The automotive accessory drive belt is a staple maintenance item. Let’s take a look at the types of drive belts, material structure, adjusting tension, diagnosing problems, and a few tech tips for working with them on a daily basis.

Everyone knows about drive belts. Even customers will often attempt to diagnose their own cars, claiming that their Altima’s “fan belt†is making noise. Of course, that car has an electric cooling fan, but the sentiment is what matters most. Drive belts have been employed since the vintage vehicles from around World War I, so it’s no real wonder that people are familiar with them. Yet, how familiar are we really with the details surrounding a drive belt? We’ll shed some light on the history of the drive belt: its evolution from one shape to another; the chemical engineering involved in its materials; and the proper way to inspect and service it.

Before we get into the nitty-gritty of the drive belt, let’s talk about practical information that may help your daily work. The purpose of a drive belt is to attach two pulleys and for one to drive the other using friction. Anything that prevents or reduces belt friction will also prevent the transmission of power from the crank pulley to the accessory pulley(s). Drive belt service should include checking tension, material wear or contamination, pulley alignment, and bearing roughness.

Types of Drive Belts

Let’s address the different styles of drive belts you will encounter when working on Nissan vehicles. All drive belts are designed to do the same thing: transmit power from the crank shaft to the accessories. Each drive belt will be made up of three primary components:

- The heat and oil resistant coating called the cover.

- The stability and strength enhancing fiber band called the tension member.

- The softest rubber, friction-providing compression section.

Until somewhat recently, the most common drive belt design was the V-belt. It is thin, using a trapezoidal compression section that wedges between the sloped sides of a deep pulley. However, this design has a few inherent problems that result in its comparatively short lifespan. Like a pencil eraser, rubber will scrub off over time from the sides of the trapezoidal compression section. Without automatic tensioning, this causes the belt to elongate and lose friction strength requiring periodic adjustment. The bottom of the belt is not providing the friction, it’s the sides only. So, if the belt ever bottoms out, it’s beyond its service life or too small for the application. Also, the V-belt requires a large, deep pulley for lots of contact area with the friction wedge. This can limit engine layout options.

Notice the trapezoidal shape of the V-belt. This quality Nissan belt also has extra material in the compression section to improve longevity.

The V-belt design was more or less multiplied and miniaturized to create the most common type of belt in modern cars called the multi-rib belt. This ribbed belt has many benefits over the V-belt. First, it eliminates the need for deep pulleys, which allow for better engine layout and design possibilities for compact cars. Second, the method of generating friction no longer scrubs significant amounts of rubber from the compression section. Additionally, since the belt is flatter and wider, the backside surface can be used to power accessories that may not command a significant load.

If there’s only one belt to power all the accessories, it’s a serpentine drive belt. Most similar in design to the standard multi-rib belt, the serpentine belt is often engineered in a way to resist the wear introduced by its circuitous route. The backing cover is reinforced on a serpentine belt to resist wear and abrasion from idler bearings or pulleys that use the back side for friction instead of the ribbed side. Nevertheless, a serpentine belt does not last quite as long as a standard multi-rib belt, so be certain to check periodically using the tips below. Just like its namesake, the snake, it bends both ways.

Properly Checking and Setting Belt Tension

This serpentine belt has a reinforced backing seen in the white threads, and it has additional material for powering pulleys using the nonribbed side.

With the different types of belt designs in mind, let’s explore how to check and set their tension properly.

There’s no way around it: checking belt tension requires tools. Nissan has an official gauge designed to check belt tension (P/N BT-3373-F), but any tension gauge will work. You should check and set the belt tension when the vehicle is cold. The gauge measures the amount of deflection in the belt with a controlled force applied. For instance, the 2003 Pathfinder A/C belt should deflect 12mm with 98 Nm of force applied. Using a different type of tool, you may be able to measure the amount of force it requires to deflect the specified amount. Either way, the proper tension or deflection measurement can be compared to a table in the service manual. Bear in mind that there is no “general rule†for tension because different belt styles, thicknesses and lengths will all deflect a different amount.

This same adjuster pulley is available with and without the mounting bracket. At the top of the adjuster nut is a friendly reminder to retighten the belt after installation.

A newer drive belt will have a different published deflection or tension specification than an older belt. Consult the factory manual to determine the appropriate tension for each particular vehicle. This is because new belts will stretch, or break in, and Nissan accounts for that behavior.

On many Nissan vehicles, belt tension adjustment is performed by physically manipulating a bolt to move an idler pulley. On other models, the accessory itself must be loosened and relocated to achieve the same effect. Both methods require periodic manual adjustment. If the belt is automatically tensioned with a hydraulic or spring-loaded assembly, there will be markings on the device to indicate whether the belt has stretched beyond service life. Another major benefit is that no periodic adjustment is necessary.

