It’s been decades since you could just add more lead to combat detonation.

The octane rating of gasoline is a measurement of the fuel’s ability to resist “pinging†or engine knock during the combustion process. The rating of most commercially-available gasoline will vary from 87 to 93. Also, it is blended for the expected temperature and the altitude in the area where it is sold, and to meet federal, state, and local environmental regulations. With the re-emergence of the high-performance engines that are available in late-model muscle cars and trucks, the use of high-octane gasoline is necessary if you are to expect maximum power from these engines.

The PCM (Powertrain Control Module) used with today’s fuel-injected engines is continually tuning things such as valve timing, air/fuel mixture, and the amount of spark advance so the engine can provide the best power along with good fuel economy and the lowest possible exhaust emissions. The PCM does such a good job of adjusting the ignition advance that almost any engine can operate on 87 octane fuel without any pinging problems, so why would anyone pay extra for high-octane gasoline?

The reason you may want to buy premium fuel is that many new engines, particularly those with direct fuel injection, have compression ratios that are over 10:1 and sometimes as high as 12:1. These high compression ratios demand high-octane fuel if they are to perform as they should. FYI, my personal vehicle is a Ford Explorer Sport with the 3.5L EcoBoost engine that has 10:1 compression with twin turbo chargers. The owner’s manual says it can run on 87 octane gasoline, but it also says for the best overall vehicle and engine performance premium fuel with 91 or higher octane is recommended (the engine horsepower and torque ratings were done with 93 octane).

Octane need

In general, there’s no such thing as too much octane. Your engine only knows when it does not have enough, and that can cause serious damage especially if there are no knock/detonation sensors present. The things that cause an engine to need higher octane gasoline include:

- high compression ratios

- large cylinder bores

- cast iron cylinder heads

- lean air/fuel mixtures

- high engine coolant temperature

- aggressive spark advance curves

- high intake air temperatures

- intake air that is dry (low humidity)

- high barometric pressure conditions, especially those at sea level

Of course, turbocharging or supercharging develops higher cylinder pressures than does normal aspiration, and therefore needs more octane. These higher cylinder pressures will make more horsepower as long as the gasoline has a high enough octane rating. If detonation or spark knock occurs, power will drop off and the result can be a destroyed engine — even a knock sensor system retarding the spark advance may not be able to do enough.

Detonation control

Low octane fuel combined with too much compression or spark advance can lead to serious engine damage.

The PCM uses input from a knock sensor to identify a detonation/knock/pinging problem, and will retard the spark advance in increments of one to four degrees at a time up to a maximum of 20 degrees in most applications. Spark control systems work so quickly you will never hear the knock, but when you operate an engine under high load conditions that was designed and power-rated on 93 octane fuel it will lose a lot of performance and horsepower on anything less. The loss of power is often 10% or more with regular 87 octane gasoline, thus the owner’s manual will usually recommend that 93 octane premium be used when the vehicle is towing a trailer or operated under high load conditions such as might be encountered driving in the mountains.

The ignition spark advance system of most carburetor-equipped vehicles does not have a knock sensor, so if you want the engine to perform its best you should have its advance curve optimized for the octane of the fuel you buy. When the curve is correct, you will also avoid the catastrophic engine damage that can be the result of too much spark advance.

There are several methods to tell if a vintage carburetor-equipped engine is experiencing detonation, among them are reading the spark plugs, listening for pinging, and using the NOx reading from a 5-gas exhaust analyzer. The proper tuning of the ignition spark advance is one of the most ignored, yet the lowest-cost tuning tricks you can use to get maximum performance from your engine.

