Diagnosing HID headlight failure requires more than just the part number of the bulb. We’ll cover the advanced systems involved in HID headlight operation and beam control, as well as some logical diagnostic strategies that may help in catching intermittent or difficult problems.

It should go without saying that a vehicle’s headlights are one of the most important systems, but who ever thinks of them until they’re burned out? A car’s headlights are often forgotten until they aren’t working, yet they literally show us the way at night. They’re also responsible for signaling other drivers as well as increasing visibility both at night and during the day. That’s why police require their operation, and why Nissan strives to improve their function. Enter Nissan’s High Intensity Discharge (HID) headlights: greatly improved luminosity and longevity over conventional head lights.

With great power comes great responsibility

First and foremost, safety precautions must be observed when diagnosing and repairing Nissan HID lights. It takes nearly 20,000 volts to produce the initial spark required to illuminate the bulb – that’s quite a zap! Also, the bulbs are quartz glass and are under high pressure when the gas inside is excited. Be sure to diligently follow all appropriate safety guidelines in the vehicle’s repair manual, and properly dispose of failed HID bulbs according to appropriate laws concerning mercury waste handling.

Many technicians are confused about some new automotive technologies, but this article should eliminate the mystery surrounding Nissan’s HID headlight systems and prepare you for the next “standard option†on your customers’ cars. Currently, only luxury or performance vehicles come equipped with HID headlights, but this will change in time as the industry costs associated with their production decreases. Will you be ready to diagnose HID headlight failure?

Why HID?

Nissan’s Xenon HID headlights produce both better quality and quantity of light over the standard tungsten-halogen bulb found in the majority of vehicles. When fully warmed up, a Xenon bulb can produce more than 2800 lumens of light that actually looks more like daylight. The HID bulb also maintains this output at a mere 35 watts. Nissan’s HID bulbs are more efficient when compared with typical halogen bulbs that produce less than 1400 lumens using nearly 80 watts. Lastly, because the HID bulb does not

contain a metal filament, it does not decompose as readily as a standard halogen bulb, and therefore enjoys a longer, brighter life.

HID headlights don’t just “turn on†like standard halogen headlights because they do not produce light in the same manner. A typical halogen lamp uses applied voltage to drive current through a filament causing it to glow and emit light. Aside from a power source, the halogen bulb does not require any additional components to operate. An HID bulb does not contain a filament, and instead produces light by energizing two electrodes within an interior tube containing pressurized gas and a metallic compound that vaporizes, mixes with the gas, and begins to glow. The “filament†in a Nissan HID bulb is a glowing bridge of plasma whose discharge is light and heat. Both the gas and the metal compound are engineered in such a way to produce the recognizable blue-white light typical of HID systems.

What happens when the switch is flicked

A Nissan HID headlight operates in three phases. First, a huge initial voltage is required to force the gas to ionize within the inner tube and create an electrical arc: the path for current to flow and generate heat. A resistor ballast and control unit produce the large necessary ignition voltage. Exercise extreme caution when turning on the bulb as this ignition phase generates more than 20,000 volts! Treat an HID headlight and its ballast like a primary/secondary ignition system. Nissan’s Xenon HID bulbs will emit light from the arc during this primary phase, but it may appear to be dim, to flicker, or to be a different color. This is normal, and will be fixed by the second phase of the headlight operation.

After initial spark, the HID control unit will intentionally supply extra power to the bulb so the arc within the inner bulb tube generates more heat. At the appropriate temperature, the small amount of metal compound within the bulb will vaporize, mix with the Xenon gas, and stabilize at the correct color. Simultaneously, the heat reduces resistance to current flow across the plasma arc between the two electrodes. The HID control unit detects this reduction and will cease providing excessive power so thebulb enters the stable third phase.

The third and final phase of an HID system is the continual operation stage, during which the control unit provides constant voltage to ensure normal, flicker-free headlight output. Nissan HID bulbs will require between 40 and 90 volts to maintain output, depending upon the bulb style. It is typically during this phase that a customer will experience the first indication of failure. A dying HID bulb will drastically dim, the light may begin blinking, or the color of the light will become reddish. It is important to note that Nissan discourages frequent on-off operation of HID headlights because it will shorten the life of the bulbs. Furthermore, a customer may complain of a failed headlight, but in reality they may have attempted to cycle them too rapidly after a short errand. If the metal compound within the bulb has not re-crystallized, the light will fail to illuminate and the bulb must rest 10-15 minutes before re-ignition.

