The diagnostic approach chosen on common fault issues can drastically change the outcome. We’ll discuss several thoughts and angles, mechanical testing, oil and fuel depositing and more.

As we all gather virtually for the BIMRS Group meeting this year, we should reflect on some of the tougher diagnostic cases we’ve dealt with on BMWs this year. Sometimes, our approach to the issue at hand can quickly score us as a hero with our customers, and others… a zero.

Much of this comes down to the diagnostic approach we choose to deploy on several common fault issues in the BMW car line, such as the dreaded intermittent misfire, those pesky VANOS and timing chain faults (in N20 and other engines), oil consumption issues, Valvetronic faults, and other driveability issues that we can struggle with from time to time.

Let’s look at a few things from a diagnostic perspective and see if we can tip the scales toward hero on most of these diagnostic scenarios. We’ll follow a general discussion approach here with several thoughts and angles, mechanical testing, oil and fuel depositing, and a few other things along the way.

Oil and Fuel Depositing: The BIG miss…

Slowly, finally, this industry (the repair side anyway) has come to the realization that carbon removal and fuel/lubrication chemistry are important, no, critical considerations. For decades, chemical cleanups and additives were considered by technicians and customers to be nothing but snake oil.

This lesson is still being learned the hard way, with techs trying to solve misfires, intermittents, fuel consumption and power loss issues, as well as no-code driveability issues on GDI cars.

In the BMW line, both fuel and oil depositing issues are prolific. It’s not just the carbon on the valves that we need to be concerned with; the deposits argument goes far deeper in the engine than that — down to the root cause — the core of the problem, if you will. And that, my friends is piston ring control.

Consider that in a majority of cases, the cause of the failure of many commonly replaced components, such as injectors, VANOS phasers, oil control solenoids, crankcase breather assemblies, turbos, catalytic converters, timing chains and more, start as a fuel or oil depositing issue that often remains un-maintained or un-resolved until a part failure occurs.

The end result is the part failure, Check Engine light or, worse, a gnarly plausibility code. Why is this worth a mention here? Because depositing is rarely considered in the “test plan†we are using to try to diagnose the fault.

Ever see a BMW test plan specifically call out the possibility that ring deposits could be the cause of your closed crankcase ventilation system problem? Your turbo coking? The slow but sure progression of oil consumption, even?

Me neither. How about a BMW test plan calling out the need to check for piston ring leakage and oil poisoning being the root cause of a P0420 – P0430 code? Nope. Didn’t think so.

How about a BMW test plan that can help us to identify carbon as the cause of your intermittent light misfire, randomly dancing across multiple cylinders as the valve is rotating in the cylinder head while the engine is running, and those valves are intermittently not seating? Negatory. Not gonna see it.

The test that is usually recommended here is a static (engine not running) cylinder leakdown test. (Hint: The static cylinder leakdown test will never catch this problem; the engine simply isn’t turning fast enough when moved by hand to rotate the valves fast enough to induce this fault.)

The fact is, the ISTA derived test plans will rarely help catch any of these issues — hence frustrated technicians.

Now that many models in the BMW car line are equipped with gasoline direct injection, these oil and fuel deposit issues are the hidden ugly secret that nobody talks about in service information, theory, or test plan discussions, and yet, these are the confirmed source of the cause of the fault in many of these cars.

For the most part, other than techs knowing that there will likely be carbon buildup on the intake valves and will correct it when they identify the problem, these deposits are rarely even considered in any diagnostic test plans. And the problem goes way deeper than just intake valves.

From a testing perspective, performing the physical testing required to detect this as the problem has become step two in most cases where the parts cannon barrel is beginning to glow red. (We’ve all been there and we need some real answers.)

Consider that these GDI engines are ultra-high compression engines, and that the bulk of our depositing issue and the slippery slope of the degradation of performance to DTC, to parts failure, and eventual breakdown, starts with piston ring oil control in any gasoline direct injected engine.

The Vicious Cycle of Depositing Damage

Think about the problem we face in the field with carbon removal. Have you noticed that, sometimes, a chemical de-carbon service works well and cleans well, yet on other cars, it doesn’t even seem to touch the carbon deposit? This is the reason that many Euro shops and BMW specialists have been disassembling the intake and walnut shell blasting the carbon off, cleaning up the intake, and putting it back together (see the note on this toward the end of the article).

