Your business model is going to change as we see a greater mix of EVs enter the market

Ready or Not—Here They Come!

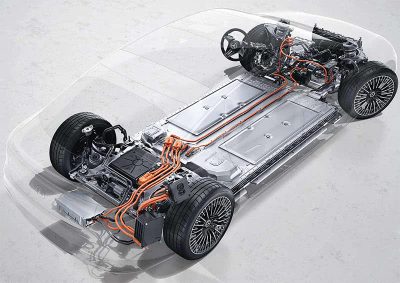

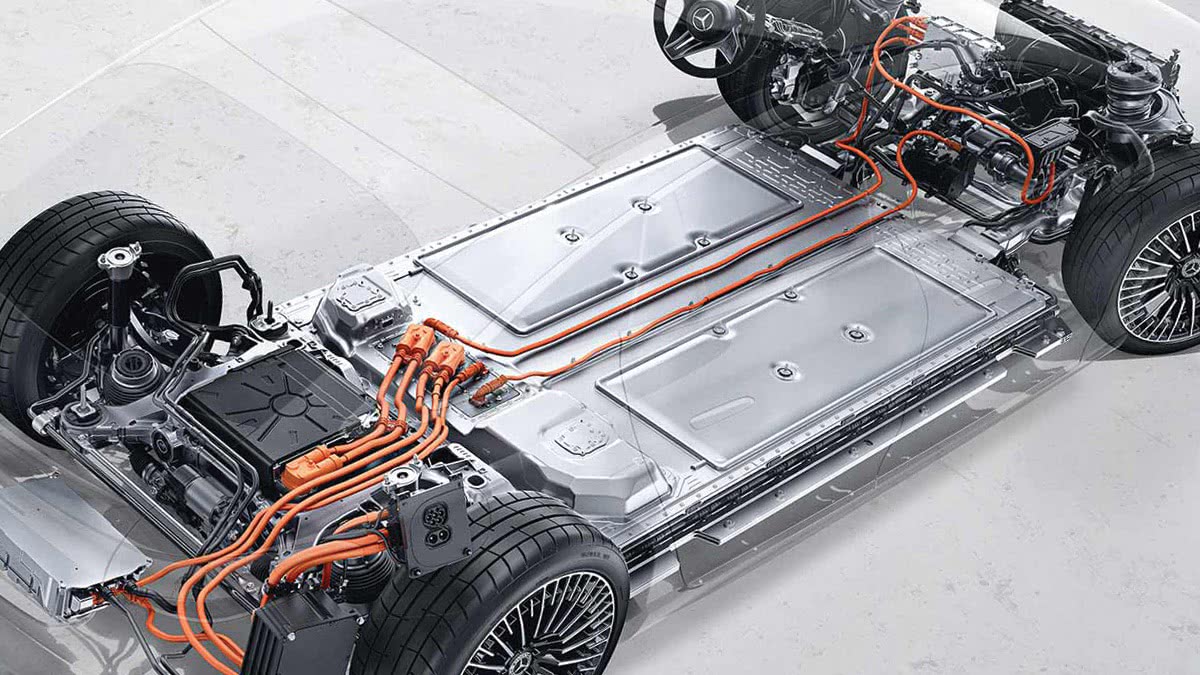

Mercedes-Benz is getting ready to go all-electric by the end of the decade, where market conditions allow. They will be shifting their focus from hybrids to all-electric, driving the company towards an emissions-free and software-driven future.

As of this writing, Mercedes-Benz AG offers battery electric vehicles (BEV) in all segments the company serves. From 2025 onwards, all newly launched vehicle platforms will be electric-only and customers will be able to choose an all-electric alternative for every model the company makes.

You would have to be living in a cave the last decade to not realize practically all other automotive manufacturers are jumping on the bandwagon. Ola Källenius, CEO of Daimler AG and Mercedes-Benz AG says “The EV shift is picking up speed—especially in the luxury segment, where Mercedes-Benz belongs. The tipping point is getting closer and we will be ready as markets switch to electric-only by the end of this decade.” We are seeing similar trends with all other major auto manufacturers so it only is a matter of time before you start to see more and more EVs in your shop. That is of course only if you are trained, ready, and equipped to handle them.

