The price of the extremely high level of technology built into late-model Mercedes-Benz vehicles is increased complexity. Today, you absolutely must know how to read wiring diagrams.

Mercedes-Benz offers the most technologically-advanced vehicles in the world, particularly in the arena of electronics. But technology does not come without a price in the form of complexity. So, you need to know how to read the “electrical road map.†In the old days life was pretty simple. Any time we had an electrical problem to deal with, we could look at a simple wiring diagram. We turned on the ignition to power up the circuits, then we turned on a switch that would either provide a power or ground path to the component we wanted to test. If anything did not work properly, we would check voltage supply, switches and ground paths.

In contrast, what happens today now that we have multiple processors linked together in a CAN network, “resistive multiplexing†and pulse-width modulated outputs? Well, power and ground are still key tests to perform in any electrical diagnosis, but now testing is much more complicated. Systems have become more integrated and therefore trickier to diagnose. Simple on-and-off voltage supplies are still used, but new analog and digital controls have been added to more precisely provide input position and control outputs. With all this computer control added to today’s vehicles, we must put down our trusty test light and learn to monitor analog voltage and amperage signals using DMMs, and time-based signals using oscilloscopes. But how will we know what wires to check and where? A wiring diagram is still a critical element to any diagnostic plan.

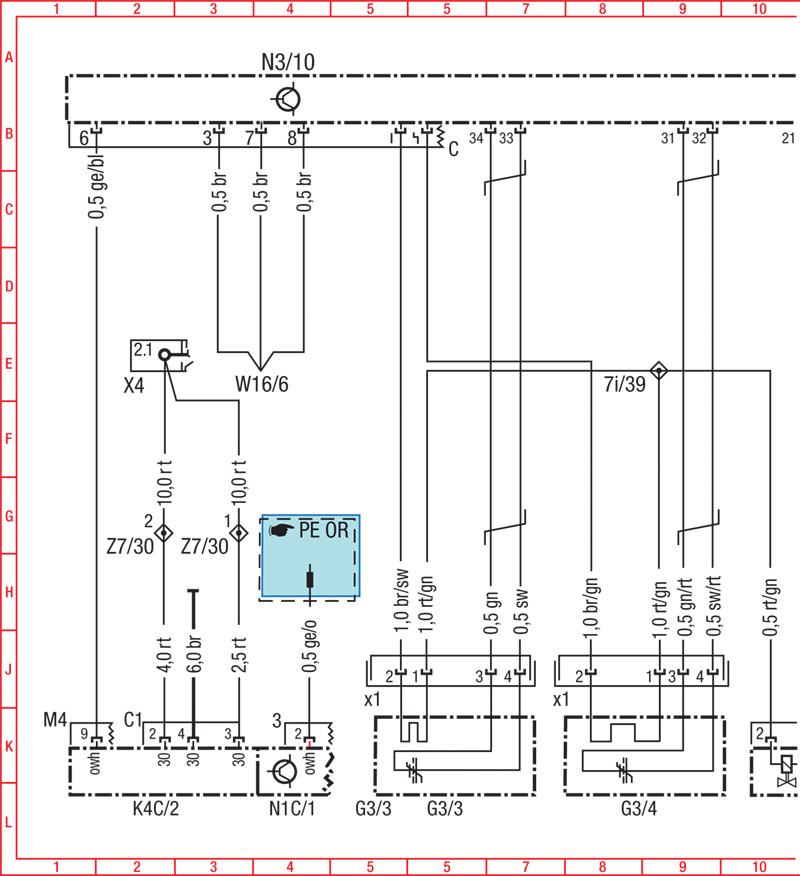

See the three components in this portion of the diagram? Notice that L5 has a coil inside of it and it matches the symbol of an AC

pulse-generator/crank sensor. Component B6/1 has three wires going to it, but look inside the component and you will see a + sign,

a – sign and a box symbol.

These three symbols indicate a power, a ground, and

a square-wave signal,

respectively. This tells us that the cam sensor (B6/1) is a Hall-Effect type that should be tested using a scope.

