If you’ve ever built an old-fashioned pushrod V8 engine for high performance, you might be familiar with a little item called an “offset cam drive key.†This is basically just a Woodruff with a step in it that indexes the sprocket to one side or the other of its slot in the nose of the camshaft, allowing you to advance or retard valve timing as you see fit to shift the power curve up or down the rpm scale. A variation on this is the offset bushing used for pin-drive‑type sprockets. Having the valves open and close earlier gives better low‑end and mid‑range output, while the opposite contributes to increased power as you near redline. But, obviously, you have to choose one or the other, and, with single-cam designs, intakes and exhausts are equally affected, which isn’t anything like optimal.

How about if you could make this dynamic with valve timing changes occurring when appropriate? Combined with separate adjustments for the intake and exhaust cams of a DOHC engine, the potential improvements in power output, efficiency, and idle smoothness become very dramatic indeed. This situation was the impetus for the introduction of VANOS (a somewhat implausible abbreviation of the German variable Nockenwellensteuerung), BMW’s name for its highly-accurate variable valve timing system. The original version, introduced in 1992 on the M50, operated on the intake camshaft only, and had just two phase-change points. This evolved into the much more sophisticated Double Vanos, which not only adjusts the timing of both the intake and exhaust cams, but does so in an infinitely variable manner.

NOTE: Valvetronic is BMW’s variable valve lift system. It uses a fast-acting (300 milliseconds for full range!) mechanism controlled by a dedicated module to dynamically alter valve lift profoundly enough to allow for the elimination of the traditional throttle and its attendant pumping losses. In many models beginning in 2001, it’s used in conjunction with VANOS for the most efficiency and power imaginable. This is a separate system that we’ll cover in a future issue of the bimmer pub.

Spiral action

The first VANOS unit, which debuted in ’92, has one helical-gear mechanism for advancing the intake cam. It only featured two phase changes, but allowed for a combination of smooth idle and improved mid-range and top-end power.

The basic mechanical principle at work here begins with a cam-drive sprocket that engages the camshaft itself through a helical or spiral gear. When engine oil pressure is applied to this mechanism (as controlled by the DME through a one-wire solenoid valve), it moves the gear axially against a spring, changing the positional relationship between the sprocket and the shaft. In other words, the cam is twisted slightly from its static position with regard to the crankshaft.

Cam timing is retarded with the engine off, at idle, and just above, which contributes to smoothness and helps get the cat hot quickly. As rpm rises, the DME applies the hydraulic pressure that pushes the gear, twisting the camshaft and providing 12.5 degrees of advance for improved response and extra efficiency. At 5,000 rpm and up, valve timing is again retarded for maximum cylinder fill. As we said, this original system is either on or off. There is no modulated control.

Double

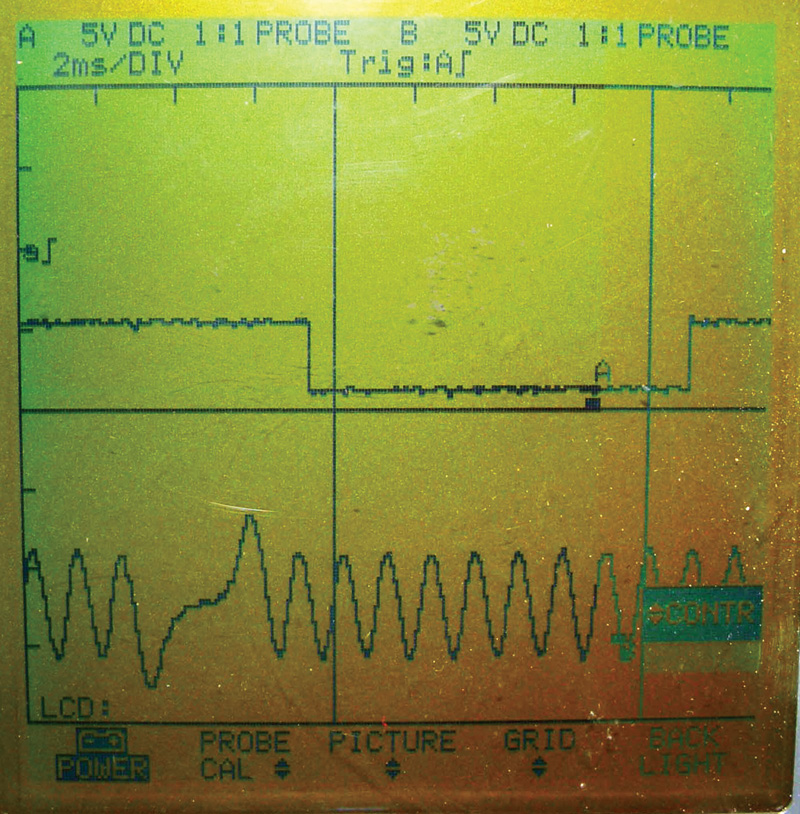

Using a dual trace oscilloscope you can monitor the crankshaft (lower trace) and camshaft (upper trace) position signals relative to one another. This is the intake cam/crank relationship on a 2000 M3. After activating the solenoid, you should see their relative positions change.

