Servicing continuously variable transmissions can be a scary thing if you don’t have any experience with these belt-driven critters. To help get you started, here’s some basic info on how they operate, which Nissan vehicles are equipped with CVTs and what services you can offer.

Nissan is the leader in the use of continuously variable transmissions (CVTs) – with great success. However, most independent service facilities are not familiar with CVT operation, diagnostics, troubleshooting, service and repair.

If it hasn’t already occurred, a Nissan vehicle equipped with a continuously variable transmission (CVT) may arrive at your shop in need of transmission service. While these belt-driven trannies are extremely durable, any automotive component can be damaged or need some form of maintenance.

Rather than turning away the work because you are not knowledgeable of CVTs, you should begin now to inform yourself of CVT operation, repair and service. The number of CVT-equipped Nissan vehicles on the road is growing by leaps and bounds and will continue to increase.

CVTs are here to stay. Because of their smooth, fuel-efficient operation – especially on smaller vehicles with smaller engines – CVTs have grown in popularity over the last several years. There are over a million vehicles with CVTs on the road in the U.S. and hundreds of thousands are being sold each year. Due to the current trend of downsizing to smaller vehicles with lower fuel costs, CVTs are likely to grow in numbers for at least the next decade or so.

The advantages of CVTs

Automotive engineers list these advantages of CVTs:

- Better fuel economy. The engine rpms stay fairly constant and therefore, operates more efficiently.

- Lower exhaust emissions. Lower engine speeds emit less exhaust gasses.

- Simplicity. Because CVTs have fewer moving parts than standard gear-driven automatic transmissions, they are less expensive and easier to build and repair.

A brief history of CVTs

The concept of a continuously variable transmission may be fairly new to the automotive industry, but the idea is over 500 years old. In1490, Leonardo Da Vinci sketched plans of a stepless power transmission device. In 1939, inventor Adiel Y. Dodge of South Bend, Indiana, was granted a U. S. patent for his “Variable Speed Transmission†but, the complicated contraption was never produced because the automobile industry was already perfecting the gear-based automatic transmission.

More recently, Van Doorne, a Dutch company, created the first viable automotive CVT. In 1958, the system was first marketed in a very small car, the DAF 600, which was mildly popular in Western Europe, but never imported to North America. The system used reinforced rubber belts, which weren’t very durable and were exposed to the weather, further minimizing their life span.

The modern CVT was born in the 1990s, when Nissan developed its own CVT, which was designed for higher torque and included a torque converter. Later, in 1999, Nissan created a separate company called TransTechnology, Ltd. By 2002, the company was renamed Jatco (Japanese Automatic Transmission Company) Ltd, and – as they say – the rest is history. Because of the relationship, Nissan is Jatco’s largest customer and the largest user of CVTs.

