Using a sophisticated self-diagnostic system makes your life a lot easier provided you know the exact options and systems the car actually has. That’s where XENTRY comes in.

While the SDS unit is the main brains of the system, the SDConnect unit is the “pass-thru†device that you may be more familiar with. The unit interprets the vehicle’s software language and communicates the information to the SDS unit so you can view it.

Elaborate CAN systems developed by Mercedes-Benz allow for considerable integration of various functions. These give the Mercedes-Benz owner some value-added features not found on other vehicles. When a car owners use the “Convenience Feature†by holding down the unlock button on their remote, they signal the doors to unlock. By continuing to hold down the button, the door modules are signaled by the RFA module to open all of the windows as well (if this feature is turned on). This releases some unwanted hot air from inside the cabin before getting in. Also, the door locks may be programmed to lock once the vehicle is being driven away and exceeds several miles per hour. Here, the Powertrain CAN passes on the vehicle speed signal to a gateway module, whose job it is to transfer information from one CAN to another. From the gateway module, the vehicle speed signal is interpreted by the PSE or door modules and commands all of the doors to lock.

CAN System Features

If the vehicle is a convertible, this same vehicle speed sensor is used to prevent the top from being operated while the vehicle is at speed for obvious safety-related concerns. This elaborate CAN system not only provides these additional features, but it allows for some comprehensive self-diagnostic features as well. Almost all data can be interpreted by the self-diagnostic software, and optional features can be “tailored†to the owner’s desires. With all of these options and features present, one of the more difficult tasks will be to properly identify the vehicle and its programmed options. We have all seen that some vehicle owners will change or remove the badging on the rear deck lid that identifies the series and engine. In addition, we all also know that each model or class of vehicle will have a few different chassis designations as the model evolves throughout its lifecycle. For example, the E-Class started off life as a 124 chassis and evolved into the 210, 211, and now the 212 chassis, but it is still an E-Class. The systems changed with the chassis development, so you cannot use the same communication protocol on a 210 chassis as you would a 212 chassis.

The SDS (Star Diagnosis System) uses the chassis “Baumuster†(“build modelâ€) number to more accurately identify the chassis and options of the vehicle. The Baumuster number has been used by Damiler-Benz almost since its inception to identify the entire product line during development and engineering. The first three numbers are always the chassis designation. The next three numbers tell us the major options — say, if it is a 4Matic model, and what the engine size is. You can also find the last two digits of the Baumuster number as the seventh and eighth characters of the U.S.-specified VIN (Vehicle Identification Number) on all but the latest chassis. This helps you properly identify the vehicle you are working on. It is always best to use the VIN to properly identify the vehicle and, with a free subscription to Mercedes-Benz EPC (you can pay a few dollars and get access to worldwide VINs), you can enter the entire U.S. VIN, and the Baumuster number will be provided for you. You will also have access to the same parts information as your Mercedes-Benz dealer’s parts department, as well as completely identifying the vehicle. This can prove invaluable when ordering parts, but always trust the experience of the personnel in your local dealer’s parts department.

