The scenario is real: Mercedes-Benz electric vehicles are on the scene, prepared for travel and headed your way for repair and service.

After developing the first automobile in 1886, Karl Benz and, separately, Gottlieb Daimler steadily refined and upgraded their pioneering internal combustion engine powered vehicles. But they also went extensively into the emerging electric vehicle surge, which saw electric vehicles become quite popular throughout the 1890s and into the first two decades of the 20th Century.

Strong, steady development of gasoline engines and widespread road development demanded greater range of movement that electric vehicles, with their battery power limitations, could not equal. This caused electric vehicles to lose favor and largely vanished from the scene by about 1920.

Mercedes-Benz has jumped into the Electric Vehicle (EV) fray in a big way with the introduction of a carefully developed complete range of electric vehicles and supporting systems called EQ. The first electric vehicle out of the gate is the highly important EQC crossover, set for introduction beginning in 2019 and full bore in 2020.Â

Popular Even Before They Are Built!

The market for these vehicles appears to be red hot, with Mercedes-Benz indicating the EQC is “sold out for 2019 and probably for 2020 as well,†according to Mercedes-Benz CEO Dieter Zetsche, speaking of the situation in Europe. Mercedes-Benz plans to have 10 electric vehicle models in the market by 2022, and has pledged multi-billion dollar investments to battery suppliers in the United States to support its vehicles. Increased lithium ion battery capacity and range, combined with electric motor and control system advances will play a significant role in the growing success of Mercedes-Benz vehicles.

The EQC setup features compact electric motors at the front and rear axles, configured differently to reduce power consumption and provide different output. The front electric motor is optimized for best possible efficiency in the low to medium load range, while the rear motor adds sportiness under full throttle. Together, the motors generate 402 horsepower and a maximum torque of 564 lb-ft. The motors draw power from latest-generation lithium ion batteries consisting of 384 cells in a modular design. The battery pack groups together two modules with 48 cells each and four clusters with 72 cells each, and is located beneath the floor, between the two axles, saving room inside the cabin and enhancing a low center of gravity.

The EQC also features an ECO Assist system that notifies the driver that he or she can lift off the accelerator pedal and coast (‘sailing’) to save battery. The system works in conjunction with data from navigation, traffic sign recognition, and info from the intelligent safety assist systems.

The 1835-pound battery pack is cooled by a water-cooling system which can also warm the battery in cold weather. Cooling is supplemented by airflow through the front grille. The battery, located beneath the floor, is protected by a strong girder frame to prevent damage from side impact.

The EQC’s front electric motor provides highly efficient driving, while the rear motor offers added punch when called for – and makes this a four wheel drive vehicle.

In addition to Comfort, Eco and Sport driving modes, a Max Range setting indicates about 250-280 miles in the EQC, with the 7.4kW on-board, water-cooled charger ready to boost battery charge. The Mercedes-Benz EQC is set up to use a Level 3 DC Fast Charger, which offers a 40-minute charge.

The End of Oil Changes

Many of us – well, some of us anyway – revel in the time when we were best friends with a spark plug wrench, could set timing right on the button for best performance, and loved the sound of that tuned engine roaring to life. Maintaining a Mercedes-Benz electric vehicle (EV), however, involves one major difference from those “good old days†– there is no internal combustion engine (ICE).

Instead we have two very powerful high voltage electric motors that should be treated with careful respect, but require no routine maintenance. No oil changes, for instance, nor spark plugs, camshafts, fuel pumps or fuel tank. Plus long-lasting brakes that regenerate the kinetic energy from braking back into the batteries means the brake pads can last longer too.

The new EQC electric vehicle operates with well-coordinated powertrain components that produce strong, quiet performance, including:

- The high-voltage battery pack

- Voltage Inverter/Converter

- Motor ControllersÂ

- Two powerful electric drive motors

The high-voltage battery pack, consisting of several individual lithium ion cells, requires thermal management — cooling and/or heating — to attain maximum life and capacity. Water cooling is supplemented with air flow from the grille, and uses supplemental heat when required in cold weather. These large and heavy battery packs need special equipment if they need to be removed safely from the vehicle. Note that handling HV components, like the battery pack or wiring, can be fatal unless proper equipment and precautions are used. Please consider having your local dealer handle these complex jobs, since one false move could be your last.

