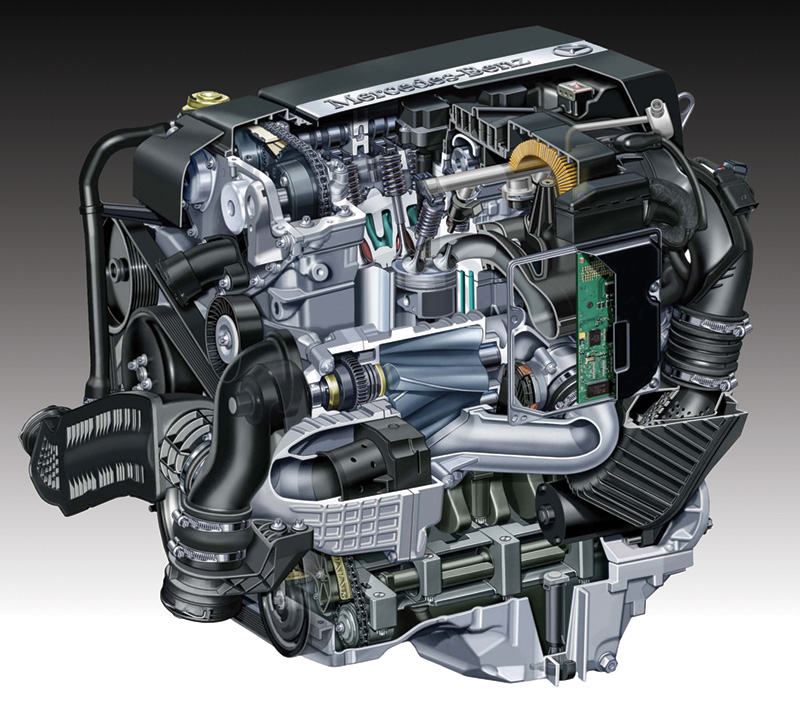

Everything from the air filter housing to the backs of the intake valves must be intact and clean if that engine is to perform properly, and live a long life without problems.

The combustion efficiency the precision-engineered intake path of a modern Mercedes-Benz engine makes possible can be thrown off by carbon deposits.

Carbon is a funny thing. It can coat throttle plates. It can build up on the back of a valve. It can leave the engine in the exhaust, increasing air pollution. Yet it is essential to life as we know it, and to the life of an engine. Since carbon is critical to both combustion and lubrication, we cannot eliminate it. However, too much of it creates problems.

Just as the service monitor tells you when to change fluids, it should also remind you that intake tract maintenance Âis needed.

Therefore, it has to be managed. We must maintain an acceptable level so that each component can perform the way it was engineered to perform. How are we going to achieve this? Through proper maintenance of the air intake supply system, we can keep carbon and sludge build-up to minimal levels, which will reduce any adverse effects on engine performance or emissions.

The big picture

The air intake system comprises the air filter housing, intake duct work, throttle body and butterfly, intake manifold and, finally, the intake valves in the cylinder head(s). Accessories attached to the intake system are the PCV (Positive Crankcase Ventilation), EVAP (Evaporative Emissions system), and EGR (Exhaust Gas Recirculation) systems. These contribute to the total air flow into the engine. Because these systems are scavenging or recycling potential pollutants, they are often the first things to look at in order to maintain a clear intake passage.

First, let’s look at each component of the air intake system. When air is drawn into an engine (or, more accurately, pushed into the intake by atmospheric pressure), anything that’s suspended in the air comes along with it. Everything from airborne dust and dirt, to moisture, to another vehicle’s exhaust emissions (cars get pretty close to each another in city traffic) is drawn into the vehicle’s intake. Air filters are fitted for this reason. The purpose of an air filter, other than providing a nest for rodents in rural communities, is to filter out airborne dirt and debris. Over time, air filters become clogged, which is why we replace them at regular maintenance intervals.

Some Mercedes-Benz owners may even switch their original air filters to a reusable foam type in a quest for more performance. These are saturated with oil to assist in trapping dirt, and holding it in suspension until the air filter is cleaned. One of the benefits claimed for these foam-type air filters is that they increase air flow without sacrificing air filtering ability, which is thought to improve the performance of the engine. Anyone versed in automotive technology, however, knows that not only will these aftermarket filters require an increase in maintenance frequency, they can also cause driveability problems and even set DTCs (Diagnostic Trouble Codes) and turn on the MIL (Malfunction Indicator Lamp). Carbon is usually not a problem at this point in the intake tract, but keeping the air filter clean is important. Ducting

Next is the air intake duct or tube. On some larger engines, the air filter housing fits right over the throttle body, providing an air-tight seal from one component to the next. On other applications, the air intake duct may be composed of metal, rubber, plastic, or a combination of these materials. The purpose of this tube is to allow flexibility between the chassis-mounted air filter housing and the engine-mounted throttle body. The engine twists and vibrates on its mounts while the air filter housing stays still, so the duct must flex.

