Whether for vehicles long out of production or for modern ones, your best source for Genuine Mercedes-Benz Parts is Mercedes-Benz.

A come-back! The very thing you do everything in your considerable power to avoid. Yet, it’s happened, and in the area of brakes, no less. A recurrence of a pedal-pulsation problem is embarrassing and damaging to your reputation, especially since the ticket for the work you did on the original visit was pretty substantial. That previously loyal customer isn’t all that happy with you.

A come-back! The very thing you do everything in your considerable power to avoid. Yet, it’s happened, and in the area of brakes, no less. A recurrence of a pedal-pulsation problem is embarrassing and damaging to your reputation, especially since the ticket for the work you did on the original visit was pretty substantial. That previously loyal customer isn’t all that happy with you.

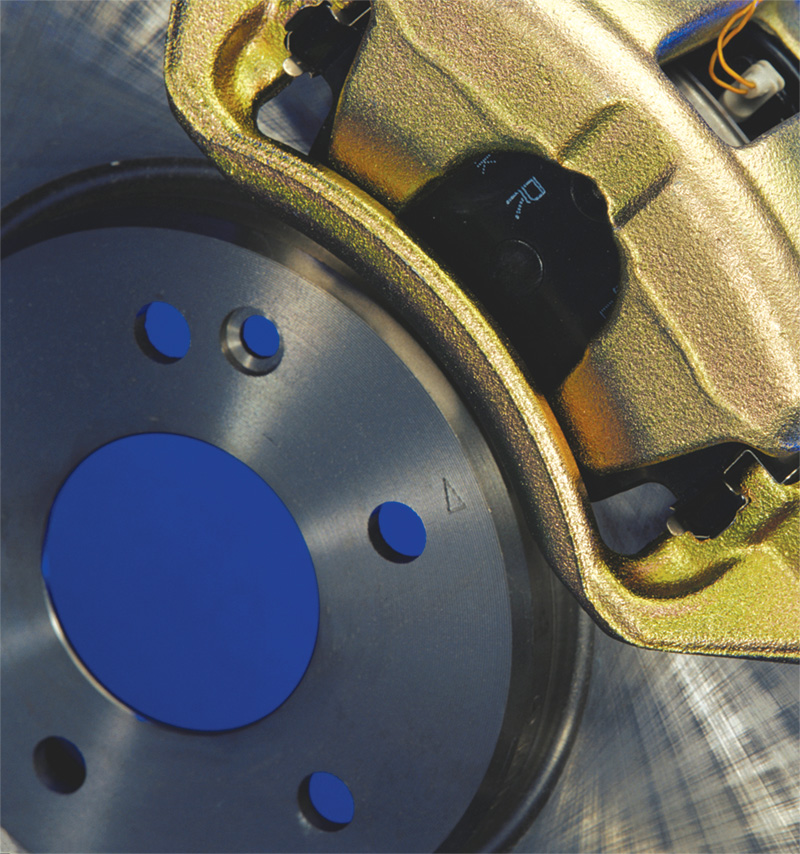

You remember doing the job. The well-kept Mercedes-Benz had covered a substantial number of miles in its few short years of life, and had developed the bumpy brake feel that’s indicative of disc thickness variation (also called non-parallelism). The underlying cause of this condition is rotor runout and warpage, which causes certain spots on the disc to contact the friction material every revolution, so they wear more than the other areas.

You’re well aware of this cause-and-effect situation, so you studiously avoid doing anything that could possibly contribute to rotor runout on every single brake job. You mark the location of discs that are going to be reinstalled, and carefully clean all the rust off the hub mounting surface. You also use a torque wrench and the proper star pattern to tighten the lugs, never your impact gun. Finally, you always take the time to give the new brakes an initial break-in with at least half a dozen gentle stops.

So, what went wrong in this unfortunate case? As you recall, the original rotors were worn pretty thin. In fact, you could see they’d need to be replaced as soon as you pulled the wheels, which you confirmed with your mic. You’ve recognized that the installation of new rotors during reline is becoming a trend — some of your colleagues say that their brake lathes are gathering dust.

You called your regular parts jobber, and he sent over brand-name aftermarket rotors at a good price. They looked fine, and after you’d applied your craftsman-like procedure to the brake job, you were confident in the results. In fact, the car was stopping smoothly when you sent it out the door. Back again in a matter of months, though.

You’re mystified. That is, until you mention the situation to a friend, another shop owner who specializes in upscale European makes. He was thrilled to be able to enlighten you. It seems that he’d been having the same kind of problems, so he did a little research. He got brand-new Genuine Mercedes-Benz O.E. rotors and aftermarket “equivalents,” and weighed them. Lo and behold, the aftermarket parts generally weighed a pound or two less than the real thing. Without that extra meat, they’re more prone to warpage.

So, you saved the customer a few dollars, but you ended up with a come-back, stress and some loss of sleep. Wasn’t worth it, was it?

0 Comments