Harmful emissions come from more than the tailpipe. Raw fuel evaporating from the tank pollutes our atmosphere, too. OBD II regulations make this a monitored system, so let’s help seal the deal.

The canister stores fuel vapors so they can be fed into the intake and burned. The three lines pictured here go to the canister purge solenoid, the fuel tank/OBVR valve, and the fuel-cut solenoid. Smoke testing works well for troubleshooting, but. use only a smoke machine designed for EVAP use so you do not over-pressurize the system.

When most of us think of automotive air pollution, we think of post-combustion emissions. We often don’t think of the raw hydrocarbon emissions that can escape from fuel storage systems. As a car is being driven, it obviously burns fuel. The level in the tank drops, and vapors fill the empty volume. Unused fuel is heated on its round trip to the engine, so it increases the temperature and vapor pressure inside the tank. These vapors have to go somewhere, preferably not into the atmosphere. The Evaporative Emissions System (EVAP) stores and mixes fuel vapors with fresh air, and supplies this mixture to the engine to be burned. EVAP control has been mandated since 1971, and in 1996 OBD-II regulations required it to be a “monitored†system. This means that as the vehicle is being driven, the ECM (Engine Control Module) watches and tests to make sure the system is properly sealed and not leaking raw fuel into the environment.

The canister purge solenoid is typically located on the driver’s side of the engine compartment. Clicking can be heard as it purges. If a valve sticks open, smoke testing will not find the problem unless you disconnect the line leading to the intake.

When the system is functioning properly, you wouldn’t even notice it’s there. The only time you have to diagnose a problem is when the MIL (Malfunction Indicator Lamp) comes on, and a code in the P044X range is present. Another possible symptom is the customer having problems refueling. When the tank cannot vent, vapor pressure builds up inside. This continuously pops off the pressure-relief valve in the gas pump that is supposed to prevent over-filling making it very difficult to refuel the vehicle. When dealing with a MIL, a surefire indication that you have an EVAP code is an illuminated low-fuel reserve light even though the gauge is telling you that the fuel level is greater than 1/8 of a tank. You can pull codes for a small leak, large leak, incorrect flow, or isolated component failure.

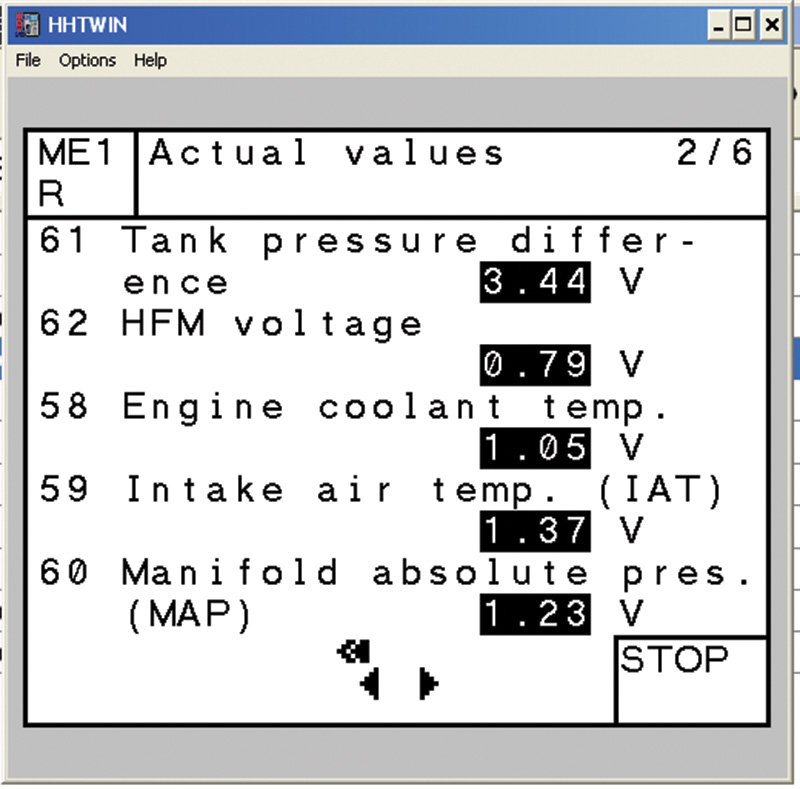

The top line of data on this SDS shows that the FTP signal voltage is just below 3.5V at atmospheric pressure. When the vent cut-off solenoid is energized, the signal voltage will drop while the system tests for leaks.

The fuel tank vents vapors to a charcoal canister. This canister also picks up vapors during refueling through the Onboard Refueling Vapor Recovery valve (ORVR). The stored air/fuel vapor combination is sent to the engine compartment and passes through the canister purge solenoid into the intake to be burned. The PCM will only purge at temperatures above 70 deg. C, and after the engine has been running for at least two minutes.

