History

The episode with the Audi A6 led to an unfortunate incident with a Tiguan at the same facility. After completing the autoscan, it was difficult to start, at times stalled, and by “feathering†the throttle had stable enough RPMs to acquire live running data for a few moments.

Go backwards

The primary complaint was an oil leak at the high pressure fuel pump. The facility opted to repair the pump with a new seal. The engine was very difficult to start and often didn’t or repeatedly stalled.

Stop Right Here

For the uninitiated technicians that work on any Direct Injection engine, NEVER open the fuel system running or not running.

| WVGAV75N29Wxxxxxx |

| Engine Controller Part Number: 06J 997 026 L |

| Component: MED17.5 TFSI 2.0 |

2 faults found |

| 008213 – Intake Manifold Flap Position Sensor (Bank 1) P2015 – 000 – Implausible Signal – MIL ON |

| 000135 – Fuel Rail/System Pressure P0087 – 000 – Too Low – MIL ON |

Tools Used |

| 90 amp clean and stable power supply |

| Ross-Tech VCDS with screen capturing software |

Steps and how to

- Find a wiring schematic (the VW in this case).

- Find the correct fuse to disable the fuel pump control module at or near the fuel tank.

- With the engine running, monitor the fuel pressure at group 140.

- Wait until pressure is “approx 8 bar†and switch the ignition OFF.

- Leave the fuse out until the repairs are completed.

(This will maintain fuel in the rail and not starve the high pressure pump.)

Why do you ask??

Hot soak condition and fuel vaporizing 101.

Many vehicles in the market and especially FSI (Fuel Stratified Injection) models will energize the fuel pump control module, engaging the fuel pump when the driver’s door is opened. Let’s call it pre-prime.

An interesting fact (tested and proven) concerns engine coolant temperature.

The hotter the engine, the longer the fuel pump remains ON and vice versa.

So imagine an engine at operating temperature, inadvertently operating the fuel system. Imagine opening the driver’s door with the fuel system opened to the environment. Therefore keeping the pressure up minimizes vapor lock on hot engines ie: hot soak.

Back to the Tiguan

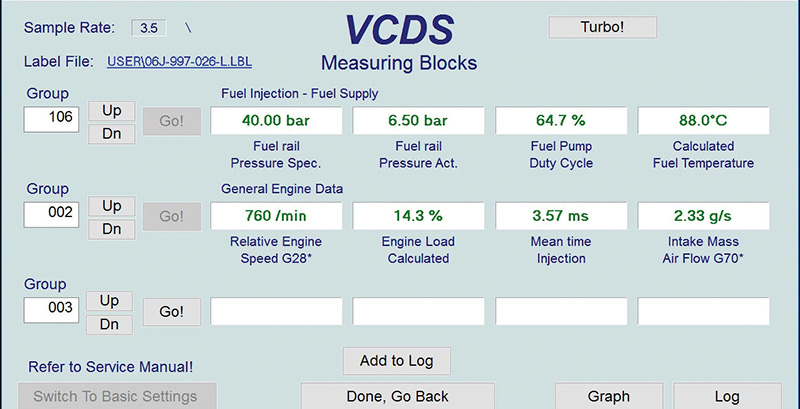

At idle and with the engine complaining (noisy as well), the images were captured at groups 106 and 002.

For this short running time and viewing the screen capture after the engine was shut down, there are some questions about the replacement high pressure fuel pump.

| Group 106 field 1 | The ECM is requesting 40.00 bar |

| Group 106 field 2 | Actual fuel rail pressure is far too low at 6.50 bar |

| Group 106 field 3 | The in tank fuel pump is commanded at 64.7 percent |

| Group 002 field 3 | Mean injection time is 3.57 ms |

(This is looking more like a port injected model.)

What was replaced?

Where is the original part and where was it purchased? The search was on and within a few minutes the original part was found. The original appeared to be defective where the seal resides, and we also found the original cam follower inside the original fuel pump. The follower or cap rides the camshaft, pushing on the spring loaded shaft that creates high pressure. The four lobe design reduces the piston stroke compared to the earlier three lobe design.

