Since they were introduced in 1983, BMW diesels have shown themselves to be very durable and dependable. That is, if they receive proper maintenance. No? Then you’ll need to do some diagnosis before you fix anything.

Tens of thousands of loyal, enthusiastic BMW diesel owners and drivers enjoy tens of thousands of miles of spirited, trouble-free economical driving year after year. Now and again, however, driving is not so trouble-free and problems intrude on the pleasures of driving a BMW. Here are a few issues – some major, some not — that bear reporting, basically falling into three broad areas:

- loss of power

- fuel delivery

- engine damage

Turbochargers are a probable cause of power loss

Diminished power is perhaps the most common diesel ailment, and – almost  universally — falls on turbocharger-related issues. BMW diesels rely on turbochargers to give them the punch needed for superior performance, but can fail to operate normally causing significant power drop, or fail and require significant repair. Things that can have a dramatic effect on a turbo’s life include:

- Loose or split vacuum hose

- Insufficient or incorrect oil

- Ignoring normal service intervals

- Clogged crankcase breather

- Oil feed line blockage

If turbo failure is suspected, but no definitive symptoms are apparent, a quick check of vacuum pipe connections and the condition of the vacuum reservoir is in order — the problem could be simply a disconnected or cracked vacuum hose. If these are okay, a diagnostic scan can show DTCs (Diagnostic Trouble Codes) specific to turbo operation. Some diesel turbo-related codes, symptoms, and causes include:

- 3F01 Boost Pressure sensor inactive. There is one pressure sensor located above the turbo and another one under the inlet manifold that control the EGR valve. Removal and cleaning of this valve may clear it, but replacement may be required.

- 4521 Boost pressure control pressure may be too high.

- 4530 Boost pressure control pressure may be too low. This can indicate clogged variable vanes in the turbo, and it may be necessary to check vane operation manually.

- Turbo Whistle. Wear and tear over thousands of miles of spirited driving may cause some turbos to whistle more than others, but if the whistle is more of a scream that sounds like a police siren and the engine has no power over 1,000-2,000 rpm, check the play on the turbo’s shaft ASAP.

Remove the air pipe to the turbo’s inlet after the engine is cool and grip the turbo’s shaft between thumb and forefinger to check side to side (radial play) and end to end ‘float’ (axial play) on the bearings. Axial float should be 0.025mm to 0.1mm which can hardly be felt, while radial float is normally 0.3mm to 0.6mm, felt as a definite rocking. A dial gauge is required to accurately measure float, but if either axial or radial float feels excessive the unit may need immediate attention.

Unusually high oil consumption with blue exhaust smoke can indicate worn turbo seals, and in very rare instances the engine can begin to run on its own crankcase oil, causing plumes of smoke from the rear of the vehicle. In this case, turning the ignition off will not stop the engine running, and engine seizure could happen – the engine must be stalled, possibly by covering the intake with a suitable piece of heavy plywood. With a manual transmission, popping the clutch in a high gear with the brake pedal engaged might do it.

