You need to know the following air/fuel mixture tuning techniques for carburetors if you want to be able to get your customers’ vintage or muscle cars to perform their best on today’s reformulated gasoline, but much of what we’re presenting here will also work on any fuel-injected (with a programmable computer) engine.

Gas is different

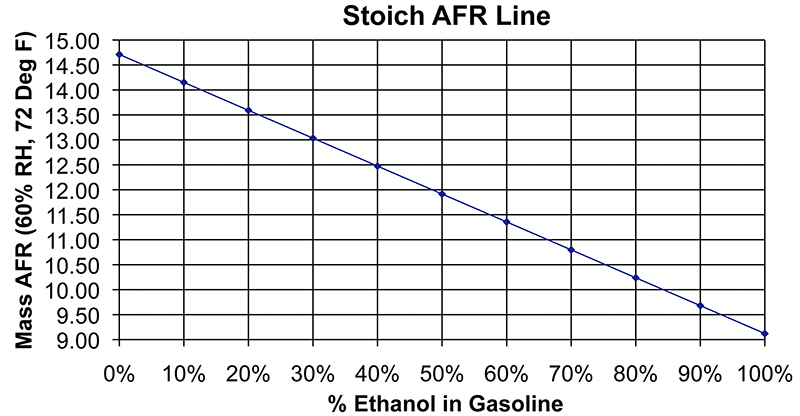

The formulation of gasoline today is very different from the leaded gas of the past because of both political concerns and environmental regulations. These new reformulations are blended for the purposes of producing the lowest possible evaporative emissions and reducing the pollution from the exhaust. In many parts of the country, oxygenates such as ethanol are being added to gasoline in an attempt to reduce both exhaust emissions and our dependence on foreign oil.

Anyone who is concerned about engine performance and reliability needs to keep on top of the ignition and air/fuel mixture tuning changes new gasoline formulations require for maximum engine efficiency. Reformulated gasoline has lower levels of sulfur, benzene, olefins, and reduced vapor pressure. This affects jetting requirements because the burn rate/characteristics and BTU content of the fuel is different from what was available back when the car was new. In short, reformulated fuel can negatively effect the power, fuel efficiency and drivability of an engine by 3 to 5% or more even when the engine has the correct air/fuel mixture and ignition spark timing for every driving condition.

The air/fuel mixture

The leaded gasoline that the engine in a classic or muscle car was designed to use allowed it to perform very well even if the spark timing or the air/fuel mixture was not properly tuned. The same cannot be said for the unleaded reformulated gasoline of today. Unless these two factors are properly tuned, the engine will not perform as it should.

The stoichiometric, or chemically ideal, mixture of air and fuel for an engine running on gasoline is 14.7 to 1 (14.7 lbs. of dry air to one lb. of gasoline). In a perfect world where an engine has this ideal air/fuel mixture, all the energy gasoline and all the oxygen present in the cylinder will be consumed during the combustion process. The burn rate and energy content of this one pound of gasoline, however, will change as the formulation of the gasoline is changed (such as with the addition of ethanol). When you’re tuning a carbureted-equipped engine, a 14.7 to 1 a/f mixture can be too lean because of the operating losses in the induction system due to intake runner and cylinder wall wetting. The design of the intake manifold can also cause the air/fuel mixture to vary from cylinder to cylinder. If any one cylinder has an a/f mixture that’s too lean, it will tend to misfire. Today’s reformulated gasoline may require the use of slightly richer a/f mixtures than were needed in the past.

Tools for reading the air/fuel mixture

The ideal air/fuel ratio an engine needs to produce maximum power and fuel economy, and minimum exhaust emissions can best be calculated in the laboratory with a dynamometer. Since we are working with an engine that’s running on a blend of gasoline that’s different from what it was designed to run on, we have been using the readings from a five-gas exhaust analyzer to determine what air/fuel mixture the engine needs to have to run its best with today’s gasoline.

