NOx failure without a MIL is not very common on newer Nissan and Infiniti cars, but older vehicles still have this type of emissions failure.

Do you remember the last time you had to diagnose a NOx failure? It may have been a while for some of us. Newer cars almost always develop a fault code long before they fail a tailpipe test, but Nissan cars don’t wear out so easily, and there are many older models still serving as daily drivers.

Some “fresher†technicians may have never encountered a NOx failure, and when you’re not familiar with the potential causes of the failure and efficient NOx diagnostic methods, finding the problem can be a real pain. This article serves as an intro to NOx for the uninitiated, a refresher for those who are out of practice, or perhaps just edification for its own sake for those in states without emissions programs.

What NOx is and why it’s bad

NOx (nitrogen oxides) is a term used to describe these environmentally harmful nitrogen/oxygen molecules:

- NO (nitrogen monoxide)

- And NO2 (nitrogen dioxide)

Unlike N2O (nitrous oxide), they’re no laughing matter. Nitrogen oxides cause smog, cancer, acid rain, and respiratory ailments. Most NOx in the atmosphere is generated by human activity, and the largest single human generated source of NOx is transportation: cars, trucks, buses, etc.

There’s no point in feeling vaguely guilty every time you climb behind the wheel. We can’t function without transportation, and advances in technology have greatly reduced vehicle emissions. Every new generation of vehicles pollutes less than the last. The U.S. Environmental Protection Agency (EPA) sets new goals and Nissan engineers find innovative ways to exceed them, such as the new Nissan Leaf; the first fully electric zero emission vehicle available at an accessible price. What we can do is keep older cars functioning properly, including maintenance and repair of emissions systems.

How NOx is generated

Our atmosphere is composed primarily of nitrogen (N2) and oxygen (O2), 78% and 21% respectively; the ingredients for NOx surround us. However, the nitrogen molecule (N2) is mostly inert and can’t be split apart without some force, so it’s not normally available to bond with oxygen. Nitrogen and oxygen molecules can be broken then shuffled together in the following ways: bacteria, lighting, burning biomass and heat. Since we’re concerned with fixing cars, we can probably safely remove bacteria, biomass, and lighting from the list of things to check for when diagnosing emissions failures. That leaves heat, but heat where?

The internal combustion engine is going to create heat; after all, combustion is right in the name. However, if the combustion temperature is kept below 1300 deg. C (2370 deg. F), the creation of NOx is greatly reduced. Since pocket thermometers can’t be used to measure combustion temperature, we’ll have to look for things we know can cause increased combustion temperatures, such as:

- Lack of Exhaust Gas Recirculation (EGR) function

- Incorrect ignition timing

- Poor fuel control (lean mixture)

- Overheating

- Incorrect spark plugs

- An excessive compression ratio

EGR

The Exhaust Gas Recirculation (EGR) system exists to reduce NOx. If the car has an EGR system, checking its function should be near the top of the diagnostic checklist. EGR reduces combustion temperature and pressure by introducing inert gases (exhaust gases) to the air fuel charge. When testing an EGR system, you must verify these three things:

- Valve function

- EGR flow

- EGR control

The EGR valve must be able to open and close. On older cars, this is usually tested by applying vacuum to the EGR valve diaphragm with a hand-held vacuum pump. You should observe that the valve holds vacuum (doesn’t leak), and that the valve opens when vacuum is applied and closes when vacuum is released. Over time, carbon deposits build up on the walls of the EGR passage, reducing the volume of gas that can flow through the passage, which will decrease the effectiveness of the EGR system. A clear passage is usually verified by operating the EGR valve with a vacuum pump while the engine is running at idle, then observing whether the engine stumbles or stalls. Be careful here; the EGR passage may be partially restricted, and the engine may stumble a little bit, even though the EGR volume is insufficient.