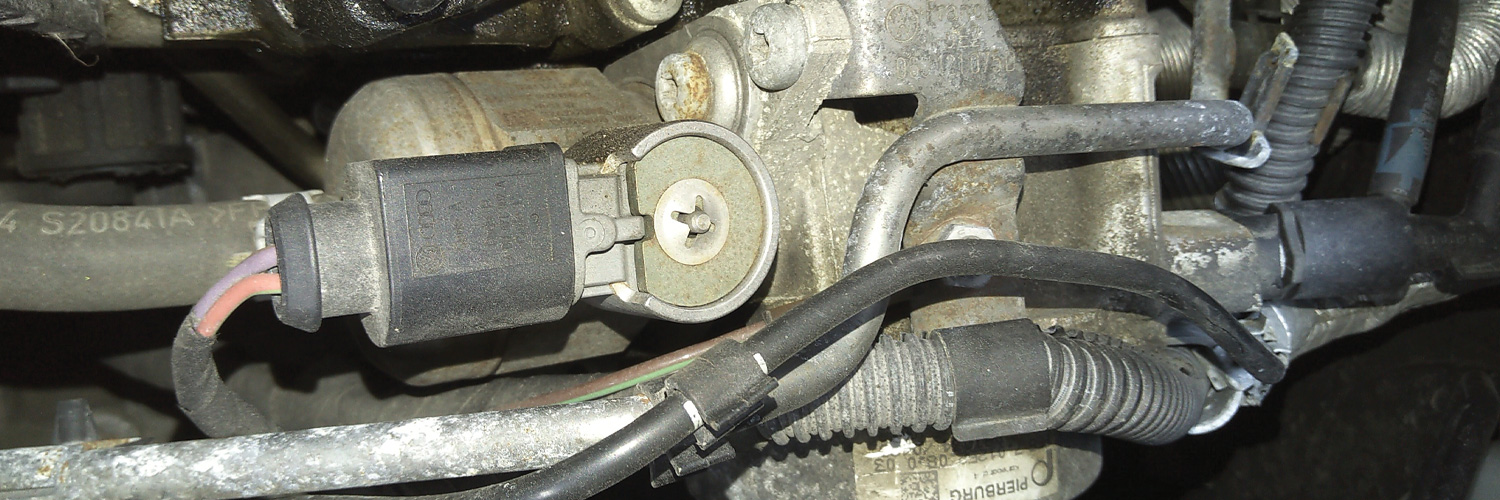

Time to inspect

The technician was asked to remove the pump following the above instructions and we placed the replacement pump beside the original.

The follower or cap is missing from the replacement. No comment and keeping it clean! Reassemble again with the correct parts and measure.