System diagnostics

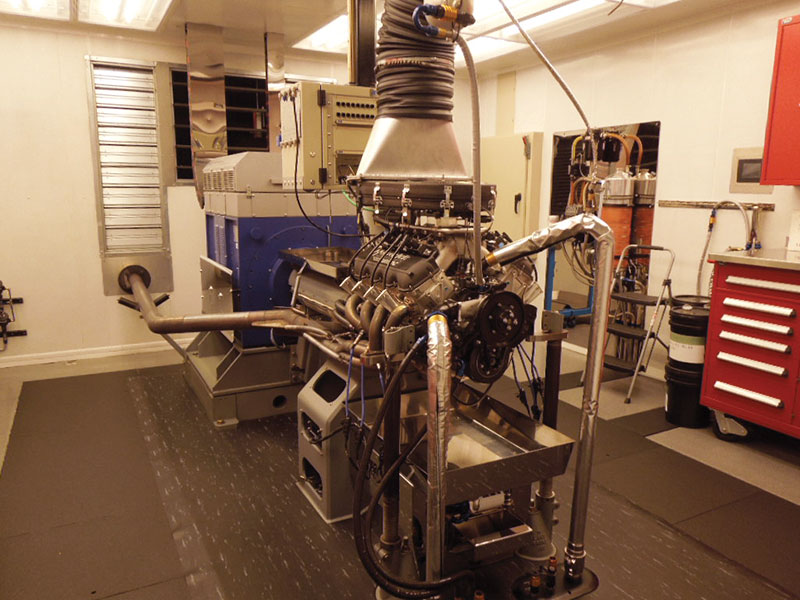

The man hours spent in the dyno room programing the PCM for maximum power and reliability translate into winning races. The air induction system used when the engine is on the dyno allows the operator to match the air temperature, pressure, and density to what the engine will see during actual race conditions.

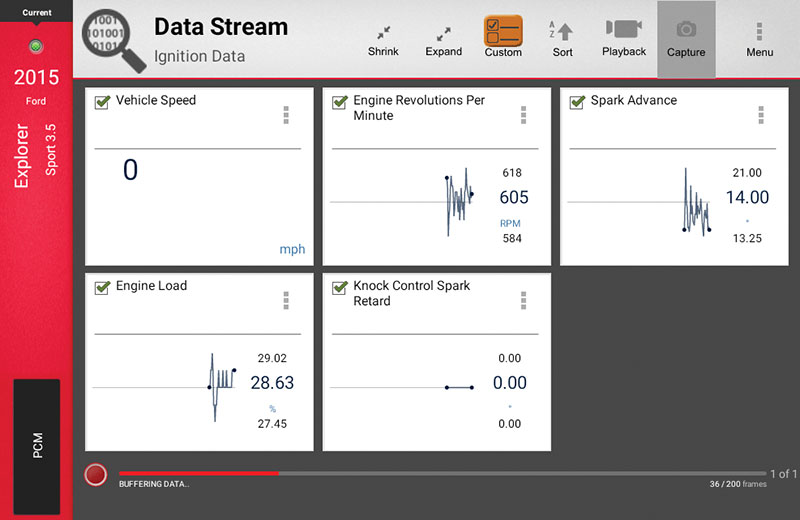

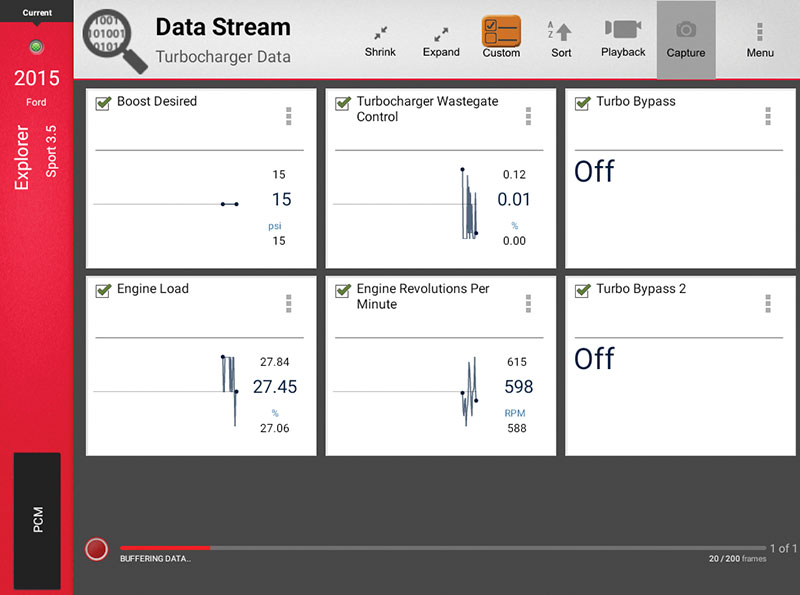

A diagnostic scan tool such as the MAC Tools MDT10 can be used to determine if and by how much the knock sensor system is retarding the spark advance in order to avoid spark knock/detonation when the engine is under load. You could then fill the gas tank with a higher-octane gasoline to see if the knock reading on the scan tool is still present when the vehicle is driven under load. If 93 octane gasoline is not sold in your area, you may be able to purchase some 100 octane unleaded fuel from a performance gasoline supplier. Then you can see if the there is still a spark knock-detonation issue and find out how the engine performs with high octane gasoline. The MDT10 or equivalent scan tool can allow you to read and record the spark advance, rpm, vacuum (vacuum and boost pressure on a turbocharged or supercharged application), throttle position, and any knock sensor signal present during various operating conditions.

