If it hasn’t happened yet, it soon will. A vehicle with a continuously variable transmission (CVT) will drive into your shop needing service. You’ll be faced with a choice: You can tell the customer that you can’t service his “beltbox†and wave goodbye to him, his car, any other vehicles in his family — and perhaps to any future business he may have provided. Or, you can be prepared to inspect, diagnose and repair his vehicle, make a profit, satisfy a customer — and add another patron to your business base. It’s all up to you.

CVTs are not going away. They’ve been growing in numbers over the last five years and are likely to grow by leaps and bounds for at least the next decade or two. Industry experts predict that over 50,000 vehicles with CVTs will be sold in the U.S. this year. That’s likely to continue to increase for the foreseeable future.

A New Concept? Not Really!

Although the idea of continuously variable transmissions may be relatively new to the American automotive scene, the concept is over 500 years old. Leonardo Da Vinci sketched drawings of a stepless power transmission device in 1490.

A U.S. Patent was issued to inventor Adiel Y. Dodge (no relation to the Dodge brothers) of South Bend, Indiana, on July 4, 1939 for his “Variable Speed Transmission.†The intricate device employed two disc rollers within two opposed shells to transfer power from an input shell to the counterpart output shell. Dodge had applied for the patent four years earlier, in 1935. By the time the patent was approved, others in the automobile industry were well on their way to perfecting the gear-based automatic transmission and Dodge’s complicated device never saw production.

In 1958, Netherlands-based Van Doorne brought out the first viable automotive CVT (called Variomatic) in the tiny DAF Daffodil. About a million were sold in Western Europe and the UK, but it never cracked the U.S. market.

The DAF Daffodil was powered by what looked like half a Beetle motor, an aircooled 600 cc flat two of 30 hp. Even that was was more than the fabric/rubber belts of the time could handle.

The drive system consisted of a differential/ transmission with two sets of conical plates (often called “split sheavesâ€) that were actuated to change the working diameter, hence the output ratio to the drive axle. The DAF’s rubber-based drive belts were exposed to the elements and lacked durability. DAF owners quickly learned to keep a couple of spare belts in the boot (trunk to you). Van Doorne’s business and patents were later sold to Volvo and were used in the popular European Volvo 300 Series until 1991.

It wasn’t until 1989, when Subaru introduced the Justy GL, that CVTs were taken seriously on this side of the Atlantic. The Justy was a low-cost, entry-level hatchback with few amenities and frills. By 1994, the Justy was only available with a 5-speed manual gearbox. As with many other small, inexpensive Asian and European cars, the competition from the likes of Honda and Toyota eventually spelled the end for the Justy, and Subaru began to focus on its newer upscale vehicles.

The 1989-1993 Subaru Justy was the first mass produced vehicle with a CVT to be sold in the U.S. (courtesy Subaru).

Honda launched the CVT-driven Civic HX Coupe in 1996 and kept it in the line until 2005. It sold well in California, but not as well elsewhere. In 2002, Saturn debuted the Vue with an electronically-controlled continuously variable transmission made in Hungary under a GM joint operation with FIAT. It was also used in the 2003-2004 Ion Quad Coupe, but was phased out in 2005 and replaced by a 4-speed automatic. Also in 2002, Audi began importing its 3.0L A4 model with a unique chain-driven CVT for FWD versions. In the last few years, CVTs have been popping up in many Asian and domestic models.

Toyota and Lexus hybrid vehicles use a type of transmission, called E-CVT, as part of the company’s Hybrid Synergy Drive (HSD) system. It’s not a belt-driven CVT, but utilizes a planetary gear system. It can most accurately be described as a “torque blending device.†The Ford Escape and Mercury Mariner Hybrids also use this technology, licensed from Toyota. For the sake of avoiding confusion, those transmissions will not be detailed here.

