Automobile emissions are a hot topic among environmentalists, drivers and technicians. Mercedes-Benz vehicles utilize emissions systems, such as Exhaust Gas Recirculation, to reduce harmful pollutants. Let’s keep this system operating properly and do our part to clear the air.

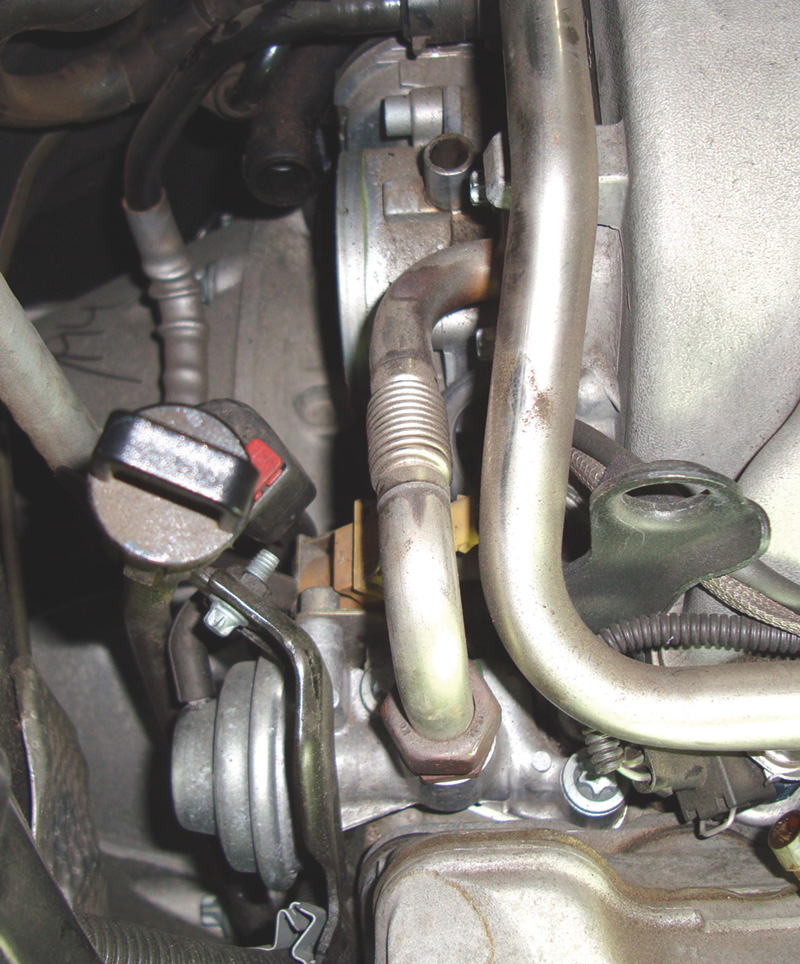

Here is the layout of a late-model EGR system. The EGR valve is mounted on the cylinder head. The EGR solenoid is on the valve itself. The EGR pipe feeds exhaust gases to the intake manifold.

Take a deep breath and enjoy the fresh air. It wasn’t always this way. Since the 1960s, the automakers have made tremendous strides in reducing the air pollution their vehicles produce, and Mercedes-Benz has always been in the forefront of this effort. Hydrocarbons (HC), carbon monoxide (CO) and oxides of nitrogen (NOx) make up the terrible trio of gases that have been targeted. In this article, we’ll look at what M-B has done with EGR (Exhaust Gas Recirculation) to reduce the last, and what you need to know to keep that system functioning.

Computerized engine management allows for leaner air/fuel mixtures, which help keep HC and CO down. But these leaner mixtures lead to higher combustion chamber temperatures in the neighborhood of 2,500 deg. F., which cause the formation of NOx. To counteract this, a small portion of previously-burned exhaust gas is introduced into the intake charge, diluting the charge and knocking the top off the peak temperatures, which cuts NOx.

When EGR is not working the way it was designed, NOx goes up and/or drivability problems can occur. Three-way catalytic converters, of course, also reduce NOx, but here we’re dealing with the EGR system only. If there is insufficient EGR flow, NOx emissions will increase. Excessive EGR flow promotes inefficient combustion and misfiring. With OBD II, EGR systems are monitored for their performance through a series of computer-controlled tests called monitors.

