One of Mercedes-Benz’s main focal points is safety. SBC brake systems reduce stopping distances and allow the driver more control over the vehicle. Let us maintain this system to keep it at its optimal performance.

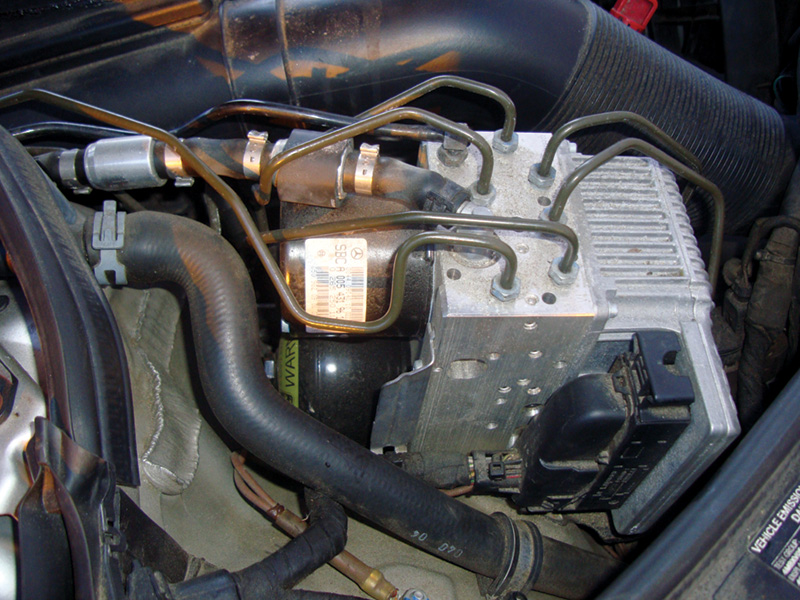

The heart of the Sensotronic braking is the SBC hydraulic unit. You can see the high-pressure hydraulic pump on the left and a pressure reservoir below it. This unit actually produces the fluid psi that stops the vehicle.

Mercedes-Benz has always believed that cutting-edge technology can be used to make vehicles safer, not just more efficient and luxurious. Nowhere is this more evident than in the company’s braking systems. In the past, it was possible to lock up the wheels during a panic stop, causing a loss of directional stability — at that point the driver is no longer in control of the vehicle. Anti-lock brake systems have pretty much eliminated this dangerous situation since 1984. These computer-controlled systems have evolved throughout the years into ASR, ETS, ESP, BAS, and, finally, the Sensotronic Brake Control system (SBC). With conventional brakes, when the driver applies the pedal, muscle force levers a master cylinder piston forward providing pressurized fluid to the calipers. With Sensotronic, on the other hand, the brake pedal serves as more of a sensor, signaling the SBC unit to send braking pressure to the wheels. This improves response time and provides more precise control of braking pressure.

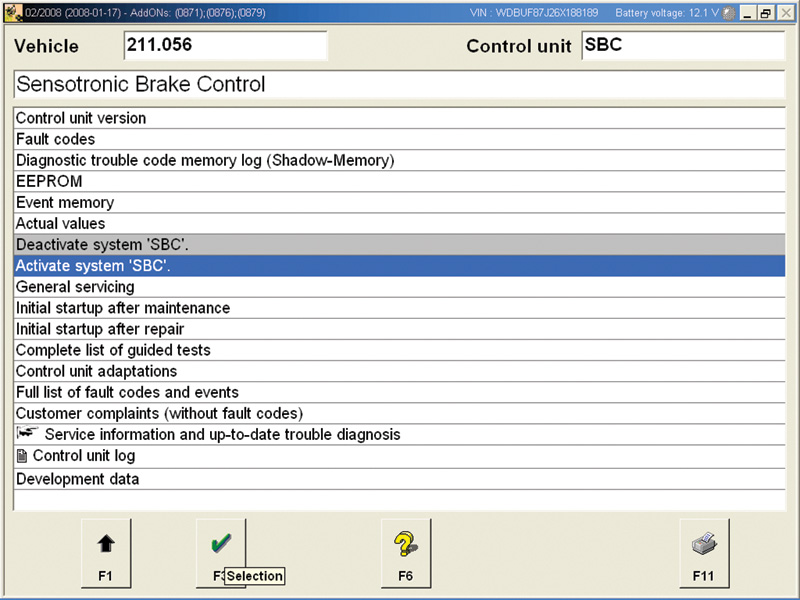

The SDS is needed to de-activate and re-activate the SBC system before any brake job or other service work can be performed. This reduces SBC pressure, and fluid lines can be opened.

