We as technicians are handed puzzles that need to be solved daily. These puzzles come in the form of broken automobiles; broken due to natural wear and tear, a collision, or previous repairs to name a few reasons. We are expected to quickly and accurately determine the root cause of a failure, and what the appropriate repair should be.

To accomplish this, we rely on skills that have been developed and refined over time. We analyze data, research service Information, and use knowledge gained repairing other vehicles. In other words, we rely on our troubleshooting IQ.

A traditional form of measuring intelligence is the IQ test. The term IQ, which stands for Intelligence Quotient, was first used by German psychologist William Stern in 1912. The research of Stern and his peers have influenced much of modern views on intelligence. In part, their research broke intelligence into two main categories — crystallized and fluid.

Crystallized intelligence is based in facts and experience. This is knowledge that has been learned through studying and from experiences throughout the course of one’s life or career. Fluid intelligence, however, is based in logic and deductive reasoning. This is intelligence that reads between the lines and picks up on clues or patterns that are not obvious at first glance.

Both types of intelligence are important to us as technicians, but crystallized intelligence will only carry us so far. That is why fluid intelligence is critical to troubleshooting. The ability to piece together a puzzle without knowing what the outcome will be, the ability to infer missing variables based on known data, and being able to make leaps in logic are crucial to being a successful troubleshooter. Blending the two intelligences together creates a balanced approach to solving the puzzles that broken vehicles present us with.

An IQ test focuses on measuring fluid intelligence, testing abstract reasoning, and spatial awareness. Read through the following vehicle study with the mindset of an IQ test focused on fluid intelligence measurement.

A 2012 Infiniti QX56 was towed into the repair shop because it would not start. The Infiniti had been driving down the freeway when the engine stopped running with no warning or indication of a problem. After stalling out the engine would crank over, but not start.

Once the luxury SUV was lowered off the flatbed, the symptom was verified. The engine cranked over, but it would not start. The engine cranked over slowly and unevenly, however.

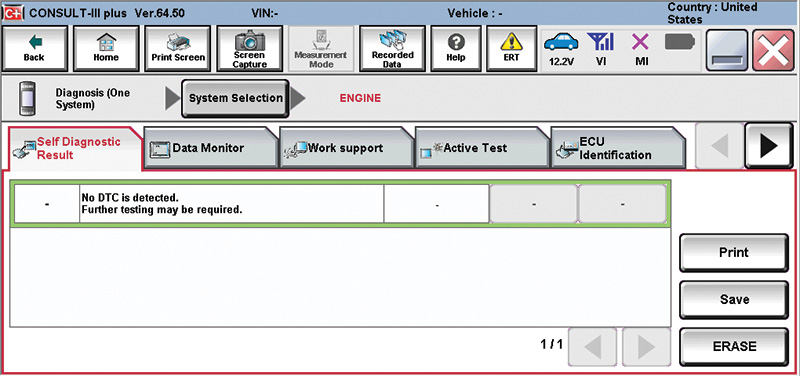

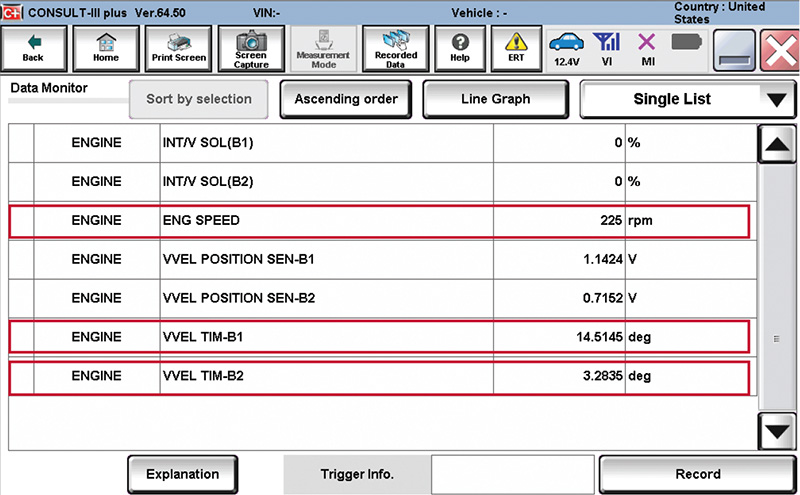

A starting system test showed that the battery was low on charge, likely due to repeated attempts to the start the vehicle. The battery was placed on a charger while further preliminary checks were performed. The engine oil was dark, but the level was correct. The coolant level was also good. A system-wide scan revealed no faults in the ECM or other modules.

With the battery state of charge correct, the engine was cranked over again. The cranking rpm was much higher, but the motor’s cranking rhythm was still uneven and the engine still did not start.

