The design, operation, and diagnosis of charging systems and battery control modules, and a look at AC ripple and the problems it can cause

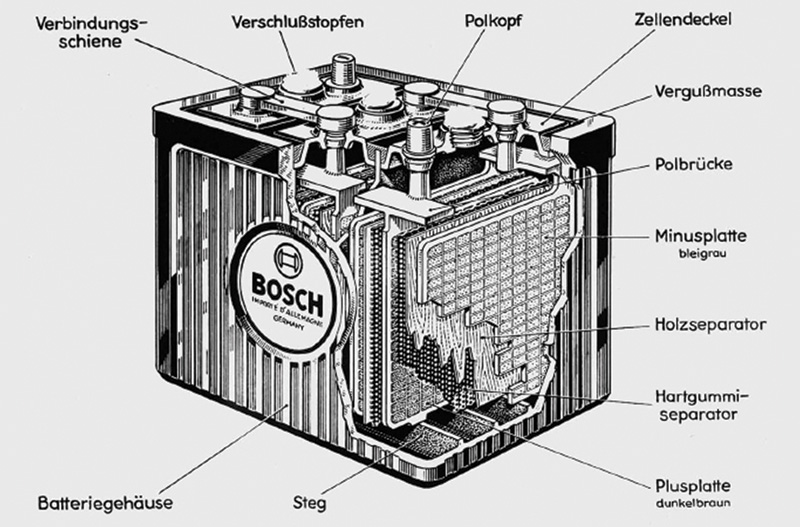

Batteries have evolved a great deal since this old Robert Bosch specimen was state-of-the-art. Note that the plate separators are made of balsa wood.

As far back as history records, man has endeavored to come up with ways to convert potential energy into kinetic energy. That is, energy which is stored by virtue of its configuration or position versus energy which is a body in motion. Early civilizations were primarily agrarian and the farmers would convert the grain that they stored (potential energy) into kinetic energy as they fed it to their animals to pull their plows and such. They would then raise crops to store, which then again became potential energy and the process started all over again. Fast forward to the modern day automobile and you find all kinds of potential energy and kinetic energy going on. We will primarily focus here on the battery, where energy is stored, the modern systems that charge them, and also troubleshooting.

Early batteries

It is not certain exactly when the first battery was conceived, but Allesandro Volta traditionally gets the credit. Archaeological digs have discovered devices that could possibly have been used to store electrical energy, but it was Volta’s experiments in the late 1700s and early 1800s that paved the way for the modern battery. Volta discovered that certain fluids would generate a continuous flow of electricity when used as a conductor. This discovery led to the invention of the first voltaic cell. He also learned that he could increase the voltage output if he connected the cells in a series. Continuing in his experiments, he found that different metals have different electron affinities so that if he used silver and zinc immersed in electrolyte he would get different voltages than if he used lead and tin.

Lead acid batteries

Lead acid batteries are the oldest rechargeable batteries in existence, and the first manufactured for commercial use. Lead acid does not lend itself to fast charging, so finding the perfect voltage limit is critical. A high voltage (above 2.4V per cell) produces good battery performance, but shortens battery life due to corrosion on the positive plates. Conversely, a low voltage charge tends to promote sulfation of the negative plates. Arriving at the ideal charge rate is where modern charging equipment comes in, which we will discuss later in this article.

Lead acid batteries also do not lend themselves to deep cycling. A full discharge causes extra strain on the battery, and each cycle robs the battery of some service life, so keeping the battery charged up is critical to longevity. A typical sealed lead acid battery will survive approximately 200 to 300 discharge/charge cycles. Corrosion of the grid plates of the positive electrode is the primary reason for this relatively short cycle life.

Lead acid batteries have low energy density per unit of weight making them unsuitable for portable devices. Also, performance at low temperatures is diminished. On the plus side, the self-discharge rate is about 40% per year, which is among the best of all rechargeable batteries. By, Ni-Cad batteries self-discharge this same amount in about three months.