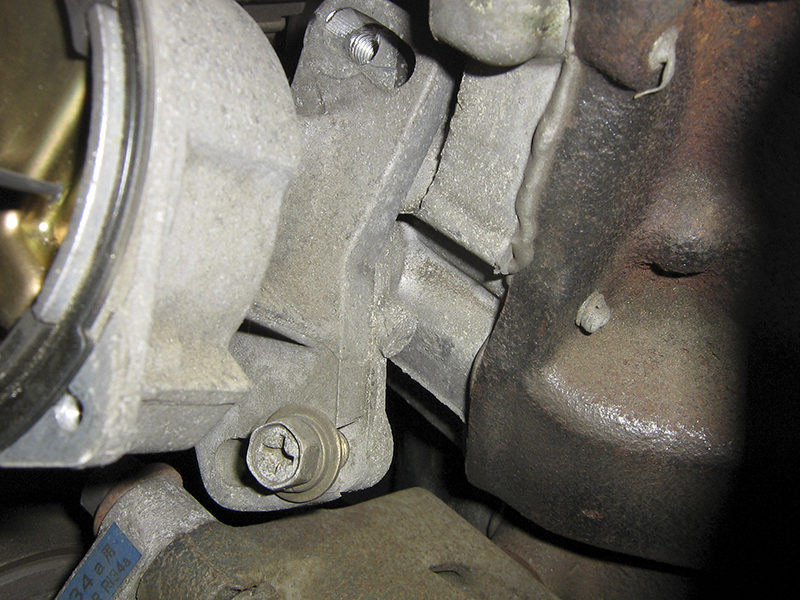

Looks like someone has elongated the timing adjustment slots beyond the normal range – a sure sign of problems.

If both the valve and the passage are OK, the only thing left to check is EGR valve control. EGR valve controls varies from car to car, so be sure you understand the system you’re working on. The manual will have all of the information you need.

All control systems share these common functions: activation of the EGR valve when desired and exclusion of the EGR valve when inappropriate. The EGR should not operate when the engine is cold, so any testing must be performed with the coolant temperature over 145 deg. F. The EGR should only operate when the engine is under moderate load, so the EGR will only operate off idle. There are also some other conditions, such as high RPM, low battery voltage, and overheating, which will prevent the EGR from working, so they should be kept in mind as well.

