Why waste fuel and produce emissions while idling at a traffic light?

You’re running on fumes and there’s not a gas station anywhere in sight. In a desperate attempt to save every drop of fuel you can, you shut the engine off at every traffic light. If you‘ve spent enough time behind the wheel, chances are you’ve tried this emergency conservation effort to avoid being left stranded. Whether you realized it or not, this is actually an effective fuel-saving strategy.

Well, time and technology have finally caught up with that old idea and put a new spin on it. Instead of using manual stop/start to nurse a vehicle into the nearest filling station, engineers have now devised a way to make stop/start actuation a practical, reliable, automatic, economically- and environmentally-friendly strategy. Shutting down an idling engine at prolonged stops produces benefits on several fronts:

- Fuel economy — It’s simple: an engine that’s not running isn’t burning any fuel. This can equate to from 15% to 30% in fuel costs depending on the driving environment. Using less fuel reduces time and money spent at the pump.

- Tailpipe emissions reduction — Another simple example is that an engine not running is not producing any environmentally-harmful internal combustion byproduct gases.

- Compounding Effect — As older cars are phased out and newer stop/start-equipped vehicles are introduced, the benefits mentioned above become available for everyone.

For us here in the United States, stop/start seems like a new idea. In Europe and Japan, however, this concept has been attempted by several manufactures for decades. Having a dense population with choking emissions has been the driving force behind the push for stop/start in those areas. Here in the States, the need or will to reduce fuel consumption and emissions has been slower in coming. Now, with the Environmental Protection Agency (EPA) demanding stricter standards for lowering emissions and mandating higher fuel mileage, new avenues must be explored. Over the next ten years, the average fuel mileage for passenger vehicles will rise to 50+ mpg. This poses a challenge to all vehicle manufacturers. Engineers are already pushing the efficiency limits of internal combustion engines, yet the public and the government are demanding other ways to save.

Conditions right?

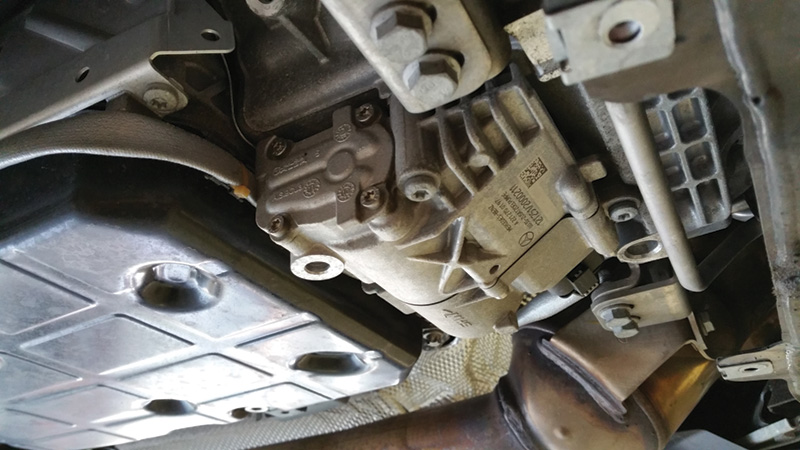

The electric transmission fluid pump maintains positive pressure to keep the transmission ready for rapid resumption of travel.