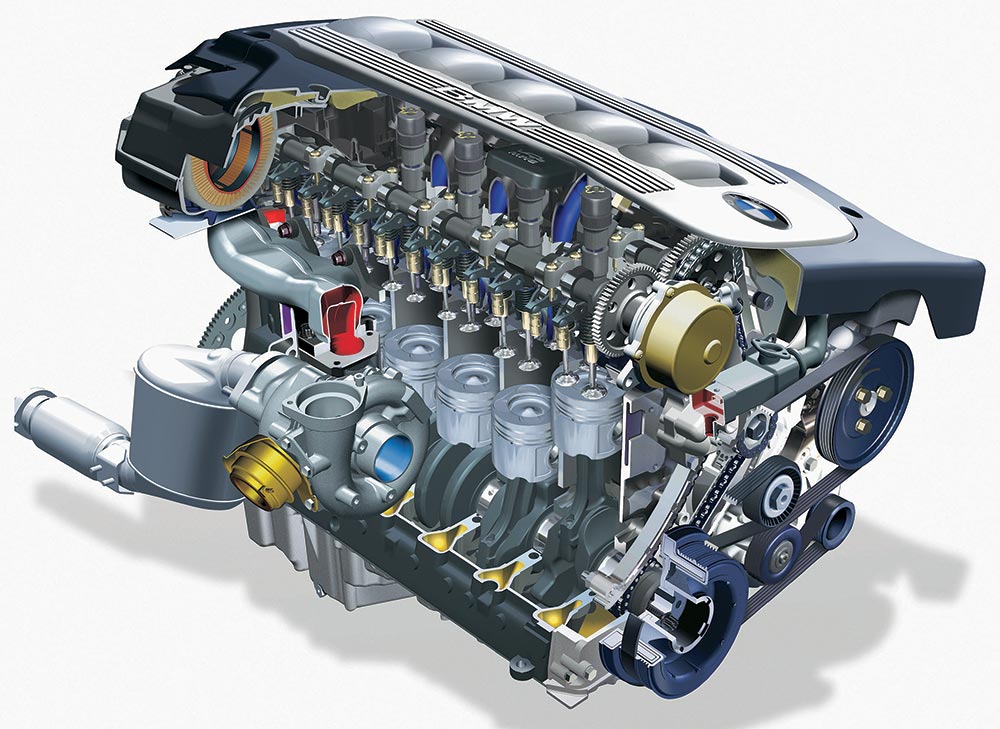

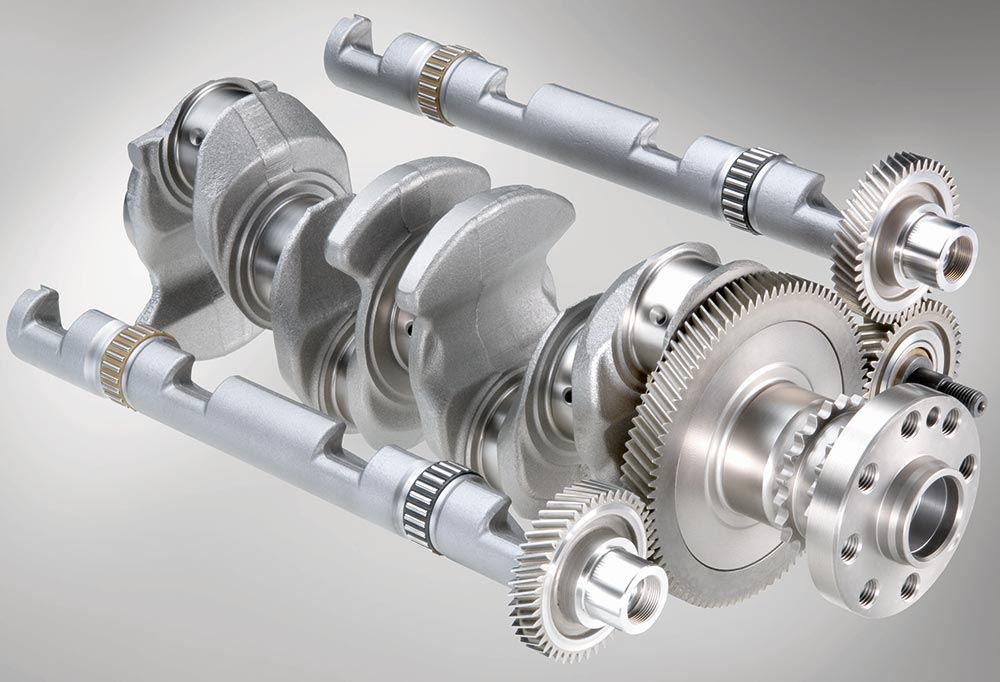

This is the six-cylinder diesel BMW introduced in 2002. Note the turbocharger and the cam drive, both of which are potentially troublesome.

Primary turbo problems

BMW turbos, vital to the power of the engine, can cease to do their job for several reasons, including:

- Boost pressure leaks, where the turbo is functioning correctly, but the boost pressure is being lost before it can enter the engine due to cracks, splits or poorly fitted hoses on the induction side. This can cause noticeable power loss, with the engine sending out excess black smoke.

- Turbo not creating boost, due to the fact that the exhaust system feeding the turbo has leaks, causing loss of exhaust volume delivery and power loss.

- Blocked or gummed-up air filters, starving the turbo.