In the past, tuning a fuel system was considered by many to be a “black art†that seemed to be done more by guess than by science. Back in the days of leaded gasoline, an experienced mechanic could attempt to tune the carburetor’s jetting by reading the color of the spark plug nose. There were a few very good tuners who could read a spark plug and make the proper changes, but most of us were just making an educated guess. Add in the unleaded reformulated gasoline we have today, and the job of reading of a spark plug is almost impossible — little or no color is left on the spark plug insulator. But now you no longer have to guess what the air/fuel mixture is because you can accurately read it with an exhaust gas analyzer and/or a wide-band oxygen sensor-based digital air/fuel meter.

Many automotive repair shops have a exhaust gas analyzer (“smog machineâ€) that can be used to read air/fuel mixture. Or, if you’re in a state such as California that requires dyno-based smog testing, you can read the air/fuel mixture under load. Using a dyno to help in tuning is good, but we always like to read air/fuel mixtures in real world driving conditions. If you don’t have an exhaust gas analyzer, there are several portable five-gas units on the market that are quite affordable, or, for about $400, you can buy a wideband oxygen sensor-based digital air/fuel meter. These modern tuning tools can allow you to observe what air/fuel mixture the engine is getting from the fuel system while the car is being driven at any rpm or load condition.

You should realize, however, that the readings you get from a five-gas exhaust analyzer or a wide-band oxygen sensor-based air/fuel meter are only as accurate as the sample of exhaust is — a smog pump or catalytic converter will cause false a/f mixture readings. We most often use a tailpipe probe to sample the exhaust for the analyzer, or the exhaust clamp from Innovate Motorsports so we can sample the exhaust without drilling any holes in the exhaust system, but either of these will have a dilution problem with pulsating or low flow exhaust. When you want the very best results, look at the content of the exhaust through direct sampling. Sampling the exhaust from a direct port in the exhaust pipe or header(s) gives readings that can actually allow you to observe if you have any fuel distribution problems that are causing the air/fuel mixture to vary from cylinder to cylinder.

Tuning the a/f mix with a five-gas analyzer

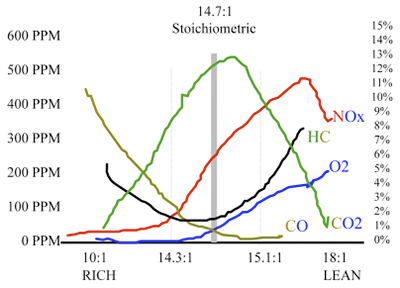

The easiest and most accurate method we’ve found for tuning a carbureted engine’s air/fuel mixture is the use of an infrared exhaust gas analyzer. Its readings indicate the air/fuel mixture, the engine misfire rate and combustion efficiency. The tuner can read what the air/fuel mixture is at any operating condition, such as idle, cruising speeds, or wide open throttle. The HC, CO2 and NOx readings can be used to determine if the ignition timing is correct for maximum power and efficiency.

The exhaust analyzer also allows the part-throttle air/fuel mixture to be checked, which is almost impossible otherwise. It’s important to note that any modifications other than jet changes and other basic adjustments should be done by an expert to avoid damaging the carburetor.

Targets

Starting points for air/fuel mixtures for most mild performance engines are:

Idle:

- 1.0% to 3.0 % CO, or a 14.1-13.4 to 1 air/fuel mixture

Cruise rpm:

- 1.0% CO, or a 14.1 to 1 air/fuel mixture with a mild performance engine

- 1.0% – 3.0% CO or a 14.1-13.4 to 1 air/fuel mixture for an engine with a high performance cam

- Note: A 0% CO or 14.7 to 1 c

- ruise air/fuel mixture is chemically ideal, but most carburetor-equipped engines will suffer misfire and drivability problems when operated that lean.

Power mixture and acceleration:

- 6.6% CO or a 12.5 to 1 air/fuel mixture for a production engine; a high performance engine with improved combustion chamber design, such as a Pro-Stock or a Winston Cup engine, in some cases may be able to use a slightly leaner power mixture of 4% CO or a 13.0 to 1 air/fuel ratio.

