Breakdown Maintenance or Preventative Maintenance?

This really won’t translate directly to the high-performance field since every racer knows enough to keep the engine oil clean and check the filters frequently for signs of distress, but it might apply to your tow vehicles — assuming that you’re foolish enough to buy into the factory hype about extended oil drain intervals.

There is a distressing trend out there that strongly suggests that the marketing teams have overridden the engineers when it comes to routine maintenance and the proper car of a modern car or light truck. Let’s face it, the job of a car or truck manufacturing company is to sell more cars and trucks. The prime financial mover for a manufacturing concern is more units sold and more market share. As we’ve moved from an agrarian society where folks interacted with their machinery every day and saw the direct results of failing to maintain a piece of equipment, the marketing people seized on this disconnect and began telling everyone that through some miracle they had perfected the lifetime sealed unit so that the working fluids or filters no longer needed to be changed.

Just to make sure I understand, there is no more break-in period, no swarf or shrapnel generated as new parts scrub into one another, no heat, no condensation, no oxidation, no shear, no contamination by minute quantities of combustion products making their way into the crankcase?

There’s no condensation on cold cylinder walls, no short-interval driving, no freezing cold winter and no blazing hot summers. We are now supposed to assume that even though the owner’s manuals of every manufacturer out there contain a “get out of jail free†clause that states that oil consumption of up to a quart in a thousand miles (or less!) is “normal,†there is no leakage the other direction, from combustion chamber into the crankcase. Oil from a low-pressure crankcase can find its way into a high-pressure chamber, but high pressure can’t make its way into a lower pressure? The laws of physics are suspended simply by declaring it so.

I don’t know about you, but I’m offended by this bovine excrement. Every engine uses oil; it is designed to use a minute amount. It has to to keep the rings lubricated. If the crankcase level remains constant, the volume of condensation, blow-by or contamination finding its way into the crankcase is equal to the consumption and the level doesn’t drop, but the crankcase is now fouled and must be drained! Yes, it’s true: Oil does not wear out. But it does become contaminated and it is subject to breakdown and chemical attack. Your oil change interval is dictated by the capacity of the sump and the volume of oil it can hold, which determines both the total additive content (10- 20% of every quart is an additive of some kind) and the mass over which the accumulating contaminants can safely be spread while still maintaining proper engine lubrication.

In my experience, you can only safely run approximately 1,000 miles per quart of crankcase capacity, assuming you use top-shelf synthetic engine oil. The 10,000 mile interval is a fairy tale, and I’ve got the pictures to prove it.