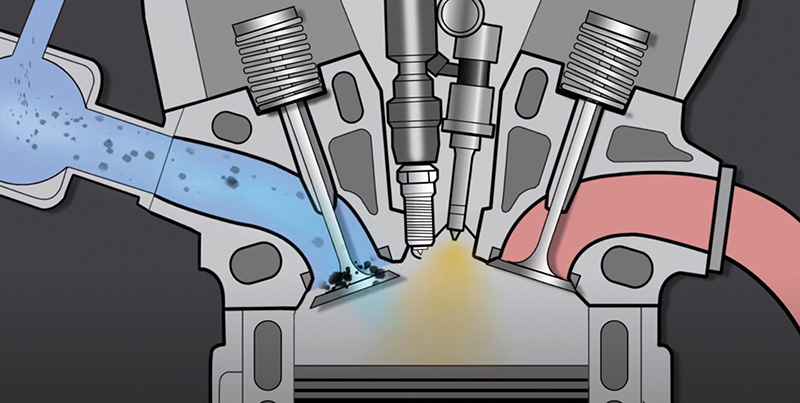

The reason is understandable once we recognize the vicious cycle of damage. Before we get to the root cause of trouble though, ask yourself this: How is the carbon even getting on the intake valve in the first place, if the fuel is now being injected directly into the combustion chamber?

Ahhh… This is the question that unlocks the answer to helping your customer (or yourself if you drive one of these cars) to avoid these problems in the first place.

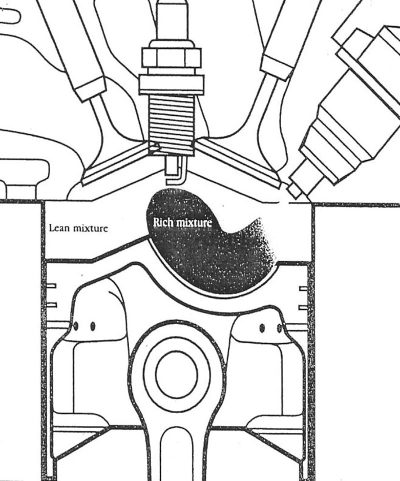

In a GDI engine, the higher compressions are designed to assist a better compression of the fuel-air charge in the cylinder. The reason that this is necessary in a GDI application goes deep into the engineering principle of using heat and compression to excite the carbon chains that bind the fuel together.

In order for the fuel to combust at all, the fuel’s molecules need to be thermo-chemically altered at the point of combustion when the (lean) high pressure injection of the fuel hits the compressed and heated air, right around top dead center.

The highly compressed and heated air charge now gets a shot of relatively cold, high pressure fuel. The colder fuel’s carbon chains begin to destabilize when impinging the hot compressed air, and those carbon chains begin to fall apart (thermally crack).

The shock of this thermo-chemical change, (known as combustion chemistry) plus the shock of the ignition coil’s spark causes an ionization of the mix, first creating a “pre-flame,†then Bang! Combustion occurs.

