These suggestions and solutions for technical problems come from service bulletins and other technical information published by Mercedes-Benz, selected and rewritten for independent repair shops.

Sparked, Unsparked and Clanked All Models with Engines 102 or 103

There’s not much you hear in a car more alarming than a knocking metallic sound coming from the engine compartment. Sometimes, happily, the cause is not mechanical within the engine but something else. Check with your stethoscope and pay attention to the high voltages, but one more thing to check is the ignition coil itself. If the iron core in a coil comes loose internally, the electromagnetic pulses in the windings can bang the core to and fro rapidly, causing this suspicious noise. Coils known to have this problem have production codes between FD 845 and 847. There could be others.

There’s not much you hear in a car more alarming than a knocking metallic sound coming from the engine compartment. Sometimes, happily, the cause is not mechanical within the engine but something else. Check with your stethoscope and pay attention to the high voltages, but one more thing to check is the ignition coil itself. If the iron core in a coil comes loose internally, the electromagnetic pulses in the windings can bang the core to and fro rapidly, causing this suspicious noise. Coils known to have this problem have production codes between FD 845 and 847. There could be others.

Crankshaft Position Sensors

If the crankshaft position sensor doesn’t work, the engine won’t start. If it fails while the engine is running, it stops immediately. A loss of crankshaft position signal, however, does not mean a failure of the crankshaft sensor. There could be other sorts of problems.

If the crankshaft position sensor doesn’t work, the engine won’t start. If it fails while the engine is running, it stops immediately. A loss of crankshaft position signal, however, does not mean a failure of the crankshaft sensor. There could be other sorts of problems.