- Variable vanes seized on the turbo from soot and carbon buildup, causing the pitch angle of the vanes to stick. This can cause either poor power pick-up or dropping power in higher rev ranges.

- Faulty info from sensors on the engine can also create power problems, where the turbo is being instructed incorrectly by the ECU — diagnostic software will help identify suspected sensors or problems.

And remember, the VTG variable vane system is the key to sound turbo – and engine — performance.

Turbocharger failure or seal replacement

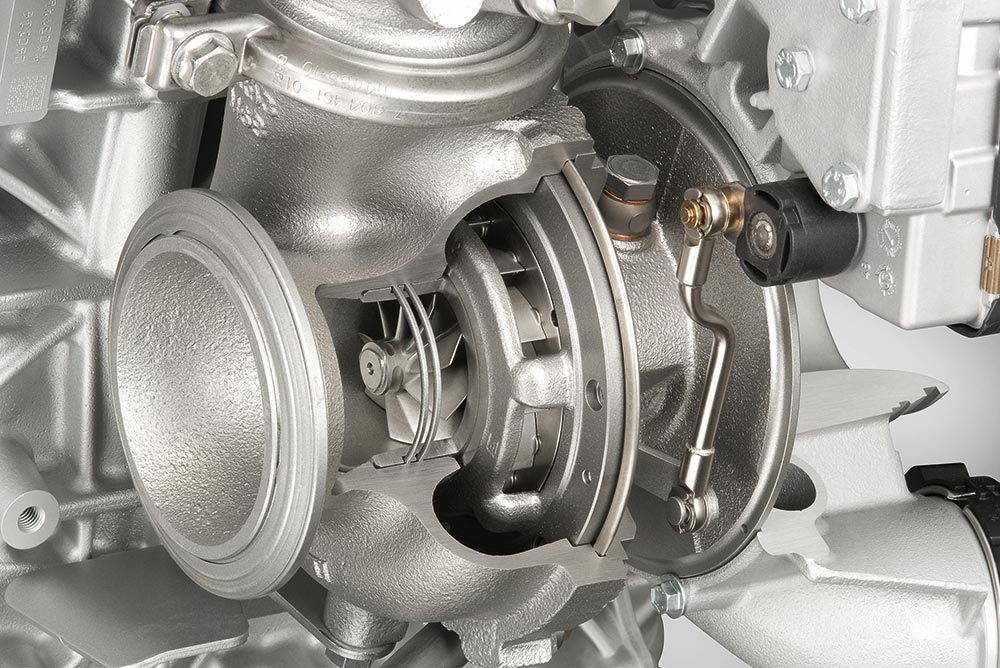

This 2008 turbocharger has electrical adjustment of the geometry of its blades, and works with an 1,800 Bar Piezo injection system.

Turbo failures on BMW diesels appear most commonly with the M47TDU20 series of engines, particularly the 2002-2003 model years. These engines saw the first installation of common-rail technology for BMW diesels, with displacement increased and balance shafts incorporated to subdue larger-displacement four-cylinder engines’ vibrations.

“Swirl flaps,â€Â butterfly valves much like a throttle body plate located in the individual intake runners, could wreck the turbo if they fail. Over time, retaining screws that hold the flaps to the actuating rods could work loose and drop into the combustion chamber, causing obvious foreign object damage. The screws could go into the exhaust manifold and then into the turbo, damaging turbine blades and housing. This problem was subsequently mitigated by changing to one-piece engineered plastic flaps.

Another possible turbo problem is a clogged crankcase breather filter. If the breather filter clogs, crankcase pressure rises, blowing motor oil past the turbocharger shaft seal. This could be diagnosed as turbine failure rather than blown seals. Turbochargers usually act up when seals, bearings, or bushings fail due to insufficient lubrication or oil contaminants that cause abrasion to the seals, bearings, or bushings in turbines spinning at speeds up to 100,000 rpm.

Changing oil and air filters at regular intervals is the best protection against premature turbine failure.