Why AGM?

AGM (Absorbed Glass Mat) battery technology became popular in the 1980s to reduce weight and improve reliability. The sulfuric acid is absorbed by a very fine fiberglass mat, which in turn make the battery spill-proof. This also allows shipping without hazardous-material concerns. AGM batteries have very low internal resistance, can deliver high currents on demand, and offer a relatively long service life. AGMs are maintenance-free as well. Additional advantages of AGM batteries are a charge rate that is up to five times faster than that of the typical flooded lead acid battery, and the ability to survive deep cycling. These characteristics make it the ideal battery for today’s high electrical load vehicles. AGM batteries do not like heat, though, which is why typical installations are in the trunk and not in the engine compartment.

What do the numbers mean?

CCA (Cold Cranking Amps) is a rating used in the battery industry to define a battery’s ability to start an engine in low temperatures. Generally speaking, it is easier to start an engine in a warm environment than in a cold one. The rating refers to the number of amps a 12V battery can deliver at 0°F. for 30 seconds while maintaining a voltage of at least 7.2. The higher the CCA rating, the greater the starting power of the battery.

RC (Reserve Capacity) is a general indicator of how long a new, fully-charged battery can continue to operate essential accessories if the vehicle’s charging system fails. It identifies how many minutes the battery can deliver a constant current of 25 amps at 80°F. without falling below the minimum voltage (1.75V per cell) needed to keep your vehicle running.

Amp Hour or C20 is an indicator of how much energy is stored in a battery. It is the energy a battery can deliver continuously for 20 hours at 80°F. without falling below 10.5V.

First things first

In order to conduct a proper charging and battery systems test, we must first evaluate the battery’s state of charge. Since the release of the model 204, it is now possible to evaluate the battery’s state of charge via the IBS (Intelligent Battery Sensor) data stored in the SAM (Signal Acquisition Module), and the CAN bus keep-awake unit recognition in the CGW (Central Gate Way).

IBS design and function

The IBS is attached directly to the negative pole of the battery via the post terminal. Along with the terminal, the mechanical part of the battery sensor comprises a shunt and a ground pin. The shunt is attached to the vehicle’s load path and is used as a measuring resistor to determine the current indirectly. On the ground pin, the existing ground cable can be conveniently attached. The electronics are located in a molded housing with a connector as an interface for energy management. It records the voltage of the on-board electrical system battery and the on-board electrical systems’ power consumption. These measurements are used by the battery sensor to calculate the internal resistance of the electrical system battery. A temperature sensor integrated into the battery sensor measurers the temperature at the negative terminal. This is then used to calculate the inside temperature of the battery.

The battery sensor provides the following electrical system values to the rear SAM control unit:

- Voltage

- The internal temperature of the battery

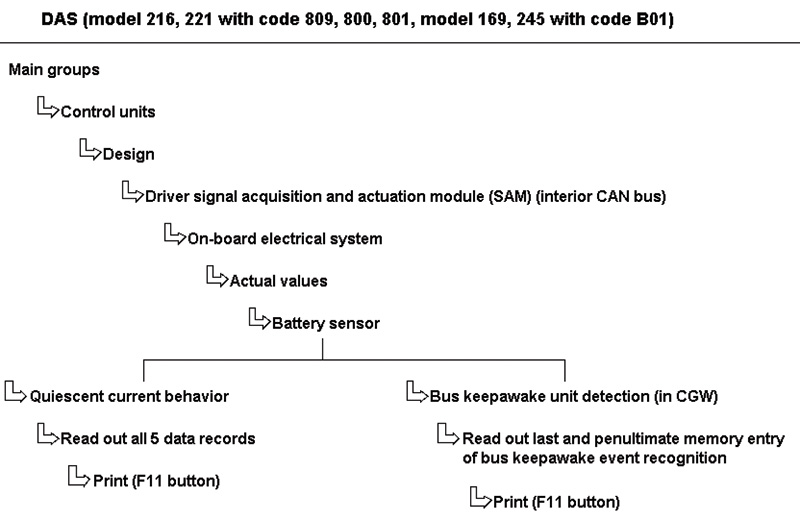

Using Xentry or other compatible scan tool, you can access not only the IBS data in the rear SAM, but you may also be able to identify the reason for the low state of charge in the battery. Below is just one of the menu options you’ll find for diagnosing the battery.