Some ISPs (Independent Service Providers) may balk at the idea, and perhaps even be opposed to EVs, but your complaints will fall on deaf ears. I can remember early in my career, attending a training class on electronic ignition (cars still had contact points), where the instructor was talking about a future where automotive ignition systems will no longer have distributors! You can imagine how the older techs (we were called mechanics then) balked at the idea. Kind of like when digital cameras came out – where do you put the film? They just couldn’t imagine how it was possible and that cars were going to get too complicated. Now most techs have no idea what a distributor is. This is where the industry is headed for now and you need to be ready.

We recently conducted an interview with Tony Molla from ATI about the future of EVs and getting your shop ready. You can access the podcast here: bit.ly/ATI-E17

Is Your Shop Ready?

Think about which services you will no longer need to perform on an EV. No more oil changes. The routine oil and filter service doesn’t typically have a large profit margin, but what it did for you as a shop owner and technician was keep you in contact with your customer’s vehicles on a regular basis, performing routine inspections. You need to begin to think outside the box, so to speak, and brainstorm ideas to continue seeing a steady influx of vehicles to your shop. Perhaps performing a no- or low-cost tire rotation with free brake inspections.

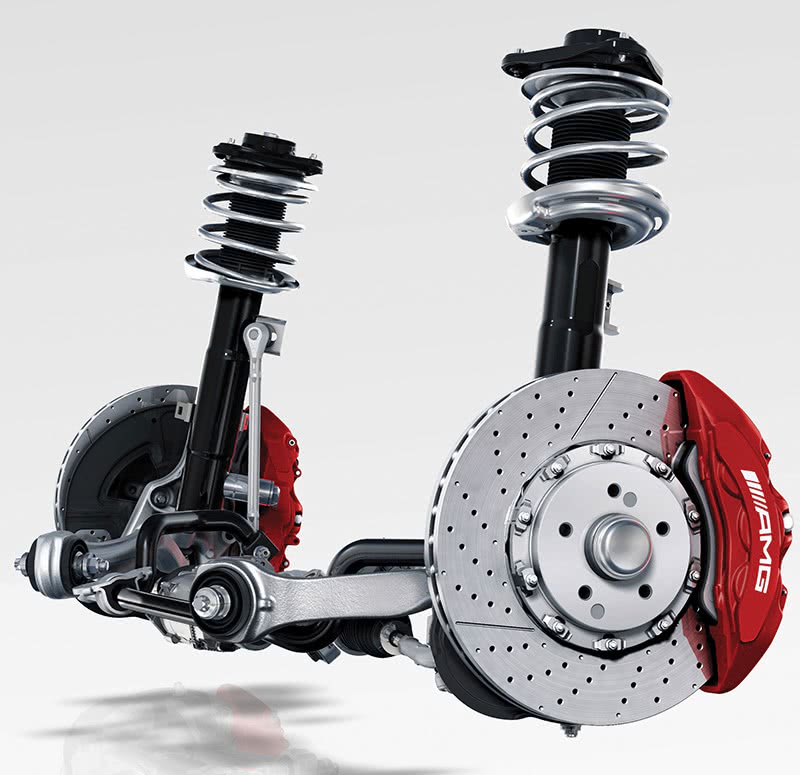

EVs still have maintenance schedules, but generally with longer intervals. According to The Detroit News, the Chevy Bolt has 80% fewer moving parts than a comparable ICE (Internal Combustion Engine) car. What that tells you is there are simply more electronics to keep you busy. EVs have no spark plugs to change, no belts, and no fuel system with related filters, pumps and such. The brake pads often last 2 to 3 times as long due to regenerative braking. However high torque at start tends to increase wheel slip, and the ASR system applies the brakes to counteract that. A source at Mercedes-Benz states that they are seeing rear pads that don’t last as long as front pads in some EV models. The point being, there’s not a lack of work but a shift in technology that will still need to be serviced.

Just as when we evolved from points and condenser to electronic ignition, and carburetion to fuel injection, there are still maintenance and repair items that will need attention. A/C systems will need to be serviced, as will door locks, window regulators, power seats and comfort systems, and telematics just to name a few.

More of your work will involve electrical systems and diagnosis as we shift towards a software-driven platform. Software upgrades, right? Make checking for needed software upgrades a regular part of a checkup (although you should be doing this already). You definitely need to have programming software, as vehicles will constantly be getting new software updates. And, as we know, sometimes those updates fix a customer complaint.