What the exhaust gas content indicates

The readings from an infrared exhaust gas analyzer will indicate air/fuel ratio, engine misfire, engine combustion efficiency and excessive combustion chamber heat (detonation) by looking at the following exhaust gases:

- CO (carbon monoxide): This is one of the gases we use to determine the air/fuel ratio. (Note: CO is partially burned fuel.)

- HC (hydrocarbons): The amount of unburned fuel, possibly an indicator of misfire. The best mixture gives you the lowest HC.

- CO2 (carbon dioxide): The product of complete combustion. The best air/fuel mixture gives you the highest CO2 reading. The ideal ignition-timing advance will also create the highest CO2 reading.

- O2 (oxygen): A high O2 reading indicates a lean mixture, possibly due to an exhaust leak or a “hot†cam (Note: when O2 readings are above 2 to 3%, CO readings may be diluted by the extra O2).

- NOx (oxides of nitrogen): A gas created by excessive combustion chamber heat. In many cases, a high NOx reading is related to excessive ignition spark advance. This causes high flame temperatures too early in the combustion process. This increase in NOx can be used as an indicator of excessive combustion temperatures, which can cause a ping or detonation problem that can lead to engine damage.

Wideband tuning

The air/fuel mixture can also be checked with a wideband oxygen sensor installed in the exhaust system. The sensor signal is then read by a digital air/fuel meter. This method determines the air/fuel mixture by looking at the oxygen/unburned combustibles in the exhaust. The readings can be very accurate, but false readings can be created by anything would changes the oxygen or unburned combustible content of the exhaust. These false readings are created when the sensor “sees†the excessive oxygen that can come from a misfire, a supercharged engine’s “blow-through†effect (at lower engine speeds), a high performance camshaft’s valve overlap, or an exhaust leak.

Using a wideband oxygen sensor-based air/fuel meter system requires that you know what air/fuel mixture your engine needs for each driving condition. This data should be available from your engine builder, or you can use an infrared exhaust gas analyzer to help you determine what air/fuel mixture allows your engine to run at its best. An extended range oxygen sensor can read air/fuel mixtures as rich as 9 to 1 and as lean as 19 to 1 (the traditional switching-type oxygen sensor is only accurate at air/fuel mixtures of around 14.7 to 1). This method has the advantage of extremely fast reaction times for the readings, but the accuracy of the reading can be affected by engine misfire, detonation, or exhaust sample dilution.

The set-up that we use is the LM-1 Digital Air/Fuel Meter from Innovate Motorsports. This unit can allow you to sample and record the air/fuel mixture data at a rate of 12 samples per second over a period of up to 44 minutes. Then, you can confirm that the tuning changes are giving the targeted fuel mixture.

Best to use both

You’ll get the best tuning results when you use both the exhaust gas analyzer and the wideband oxygen sensor methods. A wideband meter has the advantage of being in real time, while an exhaust gas analyzer has a response time delay of five to 10 seconds. The exhaust gas analyzer, while slower, has the advantage that it not only reads the oxygen/unburned combustibles, but also allows you to determine:

- the air/fuel mixture by observing the CO reading.

- the engine’s rate of misfire by observing the HC reading.

- the engine’s efficiency by observing the CO2 reading.

- spark knock, detonation or engine ping, which is caused in most cases by overly advanced ignition timing, by observing the NOx reading.

The spark plug color tuning method of days past would only indicate what the average air/fuel mixture was just before you pulled the spark plug.

