New vehicle construction techniques mean new procedures in collision repair. You must maintain the integrity of the body/chassis to Mercedes-Benz standards in case of any following accidents. Here’s one way you’re going to get that job done.

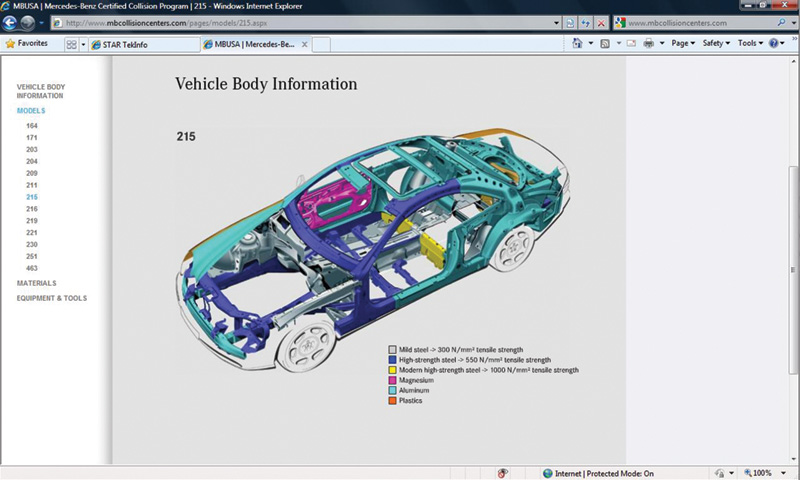

Being a Mercedes-Benz Collision Center gets you access to the website. This information is vital to making the proper repair. Here you can see the different materials used in a 215 chassis.

Mercedes-Benz is committed to safety in more than just its new vehicles. These examples of automotive perfection have always been durable, reliable, and beautiful, and it’s your job to keep them that way. When performing collision work, you have to look deeper than panel straightening and the perfect paint job. The chassis must be prepared for a possible second strike. It must perform the same way as it did the first time. You may attribute it to government mpg regulations requiring lighter vehicles, or just to Mercedes-Benz engineering prowess, but the bodies are getting lighter and stronger every model year. This is sometimes achieved by the use of lighter materials such as aluminum and magnesium. Also, to maintain crash strength, several different mild and high-tensile strength steels are employed. These are known as “hybrid†construction vehicles.

While there are advantages to this kind of construction, it does mean new work procedures for you. These different materials cannot be welded together. You must learn how to use a new and stronger method of securing panels: chemical bonding, which is an excellent alternative where welding is not possible. It also allows you to secure non-structural panels in “blind spot†areas where mechanical fasteners cannot reach. Mercedes-Benz requires a combination of riveting and chemically bonding panels to maintain chassis strength. What can we do to properly repair these well-engineered machines? Training information is available through Mercedes Benz. For more information, please contact Mr. Mark Allen, mark.allen@mbusa.com.

These are the structural rivets you need to attach modern high strength panels. They are available at your Mercedes-Benz dealer. Allow the parts department to help you pick out the right rivet when purchasing collision repair panels.

The first step in any collision repair is a visit to the Mercedes-Benz collision repair site, www.mbcollisioncenters.com. Take a look at the “Models†area to view the construction materials of the vehicle at hand. The last thing you want to do is to start cutting the inner door panel of a 215 chassis only to find out it is magnesium. When magnesium ignites, it gives off a high-intensity light that is blinding, and can lead to many dangerous shop situations. Always know the composition of what you are cutting into. While on the website, look at the area of the crash damage and determine what metals or plastics you are going to be working with. As you browse through each material, you are instructed as to the proper methods of attaching them. For instance, mild steel can be MIG, MIG brazed, spot welded, or rivet/bonded.

Clean down to the metal for bonded surfaces, but do not take off the corrosion-inhibiting material (primer). It is just not necessary. Be careful about cross-contamination between aluminum and steel particles while cleaning. Keep both of these metals apart in the work area.

Other materials such as magnesium should never be worked, and are replaced as an entire component. Aluminum cannot be resistance welded, but can be safely MIG brazed, MIG welded, and riveted/bonded. When working with aluminum, remember that its dust can be explosive. Proper ventilation is necessary to remove the particles from the air. If you’re going to working with this metal, you must avoid any cross-contamination with other metals. The reaction between aluminum dust and steel dust that occurs because they are dissimilar metals can lead to corrosion under the primer and paint. It is recommended that you have two different areas and two different sets of tools to prevent this cross-contamination. Where two different metals are attached to each other is where bonding/riveting shines. When welding, you may deform the metal. Riveting/bonding doesn’t involve heat, so that won’t happen. Corrosion protection is another benefit, if proper procedures are followed.