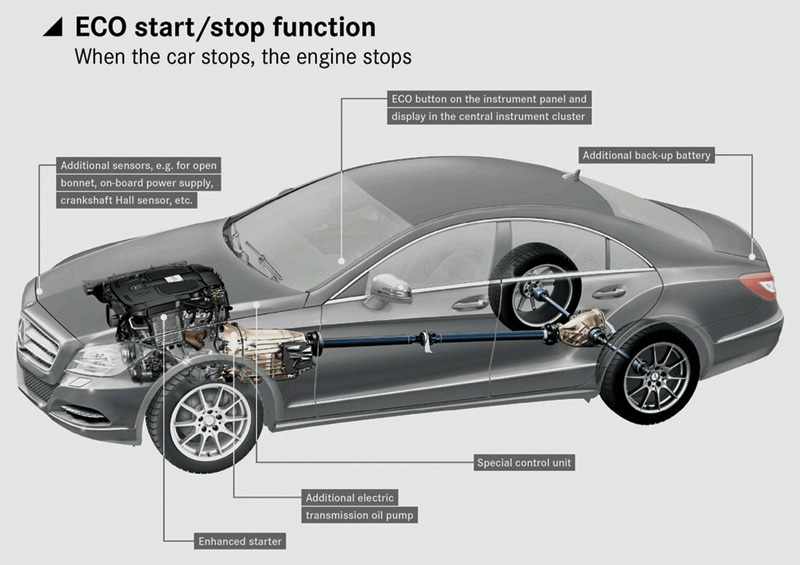

Mercedes-Benz has introduced its version of stop/start on a limited number of Blue Efficiency vehicles. Known as ECO Start, this technology is expected to migrate to all model lines in the coming years. But why wait until now to implement this technique? The answer is safety and reliability. With the technology of yesterday it just wasn’t safe and practical to shut down the engine at stop lights. That was because of long crank times and human inattention, but with today’s advanced technology those problems have been solved.

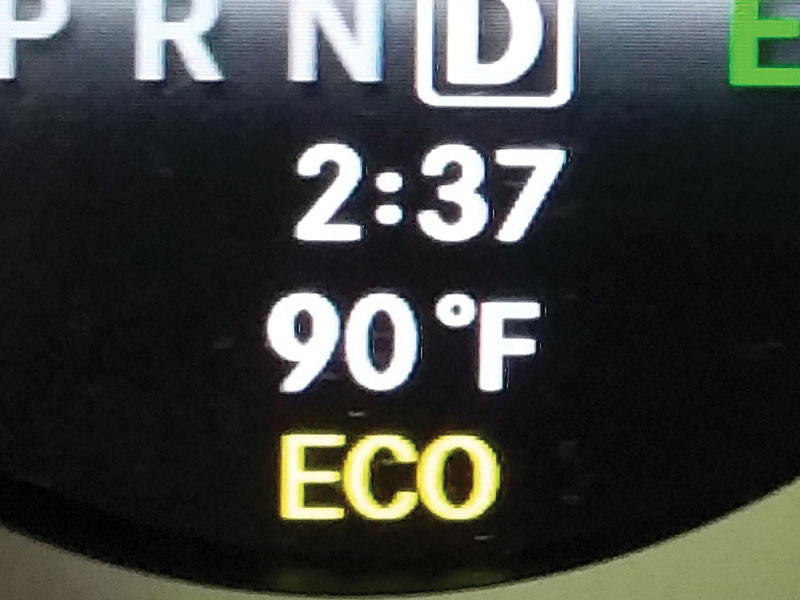

Here, the instrument cluster ECO icon shows yellow, meaning system is on but not ready for actuation.

The beauty of Mercedes-Benz ECO Start is that when it’s switched on, the system is completely automated. This allows the car to be driven normally with no special human action or influence needed. The system will not engage until a large number of predetermined parameters have been met. A complete list will depend on the vehicle type and options. Below are the basic criteria for ECO Start to be enabled:

- Hood and doors shut

- Driver’s seat belt buckled

- Engine and transmission at operating temperature

- Vehicle speed has exceeded nine mph at least once since put in gear

- Automatic transmission in Drive, or manual transmission in neutral

- Sufficient brake booster vacuum (on applicable models)

- All on-board diagnosis up to date

- Vehicle electrical demand not excessive, and at least 65% of reserve battery capacity present.

- Cabin temperature request from climate control has been met

Once all of the prerequisite conditions have been met, ECO Start activates and only requires two additional inputs for the engine to automatically shut off:

- The vehicle has stopped and become stationary.

- Brakes are applied by the driver’s foot pedal or by engaging the brake hold feature.

After ECO Start has turned off the engine, there are several factors that will trigger an automatic restart:

- If any one of the pre-conditions falls outside its parameters. In this scenario, the most likely cause for restart is that the passenger cabin temperature has gone beyond the set value.

- Brakes are released or the accelerator has been pressed

- The vehicle is in motion even if the brake pedal is depressed (i.e. light pressure and the vehicle is creeping forward)

- The engine has been off for three minutes

- The transmission is engaged in park or reverse.

