A look at how Mercedes-AMG engineers increase efficiency in a large power plant, including CAMTRONIC

While you may service a number of Mercedes-Benz vehicles in your shop, the most highly engineered models are from the Mercedes-AMG division. The AMG badge on certain Mercedes-Benz vehicles stands for “Aufrecht Melcher Großaspach.” The first two words are the last names of Mercedes-AMG’s founders, Hans Werner Aufrecht and Erhard Melcher. The last word, Großaspach, is the name of the city in Germany where Aufrecht was born.

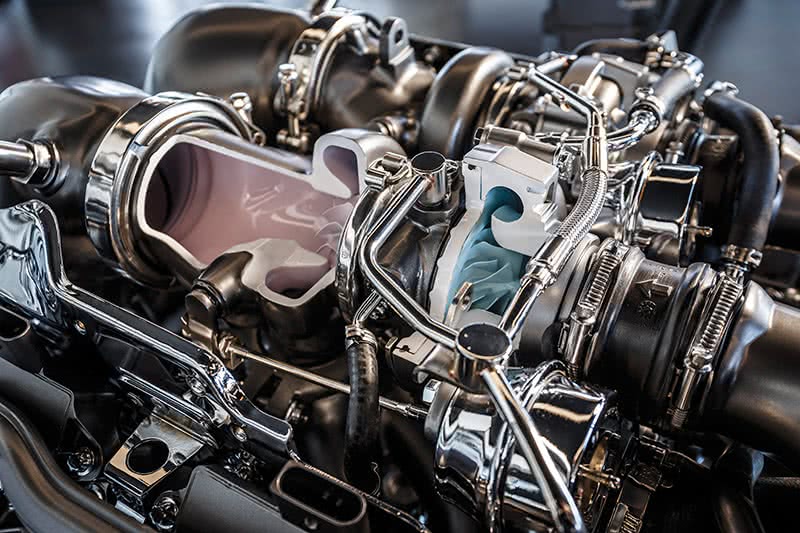

Perhaps the most important feature that distinguishes a Mercedes-AMG vehicle is its engine. With few exceptions, all of the larger-displacement Mercedes-AMG engines are handmade in an exclusive manufacturing facility in Affalterbach, Germany. In this venue, the developers live by the credo “one man, one engine,” with one single person giving their full attention to one single engine until it is finished.

Some of these vehicles have the largest power plants and astonishing power ratings, while still being some of the most efficient engineering marvels to coax even more from each drop of fuel.

Mercedes-Benz CAMTRONIC is part of the Mercedes-AMG cylinder management system. One of the features that sets apart the Mercedes-AMG is using CAMTRONIC to make a larger engine more efficient. By shutting off four of the cylinders, it also makes the remaining four more efficient by themselves, while also saving life on the valves, fuel supply, and ignition systems of the ones that are shut off.

The M152 engine is the earliest version of a power plant using these features and is based on the Mercedes-AMG M157 5.5-litre V8 biturbo engine presented in 2010, which powers the E 63 AMG, CLS 63 AMG, S 63 AMG and CL 63 AMG. Numerous components and systems are basically identical, including the displacement, bore/stroke, distance between cylinders, stop/start system and direct fuel injection technology. The Mercedes-AMG 5.5-liter V8 engine with Mercedes-AMG Cylinder Management and direct fuel injection made its debut in the 2012 SLK55 AMG. Even with peak output increased by 60 hp to 415 hp and torque increased from 376 lb-ft to 398 lb-ft, the fuel consumption is about 30 percent less, which places the newer M152 AMG among the top performers in its class. Features separating it from the M157 include new intake air ducting, new cylinder heads, modified valve drive, an adapted oil supply system and an optimized crankcase.