This spring-loaded automatic belt tensioner is actually the third version of the original (the last five digits began as EA200, then EA20A). A major benefit of buying Genuine Nissan OE parts is that they are constantly updating and improving designs. Aftermarket parts may be copying the design of the previous tensioners.

When installing a drive belt, you should inspect the adjuster for play, rust, the presence of oil, proper alignment, as well as if the belt bounces or slaps while running. For automatic tensioners, check for hydraulic leaks and spring tension to determine whether the unit should also be replaced. If a spring tensioner can be moved by hand, it’s likely worn out.

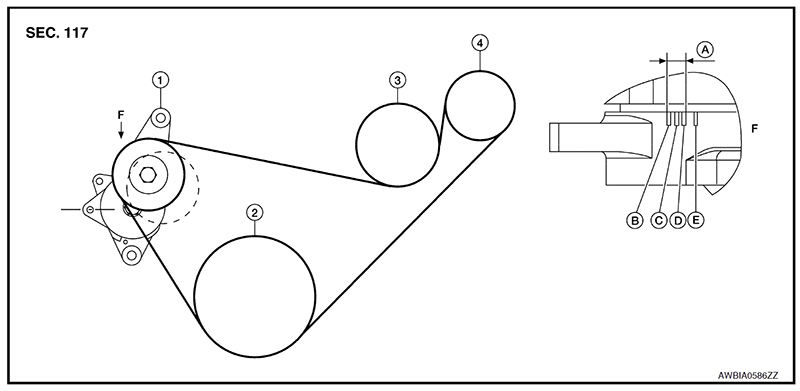

The auto belt tensioner (F) will have markings to determine whether a drive belt has stretched too much. The side view shows the markings, including acceptable range (A).

A drive belt with too much tension applied may cause the bearing to whine when the vehicle is on. Do not get in the habit of over-tensioning belts because “it’ll just get looser.†While a belt may stretch a little after the initial installation and setting of the tension, this is no reason to cause damage to pulleys and accessories in the meantime. Set the initial tension, run the engine for five minutes at 2,000 rpm, then re-set the belt tension once and for all. If you used a Genuine Nissan OE quality belt, this should be the last time you see that car for a belt!

Inspecting for Belt Wear or Signs of Contamination

A visual inspection of belt wear and contamination is necessary. Minor cracking of a multi-rib belt does not necessarily mean it must be replaced. If the belt is off the vehicle, bend it backwards and check if the cracks reach the backing band. If so, replace the belt. When the belt is on the car, rotate it so the ribs face upwards; if the belt is bad, the tension introduced should splay the cracks apart. A V-belt will lose material from its sides, which is harder to identify unless compared to a new belt. When setting a V-belt in the pulley, it should NOT touch the bottom of the pulley. The belt is designed to provide friction by being wedged in place like a dove-tail fitting, not by gripping the pulley bottom.

If there is abnormal wear on the belt backing, verify that the course of the belt does not contact any cover or metal component. Many times, an out-of-place timing cover will contact a drive belt, causing noise and accelerating wear. Repair the initial source of contact first, then immediately replace any drive belt with backing wear. There isn’t much “meat†on the back of a belt, and damage to this area can cause rapid belt failure.