CVT Operation

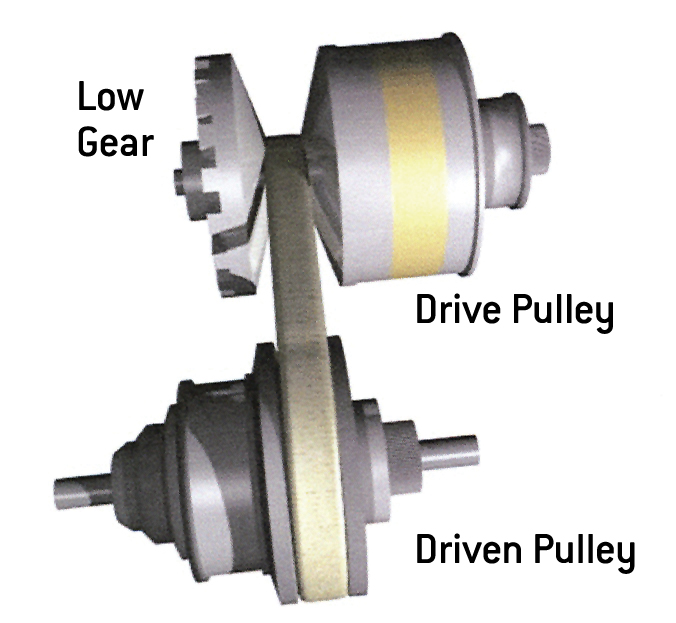

The power transfer ratio is achieved by moving the discs in each pulley closer or farther apart. Low gear is accomplished by moving the drive pulley discs apart and the driven pulley discs closer together.

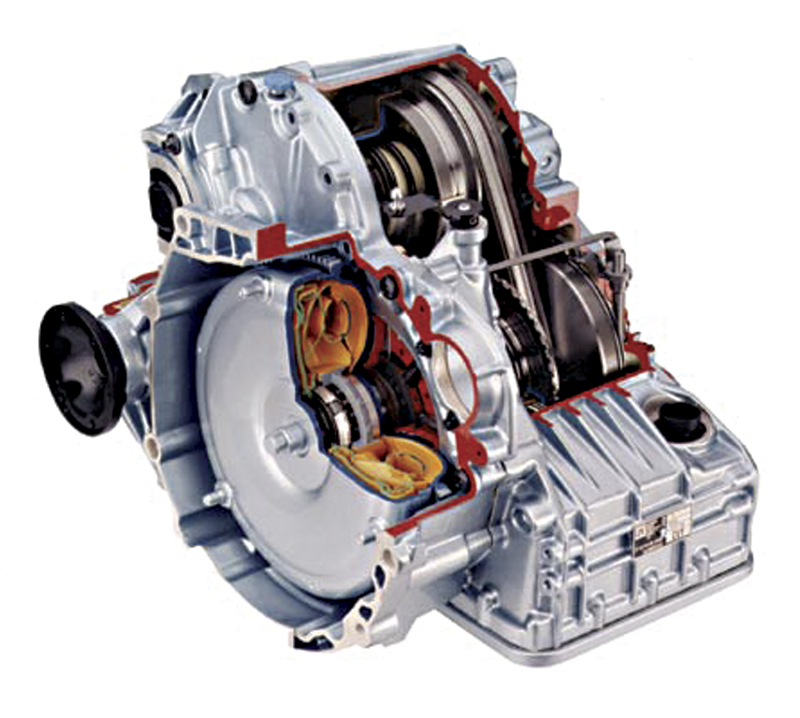

There are different styles of CVTs used on everything from lawnmowers to huge mining machinery, but the type we see in automobiles operates on the “two pulley†principle.

Each pulley consists of two conical discs, facing each other, mounted on a single shaft. A transmission control unit, or TCU, responds to sensor and other input to decide how to control the actuator system, which moves the discs closer together or farther away from each other.

There are two pulleys, one being the input or drive pulley (powered by the engine), the other being the output or driven pulley. The torque transfer belt rides in the V-notch of both pulleys.

If the drive pulley discs move apart, the belt drops lower in the notch, which reduces the working diameter and creates a lower ratio for more torque. Also, the higher the belt rides in the driven pulley, the lower the ratio. If the input discs are forced together, the belt rides higher in the notch, creating a faster speed. Likewise, the lower the belt rides in the output disc, the faster the speed. To help understand this operation, think of the gearing on a 10-speed bicycle.

The two pulleys are in a constant state of changing from one ratio to another, actuated by the vehicle’s needs. As one pulley narrows, the other widens, changing the ratio — thus the name: continuously variable transmission.

