Under development for many years, R744 systems will be showing up soon. Are you ready?

I know what many shop owners and technicians are thinking right now: When will it ever end, this constant changing of automotive air conditioning systems? Well the short answer is maybe never. As with all systems in the automobile, the drive to improve on safety, performance and efficiency characteristics will always be evolving. Much to the chagrin of independent repair facilities this is, and will be, the norm for the foreseeable future. We can only hope all other manufacturers will follow Mercedes-Benz’s lead (and it appears many are) and standardize to one refrigerant. Those shops that service multiple car lines are otherwise forced to purchase different equipment to service different vehicles. We might be averse to the many changing regulations regarding the environment but any of us who live in the Western U.S. are keenly aware of aware of the air we breathe due to the smoke from all the wildfires. Hydrofluorocarbons (HFCs) are colorless and virtually odorless, but just because we can’t see and smell them doesn’t mean they aren’t there.

Evolution

Early automotive AC systems were run on Dichlorodifluoromethane (R-12) a colorless gas usually sold under the brand name Freon-12. Although R-12, a chlorofluorocarbon (CFC), has excellent cooling properties, it was found to be terrible for the environment. According to the United States Environmental Protection Agency (EPA), chlorine and bromine atoms coming into contact with ozone in the stratosphere disassemble the ozone molecules. One chlorine atom can destroy over 100,000 ozone molecules, far more quickly than ozone can be naturally created. A reduction of upper-atmosphere ozone is blamed as a component of climate change.

In the early 1990s, the EPA banned the use of R-12 in new motor vehicles and began the phase in of R-134a, a potentially less ozone depleting substance. 1,1,1,2-Tetrafluoroethane (HFC-134a, commonly known as R-134a) has been atmospherically modeled for its impact on depleting ozone and as a contributor to global warming. Research suggests that over the past 10 years the concentration of R-134a has increased significantly in the earth’s atmosphere, with a recent study revealing a doubling in atmospheric concentration between 2001 and 2004. It has insignificant ozone depletion potential, significant global warming potential and negligible acidification (acid rain) potential. Because of its high GWP, R-134a has been banned from use in the European Union, starting with cars in 2011 and phased out completely by 2017. In the United States the EPA bans R-134a in new light-duty motor vehicles as of model year 2021, with some narrow exceptions for export vehicles.

One of the next in line of possible replacement refrigerants comes the refrigerant R-1234yf. It is one of the first in a new class of refrigerants, acquiring a global warming potential (GWP) rating 335 times less than that of R-134a. Briefly used by Mercedes-Benz in the middle of the last decade, and clearly more environmentally-friendly, it has some safety concerns. More on that later.

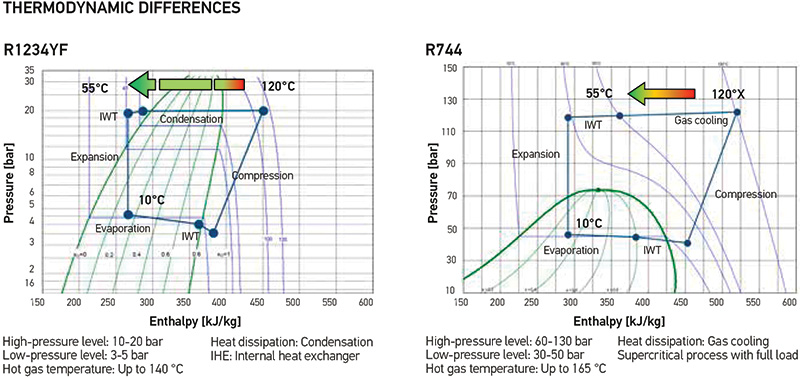

That brings us to COâ‚‚ as a refrigerant. From an environmental perspective, COâ‚‚ (Carbon Dioxide, also called R744, which must not be confused with R744a, which is Nitrous Oxide) is a very attractive refrigerant with a zero Ozone Depletion Potential and a Global Warming Potential of 1, as compared to R-134a at 1300. It is a naturally occurring substance, inexpensive and abundant in the atmosphere.