CVT Operation

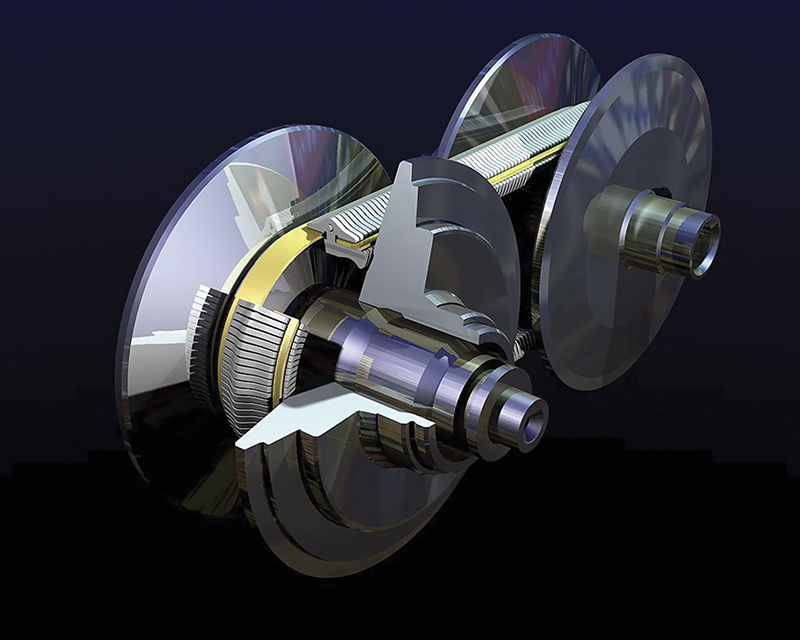

When the drive (driving) pulley actuates apart and the driven pulley actuates closer together, a low gear ratio results.