With the CONSULT III still connected to the DLC, the next step was to review scan data from the engine controller. There was an rpm signal present and the fuel pressure reading was in range. Coolant temperature and intake air temperature were correct. The camshaft timing PIDs were concerning though. The bank 1 cam timing showed 14.5 degrees, while bank 2 was only at 3 degrees. This bank to bank disparity is a strong indication of a camshaft timing issue.

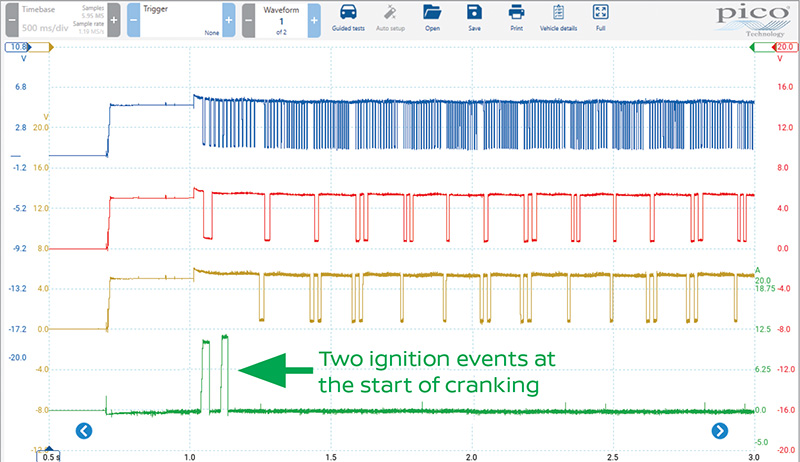

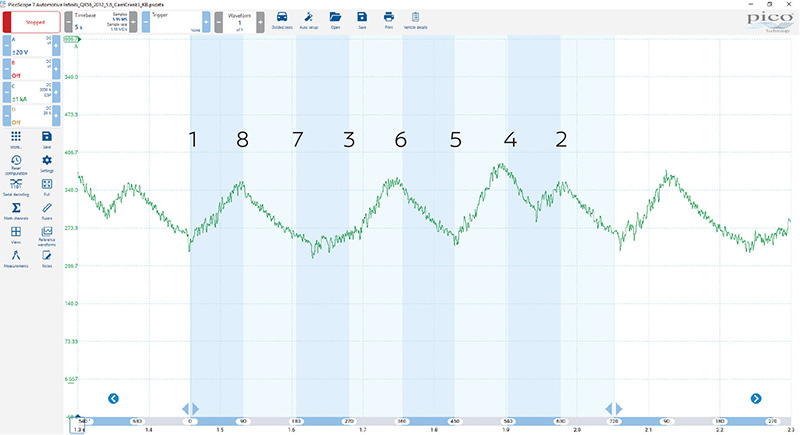

Due to the no start condition, a relative compression test was an easy and logical next step. With a high amperage current probe clamped around the negative battery cable and a second lab scope channel attached to the cylinder 1 ignition coil as a reference, the engine was cranked over again. The resulting waveform shed some light on the health of the engine, but it also raised a new question about the ignition system.

The starter motor current (channel C in green) matched the cranking cadence of the engine, showing multiple cylinders with low compression. The ignition sync (channel A in blue) showed no activity at all, indicating there was no spark control signal to the ignition coil. The test results were beginning to fall into place, but the lack of spark was a bit of an anomaly that still needed to be addressed.

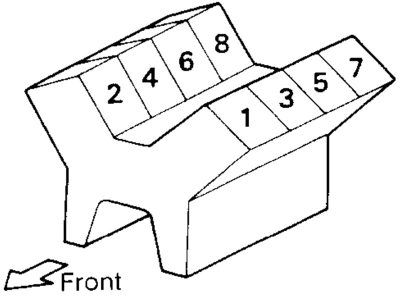

This Infiniti was equipped with a 5.6L V8 engine with a firing order of 1-8-7-3-6-5-4-2. Using the firing order, the cylinder layout, and the other data gathered so far, it was possible to determine which cylinders were low on compression even without the ignition sync. The scan tool data pointed toward jumped camshaft timing and potentially bent valves. This would mean that cylinders 1, 3, 5 and 7 would have low compression.

At this point in the diagnosis it seemed very likely that the camshaft timing had jumped on bank 1 of the engine, resulting in valve damage and four cylinders with low compression. The lack of spark was still a question mark though.