The Future is Here

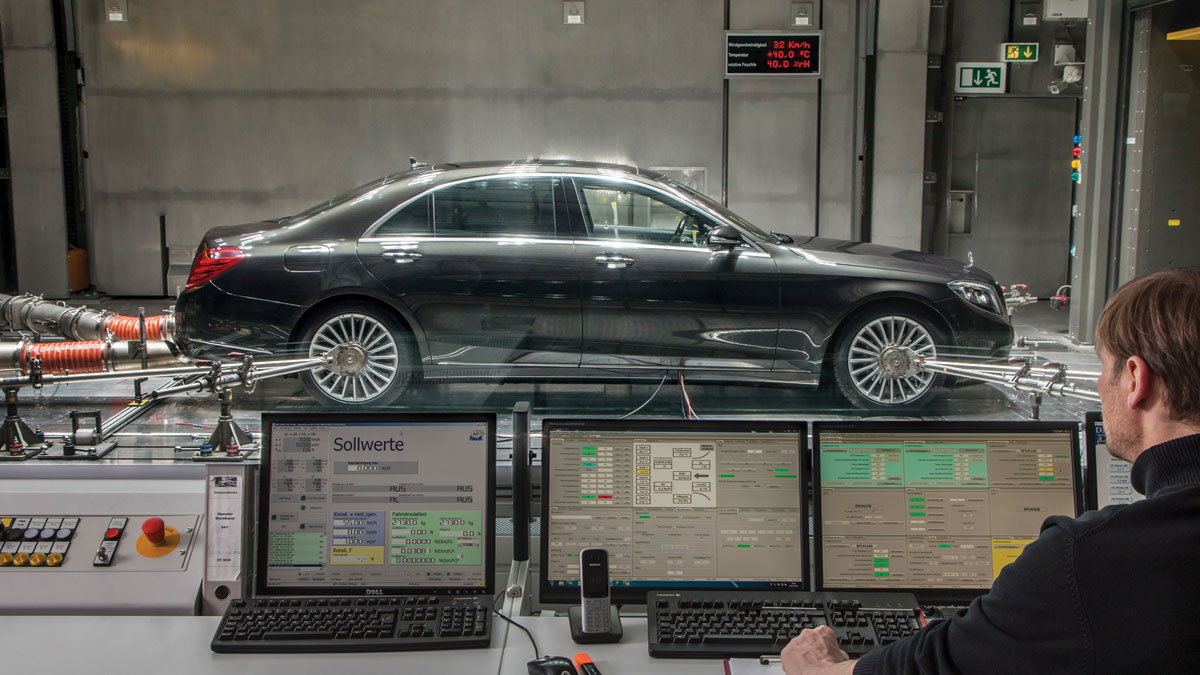

In order to comply with the legal provisions going into effect in 2017, Mercedes-Benz began to equip its vehicles with air conditioning systems that meet all the relevant performance and safety requirements. This production change exceeds the EU’s climate protection requirements. Since 2017, they have offered in Europe the S- and E-Class as the first production passenger cars equipped with CO₂ air conditioning systems. These completely newly-developed systems are based on the DIN specifications defined by the automotive standards committee of the German Association of the Automotive Industry (VDA). Thanks to their especially quick and high cooling performance, CO₂ air conditioning systems immediately provide a comfortable climate-controlled cabin even during very hot weather. This, in combination with their high environmental consciousness, makes them the long term premium solution among air conditioning systems.

Safety First

It seemed as though we were headed at one time for the use of R-1234yf as the go-to refrigerant, so what gives? Many scientists and engineers felt that it was only a temporary solution at best, including Mercedes-Benz engineers, and initially resisted its use.

In August 2012, Mercedes-Benz testing showed that the substance ignited when researchers sprayed it and A/C compressor oil onto a car’s hot engine. A senior Daimler engineer who ran the tests stated, “We were frozen in shock, I am not going to deny it. We needed a day to comprehend what we had just seen.†Combustion occurred in more than two thirds of their simulated head-on collisions. The engineers also noticed etching on the windshield caused by the corrosive gases.