Cylinder Deactivation History

I know what you’re thinking, didn’t General Motors try cylinder deactivation some 40 years ago and it was a total bust? You’d be right. However, they weren’t the first to try it—an honor that goes, we believe, to the 1905 Sturtevant. The driver could cut power to three of the Sturtevant six cylinders by turning off one of the magnetos and lifting their exhaust valves. Imagine the air and fuel passing through the engine being unburned! There were some other attempts in the early automotive era but not until the oil embargo of 1979 was the real motivation in place to try and conserve fuel and still have power.

GM debuted its V8-6-4 engine in 1981 and it was a complete failure, lasting only one year. This writer/technician actually worked for a dealer that had a GM line as well as others (you used to be able to have multiple car lines under one roof) and I was able to attend a training class devoted to the concept. The idea is sound and makes a lot of sense, the biggest problem in those days of course was the processors: they were just too slow, the technology just wasn’t there yet. Fast forward a couple of decades and now is it not only possible, thanks to Mercedes-Benz engineers it is “cutting edge.”

CAMTRONIC

We briefly looked at CAMTRONIC as a feature in the Summer 2022 issue of StarTuned and its use in the M264 engines. Let’s take a more in-depth look at its design and function. The technology is so groundbreaking that Mercedes-Benz is featuring it in its whole line up of engines.

Valve timing, lift, and duration are all critical aspects of the modern ICE (Internal Combustion Engine). As modern-day engineers continue to develop ways to squeeze out more horsepower and better fuel efficiency, the camshaft and valves were one of the toughest problems to solve in terms of a system that could actually adjust on the fly, based on engine needs and drivers demands.

Trying to get the engine to breathe better requires better air flow. To get better air flow we began to see multivalve engines, two or more intake and exhaust valves per cylinder as well as variable intake manifold runners. So now we have better all-around air flow, but it is still set at a fixed flow rate which is a compromise. When an engine’s RPMs increase, the duration of each intake and exhaust stroke decreases so that fresh air is suddenly not fast enough to enter the combustion chamber, while the exhaust is not fast enough to leave the combustion chamber. One of the best solutions is to open the inlet valves earlier and close the exhaust valves later. In other words, the overlapping time between the intake period and exhaust period should be increased as RPMs increase.

Now enter the variable valve timing (VVT) concept. We all remember the debut of this feature in the M272 engine. Problem solved in terms of valve timing, but what about the fixed lift of the valve train? Enter CAMTRONIC. Instead of having a single fixed lobe shape designed to be a compromise for best performance in all driving scenarios, CAMTRONIC can have two different lobe profiles for each valve and possibly more as engineers develop the concept.

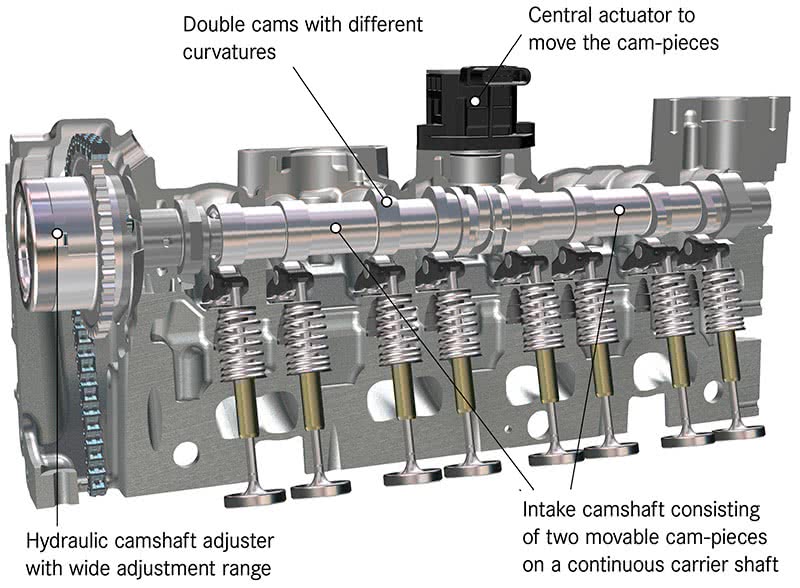

On the four cylinder engines currently, two different lobe profiles are machined next to each other, each one for a certain driving condition, sometimes referred to as small lift and large lift. In its simplest form CAMTRONIC uses a camshaft that has the lobes on the shaft able to move axially in order to position the proper lobe over the valve at the proper time. This is achieved by having an actuator mounted above the camshaft in the cylinder head cover drive a tappet down into a spirally cut groove in the camshaft. As the tappet moves in the spiraled groove, the camshaft profile is forced to move axially so that the correct profile lobe is over the valve at the right time.

