today’s modern engines. There’s far more going on under the timing cover than there used to be. Despite how complex it seems, these modern engines create more power using less gas than previous, simpler, versions. They are also far more reliable. That being said, things may break. Next time, we will look at common failures, how to diagnose them, and proper repair procedures.

The lock keys are located inside the intake cam sprocket. During cold start, oil pressure is released by the solenoid and spring tension forces the keys to engage and lock the sprocket. Once the engine warms up, the solenoid closes, and oil pressure overcomes the spring tension to unlock the sprocket.

0 Comments