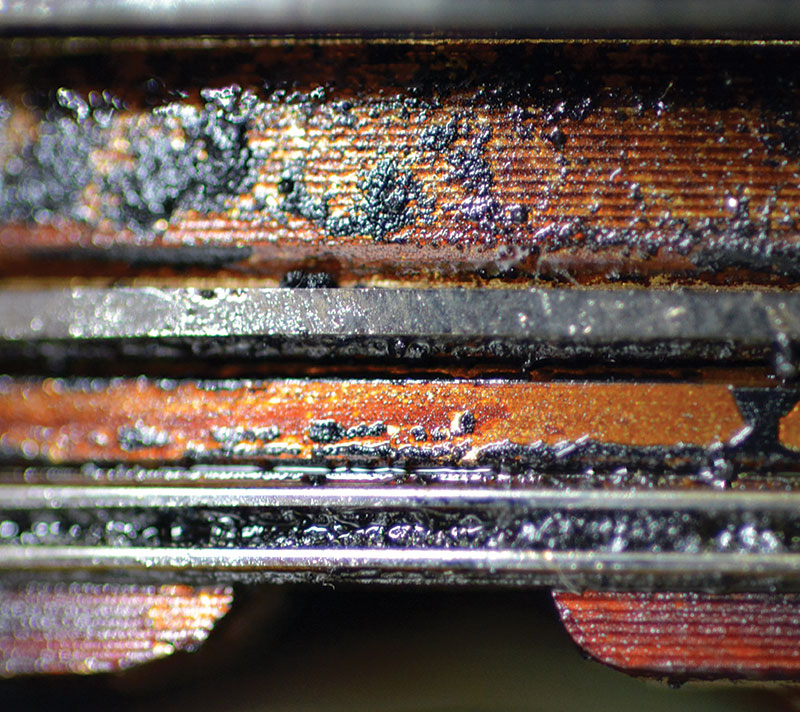

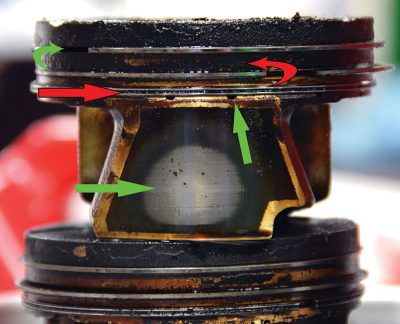

The pistons shown are from an import vehicle that mandates full synthetic, 10,000 mile oil drain intervals, and these are just a few of the pistons that have been quietly replaced (if and when the customer complains of excessive oil consumption) under a little-known factory program.

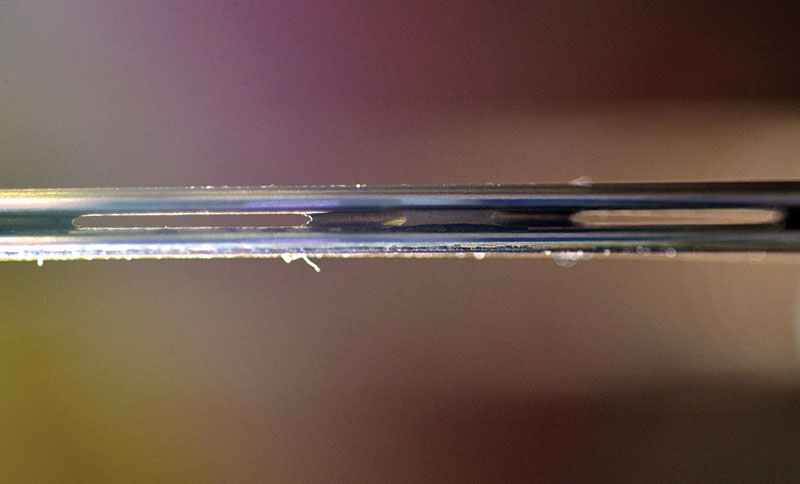

You can clearly see that the top ring has stopped working and that the entire body of the piston is heavily sludged up. If you cant the top ring into its bore and twist you can dig out a pile of hard, carbonized oil that has taken up the back and side clearance and seized the ring. With the rings seized, there’s no rotation and no self-cleaning action. The second ring is in just as bad condition, and the oil ring is completely clogged. The top ring is no longer sealing as evidenced by all the color on the land between the top and second rings. The oil control ring has two strategically placed drain slots in the bottom of the groove that were supposed to drain the scraped-down oil over the skirt and provide a more consistent oil film, but once plugged that oil flow stopped and the skirts show the result of that with increased wear.

This isn’t the first time or the first complaint I’ve seen or heard about excessive wear or oil consumption or even engine failure directly attributable to “factory recommended†extended oil drain intervals. In fact, there’s a real problem out there that no one wants to talk about. Engines that should run 250,000 trouble-free miles are failing long before that because owners believe the guy with a vested financial interest in selling you another car or truck when he says “Just run it! Trust me! You’ll be fine!â€

My advice is to ignore the factory and change your oil at 1,000 miles per quart of crankcase capacity as an absolute maximum interval, and your other fluids and filters when you see shifts in color and odor. Are you going to waste some of your money? Yes you are. Unless you’re willing to spend $25-$75 per sample and have your fluids analyzed to determine when they should be changed, you’ll waste a few bucks. But I guarantee that the few dollars you waste will be a fraction of the dollars you’ll spend installing or rebuilding an engine, or a high-tech electronic transmission, or buying expensive power steering parts and brake traction or stability control components.

Breakdown maintenance is done at the convenience of the repair shop at the price they dictate; the car or truck owner has no control over any part of the repair process. Preventative maintenance is done at your convenience and on your schedule and you can budget what you choose to have done, spreading the cost over several months if you need to. The choice seems pretty clear to me.

0 Comments