You’ve seen the big sparks rubbing your feet on a carpet can cause. All that voltage can perforate delicate – and expensive! – electronics. How to ground it out.

Electrostatic Discharge (ESD) is rarely a concern in most shops, but it should be. Even as recently as 20 years ago, most car parts weren’t sensitive to ESD, but that’s dramatically different today. It’s actually very easy (and cheap!) to prevent ESD problems, while the consequences of not doing so can cost you thousands in damaged parts and even more in lost trust with your customers.

So what is ESD anyway? Well, the human body is a big capacitor, and, as we know from basic electronics classes, a capacitor stores voltage in an electrical field. When we knock electrons off of a surface, they can build up on us, and when we come into contact with an electrical conductor, we short out our “capacitance†and discharge all those electrons literally in a flash. Ever walk across a carpet in winter when the air is dry and get zapped by a “static electricity†spark when you touched, say, a door knob, or some other metal object? That’s ESD in action.

Thousands of volts

These harmless sparks are just a small nuisance to us because even though they comprise thousands(!) of volts, the amount of electrical current (which is the part that’s deadly to humans) is very, very small. But get down to the tiny scale of a semiconductor used in a transistor or integrated circuit and those thousands of volts, even at a microampere of current, is cause for alarm since damage is almost guaranteed.

Those of us in the northern regions of the country, particularly during cold, dry winter weather, know all about static electricity — that little sting is an annoyance. But let’s face it, the folks in Florida, Texas, Louisiana and other southern states with heavy humidity, particularly in the summer, have absolutely nothing to fear from static electricity since the moisture in the air shorts out our internal capacitor, rendering us ESD-safe. Unless, of course, we remove the humidity with air conditioning (something few shops have).

We all know what static electricity is, and that the spark created when we touch a conductor is what we mean when we say Electrostatic Discharge. But why is this a problem for auto repair shops? The simple answer is that auto makers – Mercedes-Benz included – have used ever more powerful electronics in their cars in recent years. Semiconductor manufacturers, in their efforts to make faster and more powerful, yet less expensive, components, have made the microscopic features of their parts smaller than ever before.

In the semiconductor industry, smaller means more efficient and faster, and the state of the semiconductor art has us seeing features on a scale of about 14 nanometers (0.00000055 inches), or about the width of 90 Silicon atoms. Parts with features this small – and even those many times larger – are extremely sensitive to high voltages. So, letting these voltages come into contact with the electronic control units we so commonly see in cars today is a recipe for disaster.

In some cases, when we let a spark jump from our finger onto a control unit, we kill the control unit instantly. You plug it in, but it either doesn’t work at all, or many of the functions are simply dead. It’s hard to tell why, but you just know that it’s not working. But even ESD you can’t see or feel — just a few hundred volts — still causes problems.

Walking wounded

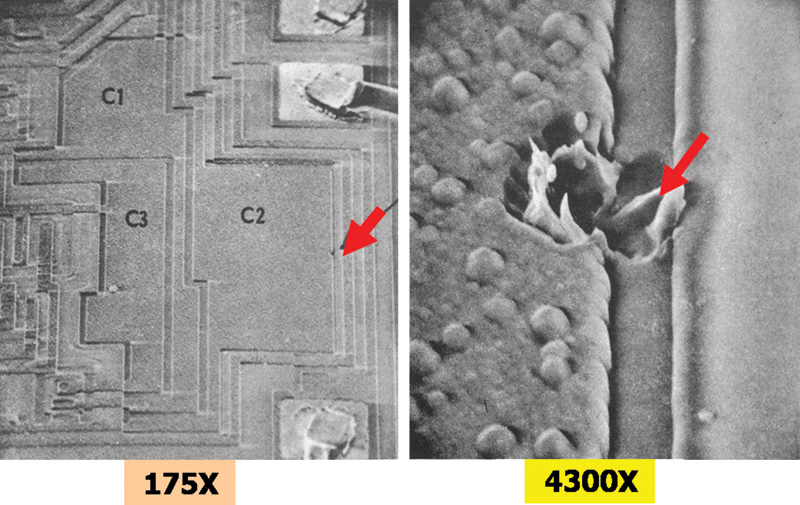

These images show the damage to an integrated circuit caused by Electrostatic Discharge (ESD). At a magnification of 4,300 times, the “crater†in the silicon is plainly visible. ESD damage can let the circuit keep working for a while, but it will eventually fail. A simple wrist strap can easily prevent this. (Courtesy JPL.)

In most cases of ESD damage, we create what is known in the industry as the “walking wounded.†This is where the component has been damaged, but not enough (yet) to prevent something from working. What happens is that, over a short time, the damage gets stressed and becomes worse and worse until the part finally fails completely. These faults are the most challenging for repair shops because we not only don’t know why the part failed, but we can expect a hit on our reputation as “the part we just replaced†fails. And, as we all know, without a good reputation, you’re out of business.

Take a look at the image of the damaged semiconductor: The damage doesn’t go completely through the chip’s “wiring,†but with a chunk like that taken out we can easily understand that it won’t be long before the whole thing fails. The folks at NASA and JPL (Jet Propulsion Laboratory) take this stuff seriously since retrieving a $500 million satellite for repairs isn’t practical. For us as ISPs (Independent Service Providers), it’s not quite as serious, but thankfully it’s easy to make sure we’re handling the expensive, high-tech components of our customers’ cars safely.

