Mercedes-Benz introduced the very first diesel-powered passenger car an amazing 77 years ago. While the company’s diesels have always been durable and easy to live with, today they also offer startling acceleration, incredible mpg, and amazingly quiet, low-emissions operation.

Almost 30 years ago, a Mercedes-Benz engineer asked a group of automotive technical journalists if General Motors had ruined the market for diesels in the United States with the debacle of the Oldsmobile 5.7L, which tended to come apart before it got to 50,000 miles. The answer was yes, with one notable exception: Mercedes-Benz. That company’s diesels were relatively smooth and quiet, and some specimens covered a million miles of real estate without major engine work. True, they lacked the sprightly performance of their gasoline-burning counterparts, and gave off an aroma that made you think of a bus station, but their dependability, durability, and miserly fuel consumption garnered a cult following and fairly decent sales figures.

Technological Light Years

How far we’ve come. Today’s Mercedes-Benz BlueTEC common-rail direct injection diesel engines provide incredible torque and acceleration (two characteristics especially desired by American drivers), superior fuel efficiency, and exhaust so clean it could hardly have been imagined just a few years ago — no more watery eyes and offended noses.

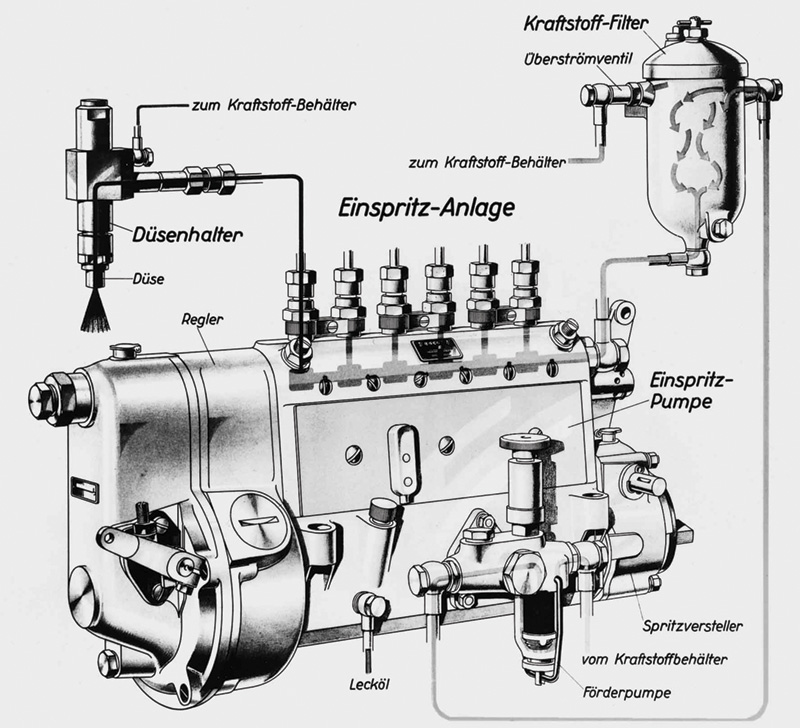

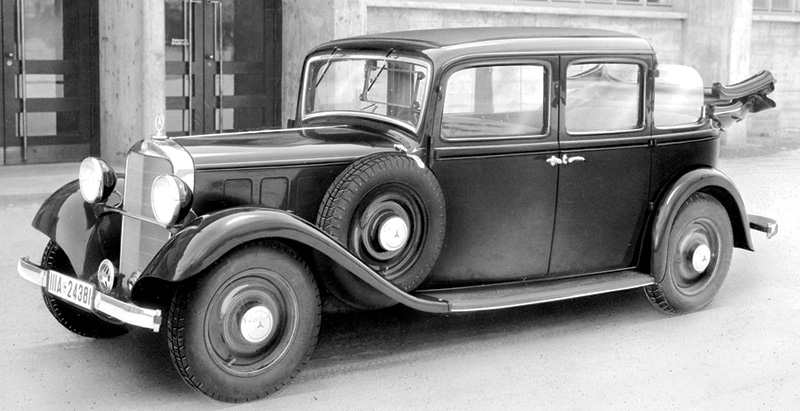

These salubrious developments are a result of collaboration between Mercedes-Benz and Robert Bosch AG, both companies with long, illustrious histories. The world’s first diesel passenger car was the 1936 M-B 260D, and Bosch has been manufacturing diesel injection pumps since 1920.

