The electric fuel pumps Mercedes-Benz vehicles have used for many decades have evolved and improved immensely. Given their continuous duty and the junk they often have to ingest, however, replacement is still a common job.

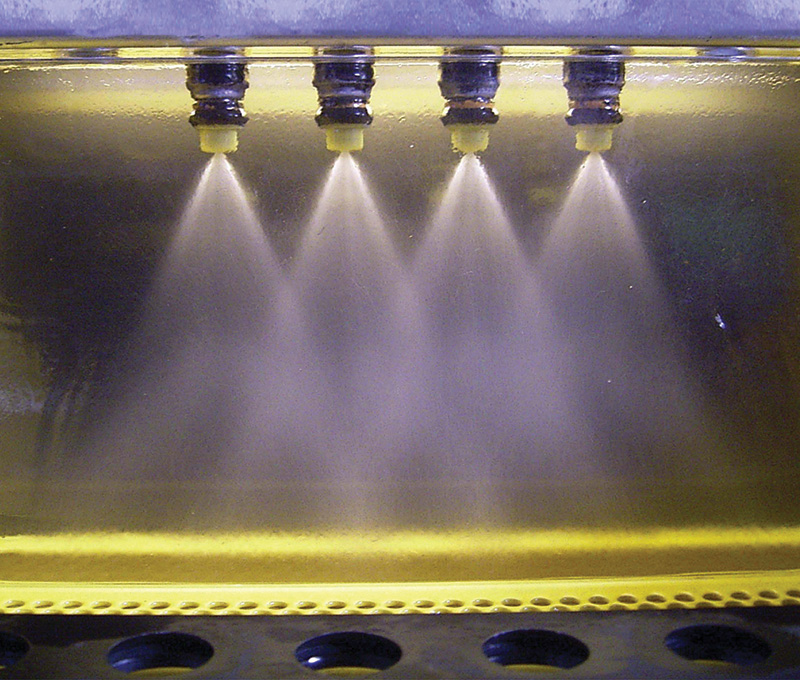

If the fuel pressure and volume aren’t what they should be, you won’t get the carefully-engineered plume of atomized gasoline that assures good performance and efficiency, and low emissions. Of course, dirty injectors have a large effect, too. These have just been bench cleaned.

Whenever you’re presented with an engine that won’t start, or runs poorly, the conventional diagnostic wisdom is that you should check the condition of the internal parts that make compression before you embark on sophisticated electronics troubleshooting. Ditto for fuel pumps. Perhaps that pump is simply worn-out, or maybe the filter is clogged. Even if it’s not quite ready to fail, can you predict how long it might keep working?

Improper psi can cause all kinds of troubles that often get blamed on something else. Symptoms include bucking on the highway, momentary cutting out, hesitation, low power, stalling (typically, it’ll fire up again after it’s cooled off), and, of course, no-starts and hard starting.