If you have a case of a discharged battery/vehicle does not start complaint, you would read out the fault menu of the IBS. Say, the following entries are present:

- Power consumption of standing lights or parking lights

- Power consumption of low beams

You may have an indication of a faulty rotary light switch. If no other faults are found, then proceed to charging and testing the battery itself. The battery must be charged using an approved charger (see SSEP catalogue located under “MB Equipment†menu of STAR TekInfo).

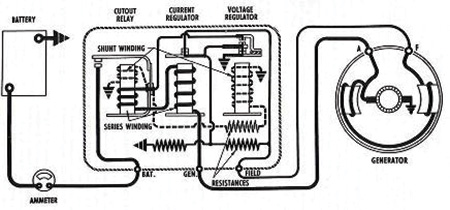

Not only did DC generators have little output at idle and slow speeds, they were mechanically complex. Look at all those segments in the commutator!

A high quality diagnostic battery charger will determine the internal condition of a battery before attempting to apply a charge to it. The charger applies an AC signal at a known frequency across the terminals and measures the internal conductance to determine battery health before attempting to charge. It is important to complete this step before moving on to testing the charging system of the vehicle. The battery should be fully charged up or replaced if it has been found to be faulty or your charging system data could give you faulty readouts. Correct charging of the on-board electrical system battery, starter battery, and buffer battery helps to ensure that the vehicle continues to start, functions properly, and has optimal battery life. The battery charging period depends on the charge level at the time. The battery is sufficiently charged when the charging current reading is < 25A. Most modern computerized chargers will determine the correct charging time and rate and also tell you when the charge is complete.

The next step: converting mechanical energy into electrical energy

The alternator (or, AC generator) first appeared in about 1960 in plenty of time for the explosion in electrical accessories (courtesy Robert Bosch).

Now that you have verified a fully charged battery and located any possible sources of battery failure, it’s time to check the charging system. As earlier discussed, we know that lead acid batteries do not like to be fully discharged so it’s critical for battery life and the vehicle’s reliability to have the charging system working properly.

The first electric generator was invented by Michael Faraday in 1831. This British chemist and physicist did extensive work in the field of electricity that paved the way for the inventions of the electric motor and transformer. Faraday discovered electromagnetic induction. He found that the electromagnetic effect a current has in one wire is able to generate electricity in another wire. Using this information, he learned how to produce a steady current. He connected two wires to a copper disc. He then maintained a steady current when he switched the disc back and forth between the two poles of a horseshoe magnet. Thus he made his first electric generator. Today’s systems have come a long way from his first invention, but the principle is still the same: Use the mechanical power from the engine to drive the alternator to recharge the batteries and sustain the electrical load of the vehicle.

Early vehicles had charging systems that depended on DC generators. When the engine was running at low rpm, the generator had little or no output, and the battery provided all the energy needed for the electrical system. When vehicle speed reached about 20 mph, or engine rpm reached about 1,200, the generator would begin to charge, and this output would help the battery with some of the electrical load (this is known as the generator “cut-in†speed). At higher engine rpm of about 1,800, the generator was capable of providing all of the electrical current needed to run the accessories (of which there were very few in those days), as well as to recharge the battery as needed. Generators typically provided their maximum output at about 1,800 to 2,300 rpm of engine speed. The pulley diameter of a generator is designed so the engine will spin the generator at, or close to the rpm at which the generator operated most efficiently. This rpm was matched to the rpm at which the engine was expected to spend most of its time. A voltage regulator protected the system from overcharging by maintaining the optimum charge voltage. You can see drawbacks to this set-up, and with the advent of more electrical loads a more efficient system was need.