What About Equipment?

What kinds of tools and equipment should you be equipping your shop and technicians with to be proficient and safe when servicing EVs? Aside from safety items, which we will discuss, first and foremost would be a Level 2 charging station, or more if space and your electric panel provides. EVs may come to your shop in a low state of charge, just how customers with ICE vehicles show up with an empty fuel tank. Also, one customer concern that is already popping up in some shops is the vehicle’s failure to charge. The on-board charger may have a fault you need to diagnose. Of course, one of the steps you’ll need to take is to charge the vehicle at your facility, to see if the problem is on their end with the home charging station or with the vehicle itself. Having a known-good working charging station in your shop can help you identify the culprit and save you time chasing your tail.

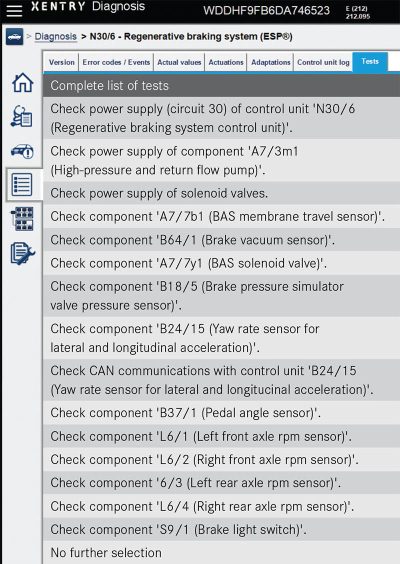

XENTRY Diagnostics and some factory-compatible diagnostic tools have HV battery diagnosis capabilities. You should consider getting something with these capabilities if your product mix supports the expense. Compare this to a diagnostic spark pattern scope for an ICE—similar expense, similar value.

Have a local electrician evaluate your shop to see what capabilities you have for charging stations. Most are fairly inexpensive and, depending on your shop configuration, are not too costly to install. One shop I spoke with had a 240-volt welding outlet that was not being used all the time and they were able to convert that to accommodate a charging station.

The Autel MaxiChargerâ„¢ Home 50A AC Hardwired EV Charger is a 240V-50 Amp Level 2 EV Smart Charger compatible with all EV and Plug-in Hybrid vehicles. There are many such charging stations on the market. Ask your electrician which might be right for you. A Level 3 charger is considerably more expensive and requires heavier gauge wiring, which brings us to the next consideration.

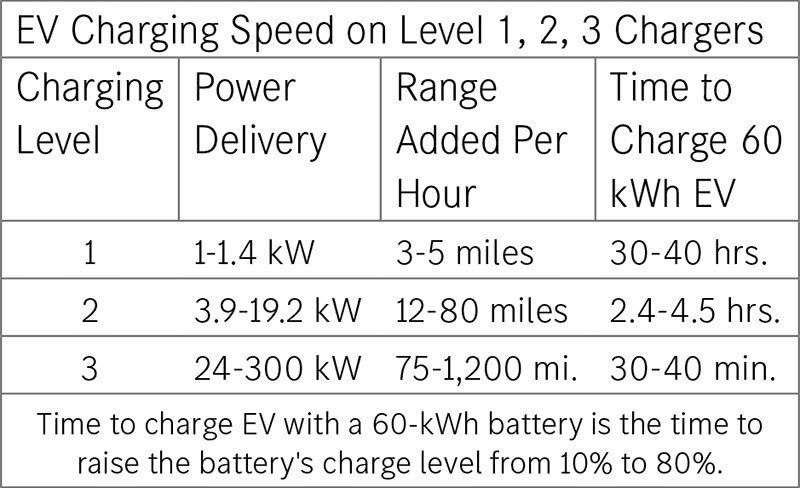

Speaking of levels—what are the levels of charging mentioned above? When talking about charging EVs there are three levels of charging available:

Level 1: Level 1 charging uses a common 120-volt household outlet. Every electric vehicle or plug-in hybrid can be charged on Level 1 by plugging the charging equipment into a regular wall outlet. Level 1 is the slowest way to charge an EV. It typically adds around 3 to 5 miles of range per hour. Not very fast, probably best for plug-in hybrids as they have smaller batteries.

