Waterborne paint is the new standard. It’s also safer, cheaper and faster. And it’s the law…

Today in North America, more and more dealer and aftermarket collision repair facilities are making the transition to waterborne paint – a decision driven by regulatory pressures, economics and a desire to be both environmentally friendly and safer. Where once the change from solvent-borne to waterborne was feared, experience has demonstrated that the transition can be seamless and productive, provided the right choices are made regarding technology, equipment, support, training and preparation.

The transition to waterborne began with automakers in the early 1990s. First invented in 1992, it was the introduction by automakers of new metallic and effects finishes that spurred waterborne paint systems past traditional solvent-borne systems. Today more than 75 percent of all new original equipment manufacturer (OEM) vehicles are painted with waterborne paints, generally using a two-step process. The car is first painted with the basecoat color and then covered by a clear coat.

It’s the law

Waterborne paints meet the requirements of the U.S. Environmental Protection Agency’s (EPA) National Emissions Standard for Hazardous Air Pollutants rule (EPA Rule 40 CFR Part 6H). The rule was published in January 2009 and requires that collision facilities be in compliance by March 11, 2011.

The rule lowers the volatile organic compound (VOC) limits allowed in coatings and mandates the use of waterborne refinish coatings. It also requires collision facilities to implement equipment and management practices in compliance with the new standards, practices that both reduce toxic material consumption and produce a savings to the facility.

Collision repair facilities that use paint stripper containing methylene chloride or engage in spray application of coatings to metal or plastic substrates with coatings containing volatile organic compounds (VOCs) of chromium, lead, manganese, nickel, or cadmium must comply in five basic areas:

Training

Paint technicians will find waterborne basecoat easy to spray, but spray techniques differ slightly from applying solvent-borne. All painters must train and certify on spray gun equipment selection, spray techniques, maintenance and environmental

compliance.

Spray Booths

Open-air spraying will no longer be allowed in any capacity within a collision repair shop. Spray coatings containing a targeted hazardous air pollutant (HAP) must conduct spray operations in a booth outfitted with an exhaust filter with a VOC capture efficiency of 98 percent or greater. Work with your spray booth manufacturer or filter supplier to select the right filter for your shop’s filtration needs.

Coating Application Equipment

Spray guns used to apply coatings must employ high-volume, low-pressure (HVLP) or an equivalent EPA-approved technology.

Spray Gun Cleaning Requirement

Spray gun cleaning operations must prevent atomized mist or avoid spraying cleaning solvent and paint residue outside a container used to collect waste solvent.

Recordkeeping

Existing facilities must be in compliance by Monday, Jan. 10, 2011, with notification of full compliance filed with EPA by March 11, 2011. New facilities built thereafter are required to comply before opening for business. All facilities must notify the agency each calendar year of any reportable changes that occurred. In addition, facilities must keep copies on file of all required documents, such as EPA notifications, employee training certifications, equipment documentation and corrective compliance actions taken.

For more detailed federal information, a complete copy of the EPA rule is available at www.haps6h.com. The EPA also provides more guidance to collision repair facilities at www.epa.gov/collisionrepair. Facilities should also check with their state and regional authorities in regards to other regulations or requirements that the newer EPA rule does not supercede. Facilities in California, for example, should ensure they also comply with the requirements of the California Air Resources Board (CARB) and the South Coast Air Quality Management District (SCAQMD).

The introduction by automakers of new metallic and effects finishes spurred the adoption of waterborne paint systems by collision repair facilities. Nissan Infiniti models for instance, feature “self-healing†Scratch Shield clear coat waterborne paint. (Courtesy of Nissan North America)

Benefits worth switching for

Waterborne paints are latex paints that provide collision facilities with a better alternative to traditional solvent-based paints. Made of synthetic resins and pigments that are kept dispersed in water by surfactants, waterborne paint contains less coalescing solvents than solvent-borne paints. Consequently, waterborne paint has significantly lower volatile organic compound (VOC) emissions compared to solvent-borne paint.

VOC emissions can be harmful to people because they contain chronically hazardous pollutants. In addition, the emissions build smog. With lower VOC emissions, waterborne paints improve air quality within body shop facilities and provide a safer way to paint and refinish automobiles.

It should be noted, however, that waterborne paints do not eliminate the need for safety equipment; rather, they lower the exposure risk to those in collision operations who handle paint. Standard safety equipment is still required, but the harsh odors associated with using solvent-based paint throughout your facility can be eliminated. In addition, waterborne paints can also reduce the amount of hazardous waste generated by a collision facility.

Another advantage that is helping to make waterborne the system of choice is their ease of use and ability to match a car’s finish, whether the original paint was solvent-borne or not. In addition, because the toner pigments in acrylic waterborne latex resins are engineered with anti-settle technology, facilities no longer need a mechanical mixing machine. Current waterborne paint technology and systems from leading suppliers allow refinish technicians to simply shake, pour, spray and expect the same performance, accuracy and durability of solvent-based systems.

Waterborne paints also dry and cure faster than solvent-borne paints, allowing vehicles to be ready for customers one to two days sooner. As with any type of paint, temperature, humidity and airflow all play a role in the curing speed. Fortunately, modern spray booths and accessory equipment can optimize these influences.

Equip for success

Converting from solvent to water won’t take much time at all – typically a month or less – especially when you partner with quality suppliers and their dedicated teams of conversion and training specialists. Importantly, you won’t sacrifice your shop’s performance or quality.

As with all refinish products, it is recommended to use the standard personal protection equipment detailed in the Material Safety Data Sheets (MSDS) for specific products. Safety equipment typically includes air-fed masks, gloves and safety glasses.