The big news now on BlueTEC is the introduction of incredibly powerful, efficient, and clean four-cylinder engines. Already for sale in Europe, they’ll be in the U.S. soon, albeit with slightly less horsepower (you’d never notice the difference) because of our country’s stricter emissions regulations.

Torque Galore

Robert Bosch collaborated with Mercedes-Benz in the development of BlueTEC technology. The company started manufacturing diesel injection pumps for commercial vehicles in 1920.

The lineup of current non-U.S.A. models is nothing if not impressive. Take the GLK 250 BlueTEC 4MATIC for example. It has the most powerful four-cylinder diesel of any SUV worldwide. With its common-rail direct-injection, it’s rated at 204 hp and, get this, 369 ft. lbs. of torque from a mere 2.14L (190 hp and 369 ft. lbs. in American trim). When this engine arrives here in appropriate models, all that torque should make its performance especially appealing to American drivers, who tend to like flexible power.

Equally important is its extreme frugality: up to 38.6 mpg (or, 6.1L per 100km if you prefer metric). CO2 emissions stand at 159-169 grams per kilometer, and it complies with U.S. BIN‑5 emissions regulations.

The GLK 200 and GLK 220 CDI BlueEFFICIENCY models with six-speed manual transmission are even more fuel‑efficient at almost 43 mpg, and emit only143 to 147 grams CO2/km.

If you should opt for the GLK 350 CDI 4MATIC BlueEFFICIENCY V6 model, you’ll be rewarded with a truly-brutal 457 ft. lbs. and 240 hp of twist along with 34 mpg. Or, a 35 hp increase on 17% less diesel compared to the previous V6.

Package Efficiency

U.S. GLK-Class SUVs will get three terrific BlueTEC diesels, with the first arriving in 2013. The powerful, yet miserly, fours are the biggest news.

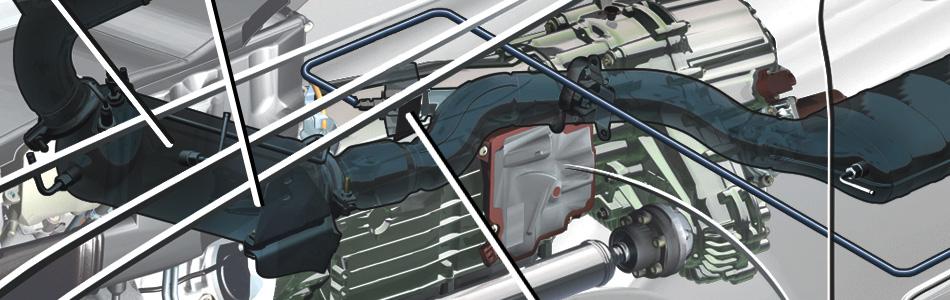

The excellent fuel economy of all GLK diesel models is achieved through a comprehensive package of BlueEFFICIENCY measures, as well as state-of-the-art engine technology. In addition to the ECO start/stop function that’s standard, these measures include the seven-speed 7G-TRONIC PLUS automatic transmission, low-friction axle drives, electric power steering, and tires with low rolling resistance.