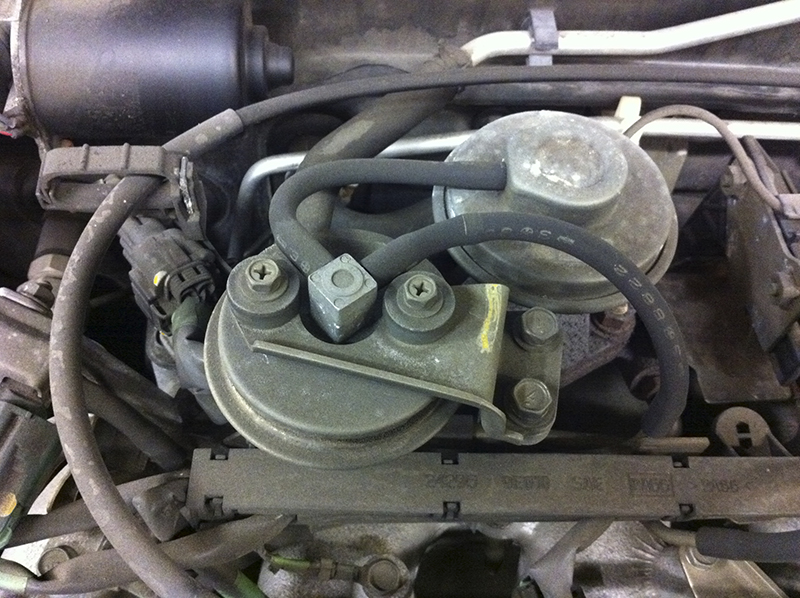

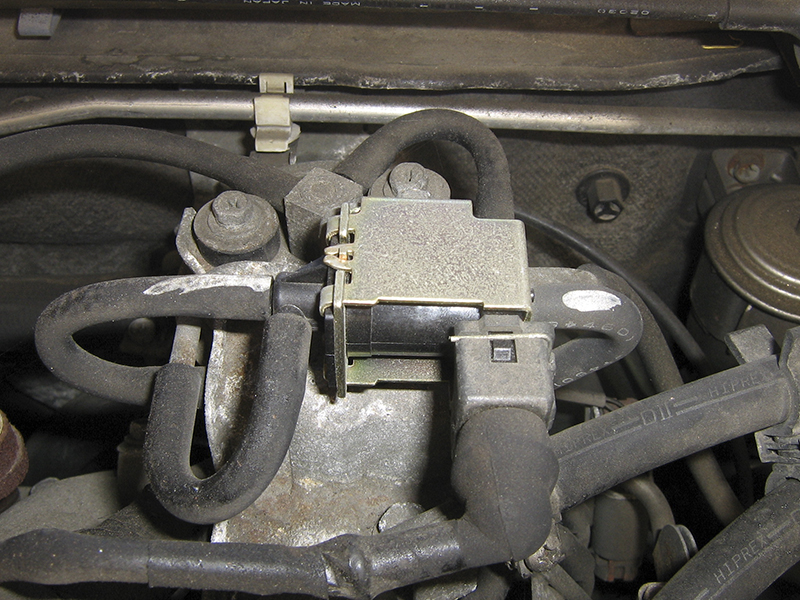

Older Nissans will use an exhaust pressure transducer to modify the vacuum signal to the EGR valve based on exhaust backpressure. As engine load increases, so does exhaust backpressure. A diaphragm-controlled valve in the transducer modulates the vacuum signal to the EGR so that EGR flow will be proportional to the engine’s load.

Older Nissans will also use a solenoid valve to allow or prevent EGR operation. This valve will prevent EGR operation before the engine has reached operating temperature, but there will be other blocking conditions as well. The manual will contain a vehicle specific system description and testing procedures. If you find the solenoid is blocking the signal when the engine is warm, check the manual for the details.

Some systems are monitored by the ECM via a temperature sensor located in the EGR passage. When the EGR is operating, the temperature sensor reacts to the passing hot exhaust gas. On cars with monitored EGR systems, there may be a stored EGR flow code to aid in diagnosis.

Newer Nissans use an EGR volume control valve. This is an ECM-controlled stepper motor that regulates the EGR pintle position. The ECM uses a pulsed push-pull signal to control the pintle position in precise steps. In the event of no signal, the EGR valve is pushed closed by an integral spring. These EGR valves can be tested using the Consult II or Consult III, depending on the model year of the car. However, you’ll likely find these more modern cars usually won’t fail an emissions test for NOx without also providing useful self-diagnostic information through the OBDII system.

Timing

Ignition timing will have an effect on NOx emissions. Advanced timing will usually cause NOx to increase, and retarded timing may decrease NOx. Base timing should always set to specification for the best performance, efficiency, and emissions. Don’t forget to check timing advance systems like mechanical and vacuum advance. Binding centrifugal weights or a stuck breaker plate can also cause problems. If the car is a little more modern and has computer timing control, it’s not a bad idea to check advance function just to be safe.

Fuel Control

Fuel control is very important. A lean-running engine will produce a lot more NOx, so it important to verify the mixture is stoichiometric (a 14.7:1 air to fuel ratio), especially in the load cells used during the emissions test. In other words: if the NOx is too high at 15 MPH at 15% load, you should verify the mixture is stoichiometric under the same conditions. The oxygen sensor should also be tested, even if the average mixture reading at the tail pipe is good.