The later-model BMWs you see in your shop are equipped with Double VANOS. Here, the timing of both the intake and exhaust camshafts is continuously variable through a range of up to 40 crankshaft degrees for the intake, and 25 degrees for the exhaust. Besides the broadening of the power curve such control affords, it also allows for the “internal†EGR (Exhaust Gas Recirculation) effect that cuts pumping losses while fighting NOx.

With Double Vanos, the intake cam is still held in its retarded position and advanced with VANOS actuation, but the exhaust does exactly the opposite. It is held in the advanced position by its spring, and retarded by the application of oil pressure.

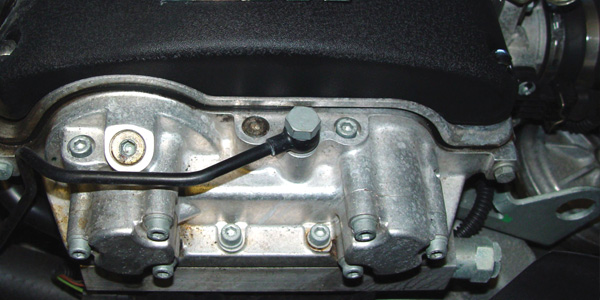

When installing the single VANOS unit, you have to make sure the gear is in its retracted position. In other words, when the gear is pushed all the way in toward the VANOS unit.

A later generation of Double VANOS operates in much the same way, but integrates the two oil control solenoids into one unit. Another change is that now there are two intake and two exhaust cam solenoids. One solenoid in each system closes to build the oil pressure needed to move the VANOS gear, and the other instantly vents the oil passages to allow the gear to return to its “home†position. In previous versions, the VANOS solenoids were continuously supplied with 12V, and the DME controlled the ground side. On systems with integrated solenoids, on the other hand, they are always grounded and the DME switches power to complete the circuit.

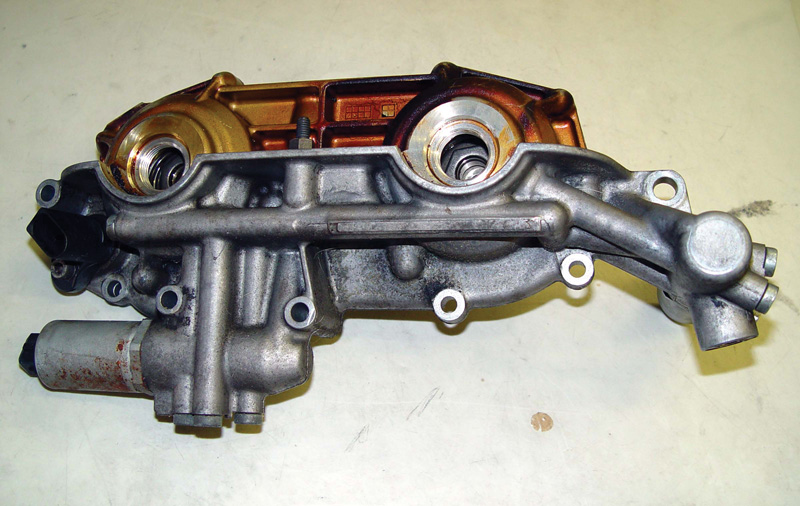

Double VANOS was the next evolutionary stage of BMW variable valve timing. This system advances the intake cam and retards the exhaust cam through a range of up to 40 crankshaft degrees for the former, and 25 degrees for the latter. It adds complexity, but enhances power output and efficiency.

As you can easily imagine, all VANOS systems require high and steady oil pressure for adjusting the camshafts quickly and accurately (any time lag may set a code). Everything from a weak pump to loose engine bearings should be taken into consideration if psi is below specs.

Scope and scan

All generations of VANOS are big contributors to the superior performance characteristics of BMW vehicles, but, just as with everything else automotive, stuff happens over time, which brings us to the art of diagnosis. Poor performance, MIL-on, and noise are typical symptoms of something gone awry in the system, and electronic troubleshooting will probably be the first thing you think of. We’ll get to pattern failings later.

When installing the variable valve timing actuators on Double VANOS, you’ll need these special tools to properly set the gear depth position. These are available through your local BMW dealer’s parts department.