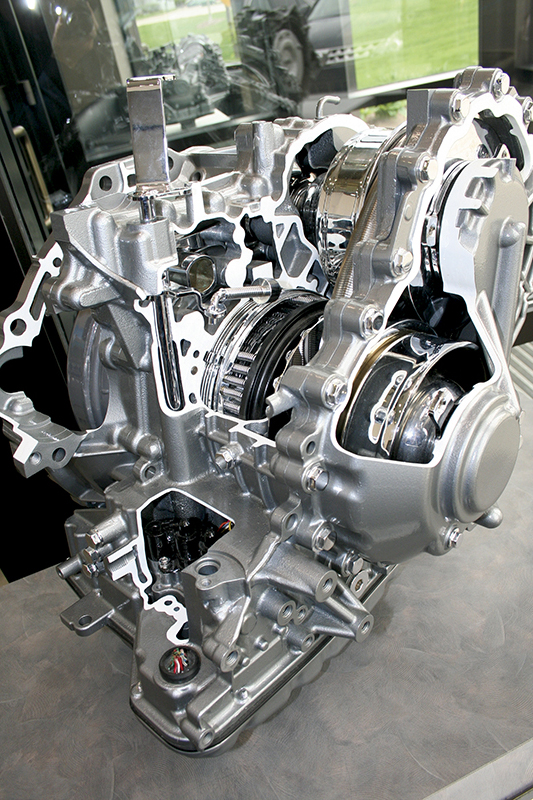

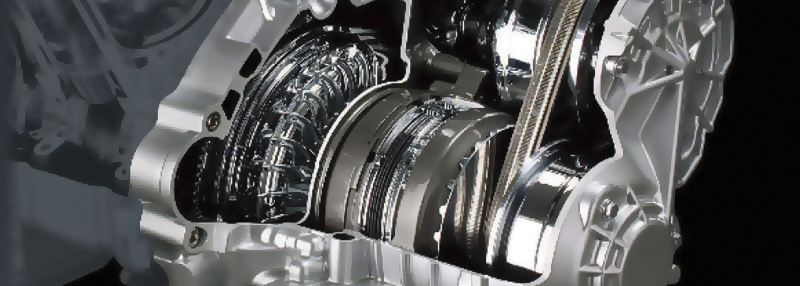

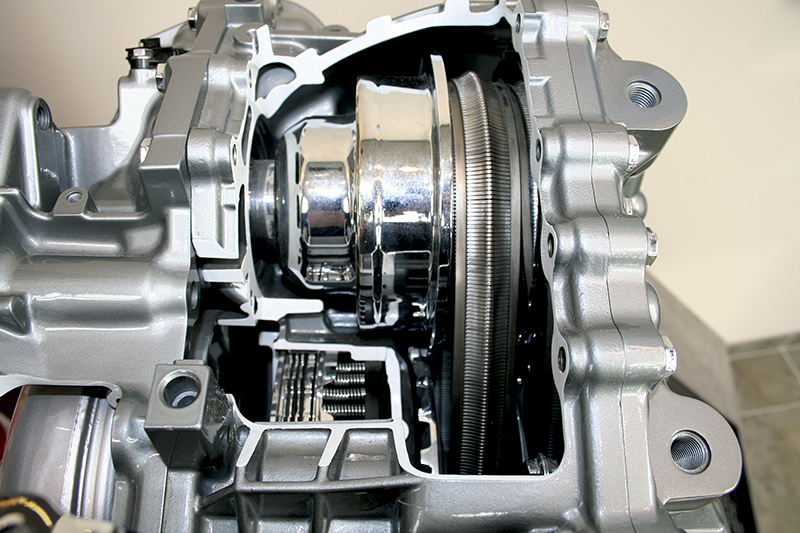

The type of CVT used in Nissan vehicles operates on the “two pulleys and a belt†principle. Each pulley consists of two conical discs, facing each other, mounted on a single axle. A transmission control unit responds to sensors and other input commands to activate an actuator system, which moves the discs closer together or farther apart.

The system contains two pulleys. One pulley is the input or “driving†pulley, powered by the engine; the other pulley is the output or “driven†pulley that powers the wheels. The torque transfer belt rides in the V-notch of both pulleys.

The two pulleys are in a constant state of changing from one ratio to another, actuated by the vehicle’s needs. As one pulley narrows, the other conversely widens, changing the ratio – thus the name: continuously variable transmission.

If the driving pulley discs move apart, the belt drops lower in the pulley notch (and higher in the driven pulley notch as the pulley discs move closer together) the result is a lower “gear†with more power or torque. Conversely, if the driving pulley discs are drawn closer together, the belt rides higher in the pulley notch (and lower in the driven pulley notch as the pulley discs move apart) the result is a higher “gear†with more speed.

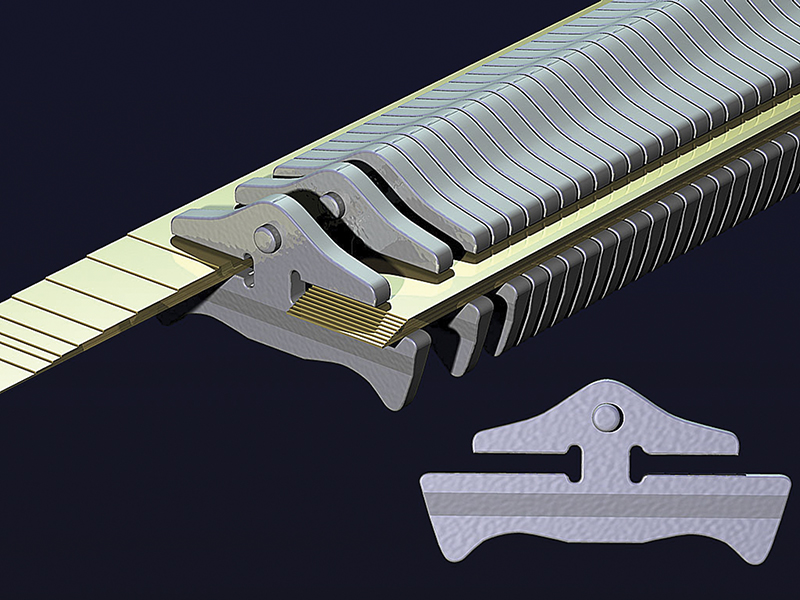

A sturdy belt transfers the power. It consists of hundreds of tiny metal plates, held together by high-strength steel bands. The key to its strength and durability is that it pushes, rather than pulls – like rubber-based automotive accessory drive belts.

Transmission operation is monitored by sensors and controlled by an electronic powertrain module to perform at optimum efficiency. Whether the vehicle needs speed for passing, or power for climbing a hill, the CVT delivers the correct ratio smoothly.