Introducing XENTRY

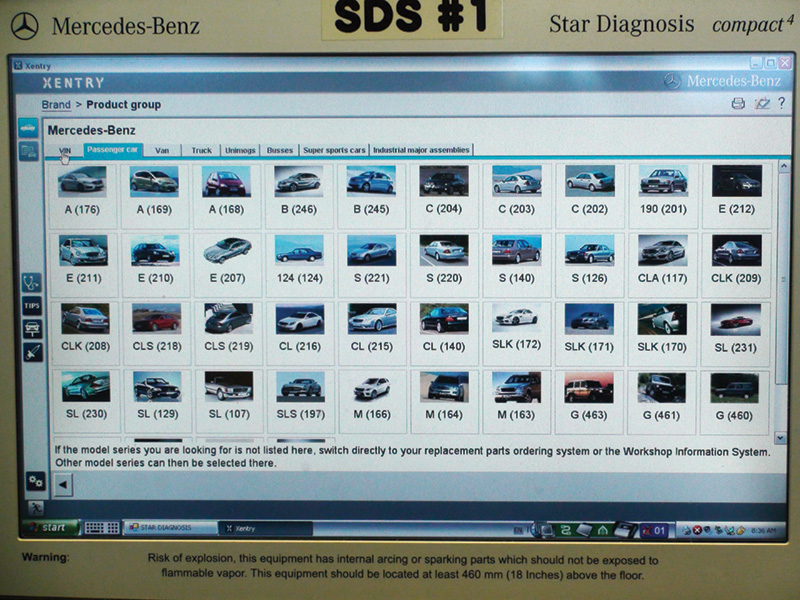

XENTRY is the updated version of SDS diagnostic software that helps you identify the vehicle, communicate with it, and perform diagnostic functions. You will see small photographs of the vehicles with their Baumuster number identifying them. This helps the SDS identify the systems and the software protocol that will be used to communicate with the vehicle. You can also simply enter the VIN and this will also identify the vehicle and its specific systems. As you become more familiar with the vehicles, this will not be necessary and you should be able to identify each vehicle yourself. Once the vehicle’s chassis designation and options are known, you can advance into self-diagnostic and programming functions. With a fully-functioning SDS with on-line access, you can perform software updates and bring new control units on-line by programming them to the vehicle. Mercedes-Benz is very cautious before releasing its vehicles to the public, making sure that all of the kinks are worked out. Unlike other manufacturers that have you go through a search for upgraded software for each control unit, Mercedes-Benz will only have you reprogram a control unit if there is a specific campaign to solve a specific problem. Software upgrades eliminate these glitches and provide seamless operation of integrated CAN systems.

These software updates may correct some concerns that your customers did not know they had, as well as issues they may be very aware of and want repaired. This one step may save you hours of diagnostic time that in the end you may not be able to bill for. A repair that is not cost-effective is bad for both you and your customer. Typically, the memory of the control unit being updated will be lost, so it is always a good idea to record all of the codes in your “Quick Test†before re-flashing any control unit. If it is required that you update a control unit, you will need to have the ignition key on and the engine off. You cannot do it while the engine is running. The control units will be awake, functioning, and communicating, and this will probably interfere with the reprogramming operation. Ideally, you need all of the other control units on that CAN to be “asleep†and not transmitting data while updating the software on a single control unit. Mercedes-Benz recommends that you have a battery voltage maintainer attached to either the battery or the jumper cable lugs while programming.

Mercedes-Benz vehicles are electronics-intensive. With the ignition key on for long periods of time, you can discharge the battery. It is always a good idea to have a battery maintainer (commercially available) attached to the lugs on the vehicle. This is particularly important if you are going to code, flash, or program a new control unit since stable voltage needs to be supplied.

XENTRY Abilities

Once software updates have been performed, you will have to road test the vehicle and see if the customer’s complaint returns. If it does, you can use the SDS to pull codes, evaluate both “freeze frame†and “live†data, and perform bi-directional control of the system you are working on. This includes features that use more than one control unit to perform a function. Also included in the SDS operating system is GFF (Guided Fault Finding). This allows the SDS to follow a step-by-step diagnostic procedure for the specific trouble code you are trying to diagnose. Some of the testing can be performed by the SDS and the results will be displayed on the screen so you can interpret them. Some of the tests are electrical that you will have to perform yourself with additional equipment such as a DMM (Digital Multi-Meter). If an electrical test is required, you will be given the pin numbers of various control units and components for checking resistance, amperage, and voltage. You will then be prompted to answer a question with the results of the measurement. This will prompt the next step of the diagnostic process. These are the same diagnostic steps a technician in a dealership may follow. The end of the diagnostic procedure will lead you to the resulting repair.Â