Modern gasoline

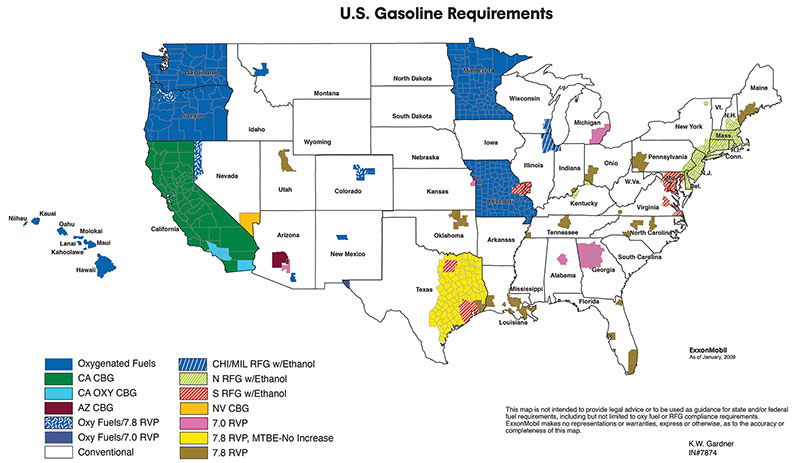

The base blend of each brand of service-station gasoline is basically the same, but each brand will mix in its own specific additive package designed to reduce combustion chamber deposits, and clean the injectors and intake valves. The gasoline is also blended for the season of the year, thus the winter and summer blends. Plus, there are quite a few areas of the country that require special cleaner-burning gasoline. There is also a push to increase the use of ethanol or other alcohol-based additives to both reduce fuel-related emissions and lessen our dependence on foreign oil. So, the gasoline sold in many parts of the country will contain up to 10% ethanol. This means that the blend of gasoline you use will not only vary from brand to brand, but also will change by the season and the location.

Performance from gasoline

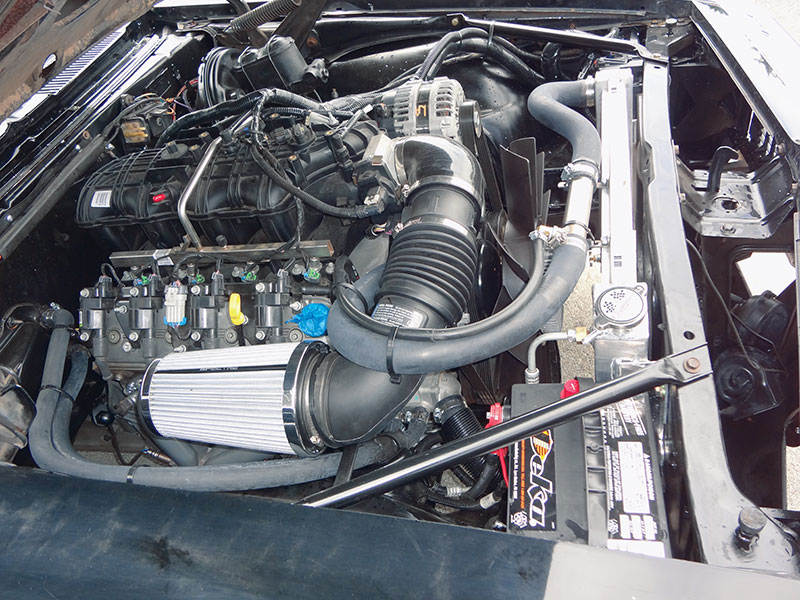

The location of the air cleaner above the headers will cause intake air temperatures to be very high, resulting in a wide variety of performance and drivability problems as the PCM attempts to adjust for the hot air.