The intake camshaft is made up of several components: two hollow-drilled sub-shafts of equal size are mounted on a carrier shaft. These are referred to as “cam-pieces” in the Mercedes-Benz Workshop Information System (WIS). The first sub-shaft controls the intake valves of cylinders 1 and 2, and the second those of cylinders 3 and 4. The surface operating the valves via roller-type rocker arms is only half as wide as on a conventional cam, therefore the space requirement is the same. When the steeper half of the cam is active, the valve lift is increased and the valves remain open for longer. Switching to the flatter half of the cam shortens the valve lift and the valves close sooner.

Load control with the smaller valve lift is incorporated by using various components. At very low engine torque the load control is conventional, using the position of the throttle flap, while at medium torque levels control uses the position of the intake camshaft, and finally at high torque levels the charging level of the turbocharger is used.

As the torque increases, the valve lift is switched to the larger level, load control once again being conventional via the throttle flap or, in the charged operating range, via the charging level of the turbocharger. Mercedes-Benz development engineers took numerous measures to ensure the most efficient combustion even with the smaller valve lift. Because of the smaller valve lift and early intake valve closure, the turbulence in the combustion chamber is reduced at the spark plug. This turbulence decisively influences the combustion speed and complete combustion of the fuel/air mixture. To compensate for this apparent disadvantage, the turbulence is increased in the lower partial load range by using a multiple injection strategy with injection ignition, while multi-spark ignition ensures reliable combustion.

The switchover from the smaller to the larger valve lift goes unnoticed by the driver. As cylinders 1 and 2 as well as 3 and 4 are coupled in pairs with one cam-piece each, it is possible to adjust the valve lift of all four cylinders within one camshaft revolution using just one double actuator. The variable, hydraulic vane-type camshaft adjusters on the intake and exhaust sides have a wide adjustment range of 40 degrees with reference to the crankshaft. This new development excels by virtue of its significantly smaller dimensions. The installation space along the engine’s longitudinal and vertical axes can therefore be made very compact.

Faults

There are not too many faults yet directly related to CAMTRONIC failure, but XENTRY TIPS bulletin LI01.20-P-070268 dealing with power loss may lead you to think you might have an issue with cams or timing. This bulletin refers to an issue in the M178/M177: Engine intermittently has reduced power (no boost reading).

Complaint: M178/M177 Engine intermittently has reduced power (no boost reading) and there are no fault codes in quick test and engine output is restored after an ignition reset.

There are two reported causes for this occurrence.

First cause: Pressure transducer or vacuum supply to turbocharger not OK.

Second cause (affects the M178 only): Crankcase ventilation/purging does not operate correctly.

Remedy 1:

- Check wastegate linkage for proper operation.

- Check pressure transducer, actuation via XENTRY.

- Check vacuum supply of vacuum pump (approx. 800-900 mbar).

If the function of the pressure transducer and the vacuum supply are OK, continue with Remedy 2.

Remedy 2 (M178 only): Replace crankcase purge line A178 010 37 01 using A178 018 04 00 purge line with check valve.

What About Cylinder Deactivation?

The M152 as mentioned above is first in the Mercedes-Benz lineup to use cylinder deactivation. In order to achieve a smooth transition between an 8 cylinder engine and a 4 cylinder, in this and subsequent engines such as the M177, a number of obstacles had to be overcome. One such improvement was the addition of a dual mass flywheel to absorb unwanted vibrations. The resulting transition is so smooth the driver only knows the processor has made the switch is by viewing the instrument cluster.