Brave New World

Since the early 1990s, Mercedes-Benz has advanced the electronics in its vehicles at an ever-increasing rate. Computer control of engine systems has spread to body controls such as windshield wipers, window motors, power seats, etc. Why all this technology on otherwise fairly simple systems? Adding computer power allows for such advancements as memory power seats, window limit, scan-based diagnostics, and CAN (Controller Area Network) data sharing. When one of these systems needs to be diagnosed for a fault, a scan tool may now be used to access that computer, see if the computer has done any testing and has come up with a fault expressed as a code. On later systems, we can monitor data on the various inputs and outputs. This gives us a tremendous time-saving advantage over checking all the inputs and outputs manually.

At this point, you may want to gamble and just replace the part that the code refers to, but all experienced technicians have found that this does not necessarily repair the problem. At some stage of the diagnostic process, you should actually go to the component in question and check the power, input/output signal and ground. An input/output signal showing no change in the data stream of your scan tool indicates that there is a problem. If this component has no ground path due to a broken wire, corrosion, etc., it cannot change the input/output signal. In this case, you may mistakenly replace a few components before admitting that you must look deeper into the problem.

Locating the component and performing electrical tests is the best way to determine what failed. Finding the component is one step in the process. As an example, suppose the component in question has three wires. Is it a shielded AC pulse generator or a Hall-Effect switch? Knowing which part you are dealing with is required to determine how to test it. You have to set your meter to AC or DC, switch to the proper scale if there is no auto-range function, and, finally, determine if it is a time-based signal, which may require the use of a scope instead.

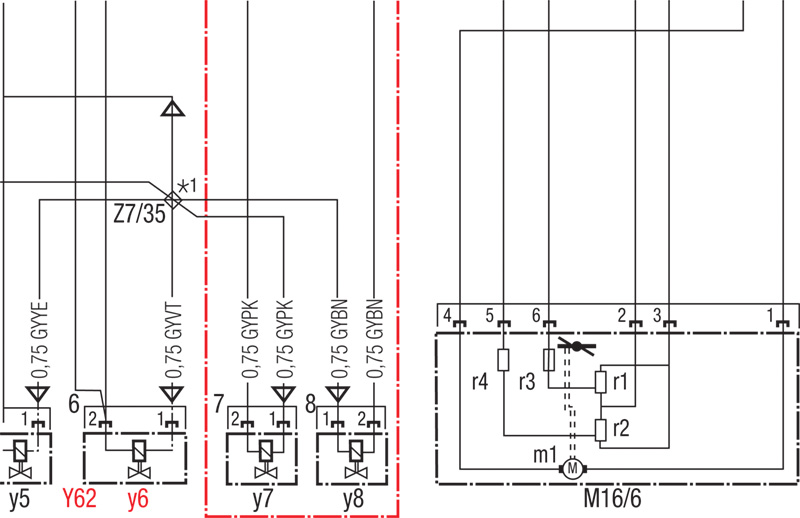

Notice the uppercase Y62 and the lowercase y6. If you look for y6 in the component location list you will not find it.

If you looked for Y62/y6 instead, it would be

identified as the number 6 ignition coil. Also notice the dotted line around y7 and y8. This indicates that these components are only there on V8 models.

Once again, evaluating a wiring diagram will allow you to come up with the proper diagnostic plan. By looking at the diagram, you should be able to tell what kind of component you are dealing with — is it an input signal or an output control? The next thing you need to take from the diagram is what wire colors you should be looking for. Finally, you should follow the path of the wiring to other components that may end up being part of the diagnostic process.

Look at the “Electrical Road Mapâ€

A wiring diagram is like an electrical road map. One will be provided for every electrical system on the car. In the old days, the vehicle’s entire electrical system could be put on a single page. Now, we have multiple page fold-outs for each individual system in the vehicle! On a positive note, when you pull up a diagram, you will only view the wires pertaining to the system you are investigating. You will also be informed when a wire goes off the page and what wiring diagram to look for to see where it continues.