If the price per gallon were not an issue, a custom fuel blender could sell you gasoline that would help an engine produce maximum power or the lowest possible exhaust emissions. Of course, it would be a lot more expensive than what you buy at your local gas station. Gasoline can be blended to match the needs of a high-performance engine whether supercharged, turbocharged, high-compression, nitrous oxide-injected, or one that’s operated at very high rpm.

There are several race fuel suppliers/blenders that offer street-legal 100 octane unleaded gasoline that fits the needs of almost any vintage muscle car engine, or modern fuel injected high-performance engine. The 100 octane unleaded fuel option also is more stable as it is blended from a better grade of hydrocarbons, which means that it will not age/degrade as quickly as pump gasoline, which is especially important with race cars that may not be fired up for long periods. Also, the formulation (including the ethanol content) will be more consistent than commercial pump gasoline.

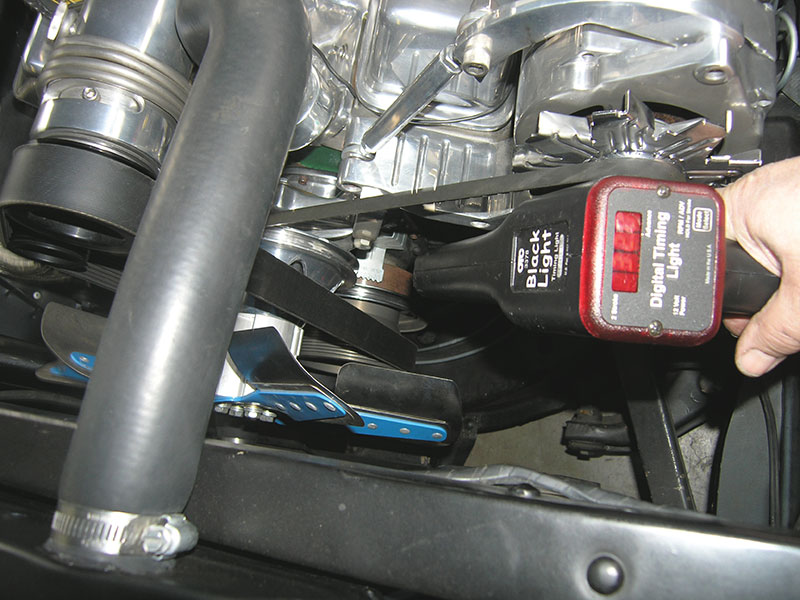

A dial-back timing light can be used to read the spark advance curve of a conventional ignition system.

Ethanol content

An MSD distributor includes an assortment of bushings and springs that can be used to change the rate and limits of spark advance.

If the gasoline in your part of the country contains ethanol, fuel efficiency will decrease. That’s because gasoline has more energy per gallon than ethanol – roughly twice as many Btus. Thus, alcohol-based fuels require a richer air/fuel ratio than pure gasoline.

The ethanol is added to the gasoline as it is loaded into the delivery tanker truck, and mixing occurs through a process known as “stop light blending.†This assumes that the ethanol will mix thoroughly with the gasoline as the tanker truck stops and starts on its way to the gas station to deliver its load, but sometimes this isn’t very complete – some portions of the fuel may have a higher ethanol content than other portions in the same tanker load. If you happen to buy a tankful of ethanol-heavy gasoline, you may experience both engine performance and drivability problems, and even hard-starting in cold weather.

Volatility

The ignition system data from the MDT10 can show you spark advance, engine load, rpm, knock control spark retard, and vehicle speed.

Reid vapor pressure is basically a measurement of the volatility of the gasoline. This measurement indicates how easily the engine is able convert the liquid gasoline into vaporized gasoline. The lighter or more volatile portions of the fuel are important when first starting an engine, so winter gas is blended with a higher RVP than summer gas. For example, in southern California summer grade gasoline has low volatility to avoid vapor lock, while the winter grade sold in Michigan would have high volatility in order to make starting easier in sub-zero temperatures. A fuel with a Reid Vapor Pressure above 8 to 10 lbs. could cause drivability and vapor lock problems, especially on a carbureted vehicle during hot weather.