Anatomy of a headlight

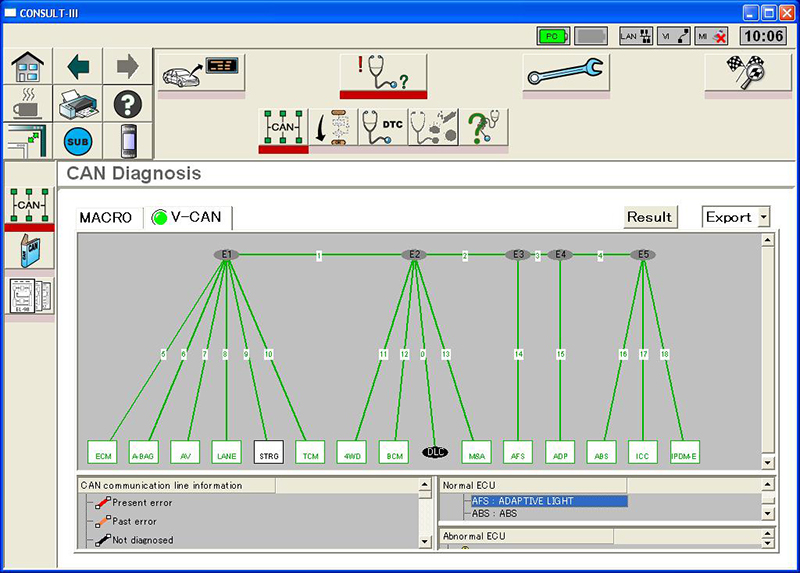

The Consult III can eliminate some diagnostic legwork by ruling out malfunction on the CAN line or the relays.

In order to diagnose dead HID headlights, it’s critical to understand the roles of and interactions between the various systems involved in their operation. All of Nissan’s HID headlight setups will contain the following components: combination switch, fuse, HI and LO beam relays, bulb control unit, combination lamp assembly and bulb.

Ensure that the combination switch is operational and the headlight fusible links are intact before proceeding with diagnosis! Start with the combination switch, which commands the body control module (BCM) over the CAN communications line to activate the headlight relays within the Intelligent Power Distribution Module Engine Room (IPDM E/R — the under hood fuse box). A failure among these devices or their wiring may result in both headlights being inoperative in HI, LO or both modes.

The Nissan Consult III scan tool provides a self-diagnosis program for all exterior lighting systems. Under the IPDM E/R active test section, choose exterior lighting. This will guarantee all relays are in place and operational, and that the CAN communications lines are responsive between the relevant exterior lighting systems and the driver controls.

Once the headlight relay within the IPDM E/R is engaged, the control unit for each side charges and then ignites the bulb. Nissan considers it normal behavior if the left or right headlight illuminates noticeably later than the other side; it does not imply that the lagging bulb is at end of life or that the control unit is going bad. However, if one side fails to illuminate at all during this step, which is the most common symptom, it could indicate a burned out HID bulb or another component.

Diagnosing HID problems

A vehicle that has one headlight out consistently can be logically diagnosed. Confirm that all relays, CAN lines and fuses are working as mentioned in the previous paragraphs. For example, a customer’s 2009 Nissan 370z only has its right headlight operational at all times. First, swap the current HID bulbs and recheck: if the left headlight is now operational, we can condemn the bulb itself and recommend replacement. If after swapping the bulbs, the right headlight remains operational, we can condemn the left-side control unit or the combination lamp assembly itself. Finish diagnosis by swapping both control units. If the left light remains out after moving control units, the lamp assembly is bad.

A common customer complaint is that one headlight will intermittently flicker and fail while driving. Almost always, customers will discover that cycling the headlights off and on tends to bring back the once-dead headlight. As mentioned before, frequent cycling of HID bulbs can cause premature failure so try to discourage this! If one headlight tends to fail while driving, it can be due to a malfunctioning control unit or a bulb exhibiting end-of-life symptoms. A similar customer complaint may be that one headlight will flicker for a while prior to stabilizing or going dark. Any time during the 3rd phase of the bulb operation, if the control unit fails to provide constant alternating current, the arc within the bulb will flicker. Likewise, as a bulb ages, the gas, metal salts, and the electrodes will eventually deteriorate and stop working.

Verify the intermittent failure before proceeding with the above-outlined logical diagnosis. More often than not, a customer’s “I’m pretty sure it’s the left one that goes out†will result in a come-back if you take their word for it. When dealing with very expensive bulbs and control units, take the time to verify the complaint! Use a jumper pack to support the battery while you wait for one headlight to fail.

Blinded by the light!

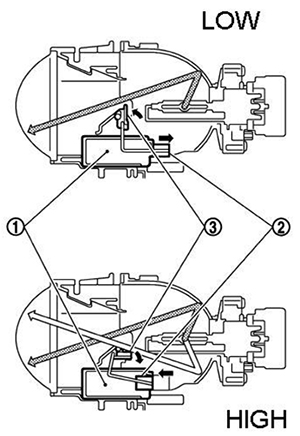

A single HID bulb can provide both HI and LO beams using a mobile valve shade (3), moved by an actuator rod (2) controlled by the high beam solenoid (1).