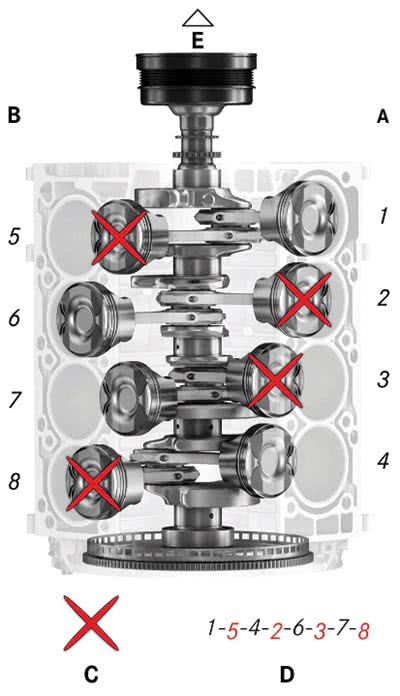

The engineering marvel is the use of CAMTRONIC to achieve cylinder deactivation. We mentioned above that in its simplest form CAMTRONIC has two lobe profiles per valve, a large lift and a small lift. In the Mercedes-AMG engine with cylinder deactivation a zero cam lobe rides next to the regular lift cam lobe.

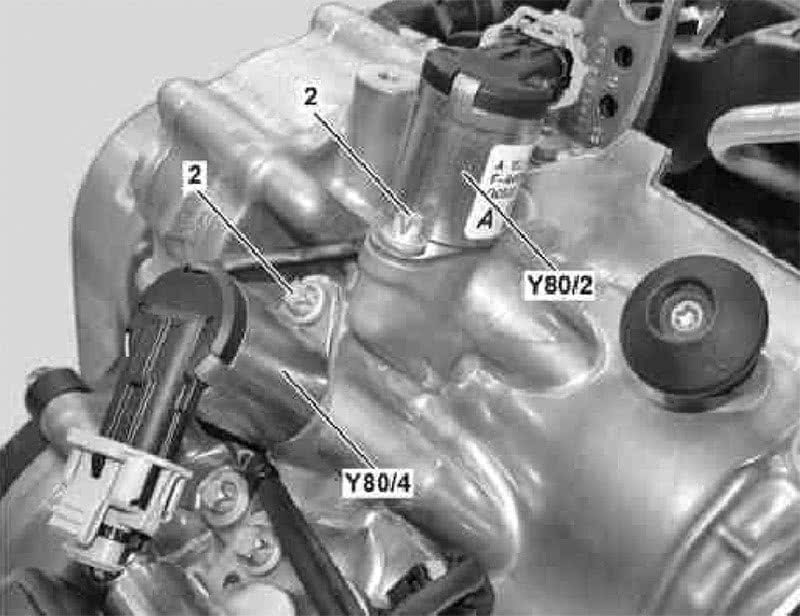

There are 4 actuators on each cylinder bank, two on the exhaust camshaft and two on the intake camshaft. On cylinders 2, 3, 5, and 8 there is a zero cam lobe next to the regular cam lobe. When called for, a tappet from the actuator moves into the spiral cut groove on the camshaft and causes it to move along its axis to position the zero cam lobe over the valve so the valve no longer opens. When the cylinder is cut off, the exhaust valves are deactivated first. At the same time, fuel injection and ignition are cut off for the respective cylinder. Air is then drawn through the intake valves at which time they are then deactivated. The purpose behind this is so that the air in the cylinders prevents a vacuum from being created causing oil to be drawn up past the piston rings. A second tappet from the actuator engages in the spiral groove in order to move the cam profile back to the 8 cylinder position as the engine management determines need.