The inverter takes direct current energy from the high-voltage battery pack and supplies it as alternating current energy to drive the vehicle’s traction motors. The traction motors are called Electric Machines, to differentiate them from small DC motors used for things like the window lifters, for example. Sophisicated electronics convert large amounts of DC current into AC to drive the electric machines. The inverter also works in reverse: AC power (from a charging station, or generated by the electric machines) is converted back to DC to store in the HV battery, or to charge the 12-volt system battery.

The EQC’s electric vehicle motor (EVM) controller is a sophisticated device that delivers variable-frequency energy to the electric machine by modifying the energy flow from the battery. Essentially it produces variable-frequency 3-phase AC, which causes the electric machine to spin at the desired speed in response to throttle inputs from the driver. Each electric machine has its own motor controller and (at least for now) they are integrated with the electric machines and cannot be replaced separately.

The electric machines are mounted using stout rubber bushings and a very strong frame, with the frame mounted with another series of rubber bushings to the chassis. This anchors the electric machines and prevents motor noise and vibrations from intruding into the passenger compartment.

Testing HV components isn’t a matter of breaking out the multimeter or oscilloscope. When you are dealing with hundreds of volts, there are a few things that are forbidden if you want to continue living: Never pierce the insulation to test voltage. Use HV-rated protective equipment and work procedures as provided by the manufacturer. And don’t even think of working on the high voltage parts without proper training. Instead, you need to use XENTRY Diagnostics or some other testing tool to question the component as to its condition. Mercedes-Benz engineers designed extensive self-diagnostic and monitoring systems into these components just so the average techjnician doesn’t have to expose themselves to potentially fatal voltages.

Brakes should last much longer due to regenerative braking. The driver can influence the amount of ‘no throttle’ braking effect from almost nothing to a really aggressive level, where the driver may never actually use the brake pads. Nonetheless, the conventional brakes do need occasional attention from time to time, as they do see some use and will eventually wear out. Mercedes-Benz recommends a check of the brake pads and system at a 50k service, although owners might want to consider an annual brake service to clean and verify the brake system’s condition to ensure proper brake operation.

Service Considerations

With EVs there are some new considerations for the service shop. In some cases you should consider farming out specific jobs – like locking out and disabling the HV system – to your local Mercedes-Benz dealer. When working with a Certified Collision Center, be sure they also understand these considerations. Some tips include:

- Safety First: To ensure safety for technicians and your vehicle, the service facility should set up and make mandatory the “Lock-out-Tag-out†(LOTO) — or similar procedure — forbidding work on any electric vehicle until making absolutely certain that the vehicle electric system is LOCKED OFF. The vehicle can only be turned back on by the individual who locked it off and who holds the (only) key, after all repair work is done. This is a national industry safety standard for work on any electric machinery, and in most workplaces failure to abide by this rule results in immediate termination of employment.

- Schedule service to recognize that a vehicle sitting in the facility for an extended time waiting for repairs could lose enough charge to require recharging before work can begin.

- Anticipate longer repair times if removal of the vehicle’s 80 kWh lithium ion battery pack needs attention, especially with heavy side impact and severity of a collision, in case the battery is damaged, or in the way of structural repair. Located under the floor of Mercedes-Benz electric vehicles, the battery pack will need special equipment to move.Â

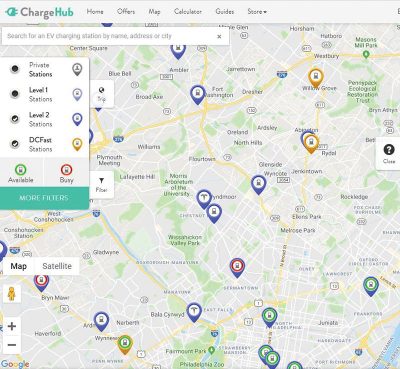

- You should consider getting an EV charger installed at your facility, if you don’t already have one. This will position your facility as “Mercedes-Benz EV Readyâ€, encouraging service business just by making the charger accessible to Mercedes-Benz drivers. Of course, if you are thinking of getting a DC Fast Charger installed, you’ll need to verify that the electrical panel is up to the task. A standard charger might use several amps at 220 volts, while the Fast Charger uses much more.