With computer-controlled braking, additional features can easily be programmed into the system. To bring the vehicle’s speed down smoothly, hydraulic pressure is reduced as the vehicle comes to a stop. When the wiper input is put on the CAN, light brake pressure is applied to keep friction surfaces wiped dry. Inputs that predict rapid brake application are looked at. With sudden release of the gas pedal, the SBC control unit precharges the brakes to remove play in the system. This helps reduce braking distances when the brakes are actually applied. SBC is part of the overall dynamic chassis control system, which includes ASR (Automatic Slip Reduction), ESP (Electronic Stability Program), ABS (Anti-lock Braking System), and BAS (Braking Assist System). Wheel speed sensors, the ASR hydraulic unit, and a brake operating unit make up the SBC system. The system wakes up when a door is opened, the remote Smart Key is operated, the key is turned on, the brakes are applied, or when the parking brake is released.Â

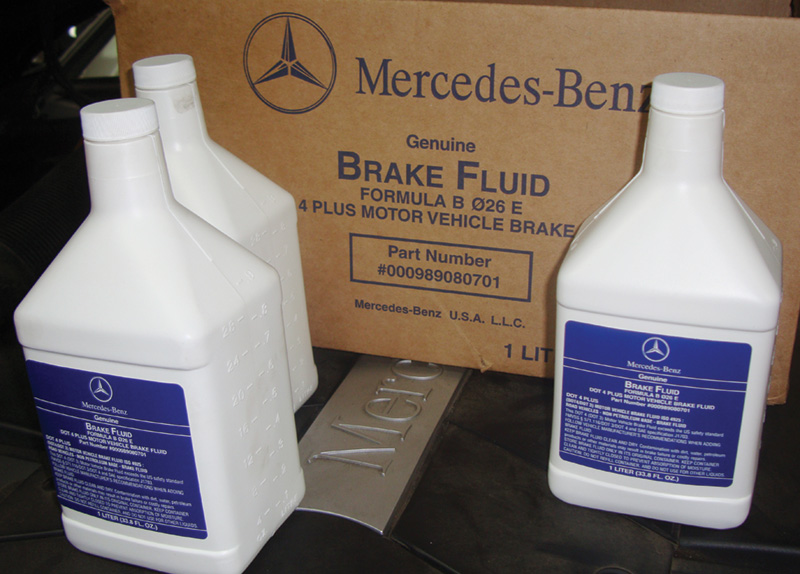

While picking up SBC components at your Mercedes-Benz dealer, you should purchase at least two liters of approved brake fluid to completely bleed the system. Since brake fluid is hydroscopic, it is recommended that it be replaced every two years as normal maintenance.

A self-check is performed when the system wakes up. Pressure is applied to the calipers while the system cycles solenoids and checks for leaks. This feature coupled with high brake pressures means we need to be extra careful while repairing these systems. SBC needs to be deactivated while servicing the system, even if only the brake pads and rotors are being replaced. This way the technician will not inadvertently activate the system while components are apart, which would cause damage and be a safety threat. This is done with a Mercedes-Benz SDS tool available for purchase from the company. Once work is completed, SBC must be reactivated. Also, if the hydraulic system is opened for service, a specific bleed procedure using the SDS must be followed. You will need somewhat less than two liters of approved brake fluid, which you may want to add to your order from your Mercedes-Benz dealer.

When the SBC is deactivated, or there is a failure in the system, you will see a warning message in the instrument cluster. Pull codes and look at pressure in the system before disconnecting any brake lines.

When the driver steps on the brake pedal, he or she is really engaging Pedal Value sensors. These two hall-effect sensors tell how much pressure is applied how quickly to the brake pedal. This information is sent to the software in the SBC hydraulic unit, which determines how much pressure is applied to each wheel. A pedal simulator gives the driver the feel of a conventional brake pedal. There is still a rod that applies pressure to the piston in the tandem master cylinder, so in the event of SBC power loss this brake pressure is applied mechanically to the two front wheels through valves in the hydraulic unit.

You can evaluate sensor inputs by looking at data in the SBC system, and you can read the Pedal Value sensor signal and individual wheel brake pressures. This information can lead to quicker and more accurate diagnosis.

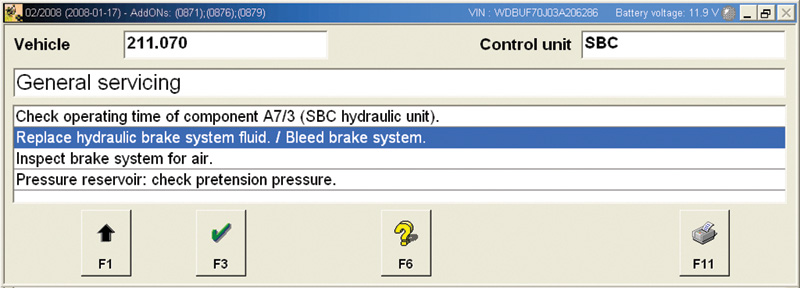

Follow the steps outlined in the bleed procedure in your SDS unit. Make sure to secure your brake bleeder lines to the screws since high pressure brake fluid comes out when opened.

Bleeding the system and checking for air after replacing any components is critical to proper performance and will eliminate any possible fault codes after work is completed. All of the steps are in the SDS when you select to bleed the system. You will need other special tools to complete the job, however. A Mercedes-Benz-approved power bleeder will have to be attached to the brake fluid reservoir to insure that the hydraulic circuits do not run dry while bleeding. The sequence starts at the right front wheel, followed by the right rear, left rear and left front wheels. You will need to secure a hose to the bleeder screw since high pressure fluid comes out when it is opened. After the process is complete, clear the codes and verify that you have no codes left in the SBC system. A test drive should be performed before the vehicle is delivered. A complete job will provide your customer with all of the benefits SBC has to offer in safety and car control, and that’s a job well done. Â

0 Comments