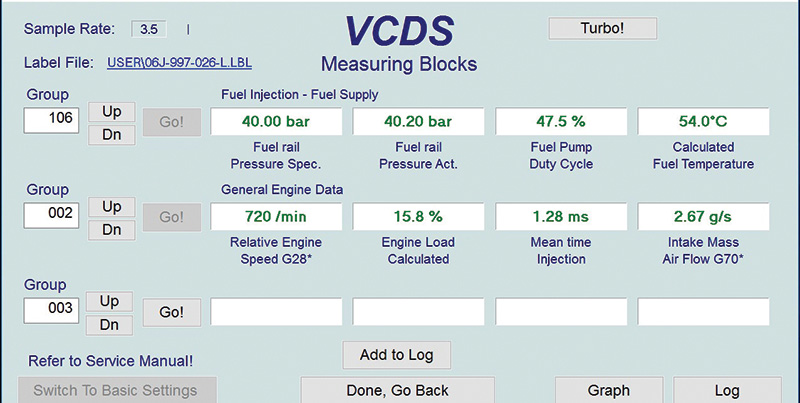

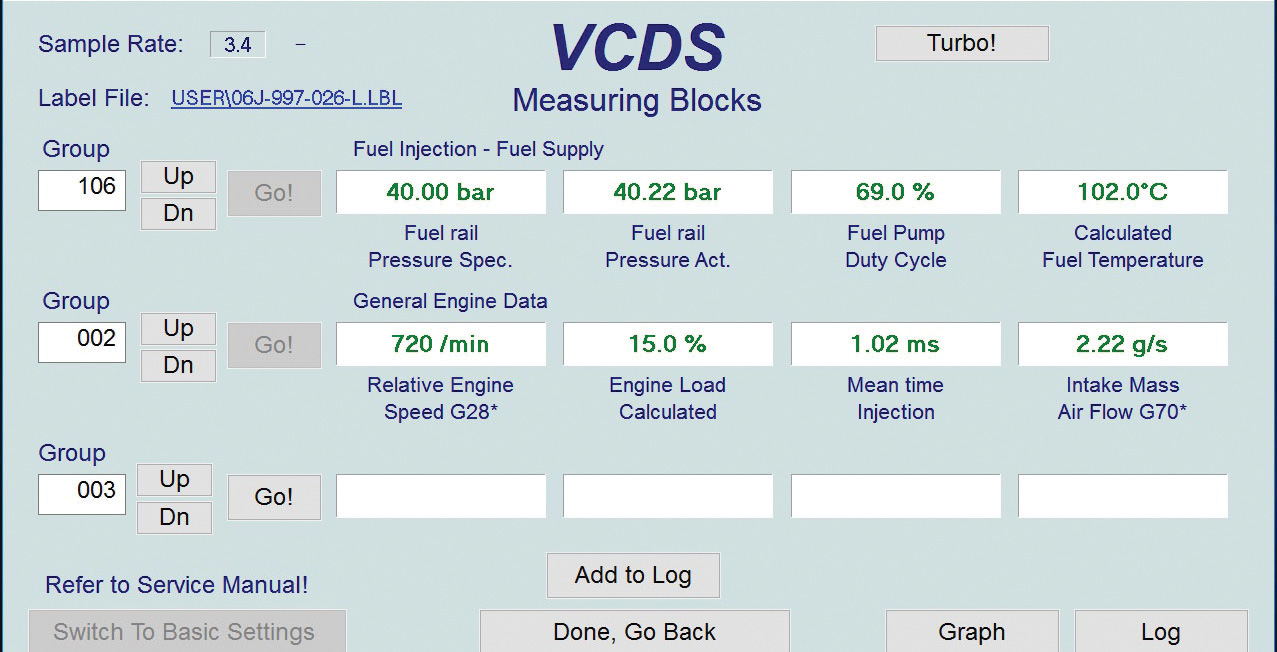

| Group 106 field 2 | Is close to specification |

| Group 002 field 3 | Looks normal for a cool FSI engine |

| Group 106 field 4 | The warmer engine is demanding more in-tank ON time |

| Group 002 field 3 | Engine management requires less injection time (warm) |

There will be many interesting images of damaged cam followers and plunger shafts found with the “Google images†service. Have a look.

Fortunately, there was no camshaft damage found with this model and luckily, because the shop has such difficulty trying to start the engine.

Despite finding this problem quickly, use this article as a guide to narrow other possible FSI related problems or faults.

Explanation and operation “If – Then – Elseâ€

If for any reason the ECM is recording fuel pressure faults, and injection pulse width is far too wide (fat), then expect the fuel tank control module to try to compensate for the difference between “specified and actual†values.

VCDS is the “go to†tool with many features comparable to a factory version, but one day I was experimenting with an Android device. 572.9 psi or 3880.0 kPa = dangerous, plus conversion from degrees C to degrees F.

I would submit that the technician who made this error did so in part due to pressure on him to finish the job in flat-rate time. I believe that this never-ending quest for “beating the clock” causes 90% of the issues that are experienced during the professional repair process. Our industry desperately needs to change the method by which its technicians are paid so that the quality issues that plague us can be minimized.