History, basics, and lifespan

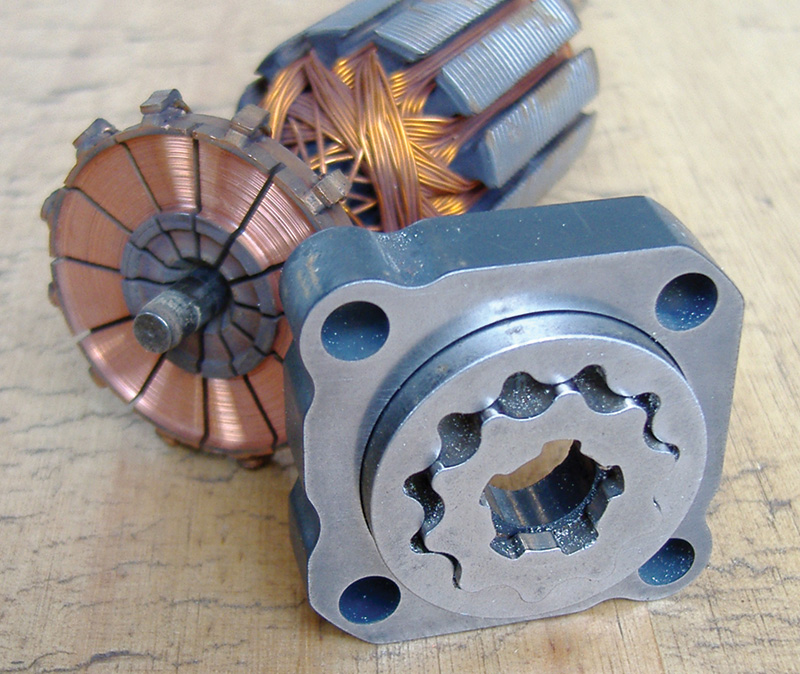

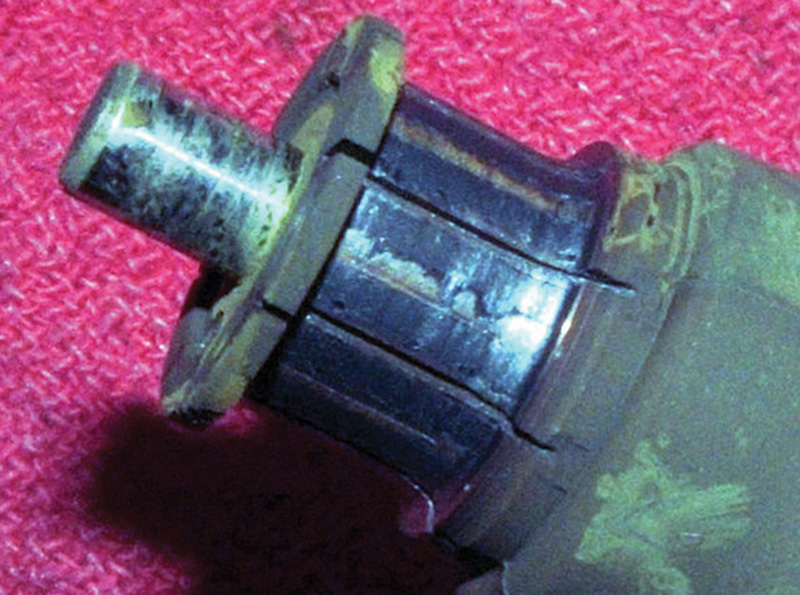

The gerotor/internal gear-type fuel pump has been used up until recently. In this older example, notice how different the commutator is compared to that of later models.

Even before the advent of EFI, Mercedes-Benz vehicles had the Robert Bosch K-Jetronic continuous injection system, which got its pressurized gasoline by means of a roller-cell pump mounted outside of the tank (its electrical ground was sometimes tenuous, leading to intermittent operation). Then came L-Jetronic, LH-Jetronic, Motronic, etc., all of which had in-tank pumps. Another phase of this evolution was the introduction of “returnless†fuel systems, wherein the pressure regulator is also in the gas tank, and the pump has a three-phase, duty cycle-controllable motor (that it doesn’t always run full-blast should increase its longevity). Now, we’re seeing gasoline direct-injection systems with up to 3,000 psi (200 Bar) of pressure, but they’re going to be the subject of a future StarTuned article.

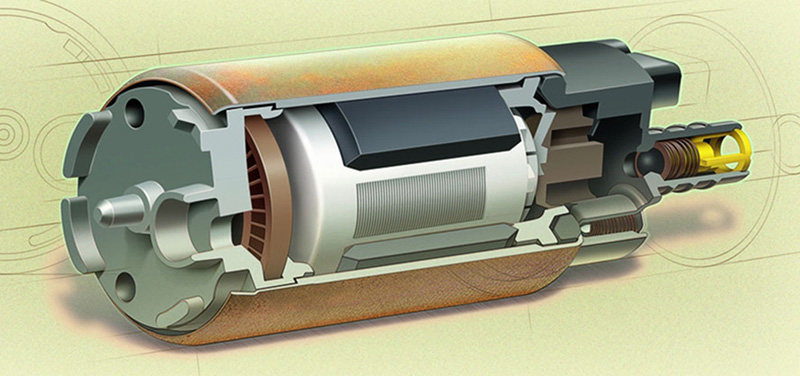

Just about all fuel pumps today are of the turbine type, which are relatively quiet. They don’t do well at swallowing debris, though. (Courtesy Robert Bosch.)

Over the years, high-pressure electric pumps have come in three varieties: roller cell, gerotor or internal-gear, and turbine. The first type, which appeared at the outset of the fuel injection era and continued for years and years, uses rollers in a notched rotor to catch gasoline and force it into a small-volume area of the housing. It has lots of moving parts and can be noisy. Gerotors use a different principle. Similar to an oil pump, they squeeze liquid by means of the eccentric action between a star-shaped rotor and a matching element that surrounds it. The turbine type first showed up almost 20 years ago, and you’ll find both single- and dual-stage versions in most late models (certain applications still used gerotors up into the last decade). Its main advantages are fewer parts, no internal friction, and less noise. They’re not always perfectly silent, though — since they spin so fast, you can sometimes get a high-pitched whine. One drawback to the design is that it isn’t capable of grinding up any debris, so it requires a very efficient pick-up strainer/screen/sock.