Wait, CBU shows similar symptoms

But wait, another power loss situation is not from the turbo at all, it’s CBU – carbon buildup, primarily in the intake manifold, and usually brought on by either low-cetane and high-sulfur diesel fuel, faulty EGR valves, or what is a common problem, “soft†driving techniques that baby the engine with no hard charging so that soot from the EGR system build up as carbon deposits in the intake manifold. Carbon build-up appears to be a problem with some 3 Series and other vehicles with significant mileage, driven gently for short, stop-and-go trips. CBU often brings:

- Weak power – sometimes very weak power

- Reduced-Power light comes on

- SES (service engine soon) light comes on

BMW issued a recall to correct EGR valve weakness on specific vehicles, which appears to have taken care of the CBU on these vehicles. But CBU is a possible problem on any diesel from whatever carmaker, and curing it can involve thoroughly cleaning the intake manifold to remove the gook built up in it, which can be done by soaking the manifold in solvent, or with ultrasonic cleaning.

Reduced power and SES lamps on could trigger trouble codes:

- 3FF1, Air Mass Sensor

- 4583 and 4585, NOx sensors

- 4AFS, zero quantity adaptation injector #3

- 4C04, check EGR

- 4595, smooth running controller

Beware of loose fuel cap!

Any of these codes could lead to replacement of multiple components and physically checking and cleaning or replacing the intake manifold, which may or may not correct carbon buildup or keep the SES light off. BMW believes diesel fuel in the U.S. typically of a lower cetane rating than that used in Europe, and is hampered by EPA regulations for sulfur content, contributing to soot creation and carbon buildup.

The lack of spirited driving could almost guarantee carbon buildup, and occasionally running the vehicle hard could well prevent this problem. And, if the SES lamp keeps appearing no matter what, before going into correction mode consider that the SES warning could be from nothing more than a loose fuel cap!

Make sure the cap clicks when tightened. If not, this will almost certainly cause an SES light. So, first check the fuel cap, tighten it until it clicks if it wasn’t tight before, and the SES may well go out after a calibrated number of driving cycles.

Common Rail injector failure, other problems

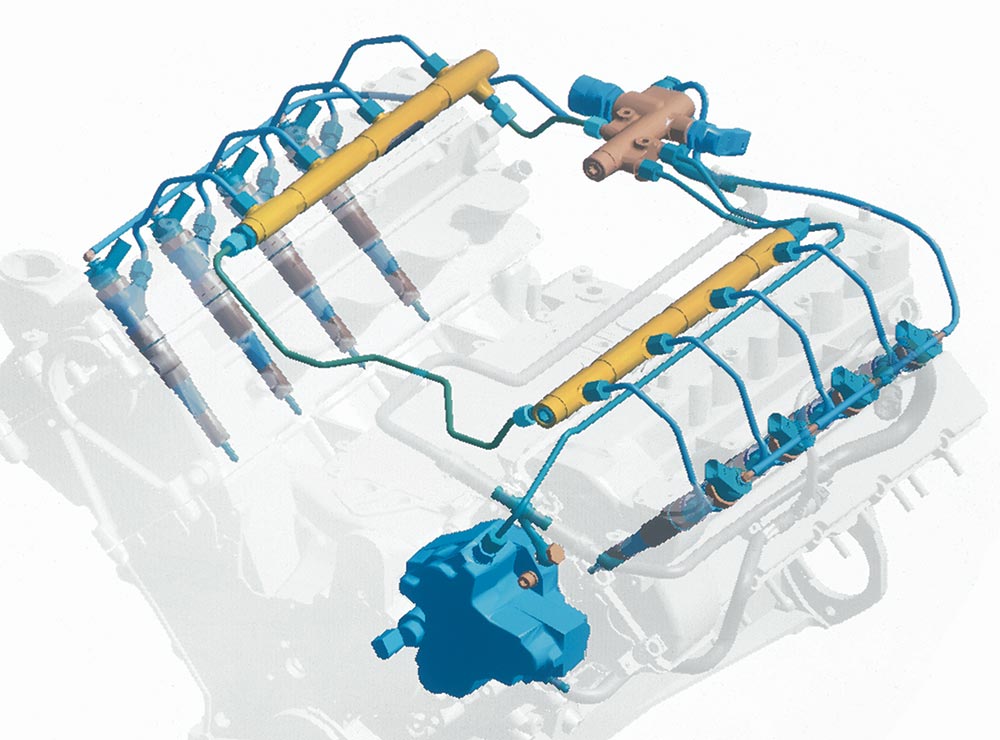

BMW began installing (very) high-pressure common rail fuel injection systems in its diesels years ago. Basically, the Robert Bosch common rail system, operating at extreme pressures of up to 30,000 psi (2,000 Bar), controls the injection of diesel fuel at the right moment, in the right quantities, and with the correct pressure. This ensures that the diesel engine not only runs smoothly, but also economically. A common rail accumulator system on a four-cylinder BMW diesel engine includes:

