Evaporative emissions have been tested and monitored by the ME since the beginning of OBD II regs in 1996. This system has been one of the more difficult air pollution-reduction systems to diagnose and verify. SDS software has made the job easier.

Believe it or not, evaporative emissions controls have been around for over four decades. For most of that time, they were relatively simple, comprising a liquid/vapor separator in the tank, a charcoal canister with a vacuum‑operated purge valve, a special gas cap that didn’t vent pressure unless it exceeded maybe two psi, or vacuum until it reached several inches, and related plumbing (many of you won’t remember that there was even a hose from the carburetor bowl vent). When the engine was started and run above idle speed, ported vacuum opened the purge valve, the stored vapors were drawn through a hose into the intake stream, and fresh air entered the canister through a filter. These systems not only reduced a vehicle’s hydrocarbon emissions by up to 20%, they also saved a little gasoline. And they were pretty much trouble-free.

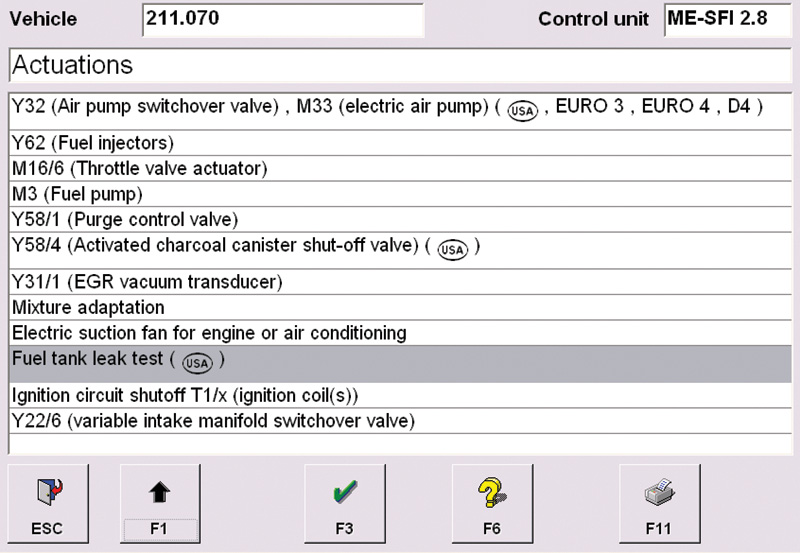

This is a good example of why investing in an SDS will make you a true Mercedes-Benz specialty shop. Under the heading “Actuations,†you’ll find various tests you can perform on the EVAP system, including activating the purge solenoid, shut-off solenoid, and EVAP leak test.

With the advent of OBD II regulations, EVAP had to go high-tech with the PCM actually performing tests to make sure the tank and hoses were vapor-tight. If not, commonly because the gas cap has been left loose after a fillup, there’ll be a MIL-on situation and you’ll get a visit from the customer. If a loose cap were the only potential problem, there’d be no need for this article. But sometimes you’ll be presented with a diagnostic mystery.

Here we are adding smoke and we have closed the cut-off solenoid. If you look closely, you can see a small amount of smoke coming from the vent. Is this enough to cause our leak code? We wanted to be sure.

Overview

Just as in the past, gasoline vapors that form in the fuel tank are directed to a charcoal canister for storage, then routed to the combustion chambers to be burned. What’s different today is the control of canister purging. In old systems, this was accomplished by the simple expedient of ported vacuum either drawing off the stored fuel vapor directly, or opening a valve that allowed manifold vacuum to do the job. Now, of course, mixture management is much more crucial, and only the ME (or PCM) can provide the precision needed.

So, the purge solenoid, sometimes referred to as the regeneration valve, is under the command of the ME. It is pulsed as necessary to allow manifold vacuum to reach the charcoal.

Under OBD II, if there’s a leak in the EVAP system the ME control unit needs to be able to detect it. If it’s less than the air that would be lost from .020-in. hole, it’s acceptable. If the leak is larger than that, but lower than that of a .040-in. hole the ME sets a small-leak code. Anything larger than that results in a large-leak code. If any individual part of the EVAP system fails, the ME detects it.