The EGR valve and solenoid are sold as one unit. The large threaded opening is where the pipe that leads to the intake manifold attaches. The liquid inside is carbon cleaning solution.

What Are The Symptoms?

When an EGR system problem is present, the symptoms often feel like they’re caused by something else. Pinging can occur, which will lead to an increase in NOx production beyond what even a good catalytic converter can handle. Most Mercedes-Benz engines have knock sensors that inform the ME (Motor Electronics) control unit if the engine is detonating. The control unit then retards ignition timing, but performance will be reduced. If EGR flow is excessive, particularly at low rpm, it can displace enough oxygen to cause misfiring. This can lead to unstable idling and hesitation. Most of the time, excessive EGR flow does not have a significant effect on drivability in the highway cruising range — the EGR is wide open at this point, depending on engine load. It is in the lower rpm ranges that the relatively small amount of EGR gas has a significant effect. EGR problems can feel like an excessively rich or lean condition, and misfiring can also cause you to mistrust the oxygen sensor signal voltages and fuel trim readings.

The MAP sensor is only used to diagnose emissions-related systems such as EGR and EVAP flow issues. You can use the MAP to monitor manifold vacuum and the open the EGR valve. Watching the change in the vacuum reading will tell about the flow of the EGR system.

On OBD II vehicles, an EGR monitor will test the integrity of the system. It is critical to understand how the ME control unit determines how the EGR system is functioning. This EGR monitor will determine if an EGR code is going to set. The system also needs to determine if there is insufficient or excessive EGR flow. If you are using a generic protocol scan tool, you may only see the EGR code P0400, indicating there is a general problem with the system. With Mercedes-Benz factory-specific software, you can often retrieve a more detailed account of a particular EGR failure. Either way, the Mercedes-Benz ME control unit is capable of determining if there is an EGR flow fault often before there is any sort of a drivability issue.

The First Steps

Block this EGR passage to eliminate the possibility of any exhaust making it into the intake manifold. If the engine runs smoother, you have a leaking EGR valve. Verify that it is not being opened by vacuum from a solenoid that’s stuck.

As mentioned earlier, an EGR flow problem can feel like an excessively rich or lean condition. Also, too much flow has a more significant effect at idle than at cruise, so test the vehicle at idle. Making the mixture leaner by creating a vacuum leak will temporarily smooth out a rough idle if the mixture is too rich. By the same token, adding propane to a lean-running engine will temporarily smooth things out. If EGR gases are involved, combustion efficiency is reduced, not because of too much or too little fuel, but because of too little oxygen in the intake charge. EGR gases have displaced some of the charge, so adding fuel or air will not correct the mixture. It’s the excessive dead (low oxygen content) exhaust gases killing combustion, not incorrect fuel mixture. Creating a vacuum leak (to correct a rich condition) or adding propane (correcting a lean condition) is a quick way we can prove we do not have a mixture problem. If spark and basic engine are tested and are satisfactory you should now start thinking about excessive EGR flow at the wrong time.