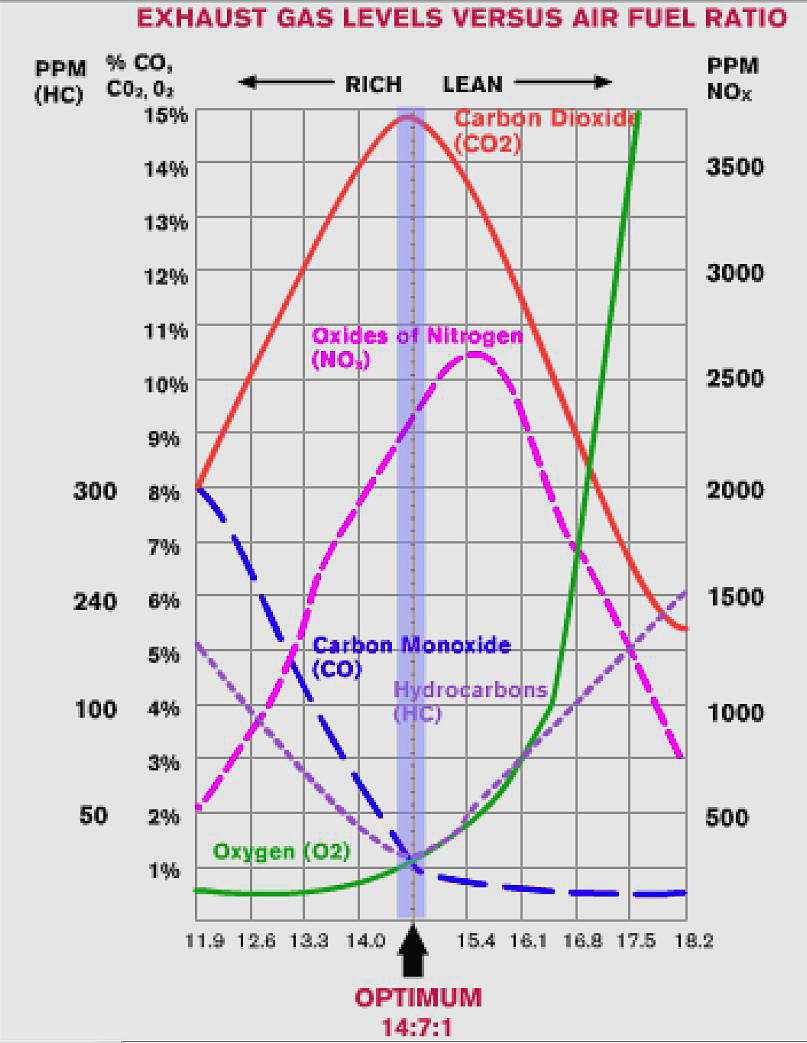

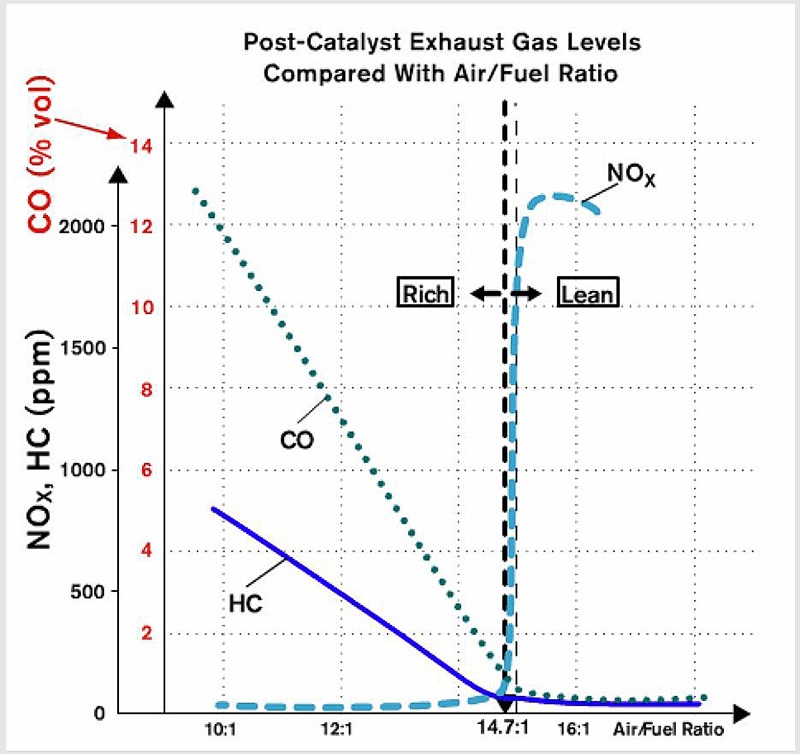

Below are two graphs. One demonstrates emission levels response to changes in air/fuel ratio pre-converter; the other demonstrates emission response to air/fuel ratio post converter. Notice that NOx gradually increases as the mixture gets leaner. If the mixture becomes 5% leaner, the NOx will increase about 13%. A lean mixture increases NOx before the converter, but the effect is nowhere near as dramatic as it is post converter.

Now compare the effects of air/fuel ratio on emissions post-converter. Notice NOx is quite low at air fuel mixtures up to 14.7:1, but there is a rapid spike in NOx as soon as the mixture becomes leaner than 14.7:1. A seemingly small 5% deviation from the ideal air/fuel mixture can cause a 2000% increase in NOx emissions post converter.