Turbine pumps use centrifugal force to generate pressure. The moving parts don’t actually touch, so there’s no wear. That is, except in the electric motor.

The question of pump lifespan is interesting. Engineers have told us that early designs had a target longevity of 10,000 hours (roughly 300K to 400K miles), then improvements such as lower amperage draw, better-balanced armatures, and more compatible materials in the brushes and commutator made it possible for them to go even farther.

Those enhancements may be very admirable, but every technician knows that in the real world fuel pumps often don’t last for the life of the vehicle (which is typically very long indeed in the case of Mercedes-Benz). What can cause the demise of such a highly-engineered component?

If you want to do some research into what’s killing pumps among your customers, you can use an exhaust pipe cutter to slice through the aluminum housing and pull out the internal components. It’s easy and interesting.

Two things: dirt, and restricted filters. You may have noticed that many of the fuel filters you replace are so thoroughly clogged that you can’t blow through them. If you had checked the pump’s amperage draw before removing the old filter, you might have seen up to twice the expected number — say, eight or ten instead of four to six. It shouldn’t take much of an intellectual leap to realize that a plugged fuel filter will make a pump work harder, and all that extra electricity will wipe out the brushes and groove the commutator, killing the pump prematurely. Increased backpressure in the system equals more arcing, heat, and wear.

Late model Mercedes-Benz replacement pumps come assembled in a module, such as this M-Class specimen. That relieves you of the responsibility of putting all the parts back together so that there are no leaks past the strainer, and there’s no unwanted contact between parts that can cause noise.

Sucking silt

Filters are one thing, but bear in mind that whatever you might find in one has already been eaten by the poor pump. That’s why it’s so important that you install the strainer/sock/screen pickup carefully so that there’s a perfect seal. Pump manufacturers have told us that the biggest cause of premature failure with replacement units is a mistake here. With the gerotor type, noise may become noticeable early on as the contaminants scuff the gears and they drag against each other, and the turbine type won’t tolerate dirt at all. Of course, if you buy the whole pre-assembled Genuine Mercedes-Benz fuel pump module that’s available for most late models, there’s no risk of unstrained gasoline making its way into the internals.

While it’s hard to prove that running on empty damages a fuel pump, it certainly can’t be doing it any good. Aside from less cooling action, contaminants will be more concentrated.

In an ideal world, the gas tank would be dropped and thoroughly emptied and cleaned, preferably with steam. Even if you have to pump or siphon out a considerable quantity of gasoline, don’t even think of putting it back into the car. The silty contaminants tend to stay in suspension, so dispose of the old stuff one way or the other — maybe you could run your lawnmower on it.

This isn’t an issue with certain late models such as C300 California-spec TZEVs because you can’t just replace the pump. The tank, pump, and sending unit come as a complete assembly.

