One of the benefits of owning a Mercedes-Benz is a seamless transfer of power from the engine to the road. To add to the experience adaptive transmission shifting tailors the vehicle to the driver. Let’s see how Mercedes-Benz manages these two feats.

You will need to have this tool at your disposal if you are going to service Mercedes-Benz vehicles.

The vehicle has no dipstick so you need to provide your own. Measure the fluid level in a drive gear with the temperature of the fluid first at 25 deg C and then at 80 deg C.

How do we isolate a drivability issue from a transmission shifting issue? This may sound ÂÂsimple, but a bucking sensation may feel like a misfire when it is actually a transmission valve body control valve coming in and out. Even if we determine that it is a transmission problem, how do we isolate if the problem is with the mechanical part of the transmission or the computerized electronic controls? Proper testing methods have never been as critical as they are today. The expense of an improper diagnosis leading to an improper repair can leave the customer with a bad taste in his or her mouth. You need to be sure of your test methods and know how to evaluate their results. Self-diagnostic features incorporated in control units today have helped in the battle with complexity. This coupled with proper training and information should leave you capable of isolating the problem and performing the pertinent repair. In The Beginning

The first step in any diagnostic process is arguably the most critical. Going off in the wrong direction can waste an incredible amount of time that you will more than likely not get paid for. The job will remain profitable if the first step is in the right direction. In the case of a drivability problem/transmission shift issue, you need to determine if it is one or the other because there are two different should give the technician an idea on what might be wrong and where to look. Try different driving patterns, such as different rates of acceleration. Also, try manually shifting the automatic transmission. You can try holding the transmission in a fixed gear and see if you can duplicate the problem. Remember, the transmission control unit will limit the rpm of the engine.

Another form of testing is to observe how the system functions and see if we find anything wrong, either electronically or mechanically. We can also make a change to the system, either electrical or mechanical, and see how the vehicle reacts.

Transmission fluid flushing can extend the useful service life of the transmission. It can remove fluid that has been over-heated and is full of clutch material. It cannot make up for worn clutch discs, so make sure the customer is aware of the limitations.

Observing inputs and outputs can be time-consuming on complex systems. This fact is what made scan tools so prevalent. With a scan tool you can observe computer controls easily. However, this is processed data and it’s relatively slow depending on the nature of the problem. Processed computer data is not real-time, like what you see on an oscilloscope. It is entirely possible for an input or output to misbehave and the computer’s self-diagnostic system never picks it up. A scan tool is a good way to get started when monitoring the computer’s control of the system, but it should always be followed by testing the system visually and with direct electrical testing.

ATF

The next major step is to check the fluid level. On later model Mercedes-Benz vehicles, this is not a simple as it sounds. You will find the fill tube, but you will probably not find a dipstick. The dipstick is now a tool to be kept by your toolbox. In addition to having the tool at your disposal, you also need to have the transmission at a specific temperature. Too hot or too cold may not give an accurate reading. The fluid level should be checked at 25 deg. C (77 deg. F.), and it should read between the “Max†and “Min†marks on the dipstick tool. Allow the engine to warm up about 2 minutes and bring the transmission temperature up to about 80 deg C (176 deg F) and the level should still be between “Max†and “Min†on the stick. The transmission needs to be in a drive gear, so make sure the parking brake is on and have a second technician in the vehicle applying the brakes. If repair work has been carried out have the technician move the selector lever into each gear a few times to evenly distribute fluid throughout the transmission.

Of course, there are always debates on what type of transmission fluid to use. In the case of Mercedes-Benz, use only the exact ATF recommended in the service literature or owner’s manual, which you can be sure is of the proper viscosity and contains the necessary friction modifiers. You may have read on the internet that any synthetic transmission fluid may be used with no adverse affects, but those that have not been tested by Mercedes-Benz will void any warranty on the unit, and may not provide the necessary fill-for-life protection the factory fluid offers. This is imperative on the later model 722.9 seven-speed transmission. The Mercedes-Benz part# A001 989 45 03 is developed specifically for this transmission. It’s higher friction consistency and thermal stability is required and it should not be mixed with another type of fluid during a service.

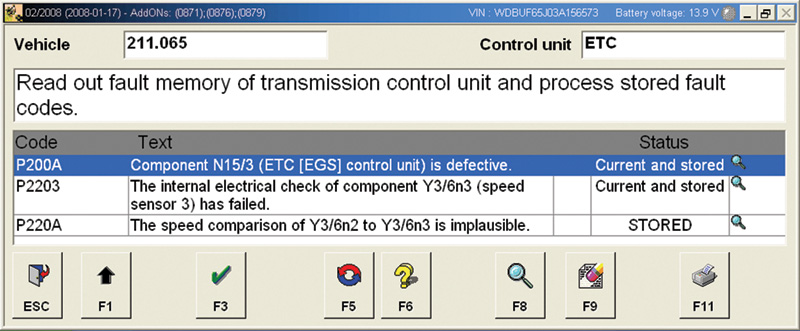

Most of the time Mercedes-Benz

computers are capable of determining a problem with their self-diagnostic system. Here, a few codes have set on this 211 chassis, and two of them are related to the same failed sensor: #3 rpm speed sensor. This sensor should now be tested directly to make sure the problem is not a wiring issue.

Back To Our Problem

Evaluating an unusual symptom like a light bucking with steady throttle, you may think misfire. While driving, you may want to look at the misfire counter through your SDS. If you do not see any misfires, then you are probably dealing with another problem. This is an example of observant testing. Another type of testing is “intrusive†testing. Here, you make a change to the system and see how the vehicle reacts. To see if a transmission solenoid is toggling, you simply need to unplug the main connector and the transmission. This connector, very often, carries the power, ground, or both to the transmission shift and pressure control solenoids. By unplugging it, we are forcing the transmission into its “fail-safe†program. For example, if the unit is stuck in a particular gear, eliminating electronically-controlled shifting isolates the mechanical transmission from its electronic control.