Nissan models equipped with CVTs

In 2003, Nissan launched its popular Murano model in the U.S. with a CVT. No less than seven Nissan models are now equipped with the company’s XTronic belt boxes:

- Murano   2003-2009

- Altima   2007-2009

- Maxima   2007-2009

- Sentra   2007-2009

- Versa   2007-2009

- Rogue   2008-2009

- Cube   2009

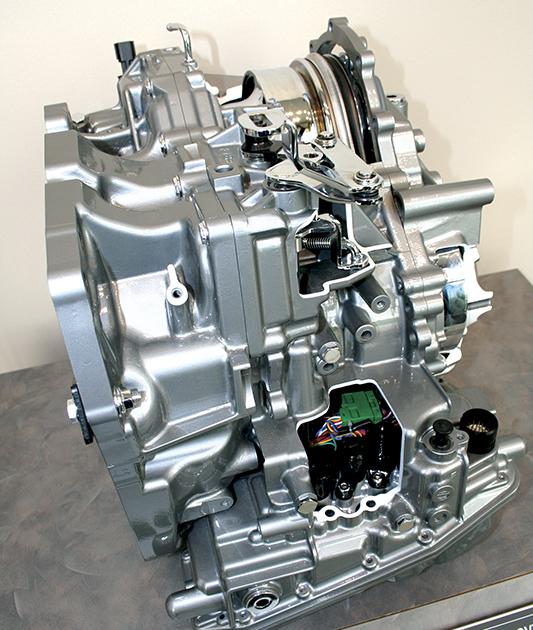

Three CVT units

Three basic CVT units are used on Nissan vehicles. They differ in size and torque transfer ability, based on the displacement and power output of the engines to which they’re mated:

The JF009E (CVT1) is designed for vehicles up to 1.8L. It’s a light, compact design with a wide gear ratio range for acceleration, performance and low fuel consumption. This unit is found on 2007-2009 Versa and 2009 Cube models.

The JF011E (CVT2) is for medium-sized vehicles up to 2.5L. It’s also is a light, compact design, but with wider gear ratio range for performance and fuel efficiency. It’s designed to handle the increased torque. This unit is used on Sentra, Rogue and Altima 2.5L models.

Jatco’s JF010E (CVT3) is used with larger displacement engines, such as those found on Nissan’s Murano, Maxima and Altima 3.5L models.

The top-of-the-line JF010E (CVT3) is beefier, with high torque capacity to handle vehicles up to 3.5L models, where hefty horsepower exists. Look for it on Murano, Maxima and Altima 3.5L models.

Servicing CVTs

Most of the service procedures on CVTs are performed the same as on any other automatic transmission. The first thing you’ll want to do is read any diagnostic trouble codes, then obtain the correct service information for the vehicle and proceed with service. Here’s a list of services you can perform, just as you would with any other automatic transmission malfunction:

- Diagnostics, clearing of diagnostic trouble codes (DTCs)

- Re-flash software

- Replacement of sensors or actuators

- Replacement of leaking gaskets or seals

- Fluid change or refill

- Service wiring and connectors

- Valve body service

If your shop has full transmission skills and the proper tools, repairing or replacing clutch packs, torque converters or gears is certainly an option. Perhaps the toughest procedure on a CVT is totally breaking down the unit to repair or replace the belt or drive discs. At this point, a remanufactured trans may be your best option – and may be much cheaper. A reman tranny will also have a warranty. Another option is a salvaged unit, but that can be very risky.

Diagnostics

Full diagnostic and troubleshooting procedures for each Nissan model are available on the Nissan TechInfo website at http://www.nissan-techinfo.com. While other sources of service information may have some or most information, only the Nissan TechInfo site will have all up-to-date information and bulletins.

Parts

As with any other sophisticated component, using the correct parts is of utmost importance. Genuine Nissan Parts are readily and quickly available from your local Nissan & Infiniti Wholesale Program Dealer. You can also obtain parts information via the Nissan Parts website at www.Nissan4Parts.com.

Special Tools

Having the correct tools to do the job properly cannot be overstated. Using an improper or homemade tool may jeopardize the operation of the transmission or cause failure of the unit. You can obtain Nissan Tech-Mate Special Service Tools at www.nissantechmate.com, or call 800-662-2001.

Just because you haven’t serviced a CVT before, you shouldn’t be afraid of them. If you want CVT business in the future, you’re going to have to start somewhere. It may as well be with the next CVT-equipped vehicle that comes through your door.

0 Comments