From the driver’s perspective, there is little difference between an ECO equipped and a non-ECO-equipped vehicle. Only a dash on/off switch and instrument cluster icon has been added. The instrument cluster icon is the only visual display that gives any indication of ECO operation and displays three different states:

- No Icon – System is switched off

- Yellow Icon – System is on, but parameters for operation have not been met

- Green Icon- All criteria have been met and the system is operational

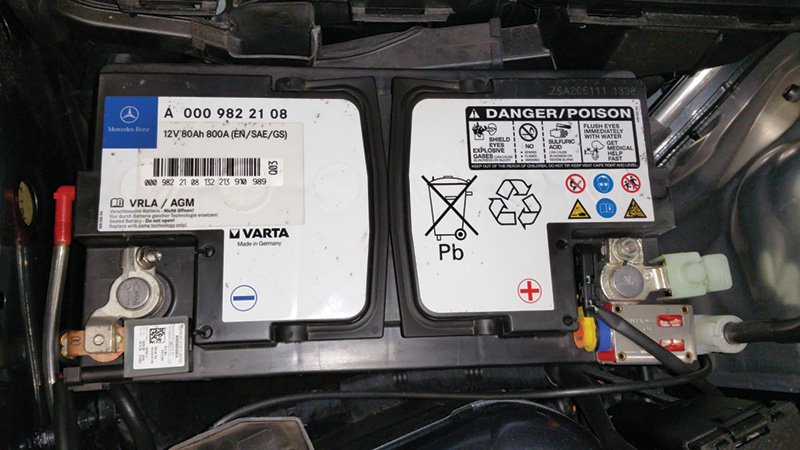

This Mercedes-Benz AGM (Absorbed Glass Mat) battery is an example of the technology that makes ECO Start possible. AGMs can recover from repeated cycling many times more than conventional wet cell batteries can.

Getting to the heart of ECO

For owners to accept ECO start, the stop/start function needs to be as seamless as possible. Mercedes-Benz has accomplished this using existing equipment and sensors with minimal addition of new parts. Most of the changes that have occurred are software based, but technicians need to be aware of the new hardware:

The ECO Start dash button is the only real input the driver can have — you can turn the system off.

At the heart of the ECO system is a heavy-duty starter redesigned with enhanced bearings and gear. These are capable of handling the increased demand placed on the starter and limit flex-plate wear from repeated engagement. In an urban area, the starter could see eight times more use over its lifecycle. Because of this, if a vehicle comes in for repair and the starter needs to be replaced, only a new genuine Mercedes-Benz part is acceptable.

ECO Start adds an additional battery to the vehicle to handle electrical functions so that full main battery power can be solely devoted to restarting. This dual battery setup is very similar to that of Mercedes-Benz vehicles of the past, using the same decoupling relay for seamless operation.

Mercedes-Benz has also added an electric auxillary pump to the automatic transmission. This pump is active when ECO Start has initiated an engine stop. Supplying the transmission clutches with fluid pressure while the engine is off ensures that on restart there will be no delay in travel resumption.

From the outside, an enhanced ECO Start starter looks the same as a normal starter. This makes it imperative that a replacement unit be looked up in EPC and ordered from your local Mercedes-Benz dealer’s parts department by VIN.

ECO Start utilizes the precision of Mercedes-Benz Direct Fuel Injection to deliver impressive restart times. Using saved data from the crankshaft angle sensor, the engine computer is able to determine the most favorable cylinder for first combustion. During restart, that cylinder is fired to speed up starting and lighten the load placed on the starter. This combination produces a restart time of 20 milliseconds or less giving the consumer an almost seamless experience.

Routine diagnostics

Dealing with ECO Start from a diagnostic standpoint should be a fairly routine exercise. At this point in ECO Start’s young life there are no known problems to speak of. If faced with a start/stop problem, the same procedures apply as with any other on-board system. Since the bulk of ECO Start uses existing modules and sensors, chances are that one or more of the prerequisite conditions for operation is not being met. Using fault codes and live data from SDS or an equivalent scan tool will pinpoint a problem. Once a problem or potential problem has been identified, follow guided tests for the given part found in Mercedes-Benz service literature.Â

0 Comments