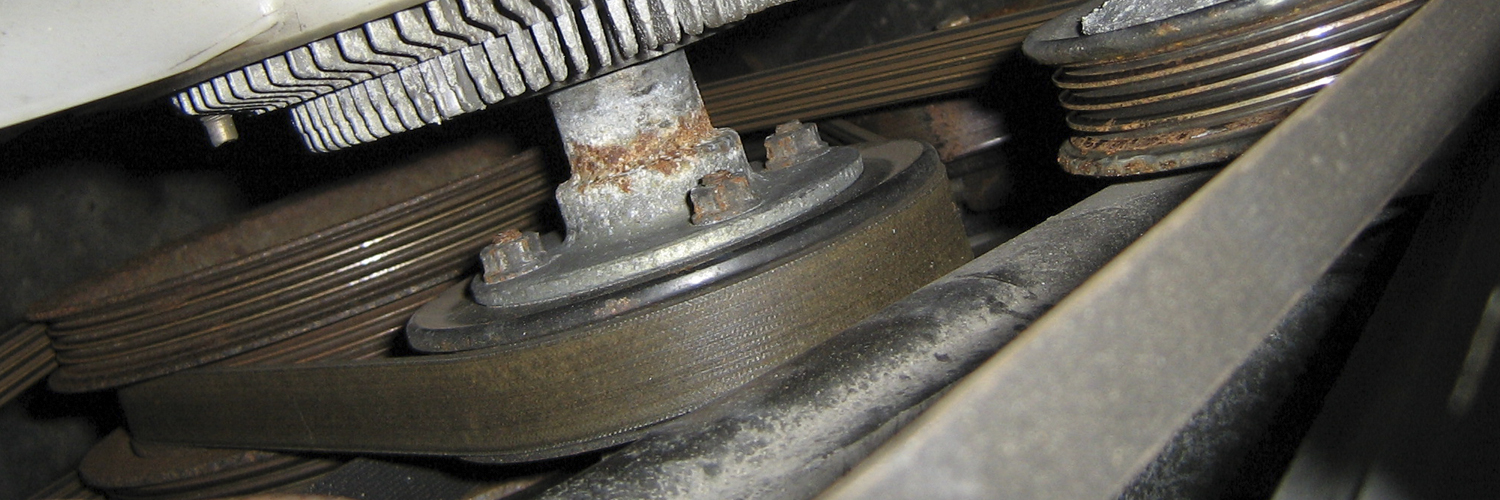

Oil contamination from power steering fluid or an engine oil leak can shorten the lifespan of a drive belt. Even if the belt does not appear to be cracking or swelling, contact with oil will affect its internal chemical integrity. Identify and fix the source of oil leak first, then replace any contaminated drive belts. A splash of oil here or there, if cleaned off quickly, will not immediately ruin a modern drive belt whose external cover is engineered to resist compromise from oil. Contamination refers to consistent oil contact over a period of time.

Some drive belts may be noisy despite having proper tension, no visible cracks, and no oil contamination. The belt material is likely glazed. Glazing occurs when the belt surface heats up too much, which can be from initial over-tensioning, pulley bearing resistance, or just over time. As long as the belt retains tension, there is no action required due to glazing.

Identifying Drive Belt Pulley Problems

Some problems with the accessories can cause drive belt failure. If a vehicle’s drive belt has broken or melted, you should suspect a seized accessory. With the belts off the car, check for binding or roughness of all the idlers and replace any that do not spin freely. Some accessories may also be the cause, so be sure to check A/C compressor clutch operation. Be careful, however, because many bearings will only misbehave when loaded. You may have to recheck for bearing noise with an automotive stethoscope after installing new belts.

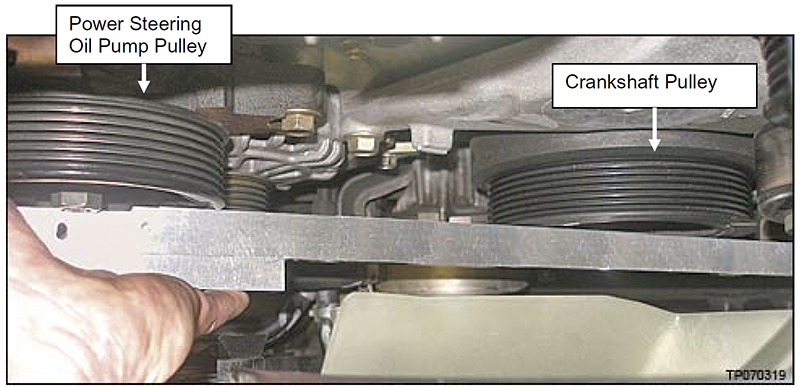

Pulley alignment and play are often overlooked inspection items. If a drive belt wears prematurely, it could be that the pulleys are misaligned, creating additional internal load on the belt. With the drive belts off the engine, you can easily use a straight edge to confirm proper alignment.

A pulley bearing that has excessive free-play may also cause premature wear by stretching the belt too much laterally.

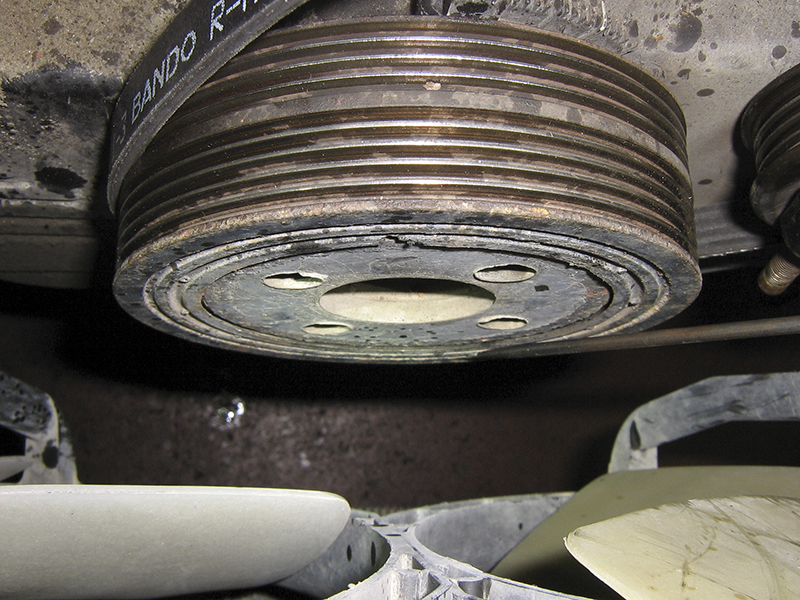

A special note about crank pulleys with harmonic balancers: the rubber can deteriorate allowing the outer pulley ring to rotate with respect to the inner. This uncommon scenario can cause belt slip symptoms, or even belt failure.