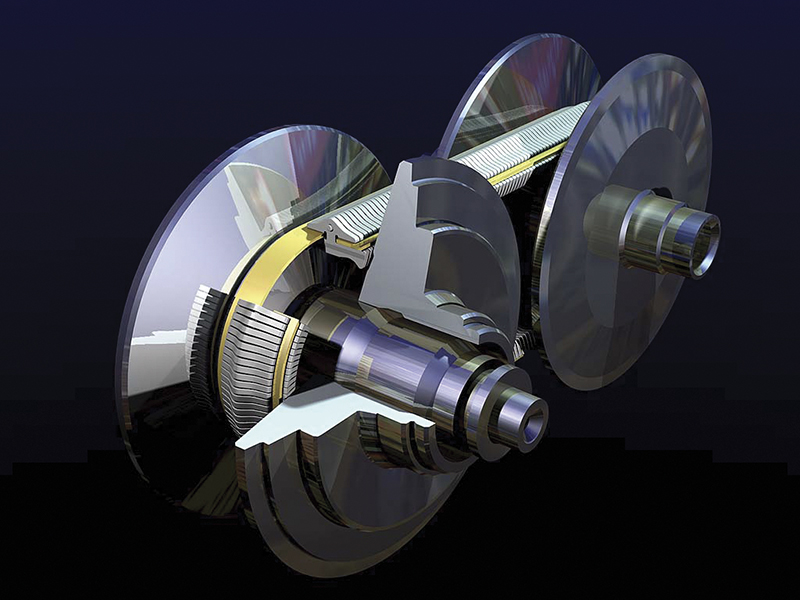

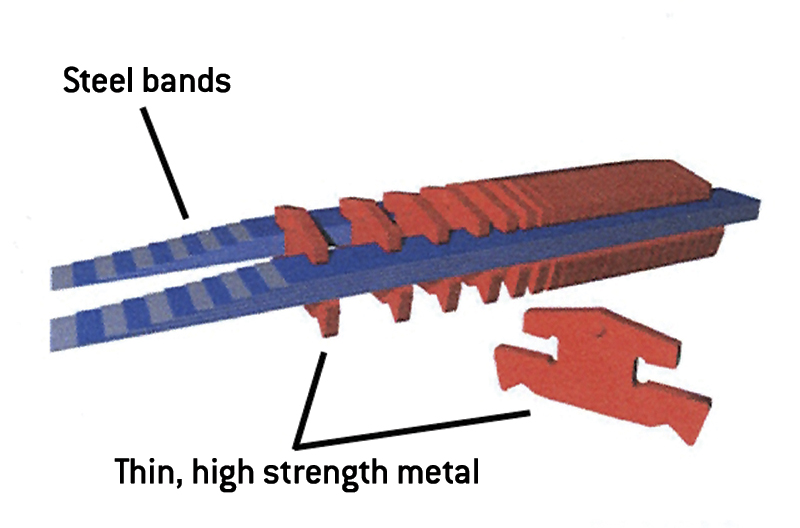

The belt that transfers the power is amazing. It’s made up of hundreds of tiny metal plates, held together by high-strength steel bands. The key to its strength and durability is that it pushes, rather than pulls, unlike rubber-based automotive drive belts. Some CVTs, however, use a fortified link-chain belt.

Early versions of the CVT suffered from belt failure. The lack of strength and durability limited the torque that CVTs could handle. Today, thanks to improved technology and metallurgy, they can be found on vehicles up to 3.5L and upward of 250 hp.

The belt is the heart of the CVT. It transfers smooth, fluid power from the drive pulley to the driven pulley (courtesy Nissan).

Electronic logic keeps the transmission operating at optimum efficiency. Whether the vehicle needs speed for passing, or power for climbing a hill, the CVT delivers the correct ratio smoothly. In fact, some manufacturers have built in artificial “shift points†to comfort drivers who expect the feel of shifting. Some units even offer simulated manual shifting.

Driving a vehicle with a CVT takes a little getting used to. Most units on the road today still experience a little of what engineers call the “rubber band effect.†When the accelerator is pressed hard, the engine revs climb quickly, but the vehicle speed lags a bit behind and catches up more slowly than you might expect. It feels a lot like a slipping clutch. CVT manufacturers promise this will be lessened or eliminated in the

next generation.

The Good, the Bad and the Ugly

When asked about the advantages of CVTs, manufacturers list:

- Better fuel economy. The engine revs stay fairly constant and it therefore operates more efficiently.

- Lower exhaust emissions, for basically the same reasons as above.

- Simplicity. Since CVTs have fewer moving parts than automatic transmissions, they are theoretically cheaper and easier to build and repair.

On the other hand, critics of CVTs also offer some things to consider:

- Currently, CVTs are more expensive to build than they should be. The use of many patented parts drives the cost up. Also, the sophisticated metallurgy and extremely tight tolerances require top-notch machinery and highly skilled labor.