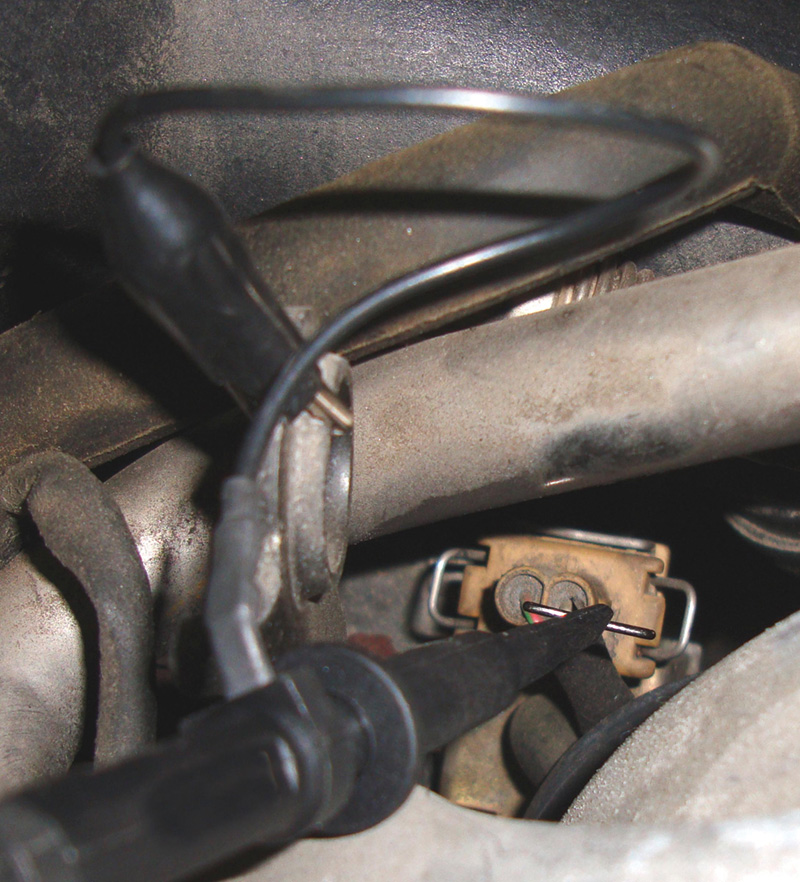

Here we are monitoring the ground control of the solenoid. A reading of 12V means it is not energized and no vacuum will flow to the EGR valve. When the ME grounds the solenoid, the EGR valve should open.

Removing the EGR valve and blocking off the passage is a way to definitively eliminate the possibility that exhaust is affecting the mixture. If the idle is better, you know the EGR is stuck open, or that vacuum is reaching the valve at the wrong time. You can attempt to “un-stick†it, but replacement is a more certain repair. If vacuum is being applied to the EGR valve at the wrong time, you need to find out why. The EGR valve should not be open at idle with the vehicle stationary. The ME control unit needs to see vehicle speed before it allows recirculation. The control unit operates an EGR control solenoid often mounted to the valve itself. In lower rpm ranges, the solenoid is gradually opened by pulse-width modulated, or duty cycle control, of the solenoid. At higher rpm, the solenoid is fully grounded and the EGR valve receives maximum vacuum and opens all the way. Monitor the ground control of the solenoid, and if it is being grounded either the ground control wire of the EGR solenoid is shorted to ground, or the ME is mistakenly grounding the wire. If the solenoid is not commanded to ground, but manifold vacuum is passing through the solenoid to the EGR valve, then the solenoid is stuck open and needs to be replaced. The solenoid and EGR valve are usually sold as an assembly, so in either case they get replaced together. Remember a stuck open EGR valve or EGR solenoid will flow excessive exhaust at idle and cause the engine to stall or run very roughly.

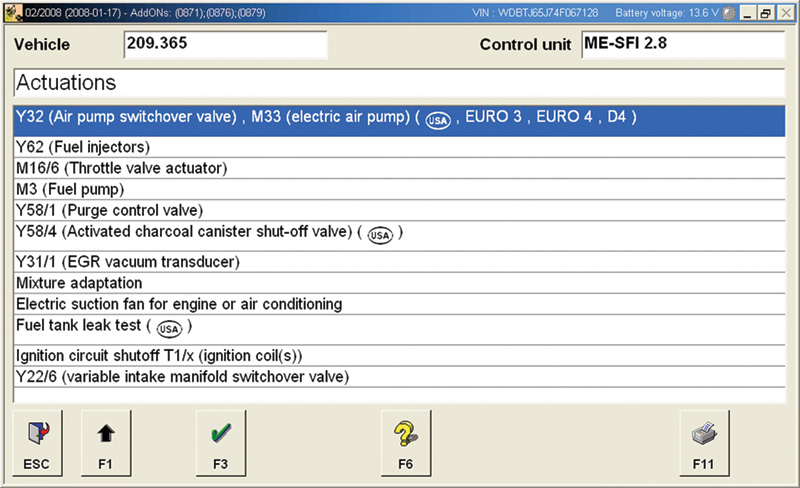

Having a Compact III at your disposal allows you to command the EGR solenoid open. This not only tests the computer’s ability to ground the solenoid, but also allows you to test the EGR system while the vehicle is in your bay.