On September 25, 2012, Daimler issued a press release and proposed a recall of cars using the refrigerant. Since then, to also meet the EU requirements on schedule for all other model series, the company has developed safe and reliable solutions for the use of R-1234yf. Daimler’s initial refusal to use it was based on concerns over its safety, but a suppression system combined with component placement to ensure refrigerant and hot engine components are separated in a collision has allows its safe use. Given that the R-1234yf refrigerant is the only one mandated by the European Union for use and available in sufficient quantities for use in vehicles, it appears that Daimler has come up with the best solution to a difficult problem. The German automakers have, however, lobbied for development of carbon dioxide refrigerants, which they argued would be safer. Mercedes-Benz has committed to introducing R744 soon, but for the time being North American models are expected to be equipped with R-1234yf.

Redesign

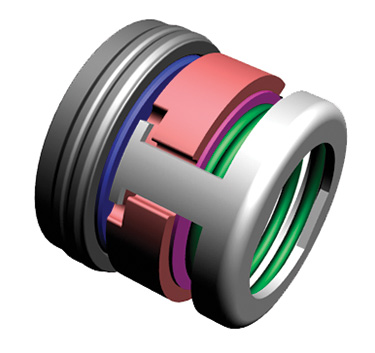

The use of CO₂ in the automotive industry requires completely new components. Operating at a pressure of more than 100 bar (1450 psi), as much as ten times higher than that of today’s systems, means that all components, including the hoses and seals, needed to be redesigned. One particular challenge is ensuring that the refrigerant circuit is leak-tight: The small size of the molecules and the high CO₂-permeability of conventional polymer hoses necessitate the use of metallic sealing rings and flexible, coated polymer hoses. Furthermore, the temperatures and pressures involved require the use of corrugated stainless steel hoses downstream of the compressor on the hot gas line.

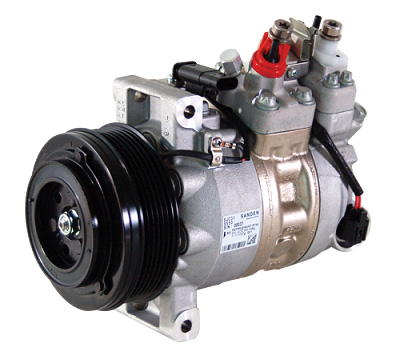

The compressor also must be designed to handle the increased pressures and flows. The compressors’ cooling performance and function exceed conventional compressors with one-fifth of the capacity (31 cc). According to manufacturer Sanden Automotive Components Corporation, Daimler’s are “the world’s first CO₂ compressors for mass-produced passenger cars.†Sanden has been developing this product with its Japan and Germany-based teams since 2014. The newest models now use a more advanced electric compressor.

“It has been quite a challenging project… for Daimler to get the R744 AC system launched in such [a] short period,†said Daimler’s Dr. Ralf Theurer. Mercedes-Benz has drafted corresponding standards together with all German automobile manufacturers and numerous suppliers in the automotive standards committee of the German Association of the Automotive Industry (VDA). Mercedes-Benz has assumed a pioneering role in this respect. It is the first automobile manufacturer to award not only development contracts but also to place production orders for CO₂ air conditioning systems and their components.

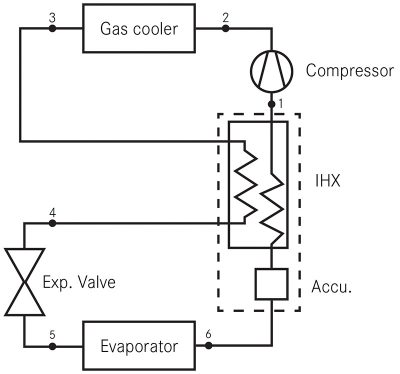

Higher pressures are not the only major difference. The second major difference occurs above an external temperature of around 25 °C, where the refrigerant pressure exceeds a critical point. Above this level, the R744 refrigerant can no longer be liquefied through cooling. In such conditions, the refrigerant is therefore continuously air-cooled by the condenser—more accurately named a gas cooler—accommodated in the front end near the coolant radiator.