Measuring EVAP Leaks

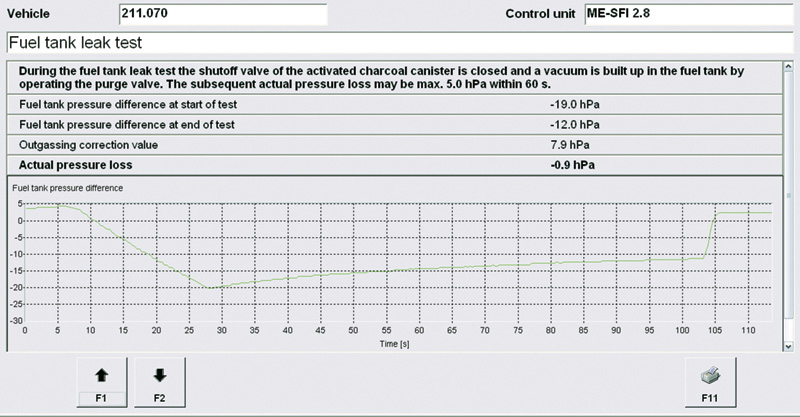

Using the Fuel Tank Leak Test, you can watch the pressure in the fuel tank in hectopascals (hPa). Here, the pressure increased by eight hPa over 60 seconds. The outgassing factor was because the gas cap was removed and reinstalled before the test.

Two strategies may be used to allow OBD II to test EVAP to see if everything is sealed properly. One uses pressure decay, and the other vacuum decay. In the former, pressure is applied to the EVAP system and measured. If the pressure drops too quickly, a leak must be present. In the latter, vacuum is generated in the system and any drop is also measured.

In either case, measurement can’t be accomplished unless the normal channels are sealed. This is the job of the canister close valve. Remember, fresh air needs to be taken into the canister to allow the vapors out. This air comes through the close valve, which is normally open. During the testing, the computer energizes the valve, closing it.

To verify that the cut-off solenoid was closing, the vent port was blocked. There should be no difference whether the cut-off solenoid is closed and the vent port is blocked since they both seal the system. However, there is a difference in the results of the leak test.

Mercedes-Benz uses the vacuum decay method to determine if there are EVAP system leaks. The regeneration valve, or purge solenoid, is pulsed open to draw the system into a vacuum. The fuel tank pressure sensor (FTP) measures the drop in pressure just as a MAP sensor measures the pressure drop in an intake manifold. When the FTP signal reaches a predetermined level, the purge solenoid is closed. With the canister close valve energized and the purge solenoid de-energized, the EVAP system is completely sealed. The vacuum should hold and the FTP signal voltage should remain steady. If the voltage changes, vacuum is being lost, so there must be a leak.

Okay, How are We Going to Test it?

You could manually close the canister close valve and open the purge solenoid. You could then watch the signal voltage of the FTP and allow the purge solenoid to close while seeing if the FTP signal voltage changes. You need to know what a good FTP signal is without any pressure or vacuum in the fuel tank to verify that the FTP is reliable. You also have to know the change in vacuum by how it affected the FTP signal.

Another way you can check for leaks is to “smoke it.â€Â An EVAP-compliant smoke machine generates a small amount of pressure and blows smoke into the EVAP system. You still need to close the canister close valve to seal the system, but you don’t need to run the engine.

Obviously, wherever you see smoke is where your leak is. You will have to expose the plumbing to isolate the source, which can be time-consuming depending on the model you’re working on. Also, if the purge solenoid is the source of the leak you will not see the smoke since it will enter the intake manifold first before exiting the air filter housing. Once you find the source and repair it, you will then have to drive the vehicle to verify your repair. The EVAP monitor is one of the more difficult monitors to run. Variations in outside temperature, fuel temperature, fuel level, atmospheric pressure, etc. all have an effect on whether or not the monitor actually runs, so this can take a lot of time. Using conventional methods will make it difficult to verify your repair. Is there a way around this dilemma?