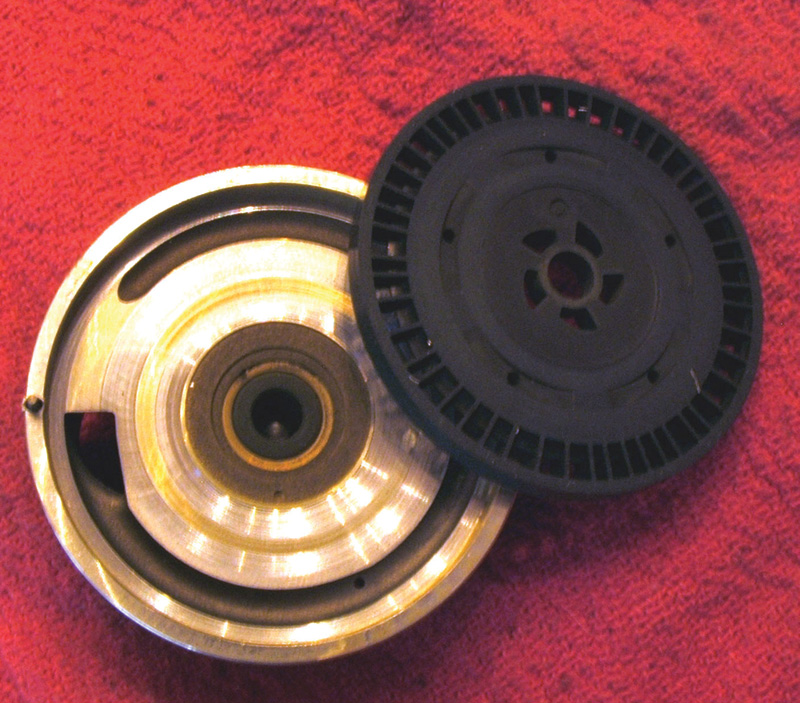

When a pump motor’s commutator gets rough like this from contaminants, heat, and the excessive electrical load caused by a restricted filter, the brushes wear out and bounce to the point of failure.

Besides dirt, another factor that damages pumps is motorists who drive with their tanks nearly empty. Gasoline is what cools the pump, and the silt mentioned above is going to be a lot more concentrated in three gallons than in 15. Suggest to your customers that they try not to run on the last dregs of gasoline in their tanks.

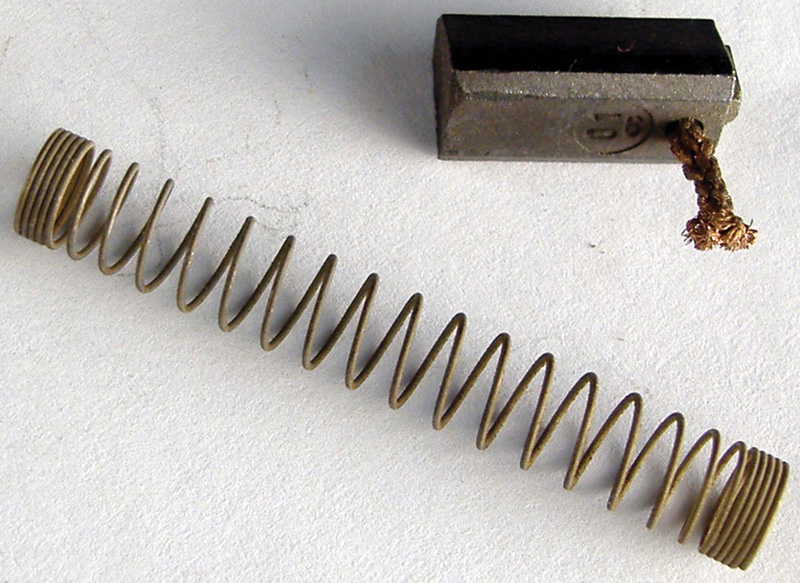

Except for a total internal jam-up, the ultimate failure of a pump’s ability to force fuel forward will be electrical. If the commutator becomes rough from contaminants or overheating, the brushes start to bounce. This oscillates the wires that connect to the brushes, and eventually one of them breaks. In older models, the tiny brush spring ends up carrying the current, a job it’s certainly not up to, and it quickly burns out. Newer units have nylon brush carriers, so when the wire breaks there’s not even this much to fall back on.

Symptoms and testing

Excessive oscillations of the brushes can cause their leads to break from fatigue. If the springs are grounded, they’ll complete the circuit, but not for long. In later versions, the brush holders are all nylon, so there’s no path to ground through them.

What are the symptoms of a failing pump, exactly? One fuel system authority says, “Typically, no-start after shut-down. You usually have some warning on the highway.â€Â A veteran diagnostician and shop owner tells us, “The problems we see are mostly intermittent failures on the road. The car cuts out, bucks, then stalls. But it’ll often start again once it’s cooled off.â€

Everybody in this business should know by now that checking fuel pressure is one of the requisite basics of performance troubleshooting, but we keep hearing that many of you out there don’t bother to do it. Get with it and customer complaints become more comprehensible. As one seasoned veteran says, “If you don’t check pressure, you might start replacing sensors or the computer to fix the problem when the pump or a clogged filter or screen might be the real trouble.â€Â

We should mention some troubleshooting tips we’ve learned over the years:

- You should see violent needle swings between dead‑head (return line clamped) and running pressures. A slow rise means trouble.Â

- Pull the pressure regulator’s vacuum hose and you should see a rise.

- Once you’re sure the hose to your gauge has all the air bled out of it, you should see that needle spring to attention almost instantly when you switch the key on. A slow pressure build points to a problem.