The distillation/vaporization curve of today’s reformulated gasoline has been changed to make it burn cleaner. Some of the lighter/more-volatile portions have been removed in order to reduce evaporative emissions, and some of the heavier/less-volatile portions have also been eliminated to reduce exhaust emissions. So, these new blends have a higher content of fuel that vaporizes in the middle temperature range and are therefore somewhat harder to light off, but are somewhat faster burning than the leaded gasoline of the 1960s and 1970s.

The formulation changes that affect how an engine will perform are the density of the fuel (specific gravity), the percentage ethanol content (if used), and the front end volatility. Each of these factors can vary as the formulation of the fuel is blended to conform to local environmental regulations, the season of the year, and how well the ethanol (if used) was blended with the gasoline. The front end volatility can be measured in the field with a Reid vapor pressure tester, but in a laboratory it is measured via an API – D86 Distillation Curve test.

Density of gasoline

The measurement of the density of gasoline is referred to as the specific gravity. When the density/specific gravity of the fuel changes, it will alter the air/fuel ratio you would get from a carburetor because the actual amount of gasoline flowing through the jets will be different. The density can also change the fuel level in a carburetor’s bowl because the float will sit higher in a denser fuel. The rule of thumb is that if you’re moving from a higher specific gravity to a lower specific gravity, you’ll need to adjust the air/fuel mixture richer by going to larger jets, and vice versa. This may seem counter-intuitive, but the lighter specific gravity gasoline will lift more readily and in increased volume in the emulsion wells and out through the emulsion boosters thereby richening the mixture. The opposite occurs with higher density, heavier specific gravity gasolines. Race fuel companies such as ERC, Rockett, or VP can supply you with the SG measurement of the gasoline they sell.

Raising the octane

The most common component used in the octane-enhancing additives on the market is manganese/MMT (Methyl Cyclopentadienyl Manganese Tricarbonyl), which is an effective octane improver at very low concentrations. When used at the recommended treat rate, you can gain a maximum of two octane numbers, but if you exceed the recommended treat rate it can foul the spark plugs and cause a build-up of rust-colored deposits in the combustion chambers. The use of too much MMT can also cause an increase in exhaust emissions, plus it can foul oxygen sensors and the catalytic converters. You also may want to know that it is illegal to use MMT in commercial gasoline on public roads in some states, including California.

There is a wide variety of performance and race fuel blends that can match the needs of almost any high-performance or race engine.

Driven Racing Oil Defender + Booster Fuel Additive is a product that uses MMT to raise the octane of unleaded gasoline. The company also advertises that it reduces valve seat wear and has corrosion inhibitors that help reduce combustion chamber and intake valve deposits. Each 10-ounce bottle treats up to 25 gallons of gasoline.

Lead — Tetraethyl Lead, or TEL — is known to be a very effective octane improver used in many racing gasolines and aviation gasoline. It is extremely toxic in its pure form, and is illegal to use in any street-driven vehicle in the U.S. since Jan. 1st, 1996. Lead will poison oxygen sensors and catalytic, plus if you were to add lead to unleaded gasoline it is not possible to calculate the octane number of the final blend.

The 100-octane option

The 87, 89, 91, 92, or 93 octane that you buy at the local service station is a good gasoline for satisfying the government’s requirements for improved fuel economy and reduced exhaust emissions. The use of octane boosters in street gasoline is not always the best way to increase the octane rating. An alternate solution is to use a 100-octane performance gasoline such as Rockett Brand 100 Octane Unleaded. This Rockett product is street-legal, and can either be used in its pure form, or blended with any street gasoline to get the level of octane your engine needs. You will always know what octane you end up with because Rockett provides you with blending charts. Visit www.rockettbrand.com.

In addition, if the 100 octane gasoline is used in its pure form, the engine will make additional power due to its “improved burn†characteristics. This is because Rockett Brand 100 contains a very select group of hydrocarbons that vaporize and burn much more readily than those found in conventional street gasoline. When more of the gasoline is burned in the combustion chamber, the engine makes more horsepower because of improved combustion.

A good leaded racing gasoline is designed to burn efficiently between 5,000 and 9,000 rpm, while most unleaded commercial unleaded gasoline is designed to burn most efficiently from idle to 3,000 rpm, which is the highest speed most engines see during the EPA test for exhaust emissions. Mixing street gasoline with leaded racing gasoline compromises the good high-speed burn characteristics of the racing fuel, thereby reducing the potential engine output, and it also reduces the octane quality of the blend.

0 Comments