To verify that the requisite cam twist has actually taken place, the DME monitors sensor inputs. BMW did not put a sensor on the cam sprocket itself and another on the camshaft. Instead, the crankshaft position sensor signal is compared to that of the camshaft position sensor. In testing VANOS, you can do much the same thing. Using a scope or graphing multi-meter, you can monitor the relative positions of these sensors. Then, you can actuate the VANOS solenoid and see if this relationship changes. As with any electrical solenoid monitoring, looking at current draw during activation is always a good idea. This can help determine if the solenoid is shorted or sticking.

You can use a scan tool to monitor VANOS activation, but it needs to have factory-specific data to give you the actual desired reading and any deviation from that to determine if the intake cam is being advanced sufficiently or not. Keep in mind that on some Siemens systems (not Bosch), a different cam sensor called a Pulse Angle Generator is used. This sensor receives a sine wave from the DME. On another wire, it receives a modified signal when the shutter wheel on the camshaft passes by the sensor. It’s difficult to scope this and watch the crank sensor at the same time.

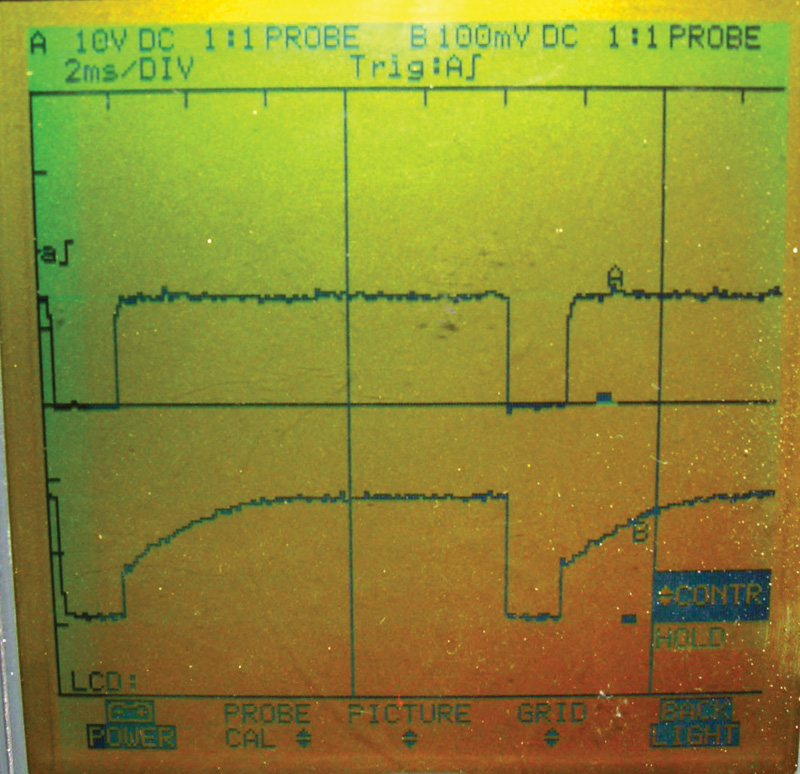

One way to analyze VANOS solenoid operation is to monitor the current pattern of an activated solenoid. Here, the intake cam advance solenoid has been activated by accelerating the engine. Notice how the voltage trace (upper) goes up to 12V during activation.

To verify that the system is operating, the DME monitors the camshaft position sensors just after a cranking event, then starts to energize the solenoids to control valve timing. You can watch the cam and crank sensors on a scope, but with Double VANOS you need to include the exhaust cam position sensor signal. Regardless of whether a Bosch or Siemens control unit is present, the cam position sensors are Hall-effect. They generate a square wave while the engine is spinning. One wire is a 12V power supply, then there’s the signal, and ground. The signal wire has a 5V reference, which gets toggled to ground to generate the square wave, but unplugged you should read 5V.

You can run the engine and watch the relationship change between either the intake cam sensor signal, or the exhaust cam sensor signal, relative to that of the crank sensor. In higher-rpm testing, you will have to speed up the timeframe on your scope. Once again, compare scan data. Look for the “actual†cam timing readings and compare them to the desired cam sensor positions, and you should be able to determine if the VANOS system is operating properly.

You can monitor factory-specific scan data. You should see three readings for each camshaft. One is the desired or target value, which is where the DME would like to place the intake and exhaust cam positions. The second is the actual reading — where the DME has determined the cams are by using the crankshaft and camshaft position sensors. The last is the minimum or reference reading the VANOS unit can have. This should help you determine the camshaft positions if the engine is difficult to start.

You can monitor the crankshaft and camshaft position sensors with a dual- trace scope. It would not be a good idea, however, to activate the solenoid manually! These solenoids have two diodes in them, so there is the danger that you could damage the unit. You can run the engine and monitor the activation of the solenoids as well as the relative positions of the cam and crank sensors to determine if VANOS is operating properly.