Level 2: Level 2 charging is most commonly used for daily EV charging. Level 2 charging equipment can be installed at home, at the workplace, as well as in public locations. Level 2 charging can replenish between 12 and 80 miles of range per hour, depending on the power output of the Level 2 charger and the vehicle’s maximum charge rate.

Level 3: Level 3 charging is the fastest type of charging available and can recharge an EV at a rate of 3 to 20 miles of range per minute, although not every EV can use a level 3 charger. Unlike Level 1 and Level 2 charging that delivers alternating current (AC), Level 3 charging delivers direct current (DC). Level 3 chargers are very expensive and can cost tens of thousands to install.

Public Charging Stations

If your business is centrally located, and space provides, you may consider installing a public charging station from a supplier such as ChargePoint. A public charging station provides both a service to your community along with promoting your shop as being equipped to handle electric vehicles. Conduct a search in your state for incentives for installing a charging station on your lot. There are also some federal incentives to help with the cost. Many states have environmental programs offering grants to help offset the costs. Call your power company and ask about programs to install charging stations. For example, Pacific Power of Oregon has a partnership program that is free of charge and will coordinate and schedule a site visit to your property to perform analysis of EVSE technology options, costs, rates, and best practices for siting, configuring, installing and management of equipment.

Safety

We mentioned safety, and with high voltage BEVs safety when working on them is of utmost importance. The voltages typically found in EVs are deadly. While we’re mentioning here some of the typical safety precautions in use by those trained to work on EVs, by no means should you even think of working on the high-voltage systems of any vehicle without proper training and equipment. There are companies offering this kind of training and equipment.

Whether servicing a Mercedes-Benz product or some other marque, every EV has a service disconnect. This is a plug or other component that is used to disable the HV system. It does not render the battery itself safe—there are other manufacturer procedures for that—but it allows technicians to work on non-HV systems in the vehicle without exposing them to high voltages. The HV system should be disabled for even routine service procedures.

When working on the HV system components—HV wiring is colored orange—it is critical that the vehicle be rendered completely safe by disabling the HV system completely. This is a level above the service disconnect system. Mercedes-Benz dealers do this using XENTRY Diagnostics after receiving special training. Our advice is to simply not fool with any potentially life-threatening situations until you also have the proper equipment and training. Electricity is invisible and dangerous.

Since technicians are always using their hands, rubber insulating gloves are typically the first line of protection. Rubber insulating gloves sold in North America need to comply with ASTM Standard Specification D120, which includes ratings, test voltages and maximum working voltages for both AC and DC systems.

The EV market is projected to shift towards 800-volt DC systems within the next few years, so service technicians should consider stepping up to class 0 rubber insulating gloves with a maximum working voltage of 1,500 volts DC. Regulations and specifications require that protector gloves, usually of leather, be worn over rubber insulating gloves. If you service hybrids now, you undoubtedly have a set of insulating gloves already but you may need to upgrade. They are admittedly difficult to work in, but the alternative is simply unacceptable.

OSHA regulations enforce the ASTM F496 specification for in-service use of rubber insulating gloves, which require recertification of insulating gloves at least every 6 months. Don’t skimp on this expense. Insulated gloves should be worn anytime a technician is working on or near the vehicle’s battery, inverter/converter or other HV components. This includes when disconnecting or connecting the battery service plug and when using insulated tools.

Speaking of tools, you’ll need a full line of hand tools available while repairing high voltage systems. Hand tools that are tested and certified for high voltage work are all readily identified by both their color—a mix of orange and yellow—and a label that uses a symbol of two stacked triangles and “1000V” printed on the tool. These tools should be fully insulated and provide protection up to 1,000V.

Procedures

Sometimes we can get a bit relaxed about procedures, one tech likes to do something one way and another has his or her own style. While that’s perfectly acceptable for some applications, when it comes to safely working on EVs you must have in place a strict safety policy and procedures list when they are in your shop. All techs should know and understand the policy even if they aren’t going to service one. Check online as there are some companies that will have a pre-written policy you can tap into.