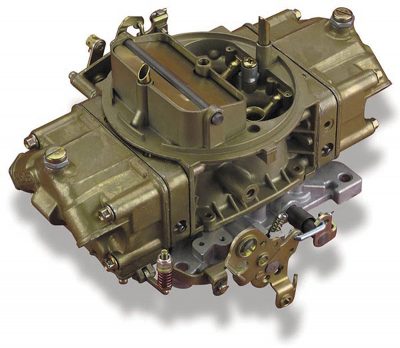

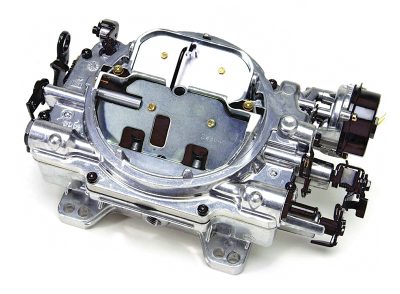

Performance carbs

While original equipment carburetors can be tuned to run quite well, many of our customers want a Holley, Edelbrock or Barry Grant for their cars. Each of these replacement performance carburetor designs has advantages and disadvantages when compared to the others on the market. The Carter-designed AFB and AVS carburetors sold today by Edelbrock as Performer and Thunder carburetors are good, but they’re not the best for a customer who likes to drive his or her car fast around corners (because of the main jet placement and the float bowl design). The Holley and Barry Grant Modular designs are very good, but they do tend to require more maintenance than most others. Our personal preferences dictate that when a customer wants a carburetor with an automatic choke, we recommend a Holley, but when horsepower is the goal, we recommend a Mighty Demon carb from Barry Grant.

The Mighty Demon is great from a tuner’s viewpoint because it has changeable idle-feed restrictor/jets, plus changeable idle and main well air bleeds. These carburetors work quite well with the high-performance air-gap intake manifolds that are becoming very popular.

These manifolds don’t use an exhaust crossover, so there’s no heat to help keep the fuel atomized as it passes through the intake ports on its way to the cylinders. With an air-gap intake manifold, the Mighty Demon does a better job supplying the richer mixtures the engine needs during idle and part throttle modes without having to modify the idle system than any other high performance carburetor we have worked with.

Fuel Delivery Circuits

A carburetor has fuel supply circuits for idle, off idle, cruise/main metering, power and acceleration that are designed to provide the air/fuel mixture the engine needs during all operating conditions. Each of these circuits may need tuning attention.

The idle system of most carburetors has an idle jet/restriction, an ICR (idle channel restriction) and air bleeds that supply the air/fuel mixture to the idle mixture screw(s) and the off-idle transition ports. The ICR limits the air/fuel mixture that is delivered by the off-idle transition ports. These ports provide fuel from the point when the throttle is first opened to when it’s open far enough for the main jets to take over (about 2,500-3,500 rpm). The metering block of a modular-style carburetor such as a Holley model 4150 does not use an ICR because the diameter and taper of the idle well serves the same function.

If the air/fuel mixture is too lean at idle and the idle mixture screws do not provide enough adjustment, the idle jet/restriction may need to be enlarged. If the air/fuel mixture is correct at idle, but lean at 1,000 through 2,500 rpm, the ICR may have to be slightly enlarged to allow more fuel to be delivered at part throttle. A lean condition at part throttle will cause the engine to miss or stumble on light acceleration and 15 to 30 mph light cruise speeds. This lean problem is very common on many original carburetors and most of the performance replacement carburetors we see today. If the air/fuel mixture is too rich at idle and/or part throttle, the idle jet or part throttle idle restriction may be too big and may need to be replaced with a smaller one. Or, you could enlarge the idle system air bleeds.

Carter-designed AFB (Edelbrock Performer) and AVS (Edelbrock Thunder) carburetors often have lean off-idle stumble problems that can be cured by enlarging the ICR on the 500 through 650 CFM units. But this cure often doesn’t work with the 750 and 800 CFM models. Many of the Holley modular carburetors we have tuned have also had some lean off-idle stumble problems, which we fixed by enlarging the idle well in the primary metering block.

Tuning cruise and power mixtures

The power enrichment system used in most domestic carburetors can be either a power valve that’s held closed until engine vacuum drops below its opening point (at which time it richens the air/fuel mixture), or a vacuum-controlled power piston system that moves tapered metering rods out of the main jets, thus causing the air/fuel mixture to become richer as the vacuum drops.

If the engine you are working on is equipped with a power valve, the main jet size is what determines what air/fuel mixture is delivered to the engine at light load/cruise speeds, and the power valve restriction (under the power valve) is the determining factor in how richer the air/fuel mixture will be when the power valve is open. A 6.5 “inch” power valve will be open and supplying the richer air/fuel mixture needed under high power demands anytime the vacuum is below its 6.5 in. Hg opening point.