To single out one of these, the 7G-TRONIC PLUS, which is standard on all 4MATIC models of the GLK-Class, boasts extremely low converter slip and optimized efficiency. A central role is played by the new torsion damper, which effectively eliminates torsional eccentricities and vibrations in the transmission. The lower the rpm and the lower the number of cylinders, the more severe these can be. This results in a conflict of aims between comfort and fuel-efficient operation. Mercedes-Benz developers resolved this by using what is known as a twin-turbine damper, which is also fitted with a centrifugal pendulum on the diesel models. Depending on the rpm, this moves the centre of mass and allows comfortable operation even in the most economical operating range. Furthermore, the optimized damping allows a marked reduction in the slip of the torque converter lockup clutch even under low loads, which also contributes to fuel savings. This technology also allows an even faster response to driver commands via the accelerator pedal. Friction-optimised bearings and new transmission oil thermal management help reduce fuel consumption, too.

Less Squeeze & More EGR

As far as engine technology is concerned, these amazing enhancements to power, efficiency, and clean running have their foundation in numerous engineering features, not just BlueTEC per se. For example, NOx emissions have always been a problem with diesels because their super compression ratios result in the high peak combustion temperatures that produce oxides of nitrogen. So, M-B first reduced the “squeeze†ratio. A typical diesel might have a ratio of 20:1, or higher, but Mercedes-Benz found that with the BlueTEC’s Garrett turbocharger, the engine is cleaner and more fuel efficient with a ratio of 16.5:1. The vanes of the VNT (Variable Nozzle Turbine) are controlled by the CDI module according to load, and the air-to-air intercooler can take up to 150 deg. F. out of the intake charge.

Other important anti-NOx strategies were to increase EGR flow rates to unusual levels — up to 50%! — and intercooling this inert gas to make it even more effective at keeping those peak temps down.

You may think that EGR and diesels can never work well together because there isn’t enough intake manifold vacuum to draw in any appreciable volume of exhaust gas. Normally, that would be true, but Mercedes-Benz engineers came up with a logical solution: a throttle controlled by the CDI module to produce the required amount of vacuum whenever needed.

Of course, these engines rely on the most highly-evolved version of the Mercedes-Benz Common Rail Direct Injection (CDI) system, which can produce fuel pressures approaching 30,000 psi. The highly-engineered injectors are faster than ever before, and the latest versions can handle an astonishing number of injection events per combustion cycle. This ability spreads out the introduction of fuel into the cylinder even more than previous versions could, which reduces the violence of the combustion event, thus enhancing smoothness and practically eliminating diesel clatter.

