These suggestions and solutions for technical problems come from service bulletins and other technical information published by Mercedes-Benz, selected and rewritten for independent repair shops.

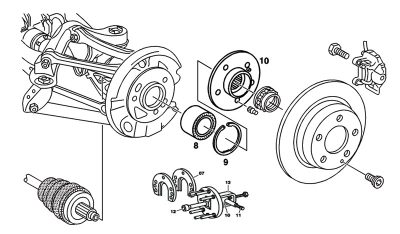

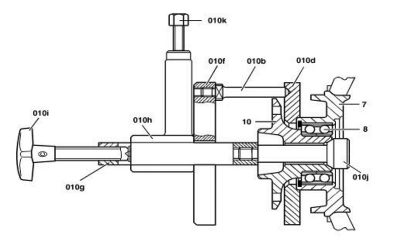

Removal of Rear Axle Halfshaft Flange with Double-Row Tapered Roller Bearings and Modification of Special Tool

Models 300TE, 300TE 4 Matic, 300TDT and E320 Wagon

These bearings can only be pressed out of the rear halfshaft flange with the wheel carrier removed from the vehicle first, and then by the use of a stationary hydraulic press to remove the double row tapered roller bearing itself.

These double row tapered roller bearings require extractor force three times that of the force required to pull the double row tapered ball bearings used on other models. The puller special tool number 202 589 04 43 00 is not designed to handle such forces.

The special tool puller should be modified with a shear pin, which is installed at the pressure screw of the hydraulic press. The pin will shear at a force of 40Nm, thus preventing any further pressure build-up at the hydraulic press, making the application (except on Model 124.090/092/193/290) of this tool safer on all vehicles. The modified pressure screw is available with the shear pin as a spare part under the following special tool part number: 202 589 04 43 11.

Note: Prior to removing the double row tapered ball bearing from the installed wheel carrier, review the following document in WIS: AR35.20-P-0130B.

Synthetic Oil Recommended with FSS

All models equipped with the Flexible Service System

In case you haven’t heard, Mercedes-Benz USA has changed the engine lubricant recommendation for all FSS-equipped vehicles (1998 and up): Use only MB-approved synthetic motor oil. Approved synthetic engine oils are listed in the MBUSA oil specification sheet 229.3 or 229.5 which also meet API SL/SM classifications. Oil specification sheets 229.3 and 229.5 for worldwide use can be found on the Workshop Information System (WIS).

MBUSA requests that all service facilities institute this transition from standard mineral oil to approved synthetic oil equipped with FSS technology.

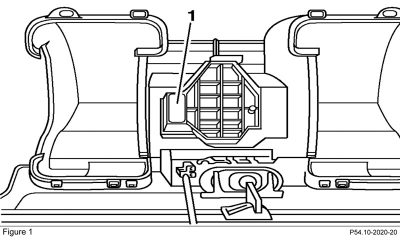

Replacement of Model 129 Automatic Climate Control Blower Motor, 1996 and Up Production

Effective with March, 1996 production, the overall dimensions of the blower motor have been changed. The overall length of the new blower has been shortened, so if the

newer blower motor is installed it will shift due to not being seated. That is, unless an adapter around in the blower housing is used.

The adapter piece is supplied with the new blower motor, and must be inserted as shown for the new blower motor to properly seat in the blower housing.

Note: The blower motor used prior to 3/96 production is approximately 12.5 mm longer than the newer blower motor. The longer unit can be used in vehicles made after that date if the end stop is removed using a suitable tool.

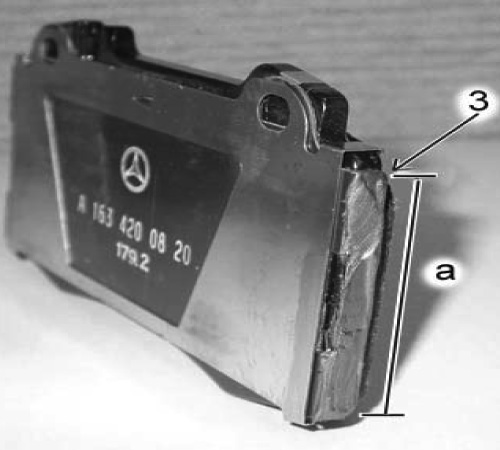

Front Brake Squeal

Models ML430, ML500 and ML55 AMG

Although squealing brakes are not the problem they once were, the condition still shows up from time to time. It may be aggravated by cool, damp weather in combination with light braking effort. Besides switching to improved friction material, it’s been found that the judicious application of brake paste to the ends of the pad backing plates as shown can reduce the noise. If you receive customer reports in the above model vehicles of brake squeal emanating from the front of the vehicle, please order the improved brake pads available from your local M-B dealer’s parts department, and perform the following procedure:

- Remove the existing brake pads. Reference WIS document AR42.10-P-0161GI.

- Apply brake pad paste to the ends of the replacement brake pads’ backing plates as shown. Reference WIS document AR42.10-P-0161-01GH

Note: Do not allow any paste to contact brake pad friction surface or apply paste to any other areas besides those specified. Immediately remove any excess paste that contacts pad front or back surfaces. - Install the improved brake pads. Reference WIS document AR42.10-P-0161GI.

Parts Information

| Qty. | Part Name | Part Number |

| 1 | Brake Pad Paste | A001 989 87 51 |

| 1 | Brake Pad, Front | A163 420 10 20 |

Automatic Switching Off and On Of Electrical Consumers

All Model 211, E Class Vehicles

If you encounter the message, “Malfunction: Electrical Loads Switched Off†in white in the instrument cluster multi-function display on a Model 211 vehicle, this may be normal. Messages that appear in white inform the driver that loads not influencing driving safety have been switched off until the electrical system voltage has stabilized.

If battery voltage is too low, the heated seats and/or rear window defroster may switch off automatically. This is normal operation of those features and is indicated by flashing of the indicator lamps in the corresponding switches.

0 Comments