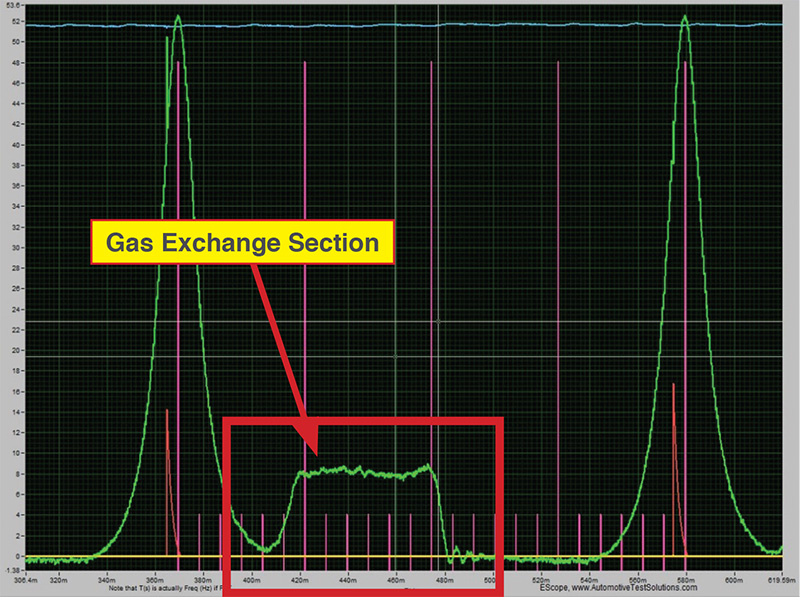

When combustion occurs, any interruption in the cylinder’s engineered tumble and swirl characteristics from carbon depositing will break up this fuel-air charge, create hot and cool spots in the combustion chamber, and detonation and incomplete combustion are the inevitable result (low power and misfire).

This degradation of combustion, of course, will accelerate the rate of deposit buildup and piston ring coking in the engine if left untreated.

So in essence, a GDI is a compression engine of sorts, with spark assist. Reference the Bosch spark-assisted HCCI GDI engines now in the Mazda cars, where ignition spark is only needed at cold start. After that, the engine will run sparkless on gasoline, just as a diesel does.

Now, if we can understand that a GDI is, mechanically speaking, more like a compression engine than a multi-port injected engine is, then we can really start to internalize just how important control of those piston rings, and therefore the compression, becomes in the engine driveability discussion.

Just knock down a diesel engine’s compression by 50 or 60 psi and see how it runs. Not well.

Same thing is true on our BMW GDI engines. When you (slowly, but progressively) coke up those piston ring lands with carbon and the compression drops over time, the vicious cycle of damage has begun.

With this in mind, we can answer how the carbon gets on those intake valves.

When compression drops as ring coking increases, it is not only compression that suffers, but the base engine’s crankcase pressures also increase. At the same time, two other nasties are starting to build.

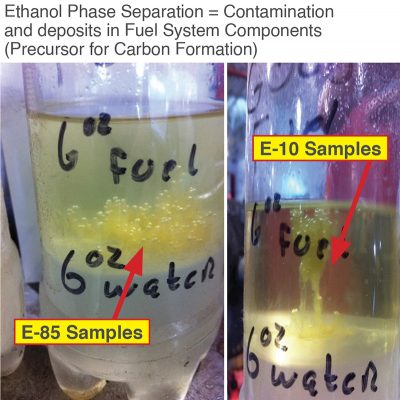

First, we know that the contamination of unburned fuel, soot from combustion, and moisture bypasses the rings and contaminates the base oil. This is why the extended oil change intervals are so destructive to grocery-getter cars. But at the same time, oil is also being pulled up past the rings and burned in the cylinder.

Now, enter the VANOS system, which controls valve overlap, amongst other strategies. The VANOS is doing what an EGR system used to do, which is to provide the cylinders with inert gas for the purpose of NOx control. The way it does this is to swap gasses from the exhaust and mix them with intake air.

OK. If we now have increased crankcase pressures and contaminated unburned fuel vapors being swapped around in the engine’s cycle via this method, the excess unburned fuel vapors along with the degraded oil vapors and the engine oil that just burned in that combustion cycle are both now pushed back into the intake manifold.

This is the source of the carbon we see collecting in the intake runners and building on the valves themselves. Back to those piston rings for a moment.

It is imperative to clean the piston rings regularly to first prevent, or after a fault, to mitigate, the problem that already exists in the engine. Replacing just the failed part you are diagnosing does not address the root cause of the failure of that part in these cases.

To answer why the carbon removal chemistry sometimes works and sometimes doesn’t, consider the above-described cycle occurring with various different oil brands and different fuel brands, as well as different environmental conditions in the engine. Think heat, moisture, temperature, the customer’s driving cycle, and level of contamination and piston ring coking.

None of our customers really ever use the same fuel, same oil, nor drive the same way consistently with that vehicle. So each car we face in the bay has a different chemical-carbon cocktail being made as they drive. A good friend of mine who has studied this issue with me for over 20 years put it in very simple and understandable terms.

He says the car is what it eats. Meaning, the problems we see related to deposits are directly related to what we feed that car. And how we drive it. Take all of the mechanical cycle and chemical differences in these carbons and throw one more critical factor in the mix: how the customer actually uses the car.