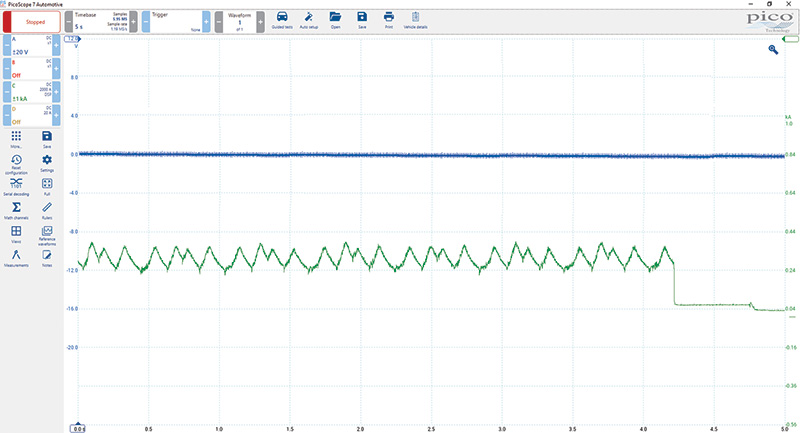

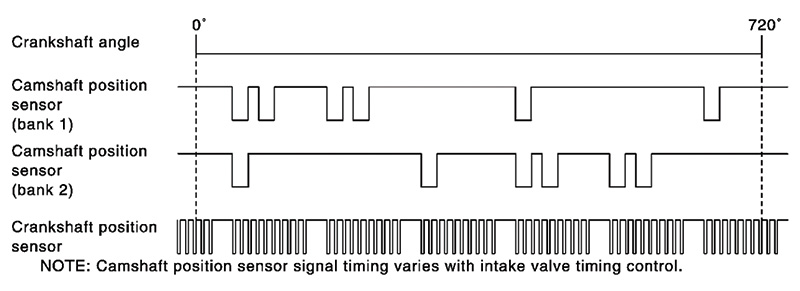

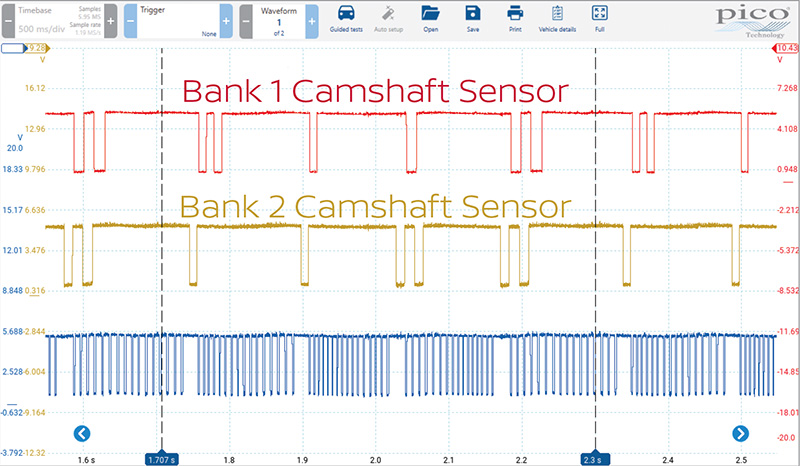

To confirm if the camshaft timing had indeed jumped, a lab scope was connected to the crankshaft sensor and both camshaft sensors. An amp clamp was also connected to the fuse for the ignition coils. The resulting waveform answered the no spark issue, as well as the camshaft timing.

There were two ignition events at the start of the engine cranking over. Subsequent tests showed the same results. There were one or two ignition events each time the engine was cranked over. The lab scope capture seemed to show that the engine control module was disabling spark, most likely due to the camshaft timing issue. After consulting with a trusted Nissan/Infiniti expert, these suspicions were confirmed. There is an engine management strategy that will disable spark when camshaft timing is outside of certain parameters.

With the no spark question now answered, the focus was shifted back to the camshaft timing. Using the crankshaft-to-camshaft correlation diagram found in service information, it was clear that the bank 1 camshaft had jumped time. The cam sensor patterns showed the bank 1 cam was significantly advanced.

In the end, the engine on this QX56 was condemned. An oil sample revealed large amounts of metal and bearing material, and the engine had over 160 K miles on the odometer. All these factors added up to an engine that was not a good candidate for new timing chains and a cylinder head repair.

Troubleshooting is not a black and white activity. There are often different ways to get to the answer on a vehicle; much in the way there may be multiple ways to solve a math problem or geometry proof. One way it is not necessarily better than another if the result is an accurately diagnosed vehicle in a reasonable amount of time.

On a fundamental level, troubleshooting is a very personal process. It requires a process that needs to be developed and refined through experience, study, and a willingness to admit mistakes and learn from them. A well-rounded troubleshooting IQ requires both types of intelligences, crystallized and fluid, working together in unison. This is not always easy to achieve, but well worth the effort.

0 Comments