Enter the alternator

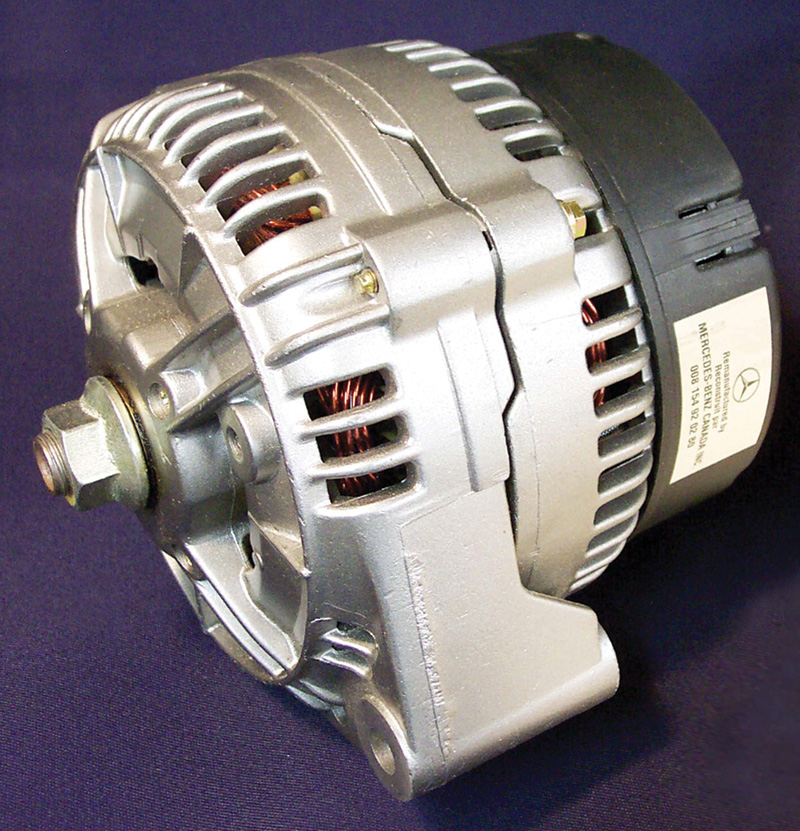

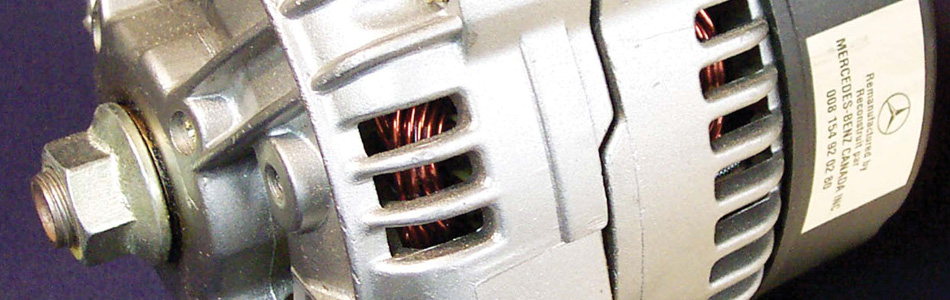

Genuine Mercedes-Benz remanufactured alternators are so carefully re-done that they’re as good as new.

Alternators have a great advantage over DC generators of not using a commutator, which makes them simpler, lighter, and more long-lived than their predecessors. The stronger construction of alternators allows them to turn at higher speed — typically twice engine rpm — improving output when the engine is idling. The availability of low-cost solid-state diodes from about 1960 allowed auto manufacturers to substitute alternators for DC generators. Automotive alternators use a set of rectifiers (diode bridge) to convert AC to DC. To provide direct current with low ripple, automotive alternators have a three-phase winding. There are typically three separate windings of wire in the stator that so that the AC current that is generated is slightly out of phase in each one. The peaks and valleys of the rising and falling current do not happen at the same time, rather they are staggered a bit. This increases and smooths the electrical output of the alternator much the same way that a 12-cylinder engine runs more smoothly than a four cylinder does — there are more power pulses happening in each revolution allowing more total power and better smoothness.