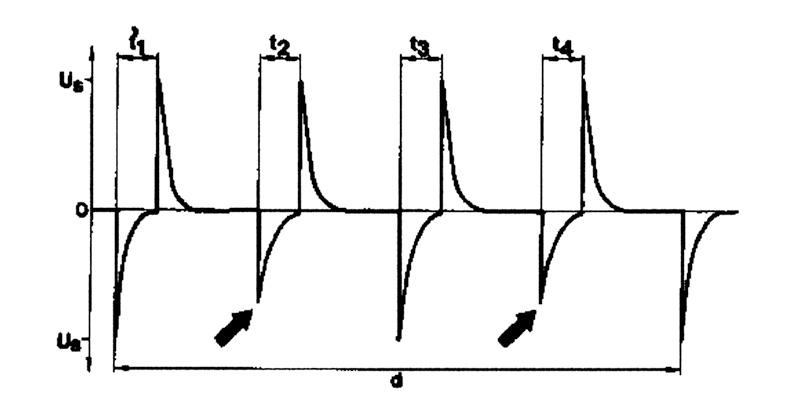

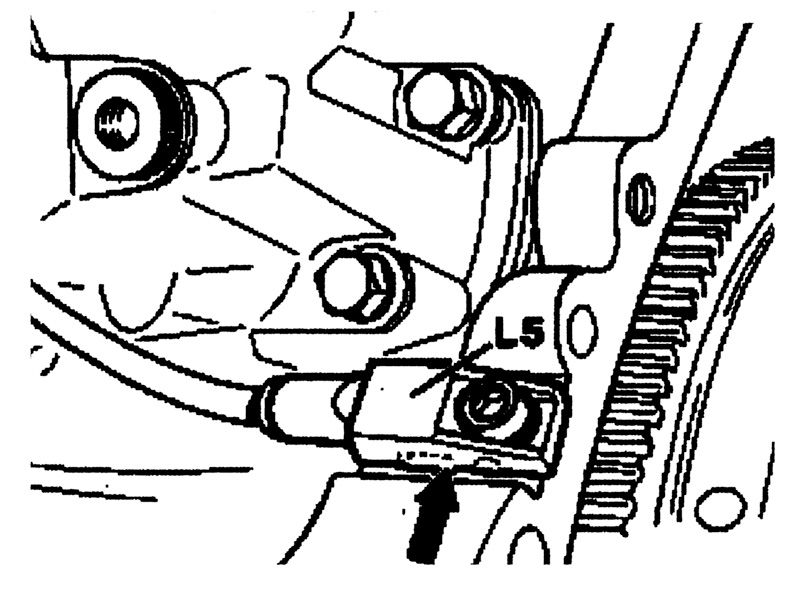

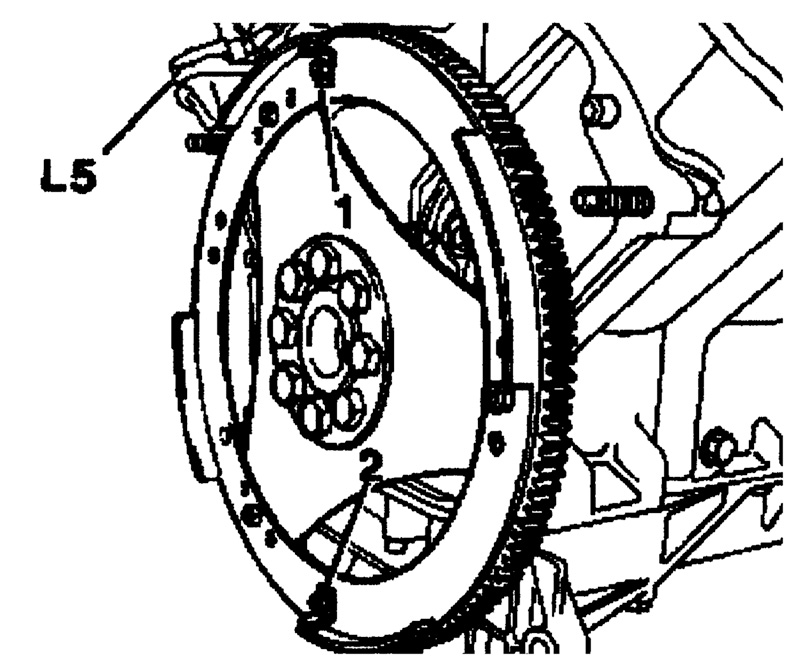

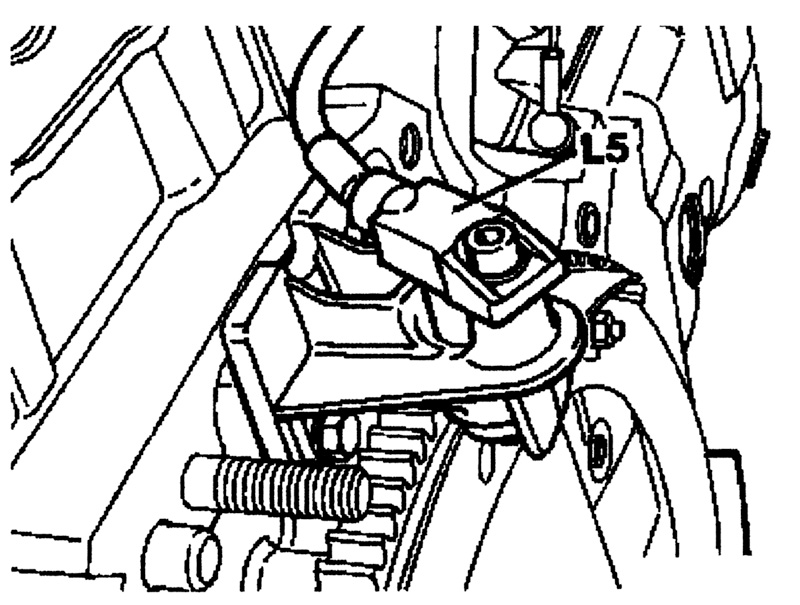

If you find an alternating current signal, but there is still a starting or running problem, check the signal not only with a voltmeter but with an oscilloscope. Some sensors should have pulses of sequentially variable amplitude when the flywheel includes segments and magnets. On cars where the sensor follows the flywheel teeth directly, the signal should be even.

When replacing the sensor, make sure it does not contact any part of the flywheel, but also measure to confirm that it is close enough to the teeth to generate the signal (check the specifications for the car to confirm the minimum alternating voltage

|

|

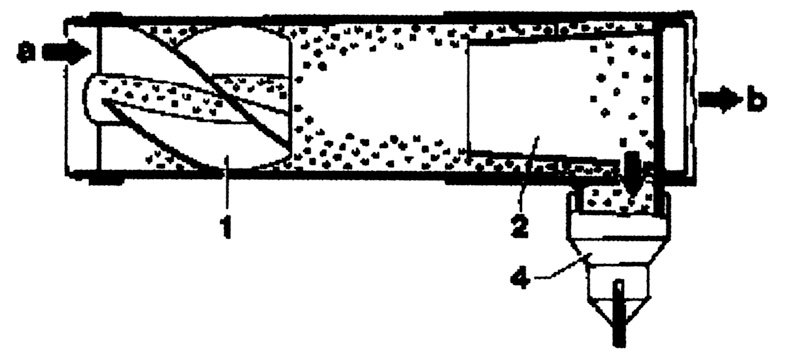

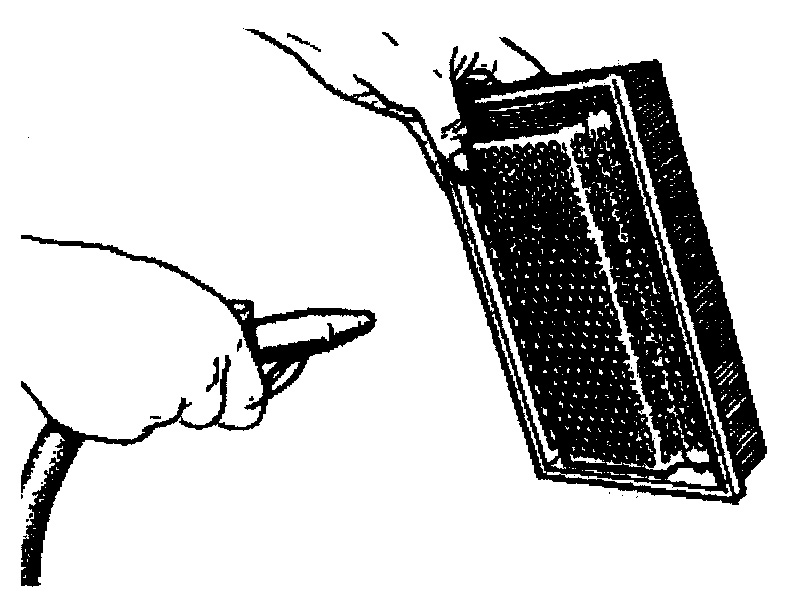

Cleaning the Cleaners

You don’t have to replace every filter anytime you discover dust on it. Certain air filters, like the cyclonic version or the steel-mesh backed flat filter, allow removal of large amounts of dirt by compressed air. In areas with very large amounts of airborne dust, it is frequently good practice to clean out the filter housing and the surface of the filter itself periodically before you replace the filter element itself. Many air filters actually become more effective with use, as particles fill the larger micropassages. Eventually, of course, all filters will present enough obstruction to airflow to impede the engine’s breathing, and then it is time to replace them.

|

|

0 Comments