OSHA: As of this writing, I have pored over OSHA (The US Occupational Safety and Health Administration) regulations regarding Lock Out Tag Out (LOTO) procedures and I may be more confused than ever. Nevertheless, the bottom line is that you do need to have a procedure to “lock out” the potential for accidental release of stored energy from machinery and equipment. Believe it or not this applied to ICE engines as well. It just was much simpler, the technician just put the key in his pocket and no one could accidentally start the vehicle. With perimeter energized key fobs you can’t do that anymore, so I would suggest a lockbox for each tech labeled and placed away from the possibility of energizing the vehicle. You can read more information about the OSHA regulations here: osha.gov/sites/default/files/publications/factsheet-lockout-tagout.pdf.

Familiar Systems with New Technology

As you begin to service EVs there will be some familiar systems but new technology you need to become familiar with in order to service them properly. Below we list a couple of these, but this list is not comprehensive.

Servicing A/C

We mentioned you’ll still be able to service A/C systems, but EVs and hybrids generally have some different servicing requirements.

Instead of a belt-driven compressor, the HVAC system in an EV uses an electric compressor, consisting of a spirally wound fixed scroll and variable scroll, with a brushless motor running on high voltage AC. This is supplied by either a small inverter, which inverts DC battery power into AC, or an electric motor that’s built into the compressor housing, and powered by AC voltage from the vehicle’s power supply system. This allows the A/C system to operate even if the engine is not running (which is why you need to power down the system—more on that later). Of course, the HV system must be completely powered down before you can even touch the compressor—the service disconnect isn’t enough.

Conventional A/C systems typically use PAG or Ester oil, however, all-electric and hybrid vehicles require a special polyolester (POE) type oil. This oil has high dielectric or non-conductive properties that are designed to lubricate the compressor while protecting the compressor’s electrical windings.

Research has shown that as little as one percent of PAG oil in an EV or hybrid system can affect the dielectric properties, reducing the insulation resistance of a compressor from over 10 Megohms to less than one Megohm. An impaired winding can damage the compressor, or even shut it down completely because of small voltage leaks that may occur. More importantly, it can also conduct high voltage to the compressor housing and connected components, causing a harmful and potentially lethal shock to anyone coming into contact with it. Obviously, you need to have an EPA Section 609 refrigerant certification, but consider some training through MACS (macsmobileairclimate.org) or some other qualified training facility to get you and your crew up to speed.

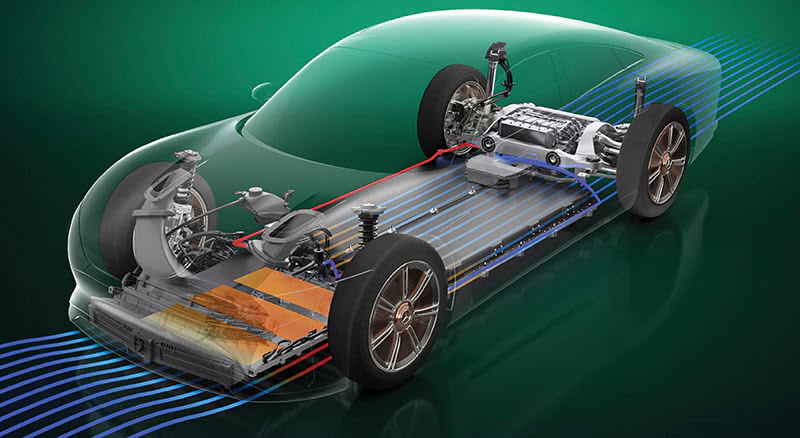

Cooling Systems

Yes, there is a need for cooling but not the same as for an ICE. The electric motor(s) and inverter/converter need to be cooled, as well as the batteries. Batteries are much more efficient at the proper temps, so they have heating and cooling as well. Liquid cooling combined with air flow is the method of choice for now, but as weight is already a big concern for EVs, Mercedes-Benz engineers are currently working on systems that can work with just air movement. Accessing the proper maintenance procedures through the MBUSA ISP Portal (startekinfo.com) and the Workshop Information System (WIS) is imperative to using correct coolant and techniques when servicing.

Regenerative Braking

Many parts of the braking system remain the same, however you need to become well-versed in the regenerative aspect of the system. Also, other systems such as ASR are harmoniously deployed to contribute to the overall proper function of the brakes.

The EV market is expected to expand exponentially in the rest of this decade. Your best business model will include an investment in tools and training for your technicians, as well as clearly written procedures and policies. Start now so that in 5 years or so you’re not left wondering what happened to all the cars in your shop.

0 Comments