Mercedes-Benz developed DAS (also known as SDS), and here are all the components. The large black box to the right of the laptop is the Diagnostic Multiplexer. This multiplexer switches communication between control units on vehicles with the 38-pin and 16-pin diagnostic connectors.

Mercedes-Benz developed DAS (also known as SDS), and here are all the components. The large black box to the right of the laptop is the Diagnostic Multiplexer. This multiplexer switches communication between control units on vehicles with the 38-pin and 16-pin diagnostic connectors.

Any diagnostic process must incorporate three fundamental steps:

- Assessing the problem

- Gathering pertinent information on system operation

- Combination of a diagnostic plan along with proper execution to isolate the cause

An indispensable weapon in our troubleshooting arsenal is the self-diagnostic capability of the engine management computer. Here’s how Star Diagnosis provides everything we need to tap into it.

Mercedes-Benz is considered the leader in automotive technology, and the three-pointed star is an icon of engineering achievement. It is also symbolic of Mercedes-Benz’s three-tiered approach to diagnostics. This approach is a comprehensive system that includes diagnostic communication, technical information and electrical measurement. This package is known as Star Diagnosis.

Star Diagnosis is a PC-based program that has three components. The first is designed to interface with computer-controlled systems by physically linking up with the vehicle. This system is known as DAS, or Diagnostic Assistance System (also known as SDS). The second component of the system is service information. This is known as WIS (or WISnet), or Workshop Information System. The final component is HMS990, or Hermann Measurement System 990. This allows you to complete the diagnostic plan with electrical tests to identify if the problem is in the computer, a related component, or the wiring between the two. The synergy among these gives us comprehensive diagnostic power.

DAS, Diagnostic Assistance System

Self-diagnostic capability has been around for decades, but Mercedes-Benz has incorporated PC computing with computer controlled systems on its vehicles. This is accomplished with DAS. The Diagnostic Assistance System can communicate with all the control units on the vehicle through the CAN (Controller Area Network). No longer do we have multiple system testers for each individual automotive system. This diagnostic scan tool is composed of Windows-based PC software with a touch-screen tablet computer, interface cables and a Diagnostic Multiplexer.

The PC holds all the information necessary to diagnose and repair computer controlled systems. This is more than just the ability to access DTCs (Diagnostic Trouble Codes) and the data stream (although those are good places to start). Diagnostic flowcharts are included in the software, along with TSB (Technical Service Bulletins — through WIS) updates and other features. Among these features is the ability to reprogram control units. This reprogramming becomes important when there is an update to the vehicle’s existing calibration. This new calibration can help a control unit improve its function or repair a problem in the vehicle’s software. It also becomes useful when control units have to be replaced and you need to download the existing programming from the problem ECU and upload this program to the new replacement.

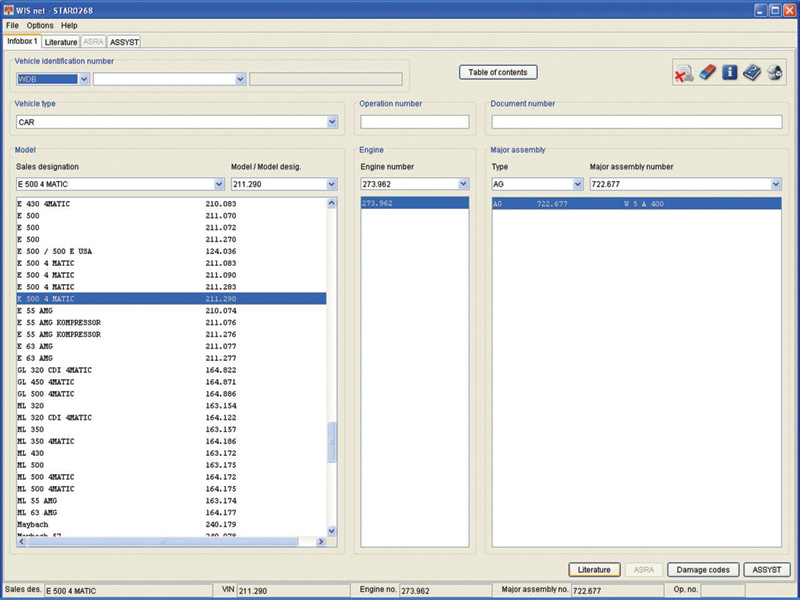

In WIS or WISnet, you first enter the vehicle

information. Then, click on the “Literature†field to get a complete list of the systems for this vehicle.

In addition to reprogramming, version coding may be required. This coding tailors the control unit to the vehicle it is placed in. As an example, version coding for a control unit in the powertrain CAN would be different for a vehicle with ESP (Electronic Stability Program) than one without. To complete the software package, Star Diagnosis is able to initialize systems. Some features of computer control require various components to be synchronized. When battery power is lost, so can the synchronization between these components. Initializing the systems “re-syncs†the various components so they can perform coordinated functions with one another. The Diagnostic Multiplexer allows the PC to communicate with all of the various control units on the car through the 38-pin and 16-pin diagnostic connectors. This adds up to extensive communication and control of the self-diagnostic capabilities in the vehicle’s computer controlled systems.