Due to the increased brightness of Nissan’s Xenon headlights, some vehicles are equipped with systems to control the beam in sophisticated ways. The most basic HID headlight will use a bulb coated with opaque material that shapes the beam when reflected against the lamp housing. Headlights that use a projection lens housing to focus the beam will be equipped with uncoated bulbs.

North America does not currently have any regulations to reduce glare by requiring leveling or advanced aiming systems. Currently, standard headlight housing aiming techniques are used to reduce glare, but Nissan employs electronic leveling methods as well as an active Adaptive Front-Lighting System (AFS). While successful in reducing glare, AFS adds an additional layer of complexity to HID headlight diagnosis.

In some combination lamp assemblies, a single HID bulb provides both high and low beam functionality. This is achieved by physically redirecting the bulb output against a different reflective surface within the lamp assembly. The redirection occurs when the high beam relay is switched and then energizes a magnetic solenoid within the lamp assembly. The high beam solenoid actuates a pushrod and moves the mobile valve shade that then redirects the beam. In systems like these, a customer may complain that one side’s high beam is out, but this is not the fault of the bulb. If only one high beam works, verify that the high beam solenoid for the inoperative side is receiving a signal from the IPDM E/R HI relay. The default position for the mobile valve shade is down – in the low beam position. A failed high beam solenoid or mobile valve shade will require replacement of the combination lamp assembly.

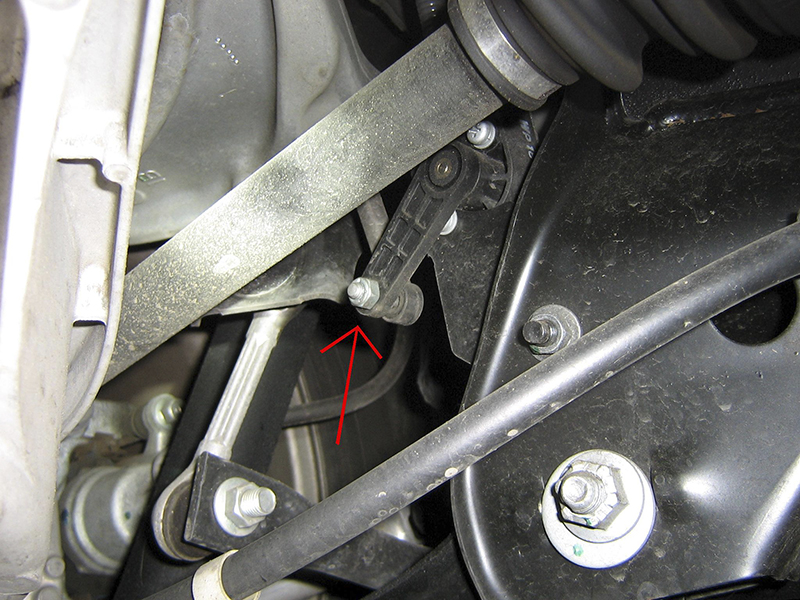

Some Nissan vehicles employ halogen bulbs for high beam functionality only. This allows for usage of an HID bulb behind a projection lens as well as active AFS. For example, the 2008 Infiniti EX35 uses Xenon HID bulbs in a projection lens set up for its low beams. The vehicle is also equipped with AFS, which allows for the front projector lenses to swivel as the steering wheel is turned dependent upon vehicle speed. The EX35 also comes equipped with a height sensor attached to the rear control arm that is responsible for detecting the pitch of the vehicle. The height sensor allows the BCM to command the AFS control unit to automatically aim the headlights lower, and reduce the perceived glare by oncoming vehicles.

DTCs for headlights? What’s next, headlight fluid?

The swivel motor position sensor, the steering angle sensor, and the vehicle height sensor all report information to the BCM. If there is an inconsistency, the vehicle will store a DTC relevant to the sensor’s system. The AFS OFF dash indicator bulb will illuminate in the event of failure, or if the driver has deliberately disabled AFS with the dash switch. The combination lamp swivel motor engages when the steering wheel has gone beyond 20 degrees from center, up to 90 degrees maximum as reported by the steering angle sensor in the column. The left swivel actuator only works when the vehicle speed is greater than 15.5 mph, but the right swivel will work at all speeds.

Headlight aim will be automatically adjusted by the AFS control unit based on input from the height sensor and how that signal differs from preset aim. The height sensor reference position is calibrated with the vehicle unloaded. After replacement of the sensor or the control arm, it is necessary to perform a relearn procedure using the Consult III. According to Nissan, adjusted axis position may differ from preset position despite normal auto aiming functionality if the suspension is worn.

Staying knowledgeable about modern vehicles is critical in an automotive world that is technologically advanced, and where changing out a headlight is not as simple as it used to be.

Always refer to the correct lighting systems service information for the vehicle you are servicing. Log onto the Nissan or Infiniti Service Information websites at www.nissan-techinfo.com or www.infiniti-techinfo.com for the specific information.

0 Comments