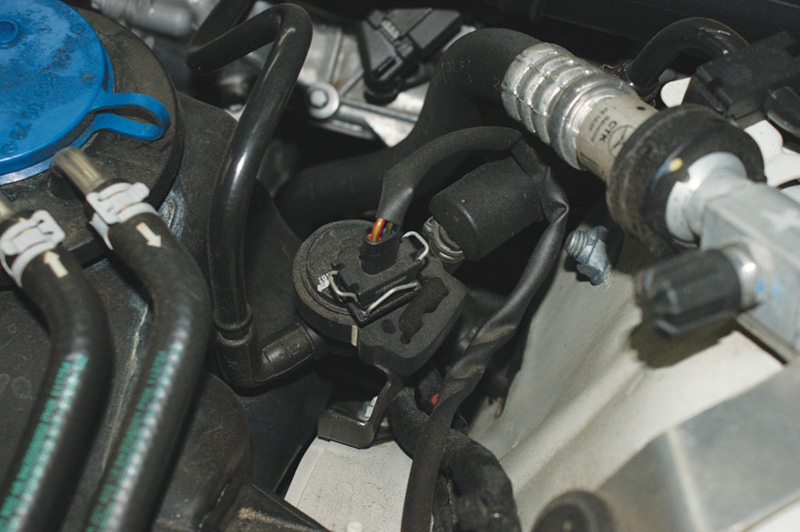

The vent cut-off solenoid normally allows air into the canister, but can be closed for a leak diagnosis. Contaminants can get into the solenoid and cause it to stick open or closed. This is why it is tucked away in the body of this ’98 129 chassis.

The EVAP system is monitored using the vacuum-decay method to determine if there is a leak in the system. Normally, the vent cut-off solenoid is open allowing fresh air into the charcoal canister to mix with fuel vapors. When the purge solenoid opens, it allows this mixture to be drawn into the intake. To see if the system is leaking, the PCM closes the vent solenoid and opens the purge solenoid. Now, vacuum is being generated in the EVAP system, and is measured by the FTP (Fuel Tank Pressure) sensor. It’s just like a MAP sensor for the EVAP. With vacuum present, the FTP signal voltage drops. The computer then closes the purge solenoid, trapping the vacuum.

If the vacuum holds for approximately 30 seconds, the system gets a passing grade. If it doesn’t, the FTP signal voltage will stay high indicating there is a leak in the system. When testing EVAP. monitor the signal voltage of the FTP. With the gas cap removed, you would normally see about 3.5 volts. With the purge commanded open and the vent solenoid closed this signal voltage can drop to under .5V. Then, unplug the purge solenoid. The vacuum should stay trapped in the system and the voltage should remain low. If there is a leak, you will see the voltage increase over time.

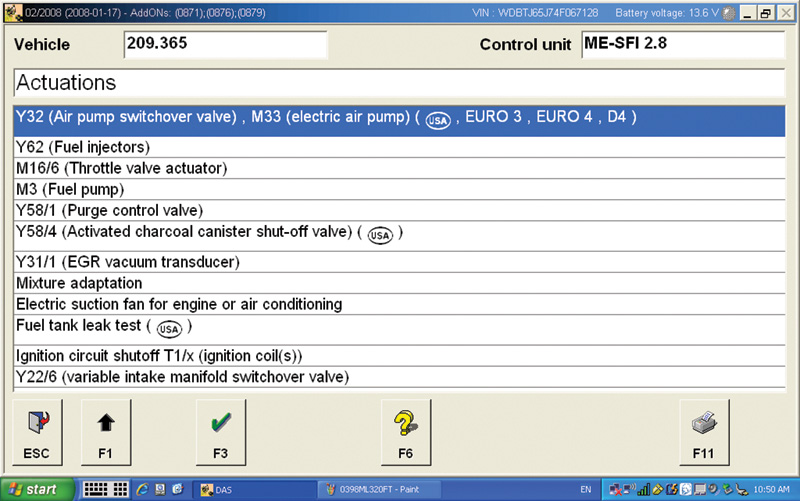

As well as being able to activate individual components such as the purge and vent solenoids (lines 5 & 6 from the top), you can also run the Fuel Tank Leak Test (line 10 from the top) to see if the problem is present, or to check your work.

If you’re going to smoke-test the system, you must do it from several points. Some canisters have check valves that will not allow positive pressure to pass. On these, seal off the ports and apply a vacuum to test for leaks. You can also test purge and vent cut-off solenoids the same way. With the use of SDS (available for lease from Mercedes-Benz) you can run this monitored test and observe the results right on the scan tool. In the event that you have not invested in an SDS, you can still perform step-by-step testing, but you will have to drive the vehicle to run the monitor to test your work.

Knowing how a system works is half the battle in any diagnosis. When dealing with OBD II codes in the range of P044X, you will be able to test the system the same way the engine management system does and find the solution quickly. A cost-effective and accurate diagnosis is what you and your customer are both looking for.

0 Comments