Mercedes-Benz has a component identification legend to go along with every wiring diagram. Each component, connector, splice and ground is given an alpha-numeric designation. Grounds will start off with the designation “Wâ€, so “W9†represents a ground. You can look in a ground location index to see where “W9†is located. You may see “W9†in more than one diagram indicating that more than one component uses this ground.

In wiring diagrams, two perpendicular lines often represent a ground, not the three lines of decreasing length you may be accustomed to. Splices are represented by the letter “Z,†and connectors by the letter “X.†In the case of a splice, you will see a wire passing through a diamond with a designation such as “Z3â€. If you were to look in another section of the diagram and see the same “Z3†designation, you would know that these wires are spliced together. The same goes for an “X†designation. If you see two wires going through the “X7†connector, for example, you would know they are in the same connector. The number in the box refers to the particular pin in the connector that the wire goes to. More on tracing wiring will come later.

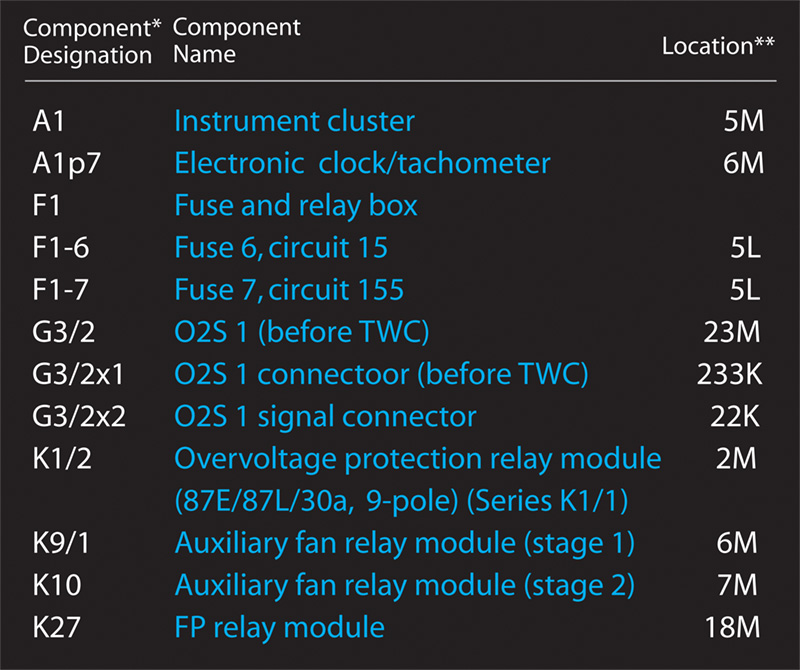

Here is the wiring diagram legend. On the left, you see the component ID designation, followed by a small description, and finally on the right the coordinates indicating where to find it on the diagram.

All locations can be looked up the same way. Refer to the splice or ground location index and look for a letter/number combination, and you will be given either a written description or a photograph. Components are done much the same way, but since they are so numerous they cannot all use the same letter. The entire alphabet is used to name types of components. For instance, “K” indicates it is some sort of relay, “N” represents control units, and “S” is for switches. Further, “A” is for sub-assemblies such as the instrument cluster, and “B” is for sensors, “F” indicates fuse boxes, “M” stands for motors, and “Y” almost always represents solenoids. Remember, these designations always start with a capital letter, not lower case.

After looking at the capital letter/number symbol you may also see a lower case letter/number symbol. These tell us that there is more than one component incorporated into the main component. For example, on a 2000 Mercedes-Benz 320 sedan with the 112.941 engine, look at the Powertrain wiring diagram. You will see in coordinates 32L and 33L the component “y7†and “y8â€. Look in the legend and you will not find these components, but look next to “y6†and you see an upper case “Y62.†These are the coils of the ignition system. So, looking at the wiring diagram legend you see, from left to right, the alpha-numeric designation, followed by the component name, and finally to the right another alpha-numeric number. This letter-number combination is used to indicate where the component is located in the diagram. If you look along the side of a Mercedes-Benz wiring diagram you will see letters starting at the top left hand side working their way down. These letters coupled with numbers along the bottom of the diagram form a grid pattern. By matching the letter and number coordinates of the component on the diagram, as you would “X” and “Y” coordinates on a graph, you should easily find the component you’re looking for. Now that you have found are components on the diagram, you can start tracing wires.