Studious avoidance

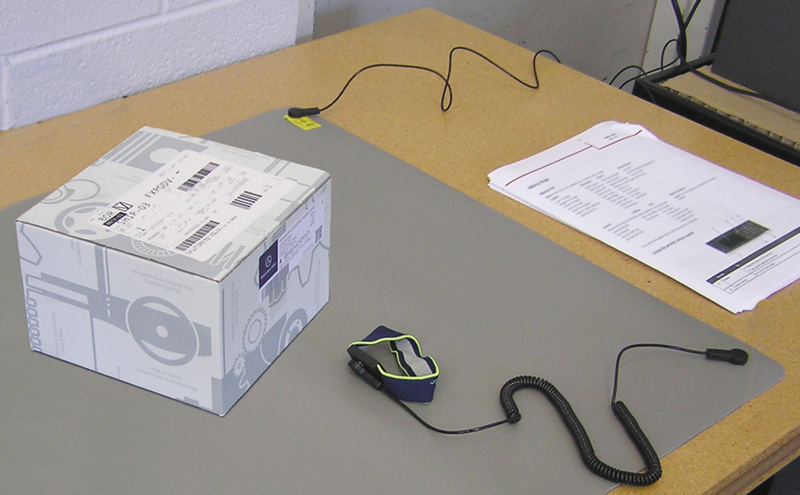

Whether labeled or not, treat any components that arrive in ESD-safe packaging the same: Only open the packaging on an ESD-safe mat after you’ve donned your ESD wrist strap.

If it’s humid, say above 50% relative humidity, we generally won’t see or feel ESD sparks. But nobody should rely on high humidity to prevent ESD damage because even then it is possible to build up enough of a charge to cause trouble if the conditions are just wrong. So that means you techs down on the gulf coast, say, need to heed these precautions just as much as those up in the cold, dry north.

Okay, so we know what ESD is and how it causes damage. What can we do about it? There are few things you can do, and the good news is that none of them is expensive, inconvenient, or difficult.

The first step towards eliminating ESD damage is to handle electronics properly. Never touch the connector pins, even on the wiring harness side since that wire might lead to a pin on another control unit. After disconnecting a connector, only touch the outside of the control unit’s housing.

A second step is to discharge yourself any time you’re working near electronics that might be sensitive. To do this, simply touch a larger piece of metal (but not metallized plastic!). The inherent conductance of the metal will equalize your body’s voltage and remove the residual charge. By “larger†we’re not talking about your keys, but something a little more substantial, like the car body or even just the door handle.

One step that does NOT work against ESD is a metal work surface: Covering the top of a workbench with aluminum or galvanized sheet metal is not “ESD-safe.†Instead of safely bleeding off the charge gradually, it instead conducts the ESD voltage more efficiently to the sensitive component, just making the danger zone for ESD larger. The same effect comes from wrapping a part in aluminum foil — that’s worse than nothing. That’s why you see some parts arrive in special ESD packaging: That special grid or coating on those silvery or pink bags has some resistance, which bleeds off the voltage instead of conducting it right to where you don’t want it.

Ground strap

Don’t ignore these labels: They are there for your own protection. No sense installing a pre-damaged part. Protect your customer’s car and your reputation by following the simple and inexpensive ESD safety procedures.

These two steps can get you though 98% of a typical day, mostly because you’re not often working directly on ESD-sensitive parts. For the other 2% of the time, there’s one more step you should take: an ESD strap. That is, a small “bracelet†made of stretchy (and electrically-conductive) cloth, with a means of attaching a wire. The wire goes to either the building ground (through a grounded electrical outlet or cold water pipe, for example), or the vehicle ground, depending on which is more convenient for you. You attach an alligator clip to your ground point, and the extensible cord keeps things comfortable. You should be reminded to use it any time you get a spare part that has ESD packaging around it — put on the strap before opening the package.

The strap does conduct electricity, but not very well. ESD straps generally have a built-in resistance of several thousand Ohms. Wearing a home-made metal strap, for example, is a very bad idea because this sets you up for a dangerous electrocution risk. Even if the electricity conducted by an all-metal strap doesn’t kill you (and it can!), the metal can get very hot and cause serious burns if enough current passes through it. The bottom line: Use only a purchased dedicated ESD strap, and never one that does not have built-in resistance.

We work with our hands, so a strap might get in the way. No problem, just wear it on your ankle! It works just as well, and we’ve found that it stays out of the way.

The Mercedes-Benz ESD protection kit includes a high-quality ESD wrist strap, a durable ESD mat for the top of your workbench, and cables to easily connect these elements together and to a source of earth ground. Using this kit helps minimize the risk of damage from ESD to sensitive electronic components.

A good ESD strap can be had for less than the cost of a Starbucks coffee, and if you shop carefully you can get one for less than the cost of a newspaper. So price is no excuse for not purchasing this essential piece of gear. Sure, when you were working on 124s nobody needed an ESD wrist strap, but let’s face it: A new 222 S-Class has more computing capacity than the space shuttle (!), so it should be clear that times have changed.

Mercedes-Benz offers a complete ESD Kit under Part Number W000 589 52 98 00, which you can get from your local dealer. The kit includes not only a high-quality wrist strap, but an ESD mat for your workbench and some convenient grounding options. Similar kits are also available commercially, since ESD safety is not limited to the automobile industry.

As we work on newer and newer cars, we automotive technicians must take action to prevent Electrostatic Discharge from causing damage. The damage isn’t visible since it’s hidden inside the semiconductors, and it also isn’t always obvious right away. If we don’t do anything about it, we can expect customer complaints and comebacks, with the inevitable dent in our reputation, along with the costs for fixing what we broke. Yet, it is easy and inexpensive to be 100% protected against ESD damage with a wrist strap, along with some common sense. So, there’s no excuse not to add ESD protection to your toolbox today.

Download PDF 〉

0 Comments