Engine Management

All the engine functions in the M152 are executed and controlled by an extremely efficient Bosch MED 17.7.3. control unit. Subsequent control units for newer models are continually improved upon. Remember what we mentioned about the failure of the GM V8-6-4? Not only was it a mechanical failure but the processing of the changeover was just too slow. This state-of-the-art Bosch engine computer controls not only the direct fuel injection, cylinder shut-off and variable oil supply, but also communicates with other onboard control units. The microprocessor has more than 30,000 different parameters and functions stored in its memory, and is able to perform up to 260 million individual operations per second. To reduce the load on the engine control unit, there are eight individual ignition coils with an integral electronic module known as an ignition amplifier at each cylinder. These ensure a strong ignition spark at all engine speeds and under all load conditions. Eight high-voltage power stages are responsible for highly precise actuation of the piezo-electric injectors.

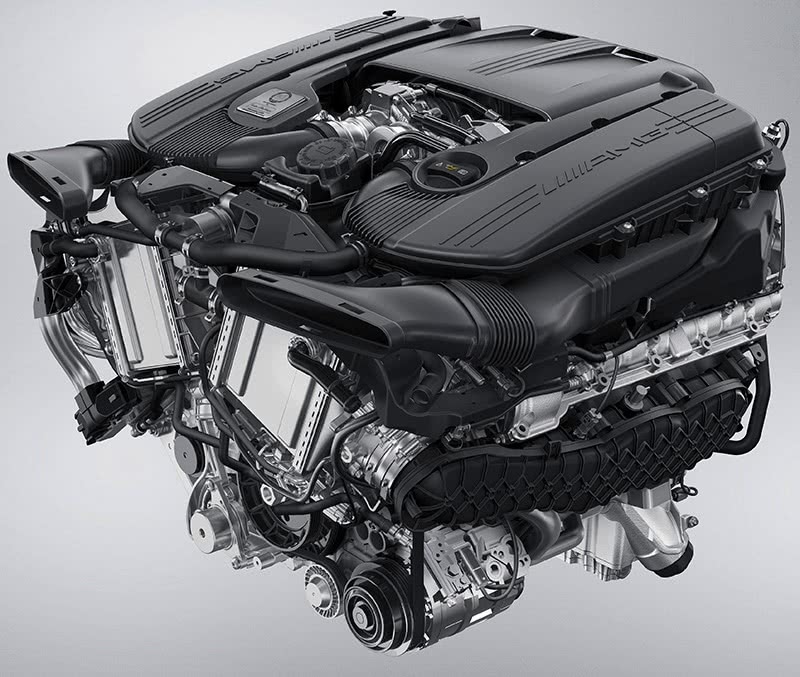

Handcrafted AMG 4.0L V8 Biturbo Engine

Not satisfied with the status quo, Mercedes-Benz engineers are continually improving and getting more power and efficiency out of smaller power plants. Mercedes-AMG has developed a high-output yet more compact engine for a new era of performance. The 577-hp 4.0L V8 biturbo engine is more responsive, yet more fuel-efficient, than its larger predecessor. Its massive torque reaches its 627-lb-ft peak from 2,500 to 3,500 RPM, for a 4.5-second 0-60 time and instant acceleration at any speed. Yet even with its advanced design and technologies, each Mercedes-AMG G 63 engine is still hand-built and signed by its own craftsman.

This new Mercedes-AMG V8 engine has two turbochargers which are not mounted on the outside of the cylinder banks but rather inside the engine V, sometimes known as a “hot V configuration.” The advantages of this is that the engine has more compact dimensions, which allow a low installation position as well as optimum weight distribution between the front and rear axles. The “hot V” also optimizes the supply of fresh air to both exhaust gas turbochargers.

The larger 5.5 liter V8 may be one of the last big displacement V8s you’ll ever see from Mercedes-Benz, as engineers are continually getting more and more performance out of smaller power plants. But you should still brush up on these engines, as well as getting more familiar with CAMTRONIC, as this is the technology of the future.

0 Comments