The Other Side

If flow is insufficient, expect slight pinging, a failed emissions inspection with high NOx, and/or a MIL (Malfunction Indicator Lamp) indicating a code in the P0400 range. There is usually no severe drivability symptom associated with low EGR flow. The first test to perform is to simply open the EGR valve at idle and see how the engine reacts. Older engines with the EGR mounted on the exhaust manifold usually only flow enough exhaust to produce a rough idle. Newer engines with EGR systems mounted on the cylinder head will flow enough to cause the engine to stall right away. It only takes 5 to 6 in. Hg to fully open the valve. The valve should also hold vacuum for a few minutes. Chances are if the valve is not holding vacuum it is not opening in the first place and you will probably notice very little change in engine performance.

The next step is testing the solenoid. The solenoid receives ignition-on power from the vehicle’s power distribution system. The ME control unit grounds the EGR solenoid to allow manifold vacuum into the EGR valve. You can either ground the solenoid yourself with a jumper wire, or if you have a Compact III, you can use the Activations Menu to actuate the solenoid. Any result less than a quickly stalled engine indicates a low-flow issue. In order to pass the EGR monitor for OBD II, you should evaluate the EGR system the same way the ME control unit monitors it.

When dealing with an insufficient flow EGR code such as P0401 or P2001 you need to have a method to test flow. As you can see here, the EGR pipe is almost clogged. The ME control unit can see this restriction and flag the code. Cleaning out the pipe will fix the problem.

Testing the Flow

Since the early 1990s Mercedes-Benz vehicles have migrated away from CIS fuel injection and exclusively use LH or HFM mass airflow type systems. Testing EGR flow by monitoring the change in the mass airflow reading is very difficult. Mercedes-Benz chose to use a MAP sensor to monitor manifold vacuum not for fuel control, but for diagnostic purposes. Through the MAP signal, the ME control unit can watch the change in vacuum when the EGR is opened. If it indicates 18 in. Hg at 1,000 rpm and the EGR is opened, the manifold vacuum will drop. The larger the drop in manifold vacuum, the greater the flow of EGR gases. If the MAP signal change is insufficient, the ME control unit deduces that the flow is insufficient also, and a code is set. You can simulate this by monitoring the voltage on the MAP sensor at 1,000 rpm and grounding the EGR solenoid. (Remember that when manifold vacuum is low MAP signal voltage is high, and as vacuum increases MAP signal voltage decreases.) You should see the MAP voltage increase over 1.5V as the manifold vacuum decreases and the engine runs rough.

If the voltage increase is too small, flow is being restricted. You know the valve and solenoid are working, but the EGR passages (typically the pipe) must be blocked with carbon deposits. A typical MAP sensor reads 4.5 volts with the key on and the engine off. Once you start the engine, vacuum brings the signal voltage on the MAP to just about 1.4 volts. Hold the engine at 1,000 rpm (it would stall at idle) and energize the EGR solenoid. The engine should start to run roughly immediately. If not, this usually means the EGR solenoid is sticking closed and may flag a code for insufficient flow. The code sets in the small amount of time the solenoid is commanded open, but the ME does not see a change in MAP signal voltage — it should rise to just about 3.0V while the EGR is open. De-energizing the solenoid should return the engine to a normal idle right away. Otherwise, check for a solenoid or valve sticking open.

Coming To A Conclusion

Once the repair is completed on OBD II vehicles you have the choice of clearing the code and running a specific drive cycle to run the monitor tests, or driving the vehicle through multiple drive cycles until the EGR monitor passes at least three times. If you are going to run monitors, remember to make sure the coolant temp does not drop below 80 deg. C, and keep the vehicle speed below 60 mph to prevent getting kicked out of the monitor tests. You can use your Compact III to see if the conditions are met to run the monitor. Select “Measures for initiating fault path tests,†then “EGR Diagnosis†while in the ME control unit and you will see bar graphs indicating engine temperature and rpm conditions that need to be met. Tip: Most of the time the EGR monitor is run while the vehicle and engine are under a steady and long deceleration. Manifold vacuum is at its highest, so it is easier for the ME control unit to determine EGR flow. By running the monitor while driving, you can verify that your repair has addressed the problem.

0 Comments