SDS to The Rescue

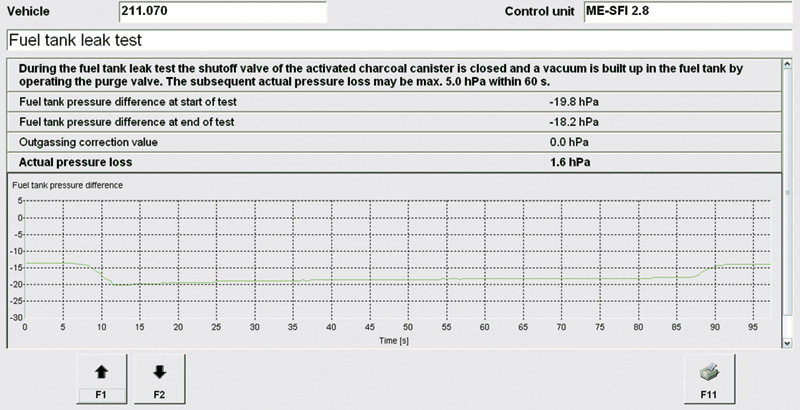

After installing the new canister cut-off solenoid assembly, the leak test was run one more time. The pressure difference is less than two hPa. This means the EVAP system has passed the leak test and should pass the monitor as the vehicle is driven.

SDS offers advanced testing of this system. Not only will it allow you to verify your repair, but it can also be used in the diagnostic process to help determine the source of the problem. When accessing the ME control unit, you will probably look for DTCs first. Once you determine they are EVAP leak codes, you can start testing. Under the heading “Actuations,†you will be shown a list of various components on the car that you can activate through SDS software. This also lets you know the computer is capable of grounding solenoids and is not the ultimate source of the problem. One of the actuations you can do is that of the canister close solenoid. This can be useful if you are smoke testing. If you apply smoke to an open system you will simply see smoke coming out of the canister vent. You can now close the vent solenoid and see if smoke comes out anywhere else.

If it still comes out of the close solenoid, then you simply have a bad cut-off solenoid. You may want to verify that the solenoid is being grounded by the ME. It may be difficult to see if smoke is still coming out of the cut-off solenoid.

The SDS software can also perform the entire EVAP test on newer chassis like the 211. This is a significant time-saver. When you are done with your repairs, you can test the system to verify that it will pass the monitor. The engine must be running for the test since you need engine vacuum to draw down the EVAP system. The automated test grounds the close solenoid and opens the purge solenoid.

Monitoring the Situation

You’ll see the FTP signal displayed in hPa instead of a signal voltage on a graph. You’ll also see the drop in pressure (relative vacuum) as the purge solenoid is opened and the cut-off solenoid is closed. Watch the FTP reading over time as the purge solenoid is allowed to close. Observe the graph as the 60-second test is run. The parameters are also given in the test screen. In the case of the 211 chassis, the SDS does not want the FTP reading to increase by five hPa over 60 seconds. On our test subject, this test has failed. To isolate the leak, you can remove and block off various hoses, and re-run the test. If it now passes, you now know the leak must be in the part of the system you blocked off.

Keep in mind that much of the EVAP system has hard plastic lines, which you shouldn’t crimp as they will probably break, creating more leaks. The safer way is to remove the line at a flexible hose and plug it. In our test vehicle (211 chassis), we temporarily blocked off the vent of the canister close solenoid and ran the test again. During the test, the close solenoid should be closed anyway, so blocking off the vent port should not have had an effect on our test — but it did. The EVAP system passed the test with the vent port plugged. This told us that the close solenoid wasn’t completely sealed and allowed the vacuum to drop in the system. On the 211, the canister close valve is incorporated into the charcoal canister assembly, therefore the entire canister had to be replaced.

Verification

Once the new replacement canister is installed, you should run the EVAP system test again. You should see the FTP reading stay stable after the regeneration solenoid is closed. If the system passes now, you can return the vehicle to the customer without the worry of he or she returning multiple times for the same problem.

0 Comments