This kit is also available at your Mercedes-Benz parts supplier. It comes with all the necessary components except the applicator gun, which is available separately. With bonding agents, rivets, repair panels, and Startekinfo, you are good to go!

When fastening panels together with either welding or riveting, you must use the proper fasteners. When riveting aluminum, you should use aluminum rivets, and steel rivets for steel. Mercedes-Benz makes extensive use of high-strength steels in its vehicles, and therefore requires high-strength rivets. All of these materials are available through your Mercedes-Benz parts supplier, who can advise you when you are ordering replacement panels as to what rivets and bonding agents are recommended. If you are using an aftermarket supplier, you will need to ask questions such as, “Are the rivets strong enough to support modern high-strength steels?†and hope that you get a straight answer. There is no point in using rivets that the panels will outperform in the event of another accident. Obviously, when dealing with high-strength rivets, you may have to upgrade your rivet gun to make sure it will handle the additional stress.

Just as areas where resistance spot welds are made need to be clean, so do places where bonding is done. But if you grind the panel down to bare metal, you’ll remove all of the corrosion inhibitor. So, don’t take off too much, only what you need to attach the panels together. You want the bonding adhesive to attach to the metal, not a painted surface.

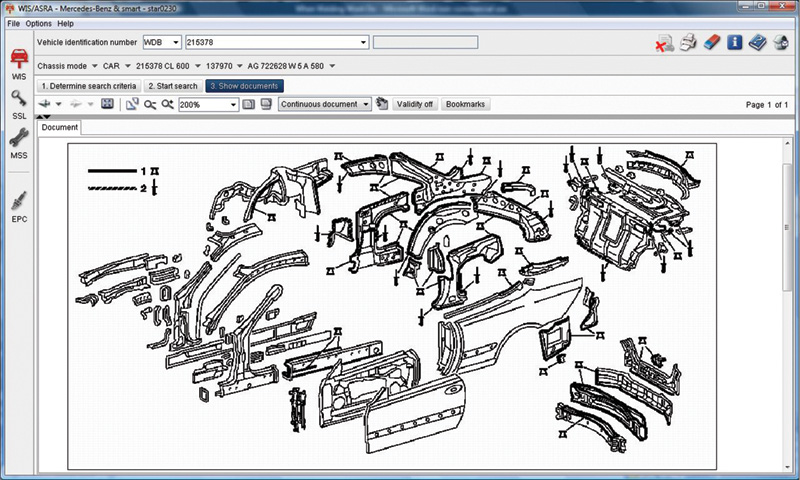

Drill out rivet holes according to the work procedures outlined in WIS (Workshop Information Systems). You can access WIS through a paid subscription to www.startekinfo.com. All collision repair procedures are included, as well as mechanical and electrical repair information. When drilling out holes, try to stay away from areas that were already welded since the metal is weaker there. The quantity of rivets used is just as important as the quality. Chamfer each hole to insure the rivet will compress the panels together freely. Size up the new panel’s proper position with the panel it will be attached to, but do not secure it just yet. Check gaps and measurements before the final assembly.

Now that you have done the prep work, you can start the assembly procedure. Begin by applying the bonding agent. Mercedes-Benz has kits available for this procedure. Squeeze half an inch to an inch of the two-part adhesive out of the tube. Now, use the static mixer, which forces the two separate parts together and mixes them evenly. This is known as “equalizing†the mixture. This helps the adhesive to dry evenly with uniform strength. Apply a 10 to 12 millimeter bead to the two panels being joined. Clamp the panels in their proper positions. If you need to reposition the panel, do not lift the panel and reapply it. This separates the bonding material and may allow for air bubbles. Instead, slide the panel into its proper position. Once it’s in place, remove all excess material. You may find that the adhesive is getting warm as the chemical reaction takes place. This is normal. After one hour, most bonding agents become workable, but they may take four to 24 hours to fully cure. You can now install the rivets. Be sure to fully cover them to inhibit corrosion. Next, work the area to prepare for undercoat and paint.

Finally

With new vehicles come new techniques. You have access to all the important tools to help you do collision repairs properly, especially www.startekinfo.com, and related collision websites. Also, your Mercedes-Benz parts supplier is there to assist you in performing safe and profitable repairs. Now, that’s just good business.

0 Comments