The process of rectifying the AC into DC is handled inside the alternator by something more advanced than a commutator: diodes. A diode is a solid state device that allows current to flow in one direction only — “solid state†means it does this without any mechanical or moving parts. It relies on the different electrical properties of the materials it is made of to act as a one-way valve for current. By arranging diodes so that current from each of the three stator wires is only allowed to pass in one direction, and by connecting the three outputs together, you get a reasonably smooth and stable DC output without any moving parts (this arrangement is typically manufactured as a single part and is referred to as the diode pack or diode trio). This lack of moving parts makes the alternator not only very reliable, but also comparatively inexpensive to build and repair.

Testing

Keep in mind that for some time Mercedes-Benz vehicles/engines have been equipped with alternators that communicate with the ME or CDI engine control computer via an interface. This results in changes to system diagnosis. When testing the alternator, a distinction is made between conventional alternators with terminal 61 without interface, and alternators with BSS interface or LIN interface. Using Xentry or other compatible scan tool, you will want to check control modules for related codes stored as well as freeze-frame data to help in your evaluation of the vehicle charging system. You can generally follow the on-screen instruction to complete testing. Steps will include (but not be limited to):

- Recording voltage output at idle and 2,500 rpm, both with and without electrical loads.

- Current output at same stated conditions

- Checking all wiring and connections at the battery and alternator.

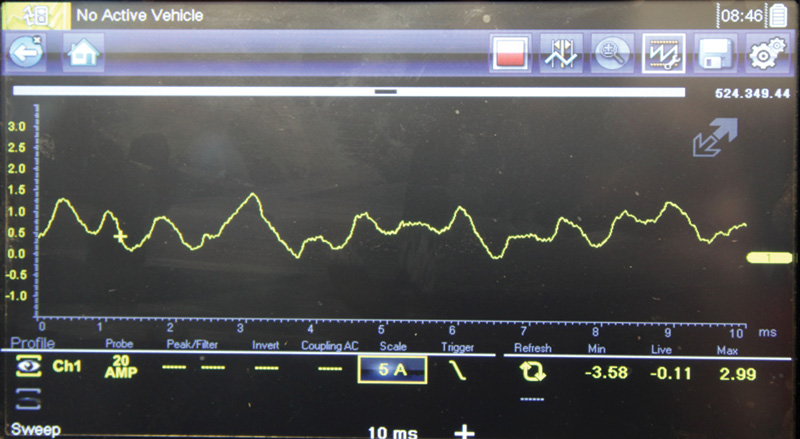

- An alternator diode ripple test.

An analysis of diode ripple is important as excess ripple may mask a problem with otherwise proper output from the alternator. If only one or two diodes have failed, the alternator may still produce enough current to meet the vehicle’s electrical needs, but it may not be enough to keep up with higher loads or to maintain a full charge. This could cause the battery to run down over time.

Diode failures may also allow AC to leak into the electrical system. AC voltage creates electrical “noise†that can confuse electronic modules and digital communications. A leaky diode also can allow current to drain out of the battery through the alternator when the vehicle is not being driven. If your testing proves that there’s an internal failure of the alternator, the repair is as simple as replacement — all the components are integrated into one unit.

Genuine Mercedes-Benz alternators are available either new or remanufactured, the latter having been thoroughly reconditioned and upgraded to the latest technical standards by the experts. The reconditioning process is subject to strict quality standards so that Mercedes-Benz reconditioned alternators offer the same quality as a new part, but at a significantly reduced price.

Be sure to verify your repair when complete so you can send your customer away all charged up!

Download PDF 〉

0 Comments