Patterns

The following are some patterns to keep in mind during diagnosis:

- On older models, the material used for the VANOS piston seals often wasn’t up to the job, and failed before 100K miles, resulting in poor performance. BMW recommends that the whole VANOS unit be replaced, but we’ll bet you’ll look for seal kits before you ask your customers to spend such serious money.

- You’ll sometimes encounter a rattling sound coming from the front of the valve train. This may be due to sprocket mounting bolts that have come loose, or to a worn-out bearing in the VANOS actuation unit. Either way, removing the valve cover will let you see and feel the movement.

- Varnish, coke, and sludge deposits can cause the solenoids and gear piston units to plug up and start working only intermittently. There are little oil screens inside the solenoid valves that are particularly prone to clogging. Poor performance and codes from lagging actuation, which the DME can detect, will be likely.

If sludge is indeed the problem, there’s a good chance that disassembly and a thorough cleaning of all the components involved with spray solvent will rectify the situation.

NOTE: For years, we’ve been seeing BMW owners lulled into a false sense of security where oil change intervals are concerned because they believe the huge lube capacity of these engines is insurance against problems. Well, sure, the presence of nine qts. or so of oil does help, but it can’t do miracles. Regular (and frequent) oil changes are still needed to avoid the deposits that cause problems, especially in intricate systems such as VANOS.

Work rules

With a paid subscription to www.bmwtechinfo.com, you can access detailed service information such as R&R of the Double VANOS unit pictured here. It’s only $30 for the day, $250 a month, or $2,500 for a year. Some shops add the daily charge to the customer’s bill.

There are some important caveats in direct VANOS service, or any other work that involves the disassembly of the system (such as cylinder head R&R) that don’t seem to be widely-understood among technicians.

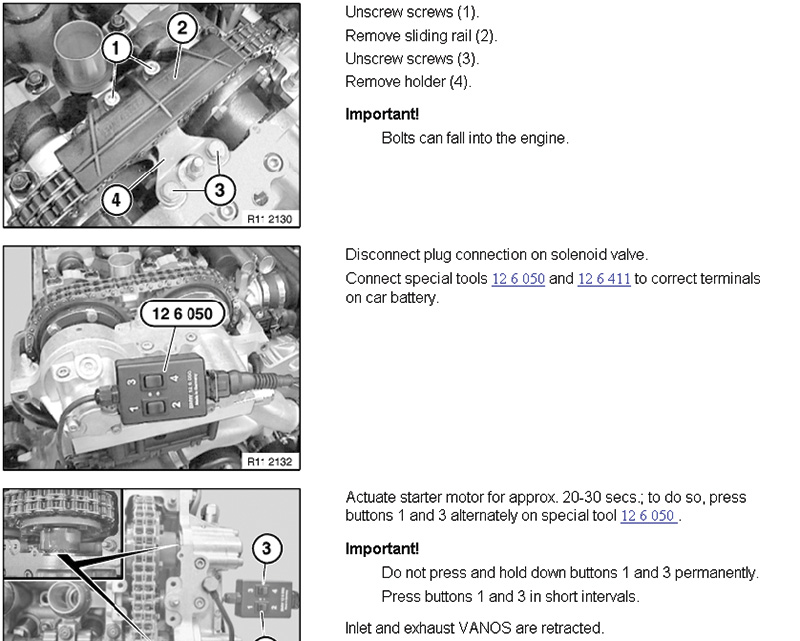

Whenever the VANOS unit must be removed, verify that the camshaft drive gear is in the retarded position before installing the timing chain. Just because you have the cams locked down in the rear does not mean that the intake cam gear is in the retarded position. As mentioned earlier, the gear is spring-loaded, but the mechanism can stick in the advanced position. Once the chain is on, the VANOS unit should be installed with the helical gear pushed in toward the VANOS unit, away from the cam gear. As oil pressure is applied, it pushes the piston outwards toward the intake cam gear. This action causes the cam timing to advance. Make sure the piston is pushed all the way in when installing the VANOS unit.

You should be aware that after engine shut-down, VANOS positions the camshafts for better engine starting, so the cams may not be in their service or default positions. To get the gears into their service positions you need to activate the solenoids for the intake and exhaust cams. Compressed air, along with activating the solenoids, will force the oil out of the pistons and position them where they need to be.

The exact procedure for servicing VANOS must be followed. Compressed air must be added to the VANOS unit to remove any residual oil and move the actuating pistons to their service positions. With the air line connected, rotate the engine twice. This will allow VANOS to return to its default position. Do not turn the engine backwards! The chain tensioner piston may be forced all the way in and this would allow enough slack for the chain to jump a tooth. The next step is to lock down the crank and camshafts and remove the variable valve timing unit. More detailed service procedures are available on the BMW service information website.

0 Comments