In some cases, the air intake duct is used as a connection point for emissions-related components. On a running engine, there is negative pressure in the air intake tube, which can be employed to draw in crankcase blow-by gases and evaporative emissions vapors from the fuel supply system, both of which are then burned in the engine’s cylinders. These gases and vapors are hydrocarbons, and may combine with small dust and dirt particles that have made it past the air filter to form deposits. These can build up in the air intake duct. In the duct itself, this will not have a significant impact on performance or emissions. However, any accumulation of deposits on the Mass Airflow Sensor (MAF), which is mounted in the duct, may have dramatic effects on how the engine runs.

Some service authorities say that a MAF can be cleaned, while others tell us that replacement is the only cure for the driveability complaints a dirty MAF can cause.

MAF

The job of the MAF is to precisely measure the quantity (by actual mass) of the air entering the engine at any given moment, and send a signal to the ECU. The ECU uses this input to determine ignition timing and fuel injector pulse width. Any contaminants that attach to the MAF sensor element will reduce its accuracy, so must be avoided. This sensor’s signals are critical to the ECU’s calculations, and can have a large effect on engine performance. MAF sensors are usually mounted very close to the air filter housing, but through resonance effects oil and crankcase gases may come in contact with the sensing element.

The next stop in the air intake stream, which is now carrying hydrocarbons and a small amount of dirt with it, is the inside of the throttle body where the butterfly valve resides. This component is what the driver is actually controlling when he or she presses down on the accelerator pedal. Regardless of whether this is mechanically or electronically controlled, on any gasoline engine rotating the butterfly is how the driver allows more air into the engine, which the ECU senses in order to use its programming to deliver the proper amount of fuel and spark advance.

The EGR valve benefits the engine by reducing detonation, but the impurities in those exhaust gases will also condense and form troublesome deposits.

Idle air control

Either an idle air control valve or the throttle butterfly itself is manipulated by the ECU to provide metered air for idle speed control. Any deposits or debris in these components will have an adverse effect on this function. The air, hydrocarbon mist and dirt mixture mentioned above can build up on the idle speed control motor and the throttle plates. Usually, when the engine has an electronic throttle the idle speed motor is eliminated because the throttle takes over the job of controlling idle speed. With significant oil/dirt build-up in the throttle body throat and on the plates (or, in the passage the idle speed motor controls), idle air flow may be restricted. The module in charge of idle speed would have to command the passage to open more to compensate for the restriction.

Evaluating scan data is a good way to determine if the ECU is indeed making this compensation. Look at the data PID (parameter identification) that shows adjustments to idle speed control. Any increase in this PID reading would indicate that the computer is making up for restricted idle air flow.

The intake manifold directs air from the throttle body to the intake ports of the cylinder head(s). In older models, this was a fairly simple task. By engineering proper volume and shape, an optimal balance could be achieved between air intake velocity at part throttle and maximum air flow at wide-open throttle. Modern Mercedes-Benz vehicles, however, typically rely on advances in intake manifold design to enhance their already impressive performance. Moveable valves or vanes have been introduced into intake manifold architecture that allow dynamic modifications of the passages to keep air velocity up during mid-range rpm to boost torque, and to effectively shorten the runners at higher rpm to maximize power output. These systems also enhance the swirl and tumble of the air/fuel charge, improving the efficiency of combustion.

You can easily see that deposits in the intake manifold runners will not only interfere with this carefully-engineered flow, but may also keep the valves/vanes from being able to move throughout their full range — or at all.

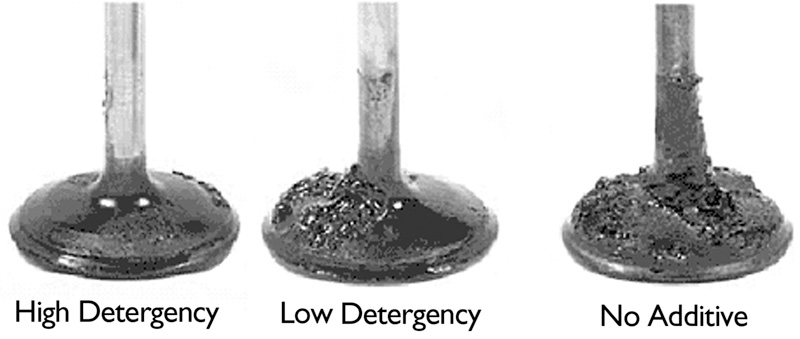

These valves make the effect of gasoline additive packages obvious. The valve on the left is from an engine that was run on high-quality “Top Tier” fuel only, the one in the middle received gasoline with the minimum allowable amount of detergent, and the one on the right had straight gasoline with no additives sprayed at it.