On the metering rod type, a power piston with a spring under it controls the rods. When vacuum drops below the spring’s opening point, the metering rods will rise, thus effectively enlarging the jet and supplying the richer mixture the power mode requires. You can change the power or cruise mixture by changing the jets, metering rods, or a combination of both.

Tuning the power system opening point can also be done to increase gas mileage. If you make it open at a lower vacuum, it will take more load or throttle opening to get the richer power mixture to kick in. You can change to a power valve that opens at 4.5 inches of vacuum instead of 8.5 inches. With metering rods, the opening point can be modified by changing the power piston spring.

The fuel economy an engine gets will be its best when the air/fuel mixture is at or near 14.7 to 1 (with non-reformulated gasoline), but many carbureted engines don’t perform very well with that lean a blend. We use a five-gas exhaust gas analyzer to find what the ideal mixture is for fuel efficiency. At the ideal a/f mixture, all the O2 in the cylinder will be burned, the lowest amount of engine misfire as indicated by HC will occur, and engine efficiency as shown by CO2 will be at its highest. Experience has shown that the best a/f mixture for gas mileage is just slightly on the rich side of the point where the misfire rate starts to rise from a mix that’s too lean to burn.

Tuning the accelerator pump

Tuning the accelerator pump squirt volume and duration is often done on a trial and error basis to obtain the best throttle response, but a 12.5 to 1 air/fuel mixture is a good place to start. One of the most common complaints we hear from our customers is hesitation on quick acceleration, which is common with many aftermarket performance carburetors. Due to cost-cutting procedures and changes in production materials the accelerator pump duration spring is not as strong as the original that was used when these carburetors were first in production. The cure for Edelbrock Thunder and Performer carburetors is an accelerator pump with a stronger duration spring (Ole’s part #1010). When we’re working on a Holley modular carburetor, we use an accelerator pump upgrade kit that has a stronger duration spring, a 0.031 squirter and a “pink†cam (Ole’s part #1330) that makes the accelerator pump more active.

Road test

Once you’ve gotten the idle, part throttle and cruise air/fuel mixture curves correct, the next step is a road test using a portable infrared exhaust gas analyzer and/or a wideband oxygen sensor. This will allow you to check the cruise speed air/fuel mixture, followed by a check of the power mode a/f ratio under load. You will be able to see what the mixture is during real-world driving conditions, then correct the mixture. A chassis dyno can allow you to tune for a loaded condition, but the airflow conditions into the carburetor on the road can cause the mixtures to change.

If a reading goes too lean at high engine loads, the first thing to do before you change jet size is to check that the fuel pressure. It must stay above five psi at wide-open throttle or the carburetor will starve for fuel. Low fuel pressure could be caused by the fuel pump not having enough volume for the engine’s needs, or the fuel tank vent system may not be letting enough air into the tank to replace the fuel being removed from it. Many replacement gas caps do not vent the gas tank as well as the original did, so you may need to add extra venting to the gas tank.

Once the ignition advance and air/fuel mixture curves are tuned for today’s unleaded reformulated gasoline, the engine should perform as well, or maybe even better, than when the vehicle was new, and you will have a very happy customer!

Resources:

- Barry Grant, Inc. Â www.barrygrant.com

- Bridge Analyzers (exhaust gas analyzers) Â www.bridgeanalyzers.com

- Edelbrock Corporation  www.edelbrock.com

- Holley Performance Products  www.holley.com

- Innovate Motorsports (digital air/fuel meters) www.innovatemotorsports.com

- Ole’s Auto Parts (fuel system and ignition parts)  www.olescarb.com

- OTC/SPX Corporation (exhaust gas analyzers) www.otctools.com

- Renewable Fuels Association

www.ethanolrfa.org/ - Rockett Brand Racing Fuel  http://rockettbrand.com/

- E-mail questions to: infor@rockettbrand.com

by Henry P. Olsen

0 Comments