Aftermath

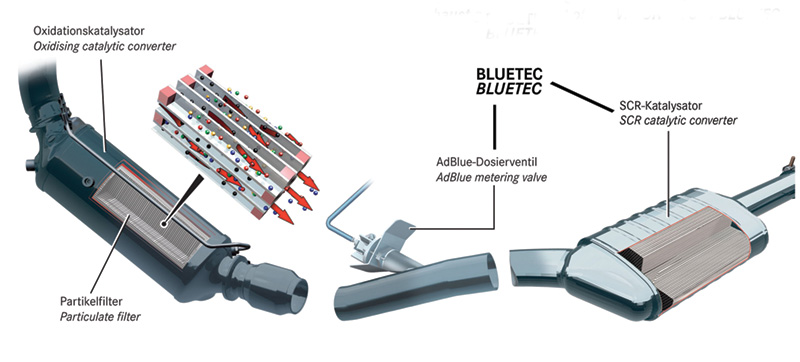

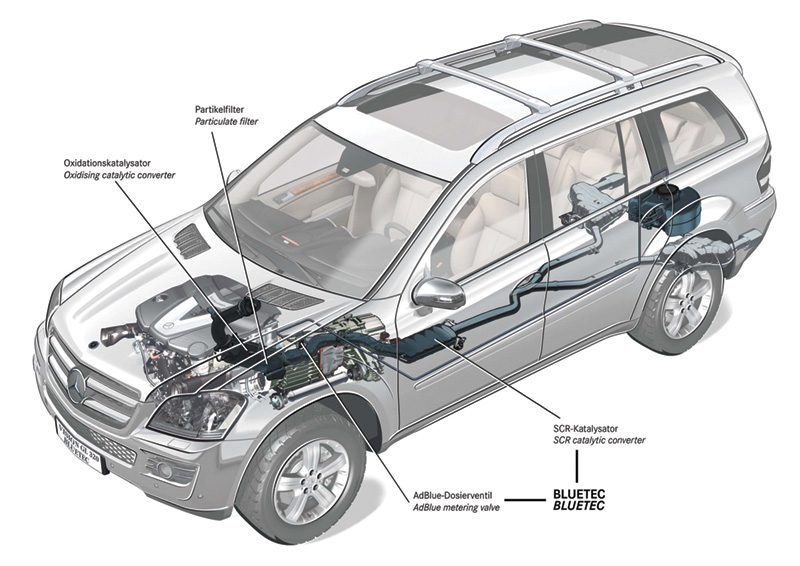

Here, note that the DOC and the DPF are contained in the same can, and where the AdBlue is injected.

Some of the most interesting aspects of BlueTEC are downstream of the exhaust manifold. The mostly-spent gases pass through a Diesel Oxidation Catalyst (DOC), which burns up carbon monoxide and hydrocarbons — the basic concept has been around for decades with gasoline-burning engines. Contained in the same “can†is the Diesel Particulate Filter (DPF), which is a different thing altogether. It actually collects the particles that the EPA has determined are harmful to human health. What happens when it fills up like your vacuum cleaner bag? No, you don’t change it. The CDI module detects the rise in backpressure and goes into regeneration mode. That is, it raises the temperature of the exhaust enough to incinerate the soot so that it blows through as dry ash. It’s sort of like a self-cleaning oven. So that you don’t melt the asphalt in your driveway, regen is performed at cruising speeds.Â

The NOx Absorber Catalyst (NAC) stores oxides of nitrogen during periods of lean operation. Then, under richer conditions (which the CDI module can create through altering injector “on†time), the NAC goes through a regeneration process, and also releases a small amount of ammonia into the exhaust stream. The ammonia is stored downstream in the Selective Catalytic Reduction (SCR) catalyst, which uses it to further reduce NOx. It’s not enough, however, to meet all the latest standards, so AdBlue was introduced in 2008 to make up the difference. It is injected upstream of the SCR.

AdBlue is a registered trademark of the German Association of the Automotive Industry (Verbrand der Automobileindustrie, VdA) for its urea exhaust additive, or DEF (Diesel Exhaust Fluid), that’s needed to get NOx emissions within mandated limits. NH3, more commonly known as ammonia, is created by the injection of liquid urea into the hot exhaust upstream of the SCR cat. It combines with NO and N0x to produce H20 and N2 – harmless water and nitrogen (N2 makes up approximately 78% of the earth’s atmosphere). AdBlue is carried in a heated tank, which should be replenished when the car is serviced. If this isn’t done and the tank runs low, a warning light will flash on, and the engine will eventually fail to start.

Working on Them

Each gallon of Genuine Mercedes-Benz AdBlue fluid should last up to 2,500 miles (how’s that for mpg?).

Early BlueTECs are finding their way into your bays by now, so here are some service issues you should bear in mind:

- This bundle of technologies requires Ultra-Low Sulfur Diesel (ULSD) fuel. While that became the standard in the U.S. six years ago, there is biodiesel to consider. B5 biodiesel is approved for these engines in levels up to 5%, but it must meet ASTM D6751 and have sufficient oxidation stability to prevent deposits or corrosion.

- Recirculated exhaust gases create carbon deposits, and cooling them only makes this situation worse. So, you will probably be cleaning EGR passages and valves, and intake manifolds and throttles often. Your customers will thank you.

- Intercooling adds to the heat load the engine must dissipate, so keep that engine coolant and the cooling system in good shape using genuine Mercedes-Benz antifreeze and parts.

- Use only engine oil that meets or exceeds American Petroleum Institute (API) rating CJ-4 to help prevent ash from plugging the particulate trap.

- A sticking injector that admits extra fuel into a cylinder can result in damage during DPF regeneration as the unit may get dangerously hot. A leaky turbo shaft oil seal can do the same thing.Â

0 Comments