Taking the road less traveled

Now that you have identified and located the component, you can start evaluating the wiring. If you look at a Mercedes-Benz wiring diagram, you will notice that control units tend to be at the top. The components for any particular control unit tend to be toward the bottom of the diagram. If you look where a wire enters either a control unit or another component, you will see a long thin rectangle with a letter/number just outside of it. This is the connector name. The rectangle will also have a number inside of it. These are the pin numbers in the connector. Very often, in the component or control unit, adjacent to the wire you will see another number or a brief description of that wire’s function. The small description may be something like “PWR,” which is obviously power, or “Air Pump,” indicating the wire that grounds the air pump relay. You may also see something like “PWM,” which stands for Pulse-Width Modulated. This lets us know this is an on/off time-based signal that should be scoped or monitored with a graphing multi-meter. If you see a number, you should know that they follow DIN (Deutsche Industrie Norm) nomenclature. That is, each number represents what is electrically found on the wire. This chart gives some of the more common symbols:

- 30(x) Battery Voltage

- 15(x) Ignition Voltage

- 31 Ground

- 50 Starter Input

- 85 Relay Control Coil Ground Side

- 86 Relay Control Coil Power Side

- 87(x) Relay Output

Control units are at the top and components along the bottom. Along the side, top and bottom of the diagram are the letters and numbers that form the grid for coordinate locations.

Let’s Review

To review what we’ve covered so far, Mercedes-Benz breaks down its wiring diagrams according to system, therefore everything that system needs to function is in the diagram. Components are indicated by a dotted rectangle. Control units tend to be towards the top of the diagram and their components tend to be toward the bottom. Smaller rectangles come off of the component, and the connector pin and connector name is given. As you follow the wires from the component, you will see letter designations, such as “Z,†indicating a splice, “X†indicating a connector, and “W†indicating a ground. Along the wire you will also see the color symbol, such as “BK†for black and “WH†for white, but before that you will see a number like 0.5 or 1.5. This is the cross-section of the wire in square millimeters. The higher the number is the fatter the wire. Here is another chart so you can compare the metric cross-section with the approximate American wire gauge:

- 0.5 = 20 AWG

- 0.75 = 18 AWG

- 1.0 = 16 AWG

- 1.5 = 14 AWG

- 2.5 = 12 AWG

- 4.0 = 10 AWG

With a subscription to the Star Tek Info website, you can download wiring diagrams and get component locations by entering the Component ID alpha-numeric designation. You get a photo of where the component is located on the car. Keep in mind that these diagrams are big, so a fast computer with a high-speed Internet connection is recommended.

Sometimes you run into variations even before you pick the diagram. You may see the choices PE80.20-2000D, PE80.45-2000A, or even PE80.30-2000C. In this case, it is the central locking system. You would have to know if the car has the Central Locking system (PE80.20-2000D), the Comfort Lock system (PE80.45-2000A), or the Infra-red Remote Locking RCL (PE80.30-2000C). The customer may not be able to help you find this out, but using your scan tool to communicate with the door lock computer should help you identify what system you have. Otherwise, you have to evaluate the diagram and maybe try to match up some components from the diagram to the car.

Preparing the Diagnostic Plan

Since a wiring diagram is a symbolic representation of the vehicle’s electrical systems, you should be able to evaluate the diagram and come up with a step-by-step procedure for checking voltage supply, input signal and output ground control. Depending on the problem, you can pull a diagram and lay out the testing process before the vehicle even arrives! Having a plan will help reduce wasted time, inaccurate diagnosis and stress due to comebacks. If we can reduce those problems, everyone will be happy.

0 Comments