Heat Exchanger

A new component introduced as part of this new technology is the Internal Heat Exchanger, often referred to as HX or IHX in many cooling diagrams. In order to obtain a high overall air conditioning system efficiency it is vital to introduce wet vapor with the highest possible potential to extract heat from the cooled air. R744 systems show a certain efficiency drop at higher ambient temperatures due to various properties—a discussion for the scientists—that requires further cooling of high-pressure refrigerant after it exits the gas cooler (condenser). The IHX is often designed as an extruded aluminum counter-flow heat exchanger, sometimes embedded in the accumulator for improved system design.

Condensers

As noted above, many workshop manuals will now reference what was previously known as a condenser as a gas cooler. Although this (as well as the evaporator) are types of heat exchangers, don’t confuse them with the inline heat exchanger added to R744 systems. In order to achieve the highest efficiency of heat exchange, the cooler uses multiport tube and fin technology. Refrigerant tubes have rows of micro channels with a diameter of about .5 mm to enhance heat transfer and to provide enough strength to withstand the higher operating pressures in the system. These tubes also have a thinner profile than those in R-134a systems which also enhances heat transfer.

Evaporators

Although still serving as the ‘cold side’ of the system, the evaporator in a CO₂ system is also completely redesigned, for the same reasons as the gas cooler. SAE Standard J639 requires vehicle manufacturers to perform assessments to minimize reasonable risks in mobile air conditioning systems, and gas at 100 bar presents its own special risks, particularly since the evaporator is essentially in the passenger compartment.

Safety

A couple of particular aspects must be observed when using COâ‚‚ in terms of operational safety. The refrigerant circuit must be secured to prevent components from bursting. This protection is provided in the form of a pressure-temperature sensor and pressure limiting valves in both the high-pressure and low-pressure circuits. A COâ‚‚ concentration above 5% in the air (normally around 0.03%) may cause headaches and dizziness, or even loss of consciousness at higher concentrations. For this reason, the system must be equipped with a COâ‚‚ sensor that measures the concentration of carbon dioxide in the vehicle interior, switches off the air-conditioning system in an emergency, and ensures a sufficient supply of fresh air.

Equipment

The KONFORT 744 recharge station was developed in collaboration with leading German automakers and is one of the very few solutions currently available that is specially designed to service and recharge R744 refrigerant systems. These new service machines differ radically in design from those intended for use with R-134a and R-1234yf refrigerants. The KONFORT 744, from TEXA S.p.A. is fully automatic and guarantees high-precision recharging, with a maximum tolerance of only 10 grams of refrigerant (and 2 grams of oil).

Special attention also was paid to the system for releasing COâ‚‚ into the atmosphere which, unlike other refrigerants, is allowable. Release takes place in a controlled manner to ensure the safety of the operator and of the system itself. The KONFORT 744, approved for use by Mercedes-Benz, also incorporates an accurate system for measuring the concentration of COâ‚‚ in the surrounding air, and suspends charging if this approaches a dangerous level.

Training

Section 609 of the 1990 Clean Air Act also established in the United States an important statutory structure to control the release of refrigerants from motor vehicle air conditioners into the atmosphere. Any person repairing or servicing motor vehicle air conditioners for consideration must properly use refrigerant recycling equipment that has been approved by the EPA.

Technicians who repair or service motor vehicle air conditioners for consideration (payment) must be trained and certified by an EPA-approved technician training and certification program. For the independent service provider that means not only finding proper training for your technicians, but also making sure they are certified. Refrigerant manufacturers and distributors have adopted guidelines by which they will not supply material unless the buyer is certified. There are several good online training and certification courses that you have access to. A few are listed here:

So get ready and ahead of the curve so your shop will be prepared when these vehicles begin to show up in your service bays. You’ll be glad you put in the extra time and preparation.

0 Comments