Obviously, verifying correct air/fuel mixture at the same conditions as the emissions test failure is an extremely important diagnostic step because the converter can’t efficiently reduce NOx emissions unless the mixture is 14.7:1 or lower.

Poor cooling

If the engine is overheating or has localized hotspots, the NOx emissions will increase as a result. Start with the basics: things like coolant level, thermostat operation, fan operation, air pockets, or any other cooling system issues. If the cooling system was badly abused and sediment has blocked a portion of the cooling gallery, this could cause a hot spot and high NOx production on one or two cylinders – although this is pretty rare.

Spark plug heat range

Running spark plugs with the wrong heat range can increase NOx. Original-equipment spark plugs are designed to run hot enough to prevent fouling, but not so hot they create pre-ignition and high NOx. Some aftermarket spark plugs are not properly designed for all of the applications they’re purported to “fit.†If they run too hot, NOx will increase as a result. Ordering plugs from a Nissan dealer by VIN will ensure a good match between plug and engine.

Compression

Technicians often think of compression pressure decreasing as an engine ages. Leakage past the piston rings and valves will increase as the engine wears. However, there are a couple of things that may have caused compression pressure to increase on an older engine.

First, if carbon builds up on the piston tops and combustion chambers, the combustion chamber volume will be reduced and compression pressure will increase. If the rate of compression increase exceeds the rate of compression loss through engine wear, the engine may develop a higher compression ratio as it ages.

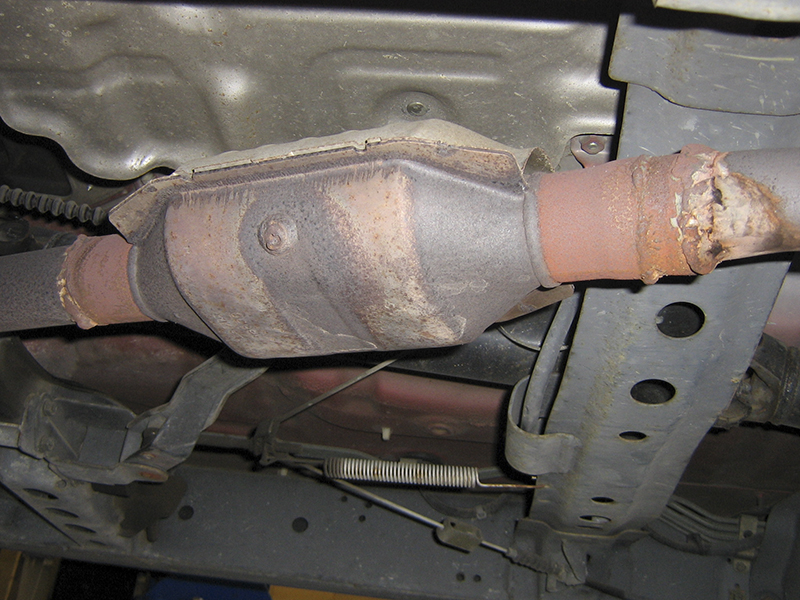

This converter was installed to “correct†a NOx failure. Two years later this truck is failing with even worse numbers. Not only was the converter an inappropriate repair, the aftermarket converter did not hold up very well.

Another way compression pressure can increase is as the result of engine repair. If the cylinder head or block deck has been resurfaced, the combustion chamber volume will decrease and compression will increase. Nissan publishes maximum resurface limits and cylinder head height specifications in the Engine Mechanical (EM) section of the service manual, but some shops choose to ignore these specifications, and that can cause some real expense for their customers when the car comes up for an emission recertification.

Catalytic converter

Three-way converters are designed to reduce NOx, as well as hydrocarbon (HC) and carbon monoxide (CO) emissions. So obviously, if the converter performance has degraded, the NOx will increase as a result. The reason the converter is last on the list of things to check is this: a new converter may temporarily mask a problem that could have been corrected more permanently with a far less expensive repair. Condemning a converter should be approached like condemning an ECM: replacement should only be considered after all other possibilities have been eliminated.

0 Comments