- Air-mass meter

- ECU

- High-pressure pump

- High-pressure accumulator (the rail)

- Injectors

- Crankshaft-speed sensor

- Coolant-temperature sensor

- Fuel filter

- Accelerator pedal angle sensor

The Robert Bosch common-rail system makes a huge difference in how smoothly, efficiently, and quietly a modern BMW diesel runs. Precisely-timed multiple injection events avoid having one “big bang,†and 20,000 to 30,000 psi really atomizes the fuel.

Symptoms of a failing injector include:

- A loud knock audible with windows down when the vehicle is cold or when the sound bounces from a wall or other solid object

- Poor fuel economy

- Rough idle

- Reduced fuel mileage

- Engine misfire

- Hard or difficult starting

- Hesitation on acceleration

This old pop tester we used for traditional diesel injectors is useless with common-rail. It only goes up to 5,000 psi, which we once thought was a lot.

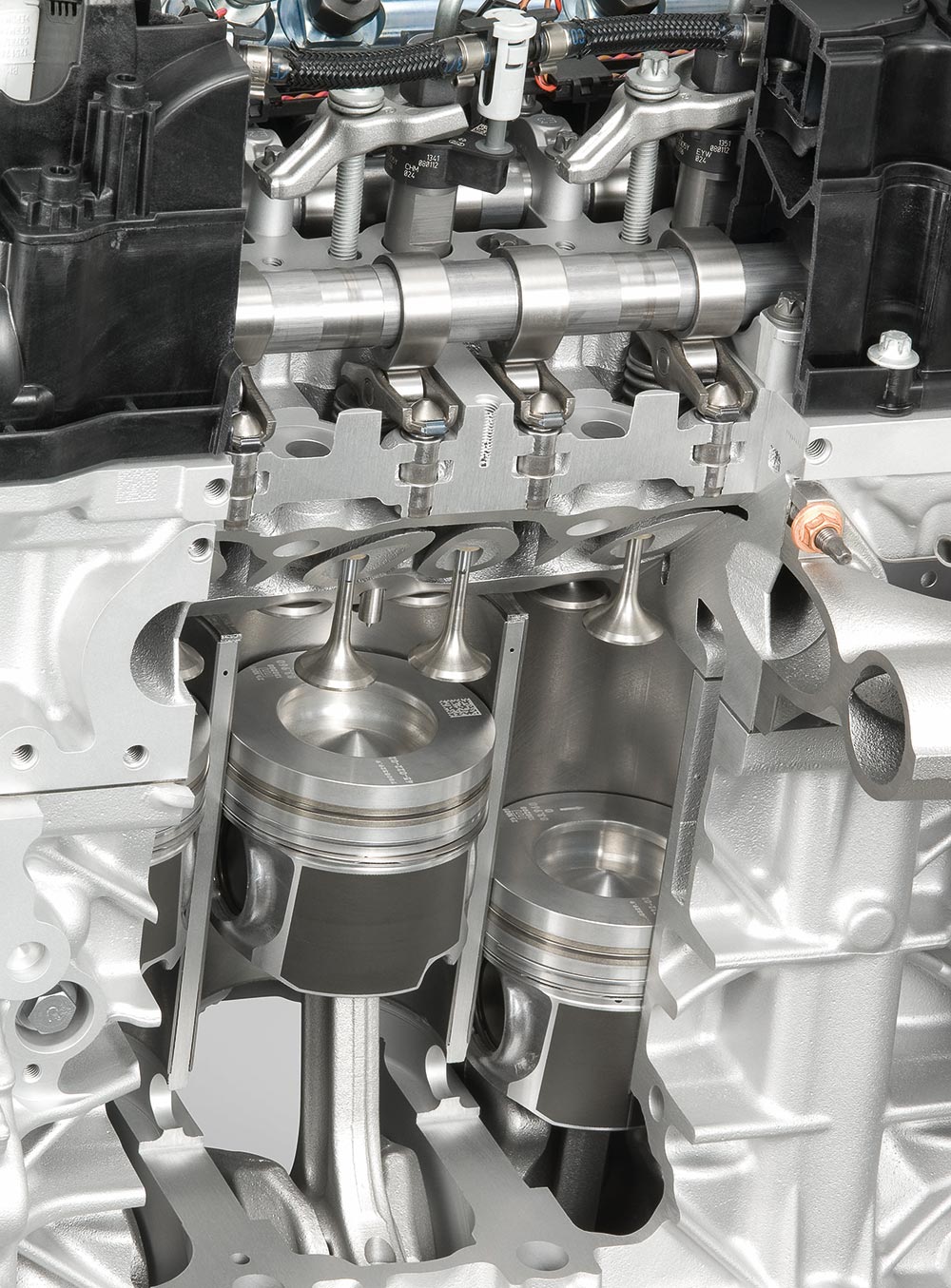

Dirty or worn-out injectors can also cause pre-ignition or detonation, death for a diesel. Detonation is a fairly common problem in which fuel remaining at the end of the normal air/fuel burning cycle spontaneously combusts. Detonation has the potential to break engine components and cause pitting and scuffing of the pistons. Common rail injection operates with vastly more pressure than previous systems, and this has a definite impact on injector longevity. The injectors fire four to five times per combustion stroke, instead of just once, and have a much smaller operational tolerance than previous injectors.

Injectors can be replaced individually, but diagnosis on the vehicle is the absolute key to validating a failed injector. The ECU must be coded when replacing injectors to recognize that the injector has been changed. Common rail is a complete system, comprising injectors, pump, ECU, rail, and sensors. Common rail pressures have hovered around 20,000 psi (1,333 Bar) for several years, and have climbed to over 23,000 psi (1,533 Bar) in some engines. Higher pressures increase the speed at which fuel is injected into the cylinders, improve atomization and vaporization, and shorten the fuel delivery time, which provides greater flexibility with engine timing, improves engine performance, reduces emissions, and improves fuel economy.