If the problem persists, you have two choices. Either look in other areas such as the engine, or the problem is in the mechanical function of the transmission. With the transmission in “fail-safe†you must be careful of engine rpm, and excessive road-testing can actually damage the transmission. This type of testing should only be applied if the self-diagnostic system and scan data are not giving an indication of what is wrong. If the problem is eliminated by unplugging the solenoid connector, plug it back in, watch the control of these solenoids and monitor the input data to see if either is causing the symptom. With older transmissions, monitoring the line pressures and solenoid operation was not very difficult. With newer, smoother-shifting transmissions, however, this can be more challenging. This type of testing may not work in every case, but it should apply in most. Mercedes-Benz vehicles are very good at self-diagnosis, and very often a code is stored indicating where the problem may lie. However, if we do not have a code to work with, we still have a starting point. The Mercedes Way

How would a transmission control unit tell if the quality of the shift is less than perfect? It could monitor the current draw of the shift solenoid, but that would only inform you of shifting problems where the electronic controls created the problem. If the problem is mechanical, the control unit would need another way to tell if there is a problem. Incorporated into the transmission are input and output shaft speed sensors. On the later model 722 transmission, three speed sensors are used. The first picks up the turbine shaft speed, the second picks up the speed of the planetary gearset, and the output shaft speed sensor does just that — reads output shaft speed.

Looking at scan data, you can sometimes find large problems with sensors, providing they last long enough for the computer to pick up. In this case, the rpm sensor #3 is no longer supplying a signal. You should back up this conclusion with electrical testing of the sensor. Look at both the resistance and the AC voltage signal.

By monitoring these speed sensors, along with the actual shift point, the transmission control unit can see if the proper relationship is maintained between the two. If the input shaft indicates a higher speed than the output shaft speed sensor (for a given gear ratio) then the engine rpm must have flared as the transmission slipped into the next gear. This can be accomplished even if the problem is not severe enough for the driver to notice. To monitor these signals directly is difficult even with an experienced lab scope user. This also tells you the transmission shaft speed sensor’s function is critical to the operation of the transmission electronic control. You need to verify that these signals are working properly before you can start condemning other components.

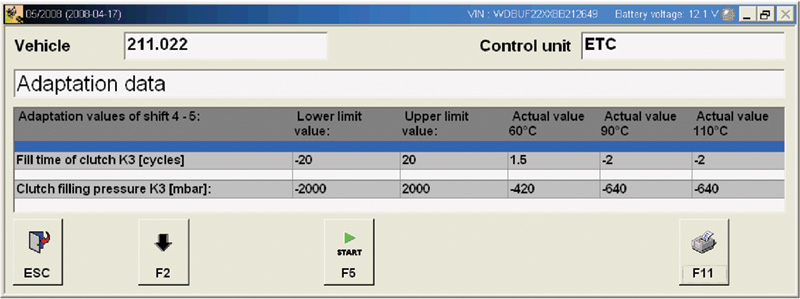

Mercedes-Benz engineers provided additional monitors for components related to shifting. You can evaluate a shift by monitoring action of the fluid. By watching how long it takes to fully apply the clutch pack and how much pressure is required to engage it, you can find out if the clutch packs are healthy. If excessive time and pressure are needed to provide grip for the clutches, they are probably worn. The SDS tool allows you to access this data for each clutch pack. This is extremely helpful when you find shifting problems only in particular gears.

In the later model Mercedes-Benz transmissions, there can be up to seven forward gear ratios. You will have individual forward gears and torque converter lockup for each gear. The operating pressure is controlled by a pressure control solenoid. In addition to the primary pressure control solenoid, each shift solenoid has its own pressure control solenoid. This allows for quicker and smoother shifts. If any of these solenoids were to stick, it would contribute to an improper shift. Let us look at an example of this data that we can use to test the solenoids. The first line of data is the “Fill Time of Clutch XX,†with the letter designation of the clutch you are looking at. For ease of Interpretation, you are given the high and low limits of the shift monitor counter.

Notice how you are given the maximum and minimum limits for each reading, followed by the actual reading. You are also given the reading at three temperatures. A higher (positive) number indicates that more time and pressure is required to engage the clutch, which implies that the transmission is worn.

The next line you is either the “Brake or Clutch Filling Pressure†in millibars. This informs us of the pressure required to apply the clutch. If either excessive time or excessive pressure is required for engagement, the clutch is worn or pressure is inadequate to complete the engagement. To further assess the problem, you can also reset the adaptations. This “zeros†out the adaptations and gives you a new starting point. A road test that runs the vehicle through all of its gears will allow the adaptations to take place so you can re-evaluate the shift data. This is very useful information when trying to determine if a replacement transmission is in this vehicle’s near future.

Service Work

If one of the solenoids or speed sensors needs to be replaced, it will probably be serviced as a unit. On many later model Mercedes-Benz transmissions, all of the solenoids and sensors are incorporated into a plastic housing usually mounted on top of the valve body. While this may increase the overall cost of a component replacement, it does provide for ease of service. Typically, transmission service work is farmed out to a reliable transmission rebuilder. A properly trained technician can, however, drain and remove the pan, remove the valve body (being careful to watch the seals) and replace the solenoid/sensor plate. In the case of the 722 transmission, the transmission control unit is incorporated into the solenoid/sensor plate. Superior Mercedes-Benz engineering should make this a rare failure with proper maintenance. There are also some other key service procedures for the 722 transmission. The housing is magnesium so aluminum bolts are used. They must be replaced when removed, then torque according to specs.Â

0 Comments