- Durability is still a factor. The heart of the unit is the belt (or chain) and the discs. Past units have not shown the durability of conventional automatic transmissions.

- Conventional automatic transmissions are rapidly improving. The newest 6- and 7-speed autoboxes nearly match the efficiency and economy of CVTs.

In all fairness, the latest CVTs have shown vast improvement in these areas and are expected to last much longer than the units currently on the road.

CVT Manufacturers

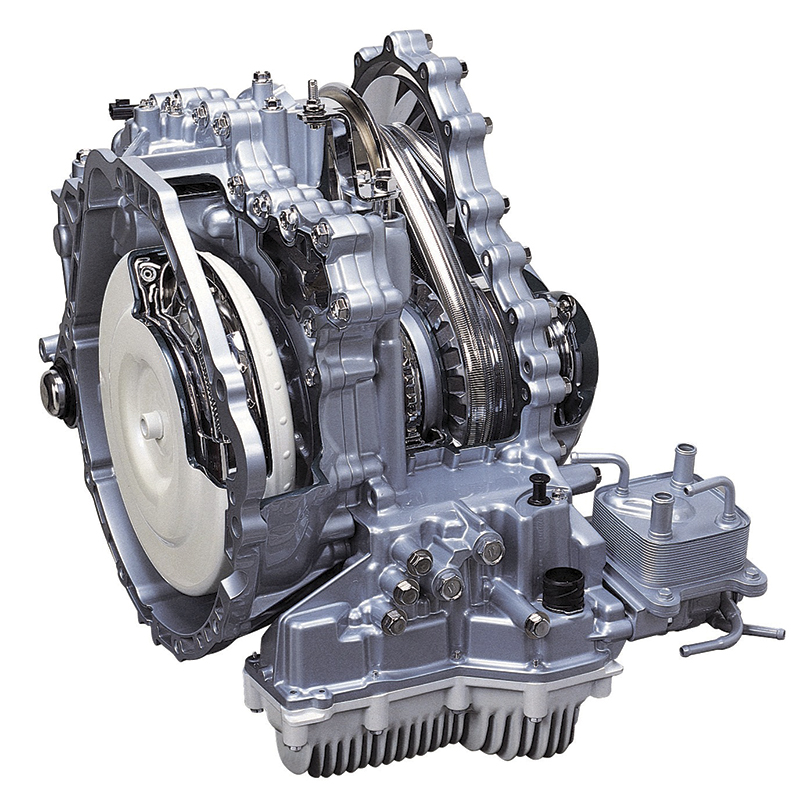

Many of Jatco’s newer CVTs include a torque converter to help avoid creeping (courtesy Jatco USA).

ZF manufactures CVTs for the Ford Five Hundred, Freestyle and Mercury Montego AWD vehicles (courtesy ZF North America).

Some automakers with foundry capabilities make their own CVTs, but mainly a few primary manufacturers supply the majority of such transmissions to the industry worldwide. Here are the majors:

- Jatco is the largest global supplier of CVTs. Once part of Nissan, Jatco was spun off as a separate company in 1999 during Nissan’s financial restructuring. Because of the relationship, Nissan is Jatco’s largest customer and the largest user of CVTs. Most of Jatco’s units also incorporate a torque converter.

- ZF, the high tech German transmission maker, markets its CVT under the Ecotronic name. The chain-driven unit used by Ford is manufactured by ZF.

Service Training & Information

Unfortunately, there doesn’t seem to be any aftermarket training for CVT repair at this time, but that may change as the popularity of this transmission increases.

The best current sources for CVT diagnostics, repair and parts information are the technical information websites of the vehicle manufacturers. Each, of course, requires a fee for use. These websites may be accessed through the National Automotive Service Task Force (NASTF) website at www.nastf.org, or individually as listed below:

Vehicle Manufacturer Technical Information Websites:

Audi: www.ebahn.com/audi

DaimlerChrysler: www.techauthority.com

General Motors: www.gmtechinfo.com

Honda: www.ServiceExpress.Honda.com

MINI: www.minitechinfo.com

Nissan: https://www.nissan-techinfo.com/

Popular Models with CVTs Domestic2002- 2004 Saturn Vue European2002-2007 Audi A4 & A6 Asian1996-2007 Honda Models U.S. Vehicles with CVTs

|

0 Comments