Fast-acting piezo injection technology, utilized in the latest common rail systems, has the potential of reducing fuel consumption by about three percent, reducing emissions by as much as 20%, increasing engine power by as much as five percent, and reducing overall engine noise.

CAUTION: Common rail works by pumping pressurized fuel into the “rail†for delivery through injectors at more than 20,000 psi. Before any service is performed on injectors or any other element of the system, it is imperative to relieve the pressure in the rail. Exposure to diesel fuel at 20,000 psi or higher could cause serious bodily harm.

BMW Common Rail systems are actuated by DDE (Digital Diesel Electronics) ECU controllers, depending on the years and engines. The first series of diesel engines used the DDE1 control unit, found in the M21-powered E30 324d and td, and the E28 524d and 524td. DDE 2 and DDE 2.1 were used on M41 and M51 engines. DDE 2.1 used an updated air mass meter with an internal air temperature sensor, while DDE2 has a separate sensor in the manifold. DDE 2.2 is an updated version of the previous DDE 2.1, and was introduced in 1995. This system was used on the M51TU engines.

DDE 3 is the BMW name for ECUs found in the M47 range of four-cylinder diesels, used in the E46 320d. DDE 4 is in the M57 range of 2.5L to 3.0lL six-cylinder engines, and the DDE4.1 was used in a twin master/slave arrangement in the M67 V8 diesels, with each ECU controlling one bank of engine cylinders.

DDE5 is another update to the M57 and M67 diesel engine controllers. It is a second-generation common rail system with rail pressures increasing to 23,000 psi (1,533 Bar) and complies with the European EU3 emissions standard. DDE 6 is used on M57 and M67 engines from 2005 on, using the same 23,000 psi common rail system.

Fault codes vary and are specific for each DDE series.

Follow the bimmer pub for future installments of our on-going diesel diagnosis coverage.

0 Comments