“The only reason we put tires on cars is to keep the computers from dragging on the ground.â€

-Attributed to a Toyota Engineer

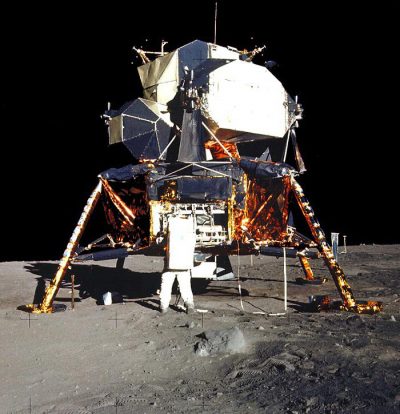

1969. Apollo 11. The Lunar Module Descent-and-Landing Computer took control of the space craft several thousand feet above the lunar surface, and this single computer controlled the main engine, thrusters, and navigation inputs bringing the ship to a safe landing at Tranquility Base. This computer operated on roughly 100,000 lines of code and it performed flawlessly over several missions doing a critical job with a tiny fraction of the hardware and software found on a typical modern car.

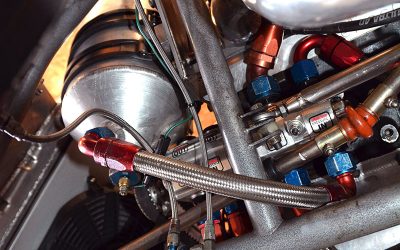

Fast forward to 2016, and the average car, negotiating in a far less challenging environment, contains as many as 100 microcontrollers, 50 onboard computers or modules, two and half to five miles of wire, and as many as 100,000,000 lines of code (that’s one hundred million there, boys and girls…). Brave new world, indeed.

The Next-Gen cars will make what we drive today seem like dinosaurs as the increased pressure to produce zero-emissions vehicles mounts. Variable-compression engines, high-compression Atkinson, modified Atkinson, and Miller cycle engines are all on the market, or coming out in the next few model years. Dry sump systems, too. This will apply undue pressure on the system that produces the service techs of tomorrow, and, frankly, we can’t meet the demand today. Just as we have paramedics and paralegals, we are past the point of needing para-engineers to work on our modern automobiles.

In a classic example of putting Band-Aids on bullet holes, we have allowed the car makers to sell us all on the idea of the “directed repair process,†which has resulted in an entire generation of techs with no real working knowledge of the underlying engineering that makes our cars hum. We have been made into bakers — add this much flour, this much sugar, a bit of butter, and suddenly we have cake! Unless it turns out to be biscuits. Then we’re just confused because we don’t have access to the design and operation parameters that would let us perform a more traditional style of diagnosis and at least figure out how our cake turned into biscuits!

Here’s what I’m seeing from my vantage point: The manufacturers are throwing in the figurative towel. Even their own tech lines can’t help anymore past telling us to bolt this part on or overlay this harness. The only real good they do is that they authorize the “guess†so that at least we can recover all or part of the time we spend trying a half dozen different things to get the customer on the road again. Sadly, the power to authorize repair “attempts†is being eroded as in many cases they advise us to “try this,†but then tell us to first call the district manager to get an authorization code before proceeding. That’s if you can get him or her to answer the phone (good luck with that!).

Practical vehicle life cycle is shortening as repair parts disappear in six or seven years (hard parts), and no one really knows what the anticipated life cycle will look like for those 100,000,000 lines of code. We all own computers, and we all have bought software packages. What happens every few years? You get roped into buying an update package. So what happens if the software on a ten-year-old car is corrupted? Will there be legacy support for these vehicles? Your guess is as good as mine, but I’d bet you lunch that manufacturers aren’t going to expend resources to keep an old car or truck alive when they can force you to buy the update package — surrounded by a new car or truck, of course. But, hey! What’s $30,000 to $80,000 between friends?

Everyone is going to win except the consumer if it gets to the point where the life cycle shortens to four or five years. The car makers lock in increased demand for new product, the vendors have parts to make, the environmentalists are delighted because each new generation of automobiles is cleaner. The consumers get hammered with a new and ever-increasing car payment to service, and the used car customer buys a pig in a poke, not knowing that the three-year-old car only has a realistic service life of a couple of years left in it.

The technician can’t get access to the training and information needed to fix any of them because the manufacturers themselves don’t know how they work, and the hardware and software guys are all compartmentalized, and the guy who used to have the big picture isn’t working there anymore.

The whole repair process becomes a “try this and see†with parts that cost thousands of dollars; parts that once programmed can’t be taken off the car and reprogrammed to fit another vehicle should it be determined that the part didn’t fix the problem. What this eventually becomes is a consumer chained to the equivalent of another mortgage payment for as long as he or she needs to own a car or truck. It’s either that, or we will all end up Ubering or renting a car when we need it.

Attracting a Next Gen technician is going to be a real challenge given the way the commercial side of our trade operates. We make our techs buy the means of production (tools) and then pay them based on piece work. If a tech faces a challenging problem, one that’s “off the flow chart,†the factories will not pay straight time unless you raise a mountain of hell with them, and even at that they are always poised to swoop in and take back money previously paid (after the fact and long after the vehicle has left your care) under the guise of an “audit†— basically a guilty verdict rendered after the fact and after all your defense proof (the fixed car) is long gone.

The traditional methods of drafting youngsters into automotive programs aren’t capable of attracting the kind of heads-on and hands-on guys we need to start on a career in what will become the auto service field of tomorrow. The kind of folks we need just also happen to make pretty damned good engineers, and while the engineering field isn’t a great deal more challenging from an academic point of view, it’s far more lucrative and is perceived to be a more productive and professional career path.

Let’s be honest, the physical demands of the field mean that the real time from competent to worn-out is only about 35 years, and how do you incentivize what is a de facto forced early retirement at today’s wage, or under any iteration of the flat rate system? Fact is, we can’t compete!

What does this mean to racers? Mechanics used to be the guys who loved the work, loved making and fixing things, and they were where a lot of racers came from. Now mechanics spend most of their days with a laptop updating the programs rather than learning engine fundamentals. Racing laptops doesn’t have quite the same thrill, and the results of your work aren’t quickly visible, which kills most of the passion. Your day is spent trying to make a paycheck for the family.

Fuel economy and clean air regulations will put pressure on large displacement “V†engines, slowly reducing their numbers, which means that all of our racing products will come from bespoke designs and aftermarket companies at an increased cost. No matter how you slice it, our racing industry will track the commercial side of our industry and fewer and fewer will be drawn into the performance field. Once that takes root, the law of supply and demand will drive prices and wait times for parts and services through the roof.

The repair trades and the racing associations need to start joining forces and work to encourage high-quality, passionate people to join our ranks. Running on code may be the order of the day for our daily drivers and it will be a growing part of the tuning trade, but I’m not sure that it’s enough to keep us all profitable and growing.

0 Comments