The Right Belts

Finish the job correctly by installing Genuine Nissan OE drive belts. The specifications for tension are published using these belts in mind. They are also manufactured with superior materials, able to resist oil and other solvents better than inferior drive belts. Their internal reinforcement structures are also better engineered, which prevents excessive stretching over time. Whenever you finish installing drive belts, and adjusting the tension cold, run the vehicle for approximately five minutes. After this initial conditioning, wait for the belts to cool before checking and readjusting belt tension. If you used a Nissan belt, this final tension should last the majority of the life of the belt. Using quality Nissan belts, you will have fewer customers come back to your shop for readjustment.

Check pulley alignment between the crankshaft pulley and the power steering pump using a straight edge.

Chemistry – a Brief History of Rubber Polymers

Now we know not to let oil touch the belts, but why is that? We should begin with a bit of history and terminology. Drive belts aren’t made of rubber, per se, because traditional natural rubber is made from the sap of a tree. Modern rubbers are actually synthetic blends derived from molecules found primarily in petroleum oil. There was great demand in the early 20th century to develop an alternative to the plant-derived, natural rubber. Thus began the creation of many different petroleum-derived polymers that could function like traditional rubber.

Without going overboard in the explanation, a polymer is a generic term from chemistry. Many things are polymers, some of them are man-made and some exist in nature. A polymer is formed from multiple monomers, which is another generic term for any molecule structure that can conjoin with a similar structure. For instance, we often hear about high fructose corn syrup, which is a polymer created from the naturally occurring monomer called glucose found in corn.

Nissan drive belts are primarily made from neoprene, a synthetic rubber, which has undergone one further chemical process called vulcanization. Vulcanizing a polymer will introduce substances called curatives, and that allows the manufacturer to control many qualities of the polymer. Just like engine oil additives, the mixture is unique and secret. We’re not just talking about “how stretchy†the synthetic rubber is, but also how resistant to heat, solvents and oil. To give you a sense of the control the chemical engineer has, just imagine that a bowling ball can be made from neoprene using a different vulcanization technique.

So, when oil contacts a drive belt or other rubber polymer you can start to piece together why this is bad. A slow chemical reaction occurs where the oil molecules begin to compete for the curatives within the polymer. This effect causes the properties of the synthetic rubber to change, and in the case of neoprene, the tensile strength and hardness are reduced, but the elongation increases. Tensile strength is how much pulling force you have to apply before it breaks. Hardness is what you would expect. Elongation refers to how much the material will deform before it breaks. Low tensile strength with high elongation means you would not have to pull very hard to break the material, but it would stretch a lot. This is exactly what you do not want to see in your drive belts, and now you know why you don’t want them to come in contact with oil!

Nissan also uses a superior material called EPDM (Ethylene Propylene Diene Monomer) for some belts, found often in cooling system hoses. When exposed to oil contamination, EPDM does not lose tensile strength, but its elongation significantly increases. This is why you may see coolant hoses “balloon out†when oil-soaked.

Drive belts aren’t solely composed of synthetic rubber. They also have fibers woven into the backing band. These polyester fibers tend to be a polymer of a different family called thermoplastics. Thermoplastics are affected by heat. In the case of drive belts, woven polyester fibers will contract and shrink when exposed to heat, which is a perfect behavior for keeping tension on a pulley. The fibers are coated with another plastic, PVC (polyvinyl chloride), which allows them to flex without fraying. The fibers gain increased tensile strength from the significant number of threads wrapped together, as well as their length.

Like tires, you get what you pay for with drive belts. There is a lot of materials technology and engineering involved in making drive belts, and just as with tires, investing in a better quality part is better for everyone involved. Nissan drive belts are the best belts for Nissan vehicles.

Where’d the Drive Belt Go?

In some new hybrid configurations, the drive belt may have gone the way of the Dodo. Using the high-voltage battery pack and multiple computer controllers, the Altima Hybrid eliminates the A/C compressor belt. The belt-driven compressor is replaced by an electrically-driven compressor, which allows for greater efficiency. The 2012 Infiniti M series has eliminated the power steering belt by using an all-electric power steering rack that does not have an external hydraulic pump.

For an engineer, being able to control the load and demand from accessories on the fly dramatically improves fuel economy. They can do this best by turning an “always on†drive belt configuration into an “on demand†electrical system. As with all their technologies, expect Nissan to develop a way to go beyond the typical drive belt.

0 Comments