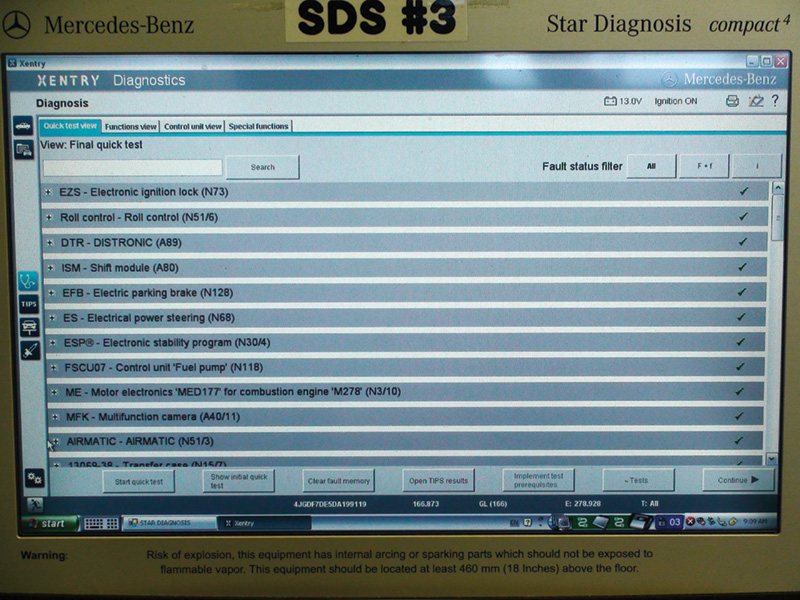

You do not have to follow the GFF procedures to diagnose a DTC or drivability problem. There are many options you can take other than just pulling codes. Mercedes-Benz strongly suggests that you start each diagnostic procedure with a quick test. In this step, XENTRY will establish communication with each control unit that the vehicle is supposed to have and pull codes. From here you have several options on how to diagnose the problem. The results of the quick test are listed by their respective control unit. In the quick-test view, you will only be shown the control unit hardware numbers, software numbers, and whether or not any codes are present. The control unit electrical wiring diagram (ETM) component designation is also provided to aid in selecting the proper wiring diagram if trouble codes are present. Since some functions require more than one control unit to execute, you can select the next tab and choose the “Function View.†This lists the functions that a customer might complain are not working. It will automatically pull up all of the control units required to execute the function. If you are already familiar with the older SDS layout, you can go to “Control Unit View†and each control unit will be listed according to its “Drive,†“Chassis,†“Body,†etc.

Once You’re Inside the Control Unit…

You can select the vehicle yourself if you are familiar with the Baumuster number, or you can select the VIN tab to enter the specific VIN. The SDS control unit will automatically query the vehicle for the control unit installed.

Once you have selected a control unit or function, you have a few choices aside from pulling codes and following GFF steps. You can start by looking in “Actual Values.†Here you can look at live data and view adaptation information that the control unit had “learned.â€Â Live data saves you the trouble of having to take a DMM and measure the voltage at each component’s signal line. If you see a voltage reading that does not appear correct, you should always support the diagnosis by checking the voltage and the wiring at the actual component. If you want to know if a control unit is capable of controlling an output, you can select “Actuations.†Here, you can command the control unit to operate the driver that controls the outputs of the system. This is a simple on-and-off test. You can measure the voltage on the control side of the component and monitor if the control unit is capable of supplying power or ground to the control circuit. Almost all of these functions need to be carried out with the ignition key on and the engine off, so have the battery maintainer attached during testing.

Mercedes-Benz strongly recommends that you perform a “Quick Test†of all the vehicle systems. Many features of these vehicles are dependent on a few control units working together. It is a good idea to look at the overall layout of the problem systems. You can select the “Functions View,†and the SDS will pull up the control units that have control over the feature you select.

Once you have established that the control unit is capable of manipulating outputs, you can often look at adaptation data. Adaptations are adjustments made by the control unit that occur over time. For instance, if the engine continues to run lean on cylinder bank one at idle, the additive fuel trim will show that the control unit needs to add fuel under idle conditions. This may indicate a vacuum leak. If you were to clear these adaptations, the vehicle may run poorly until the engine control unit learns that bank one is lean and starts adding fuel again. These learned values are often displayed as a percentage or on the Lambda control. A positive percentage means fuel is being added and a negative reading means fuel is being subtracted. In the Lambda control, the number 1 is the midpoint, above 1 fuel is being added and below 1 fuel is being subtracted.