Exhaust recirculation

In an effort to control peak combustion chamber temperatures, thus reducing the production of NOx and avoiding spark knock or detonation, the EGR system recycles exhaust gases into the intake. These hot, relatively inert gases (which contain some HCs) dilute the air/fuel mixture so that the burn is not as hot as it would be. But, coupled with combustion blow-by through the PCV system and evaporative emissions, these gases will form carbon build-up over time, and the EGR passages themselves may be blocked. The most obvious symptom here is detonation, although a loss of performance may result as the knock sensor circuit retards ignition spark. Also, carbon deposits may cause the EGR valve to remain open at idle when it should be closed. Depending on how far open the valve is, this will cause rough idling or even stalling.

The manifold runners, the tips of the fuel injectors, and the backs of the valves are the last areas to be bathed by the intake stream before it enters the combustion chamber. The fuel injectors are designed to provide the optimum spray pattern for even and complete combustion. While intake passages are of a fixed dimension, variable valve timing has allowed Mercedes-Benz to adjust the volumetric efficiency of its engines and optimize power and fuel efficiency. Once again, without proper maintenance carbon build-up can adversely affect engine performance and emissions. Short trip, stop-and-go driving, or lower-than-normal engine temperatures (stuck open thermostat, etc.) can all promote these deposits in the intake passages, and, worse, on the backs of the intake valves. Carbon can also accumulate on the valve seat and not allow the valve to fully close, perhaps resulting in roughness and a misfire code, and will act as a sponge until saturated, soaking up gasoline and causing cold driveability problems.

This type of deposit removal set-up has become popular. You simply insert the cone at the end of the hose into any convenient centrally-located source of manifold vacuum, then let the solvent compound trickle into the intake stream slowly.

Carbon removal

So, excessive carbon build up, particularly in the intake manifold and the cylinder head and combustion chamber, is something to be avoided, or, if already present, removed. There are basically three different methods we can use for this type of service. The most labor-intensive is to physically remove the components and clean them. In the case of “carboned up” EGR passages, or removing sludge from the PCV system, this is fairly easily accomplished. Eliminating excessive intake valve deposits, however, represents a significant amount of disassembly, which the vehicle’s owner may not want to pay for.

On the other hand, the air filter housing, intake duct and throttle bore and butterfly are easily serviceable in most cases.

NOTE: With electronic throttles, never spray cleaning solvent on the throttle plates as it may travel down the throttle shaft and into the electronic components of the assembly damaging them. Always spray the cleaning solution on a clean shop rag and wipe out the carbon and sludge build-up. You can verify that this maintenance has been effective by double checking the idle air adaptation PID on your scan tool — look for a reduction in the air adjustment.

There are two other methods that require relatively little labor. You can pour an approved additive into the fuel tank and allow it to be distributed through the fuel injection system. This will react with the carbon deposits, ideally softening them enough that they break up and are pumped out the exhaust. This is effective in de-carbonizing intake valves and the tips of the injectors, but does nothing to help in the intake manifold and throttle body.

The third method, which has become very popular, is to allow the chemical cleaning solution to be drawn in through the air stream while the engine is running. This allows the chemical to be evenly dispersed throughout the air intake system. It has been demonstrated in the real world that a good deal of carbon can be removed by this procedure, often to the extent that a previously failed emissions test is passed, or a driveability problem is corrected.

There are some potential drawbacks to these “tune-up in a can†solutions, however. You must be very certain that you are not doing anything that could damage oxygen/air fuel ratio sensors and catalytic converters — you don’t want to do more harm than good. As stated in previous issues of StarTuned, Mercedes-Benz does not recommend any aftermarket fuel additives other than what comes in gasoline from the supplier. Mercedes-Benz has its own tank additive, Part # A 000 898 25 45 10. Other additives are continually being tested by the company, so ask your dealer’s parts department about it, or watch for any TSBs (Technical Service Bulletins) on the subject.

Finally, advising your customers to buy only quality brand-name gasoline with a strong additive package will go a long way toward avoiding harmful deposits in the first place. Mercedes-Benz owners are a discerning group. Proper maintenance procedures will insure that their vehicles will perform the way the engineers intended them to for years to come. This will give them peace of mind, and you a loyal customer base.

0 Comments