If the customer (or your personal car) falls into what we call the “short-tripper†or “grocery-getter†category, meaning the vehicle only drives say, 5-10 miles each way to work and home, or sits in city traffic for short commutes, it will have a very fast degradation of these conditions and build deposits quickly. Sometimes, once the rings are bad enough, radically.

On the other hand, if the customer is a traveling salesperson and burns two tanks of fuel per week through the car, out driving it daily on the highway for longer stretches, then the moisture and carbon don’t build nearly as fast.

This is because the engine that is being driven more is given more time and heat in the drive cycle to burn these contaminants off, whereas the short-trip grocery-getter never even gets a chance to get hot enough to burn any of it off. This is why short trip cars coke the rings so quickly. How quickly, you ask?

We’ve done many ring-cleaning services on nearly new, 10,000 mile short-trip cars, and documented a 15-plus pound improvement in compression across the engine. In vehicles with higher mileage, (but only around the 30,000-60,000-mile range), we have seen many vehicles gain up to 30 to 50 psi compression back.

Yes, just from cleaning the piston rings.

In a super-high mileage, never-cleaned engine? We’ve documented in some cases 60 to 85 pounds of compression restored by de-carbonizing those piston rings. Your author’s own 295,000-mile Volvo pulled back an average of 68 psi per cylinder after the ring cleaning service. That was a WOW moment for me, I assure you.

Think I’m kidding or stretching the truth a bit here? Measure a few before and after cleanings for yourself in your own shop. You’ll see pretty quickly that this is the silent giant, the great, unknown healer for GDI engines. Especially for those local grocery-getters.

Believe it, when you’ve seen this work a few times and have realized the amount of power that comes back, the fuel adaptations smooth out and the customer says, “What the heck did you do to my car? It runs GREAT!†– then you’ll never stop watching for and correcting this issue.

This is the “He who shall not be named†issue in the industry, yet there is simply no repair or part replacement nor adjustment that can provide such a drastic correction to driveability and reduce the vicious cycle of damage like a total deposit removal service.

If we combine three simple maintenance services: (1) An oil system and ring cleaning (which helps VANOS too!), along with (2) A de-carbon service on the intake manifold and valves, whether by walnut shell or chemical service, and (3) an injector cleaning, we are providing the engine with the only possible way to allow the DME to return to baseline fuel control as designed.

Think about why the OBD II data adapts and moves as it does over time and watch your data before and after these services, and you will quickly become a believer in baselining the engine by cleaning it.

Let’s go back to the beginning of the article and recap the parts failures we see and replace daily, and take those failures back to their root cause that starts the degradation well before that part actually failed — and what caused most all of the DME’s adaptations to occur in the first place. Yep. Depositing.

Injectors, turbo coking, and oil supply issues, catalytic converter failures, variable valve timing oil controls, and stuck-broken phasers… Timing chain failure, O2 sensor failure… Should I keep going?

Assuming there is no defective part, unusual mechanical wear, or engineering fault, it is both fuel and oil deposits that start (and finish) the vicious cycle of damage.

As a final note on carbon removal, if you are in the habit of walnut shell blasting only, please remember that you are not cleaning, nor affecting any carbon buildup in the combustion chamber, piston ring or injectors.

It is critical that you address combustion chamber and injector deposits at the same time you perform your walnut shell blasting, or you are not providing the consumer with a proper cleanup service. You are only correcting the misfire, not the cause.

This is vitally important to understand in the carbon removal scenario — always.

Remember, with all of the great mechanical and electrical technical training provided for us at BIMRS, sometimes we need to consider baseline engine data, the vicious cycle of damage, and throw the cleaning of these carbon issues from the engine into the diagnostic mix, lest we fail to repair the root cause of the failed part we are replacing.

It is truly what we’re feeding them, ladies and gentlemen. Let’s learn the customer’s drive cycle, evaluate our data with an eye toward this baseline data theory, sell some needed maintenance, and do some good for our customers.

Remember, we can either become a “Hero†or “Zero,†based on this knowledge and how we decide to apply this to our diagnostic approach and strategy.

By Gary Smith

0 Comments