Any solid sludge collected from the treatment process is classified as “controlled waste†and should be disposed of in accordance with your local regulations. The filtrate produced from the waste treatment process should also be treated as controlled waste and not be disposed of into a public sewer without official authorization by your local authority.

When it comes to converting to waterborne, facilities should consider four key benchmarks that enable them to position themselves for a successful transition. These include:

- Use spray guns designed for waterborne paint. Because waterborne paints can rust plain steel and attack aluminum, choose a gun that is constructed of a corrosion-resistant material such as #316 stainless steel with 1.2mm to 1.4mm fluid tips. Dedicate spraying equipment for waterborne products. This will extend the life of the spray gun. Also, be aware that maintenance and cleaning differs from guns used for solvent-borne coatings.

- Cleaning your dedicated waterborne spray guns will help keep them working at their top performance and extend usable life. Check with your gun’s manufacturer for instructions on how to clean and maintain your specific equipment. Exercise caution here, as cleaners may not be suitable for both waterborne and solvent-borne spray guns.Many guns can be cleaned using a gun cleaner that integrates the use of a flocculating powder, to clean out waterborne residue from dedicated spray guns. This flocculating agent helps separate solids from wastewater, making it possible to reuse the filtrate at least 10 times before its cleaning properties diminish. This makes the cleaning process efficient, minimizing waste and cost.

- The evaporation characteristics of waterborne coatings differ from solvent-borne. Notably, waterborne systems are very fast and can often outperform solvent-based coatings. But waterborne paint requires good airflow to quickly evaporate water from the coating. For efficient drying, increasing the feet per minute (FPM) of air passing over the surface is key. Temperature and humidity also play a role in dry-times. Generally, 200 cubic feet per minute or more will lead to great results.

- Drying equipment can range from simple additions to existing equipment to installing specialized equipment specifically designed for use with waterborne automotive paint systems. Handheld blowers and floor stands can be set up in a spray booth to increase airflow and quickly evaporate water from the basecoat. Spray booths can also be retrofitted with mounted blowers or fans making it easier to start the flash process after spraying waterborne.

Specialized waterborne downdraft spray booths use accelerated air make-up systems – fans will double their speed in flash mode – to decrease dry times and improve productivity at the flip of a switch. Systems can also be fitted with temperature and humidity controls.

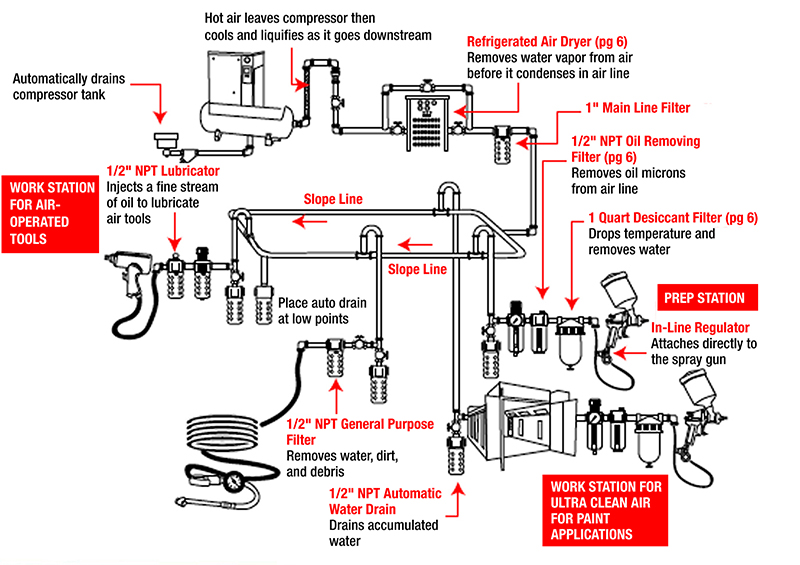

For optimum productivity with waterborne coatings, compressed air supply systems must remove dirt, dust, oil residues and other contaminants from the air supply. Note the extra filtration required as one nears painting areas. (Courtesy of Sherwin Williams Automotive Finishes)

Partner with quality suppliers

State-of-the-art waterborne spray guns, such as the digital SATA jet4000b HVLP above, are lighter in weight, quieter and offer more spray control. (Courtesy of Dan-Am Co.)

Choosing quality paint and equipment suppliers that provide training, technical support and other services required to make a smooth transition to waterborne is essential. Besides providing reliable and durable products, they should also have a clear and practical understanding of how to get the very best out of your new waterborne basecoat system. PPG, BASF, Dupont and Sherwin Williams are just some of the reputable suppliers with established training and support. You might also want to check with your industry networks for positive experiences.

Support can help you design and equip your waterborne system, based on your facility, car flow, health and safety issues and other factors. Training can cover an overview of your waterborne system, application techniques, color adjustments, spot repair, blending, waste management, maintenance and more. Note that suppliers offer a variety of classroom and hands-on training – some online, some onsite, some offsite and some a combination of these.

Consider your staff’s learning styles, then check to see what prospective suppliers offer to meet your training needs. For example, besides training at your supplier’s facility, negotiate having a supplier’s conversion and training team provide on-site training at your facility during the actual waterborne conversion period (typically one to three days). Working with your technicians on your site with your equipment – while covering application training, computer training, waste stream training and color tool training – could go a long way to making the smoothest transition possible.

Like any new material or procedure within a system, there’s a learning curve to go through. But with the right equipment and training, collision repair facilities and their technicians should not have great difficulty in switching to a waterborne system. Making a successful transition into waterborne finishes requires the right combination of support, information, training and equipment. Now, more than ever, the decisions you make today will have a long-lasting impact on the quality, productivity and profitability of your body service business.

0 Comments