- Low pressure suggests not only a weak pump, but also a clogged filter or pick‑up sock, a crimped line, or resistance in the pump electrical circuit.

- Too many psi may be due to a restricted return line.

- Just because you’ve got specified pressure doesn’t mean there’s sufficient flow. Total system volume at the Schrader of one liter in 35 seconds is a common “nominal value†in StarTekInfo. You’ll find cases where just opening the valve on your gauge will kill the engine, yet the psi reading was fine.

- On a conventional fuel delivery system, a dirty inline filter will reduce fuel volume and fuel pump rpm, and increase fuel pump current. This is because the plugged or restricted filter acts like a dead-head. On a returnless system, the restricted filter will have no effect on fuel pump speed or current, since these systems are always dead-headed anyway.

- A dirty pick-up screen will reduce fuel volume, possibly increase fuel pump speed, and decrease fuel pump current, since it will cause pump cavitation. Either a conventional or a returnless system will react the same way since there’s no essential difference on the “suction†side.

Good pressure doesn’t necessarily mean sufficient volume. In some cases, just opening your gauge valve will kill the engine. Better do a volume test.

Where’s the juice?

No or low pressure may mean the pump’s circuit is faulty. A bad control relay is a possibility, but check for poor connections before you think about new parts. Test for the presence of battery voltage at the pump’s positive terminal or wire, and keep in mind that a bad ground is a common cause of both no-starts and performance problems.

Voltage-drop testing is the best way to locate high resistance. With the circuit powered up, use an accurate voltmeter to see if you get a reading across connections and lengths of wire. Anything more than about .2 volt (or, 200 millivolts) is too much. Â

If the pump won’t run at all, it’s natural to check the fuse. If it’s blown, and the car starts after you replace it, you should still find out how many amps it’s being forced to carry. Fixing high draw now may head off a future breakdown.

You’ll need either a low-reading analog ammeter or a DMM (Digital Multi-Meter) with sufficient current-carrying capacity. As we hope you know, amperage testing is done either by hooking up the meter in series with the load, or with an inductive pickup that you clamp around the wire. The latter works best with big current flow, such as you’d find in the starter circuit, so we prefer the former for diagnosing fuel pumps. That means you’ve got to break into the circuit. Connect one of the ammeter’s leads to the positive battery post and the other to the pump’s hot wire. Look this up in WIS. The same goes for the draw specs, but we will say that if you see anything over six amps with a mid-pressure system (45 psi), or seven amps with a high-pressure version (60 psi +), you’ve got a problem.

Leaker

The fuel pressure regulator is a pretty simple device, but that’s no reason to overlook it. Whenever you see high emissions, some experts say to pull the vacuum hose off the fuel pressure regulator and look for gasoline. Diaphragms have been known to rupture.

System leak-down can cause hard starting, among other things. If psi won’t hold, pinch off the supply line. No change? Then the check ball in the pump isn’t the culprit. In cases where leak-down disappears when the return line is pinched, the problem is a perforated diaphragm in the pressure regulator. If that doesn’t make a difference, you’ve got seepage through an injector.

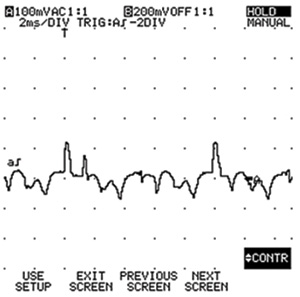

You can use a lab scope or a graphing multi-meter to observe the waveforms the pump’s motor is generating. With experience and experimentation, this will help you predict how much life is left in it.

It’s fairly unusual to find a blockage in a line, whether from a crimp, dent, or a big piece of debris, but it does happen. Identifying such a situation requires looking around underneath with a good light and an inspection mirror.

Speaking of lights, we should mention that more shops burn from droplight accidents than from anything else. Whenever you’re working around fuel, use only the LED or enclosed fluorescent type.

Ramping

Taking a good look at the waveforms the electric motor generates can help you predict how much life that pump has left in it, but the “current ramping†idea isn’t cut and dried. It’s easy enough to tap into the circuit with a lab scope or graphing multi-meter so that you can actually see the waveform, but interpretation is subjective. You really need to use exactly the same piece of equipment in exactly the same way over and over to collect a database before you can be sure of what you’re looking at. Still, with a little comparative experience, it’ll help you nail down those elusive intermittents.Â

0 Comments