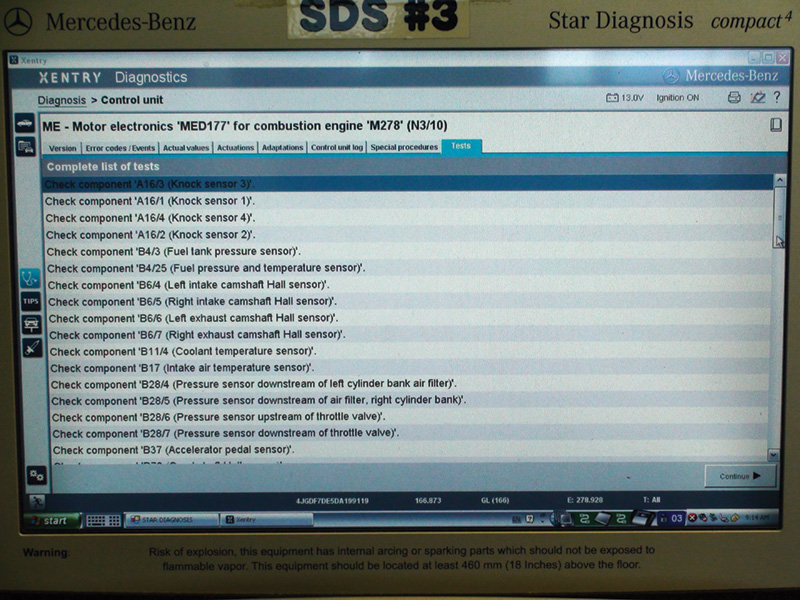

XENTRY has added a “Tests†tab that expands on the previous SDS software actuations tab. Here you can perform static and dynamic tests for each system in that particular control unit. Each test will run just as the vehicle self-diagnostic functions would run while the vehicle was being driven.

You may also find adaptation data in the transmission. Here the scales are different. Clutch volume fill times may increase as the control unit applies more pressure to a clutch as the fiber discs wear. Looking at transmission adaptation data can tell you if a particular clutch pack is worn or a shift solenoid is sticking.

Bi-Directional Controls

One change in system is the addition of a “Tests†tab in the diagnostic portion. This is slightly different from “Actuations†in that multiple outputs are activated while the engine is running to simulate the system in operation. The result is an overall system Pass or Fail. Very often you can watch the signal voltage of the system in question as the test is being performed. If you were to attempt this yourself, you would have to graph the signal voltage of the sensor in question, operate the output, and match the conditions of the test. This can be a difficult and time-consuming task. It is made more cost-effective with an SDS scan tool test. Some of these tests were previously found in “Actuations†in the older SDS software. The number of tests have been expanded and given their own tabs in the XENTRY system.

You can purchase your own Mercedes-Benz SDS unit for your independent repair shop. Simply access www.startekinfo.com, and under the “Star Diagnosis/XENTRY†heading select the “Aftermarket†field. You will be prompted to open a PDF document that has all the necessary paperwork needed to purchase a XENTRY unit, as well as instructions on how to fill out the forms and submit them.

If your diagnosis leads to a malfunctioning control unit, it is going to have to be replaced.

If this unit is deemed important enough by Mercedes-Benz, it will be assigned a Software Calibration Number (SCN). Each modern Mercedes-Benz vehicle has the VIN and SCN burned into the more important control units to prevent parts theft. The control unit will only work if the VIN and SCN match the vehicle. You cannot swap parts from another vehicle and hope that they will work. When you install a new control unit, you will need to login online to the Mercedes-Benz After Sales portal for the SCN. This number is calculated with the vehicle VIN and the software ID number in the new control unit. After the SCN is calculated, XENTRY will take over and write the vehicle data into the control unit.

By making the investment in a factory XENTRY system, you will now be able to perform more accurate, complete repairs that are both cost-effective and profitable. No more guesswork or worry that the aftermarket scan tool is giving you incorrect information, or that you cannot complete the job when programming and coding are required. This gives you an added advantage over your competition and keeps your customers coming back. Isn’t that what we are all striving for?

0 Comments