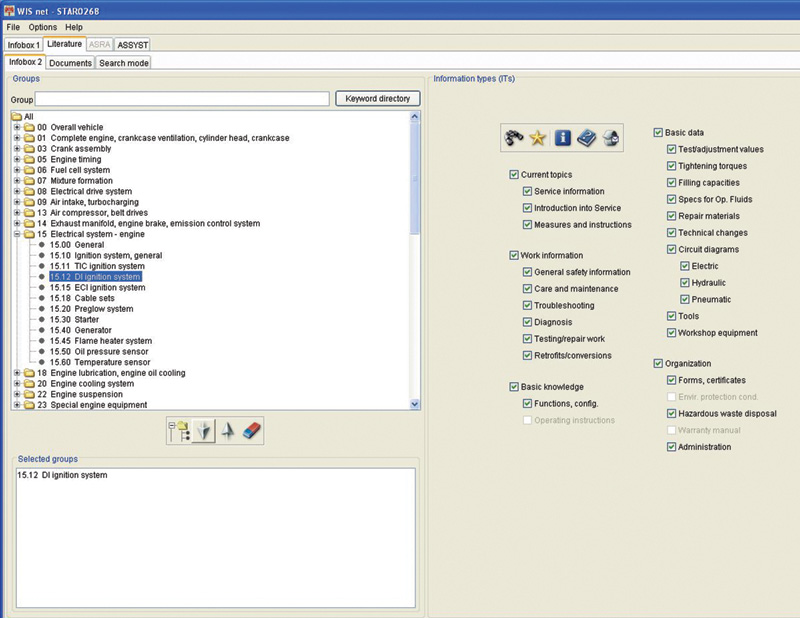

In this screen, you select the system you want information on from the list on the left. Then, hit the arrow button going down to add this system to the “Selected Systems†field. Finally, after highlighting the system you just selected, you check off the type of information you want in the boxes on the right. Click on the “Binocular†field and all of the documents found will be displayed.

Workshop Information System

An early step along any diagnostic path will include a gathering of service information. This includes component location, removal and replacement procedures, and diagnostic testing specifications. This information is not only for the initial diagnostic assessment, but is also used for any typical repair and service of Mercedes-Benz vehicles. It is organized by the Baumuster or chassis number, or by model designation. This allows Mercedes-Benz to reduce duplication of repair information and also provide information about changes that occur in the production cycle of a chassis. You can also look up diagrams by the US VIN. This WIS component is also available with a paid subscription to the internet Mercedes-Benz technical website, www.startekinfo.com. A portion of STAR TekInfo is STAR Wiring where you will find component location as well as have the capability of printing wiring diagrams. Also, under “Workshop Resources”, you can find out how to purchase any of this diagnostic equipment.

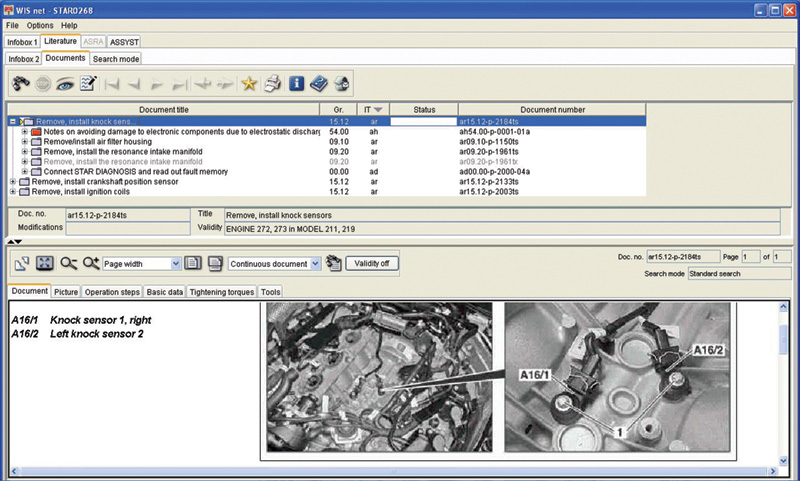

Here is the payoff of our search: photographs showing component location, procedures for R&R and torque specs. You can pick other documents to display in the top field of the screen.

Now that you have all the technical information you need, it is time to start testing.

Hermann Measurement System

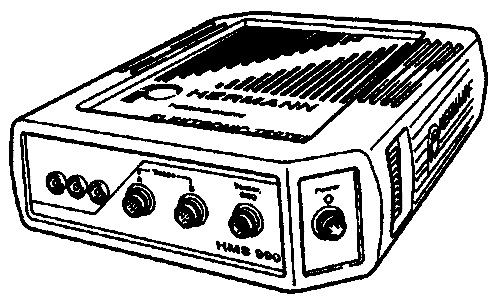

The HMS990 is designed for those who would like to incorporate their physical testing of computer controlled systems with DAS. The Hermann Measurement System is a data acquisition board that interfaces with DAS and uses it to display the electrical measurements being taken by the board. All types of electrical testing can be performed, from simple voltage, resistance and amperage measurements to voltage and current ramp patterns of operating solenoids. This advancement in testing can lead to easier diagnosis of intermittent problems as voltage and amperage can be recorded for later interpretation. Keep in mind this link between DAS and HMS is for later model Mercedes-Benz vehicles built after the W211 chassis introduction. Simply put, your test leads are connected to the HMS990 unit, which then measures the electrical signals and puts out a language that the PC program can understand and displays these signals as if we were looking at a scope.

The HMS990 is a data acquisition board that displays its reading on the DAS PC. You can use the PC’s memory to record this data during a road test to isolate intermittent problems.

A Brave New World

Those of us who have been in the auto service business for decades remember being amazed by electronic ignition when it appeared in the mid-’70s, surprised by computer-controlled fuel injection in the late ‘70s, relieved to get self-diagnostics in the ‘80s, encouraged by data PIDs in the mid ‘90s, and floored by the integrated communication of CAN as we approached 2000. By incorporating a PC and an Internet data site, DAS takes this evolution to the next logical level, and will allow you to find problems that would have stumped you without it. That’s real progress.

0 Comments