Traveling with the New Breed of EVs

Get the GPS ready, electric vehicles are here and already on the streets of America. Mercedes-Benz anticipates electric vehicles (EV) eventually making up a quarter of vehicles sold worldwide and is promoting its superior EQ vehicles as the finest electric vehicles on the road. Here is some information about the various charging options for the Mercedes-Benz EQC:

- All Mercedes-Benz electric vehicles — including the Plug-In Hybrids and the all-electric B-Class and smart models – are delivered with a Level 1 charger for use with standard 110-volt household current, and can connect to a standard Level 2 (SAE J1772) charger for faster charging (three to five times faster than Level 1). The Mercedes-Benz EQC also is equipped with a Level 3 (SAE Combo CCS) connector.

- Level 2, the most common connector, normally charges the vehicle in about 3 to 8 hours, while a Level 3 connection, when available, can charge the vehicle in in about 40 minutes. Level 2 connectors are widely available in the United States, while Level 3 chargers are somewhat less common. The number of both types are growing daily throughout the country.Â

Charging The Battery

Charging stations around the country use one of three basic financial models to deliver EV charging. These are:

- Pay-as-you-go – you set up an account with the charge provider, and they deduct the cost from your account as you use the charger.

- Subscriptions – a flat rate to charge, or a monthly fee for reduced-price charging.

- Free to use – many businesses offer free charging as an inducement to visit.

EV drivers can charge for free when available, although some operators allow only a short period of charging. Most networks involve some payment arrangements to be able to charge, such as a credit card on file. You can join more than one network if you like, or arrange your travel to avoid non-free public charging unless you’re nearly out of charge.

The cost per hour to charge basically depends on the power capabilities of the vehicle’s onboard charger as well as, of course, the hourly rate for the charge. A typical ‘fill-up’ is only a few dollars, far less than a gasoline vehicle for the same range. According to the US Department of Energy website, there are about 28,000 public locations (representing nearly 80,000 charging outlets, or about three per location average) to charge an EV, and from experience we’ve found that about one-third of these are free.

Quick Recommendations for Travel

For those planning a lengthy trip, here are some tips:

- A vehicle with only a Level 1 or Level 2 charger capability might not be the best choice for a long trip. Charge times are a few hours, and you’re limited by the vehicle’s range. The EQC has Level 3 charging capabilities, making longer trips practical.

- ChargePoint is the largest charging network, but there are several networks in the United States and Canada. Research on the Internet to see which is best for you. It’s not unusual to have several network ‘memberships.’

- Study your anticipated routes and destinations, and possibly use PlugShare (plugshare.com) or another station-finding tool to see which charging networks are along the way. Be ready to use any of them that are convenient on your schedule.

- Mercedes-Benz USA anticipates offering a smartphone app, much like the EQ Ready app available today in Germany. It can be used to assist planning and scheduling a trip, including finding correct routes to arrive where you want to go. Visit https://www.mercedes-benz.com/en/innovation/eq-ready/ to get a preview of what’s coming.

When charging at a commercial charging station, be careful to watch for slow charging speeds, and as a courtesy to others, disconnect and move the EV after you’re done charging. If you drive an ICE (Internal Combustion Engine) vehicle, again be courteous and don’t block an EV charger: You can get fuel most anywhere, but an EV can only charge in a few locations.

The new Mercedes-Benz EQC: The Mercedes-Benz of electric vehicles, indeed.

Download PDF

0 Comments