[Editor’s Note: We first met our old friend Bill when he was teaching engine machining techniques for Perfect Circle, and we’ve learned a great deal from him in the decades since. Here, he’ll dispel any misconceptions you might have about this tough, high-precision type of gasket that makes the old composite variety look downright primitive.]

by Bill McKnight, Team Leader — Training, MAHLE Clevite, Inc.

All photos courtesy Victor Reinz.

The multi-layer steel head gasket is a triumph of engineering analysis and manufacturing precision. No compressible “composition†paper/fiber materials in sight.

The MathIf you drove your car at 70 mph for 200,000 miles [almost to the moon!] and it was turning at 2,400 rpm at that speed, the cylinders would each fire 201,600,000 times. The math is simple: 2,400 rpm means each cylinder fires 1,200 times a minute (two revolutions of the crankshaft for each firing) times 60 minutes is 72,000 times in an hour. At 70 mph, it would take 2,800 hours to drive the 200K miles. So, 2,800 hours times 72,000 times per hour is 201,600,000 times! This means that the head gasket material has been compressed, then relaxed, 201,600,000 times! |

It’s hard to believe, but the Multi-Layer Steel (MLS) head gasket has been used on American vehicles as O.E. for over 20 years (the 1991 4.6L Modular Ford V8 was the first). Even after all that time, there is still misunderstanding out there about how the gasket works to seal the top of an engine, and its special attributes and service needs. As with most things mechanical, we’ll do best by starting off with understanding the basics before moving to the more complex.

Head gasket basics are pretty simple:

- We have to seal combustion pressure — 1,200 psi in stock engines, 1,800 psi or more in high-performance and racing engines.

- We have to seal coolant as it travels between the block and heads.

- In OHC engines, we have to seal high-pressure oil moving from the block to the OHC valve train.

It starts to get a little dicey when you realize we have to do the above from ambient air temps of -30 deg. F. to 120 deg. F. Next, we add today’s expected engine life of 200,000 miles or more [high-performance use excepted! Ed.] and it becomes more challenging yet. Finally, it gets to sound even more impossible when you realize we’re not dealing with a static engine, but one that is running, and heating and cooling.

What happens as an engine runs is that the cylinder head is actually lifted off the block from the firing pressure in the cylinder. It’s hard to imagine this, but the head bolts are elastic and stretch a tiny bit to allow this head liftoff. The gasket actually acts as a spring, relaxing, then being compressed again every time the cylinder fires. Of course, all through this cycling, we expect the gasket to do those three things mentioned above.

How does the head gasket do it?

The top and bottom layers are hardened stainless steel and have raised beads called embossings on their surface, which increase clamping force where needed.

In the not-too-distant past, head gaskets were of what we called the “composition” type. That is, gasket paper/fiber [if you want to go back far enough, asbestos sheeting] attached to a steel core with a metal flange or fire ring surrounding each cylinder. The fire ring was thicker than the gasket body (the paper and steel part) so when you tightened the head bolts down, the fire ring absorbed much of the load, thus sealing the combustion gasses. It was left to the body of the gasket to seal coolant. Obviously, there were enhancements added to these gaskets over the years to allow them to continue to seal as engines got more complex. The steel fire ring, by the way, would compress and relax to allow the head movement we talked about.

“Black Diamond†is the trade name for the Victor Reinz Ford 6.6L Diesel head gasket. It’s identical in every respect but the color of the coating to the OE part. Diesels generate high cylinder pressures just like racing engines, so prove the concept for high-performance applications.

The Ford 4.6L “modular†V8 was the first domestic engine to use an MLS head gasket. This modern version for that application has selective silk screened polymer over critical sealing areas.

In the 1990s, the head gasket’s job got progressively harder and harder. Engine life expectancy increased from perhaps 120,000 miles to 200,000 miles or more, and, of course, we expected the gasket to last the life of the car. The other factor that hastened the demise of the composition head gasket was the adoption of bi-metal engines — aluminum heads and cast iron blocks became the norm. Because aluminum’s expansion rate is about 1.7 times higher than that of cast iron, a radial stress was being applied to the composition gasket’s body. If the gasket stuck to the head and block, it was literally tearing itself apart as it went through thousands of cycles of expanding and contracting when you started your car, drove somewhere, let it cool down, then started it again to go somewhere else. We had head gaskets failing long before that target mileage we mentioned.

MLS was a big departure

Composite Lives On in HPOn high-performance engines, we still see quite a number of composition head gaskets being used. We can get away with this because most performance engines don’t see the duty cycles (starting/stopping) and total mileage requirements of a stock engine, so the composition gasket works for those conditions. |

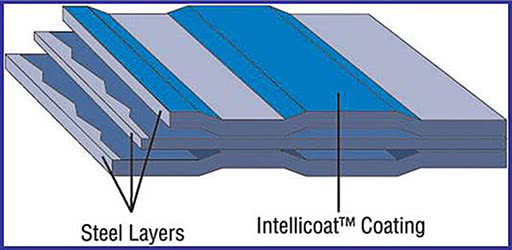

There was lots of mystery surrounding MLS gaskets when they were first introduced, but we hope there will be none for you when you finish this story. These gaskets are usually constructed of three to perhaps five layers of steel riveted together to form a stack. If you’ve ever handled one, you know that each layer is separate, not glued or bonded to the other layers. The top and bottom layers are hardened stainless steel, a.k.a. spring steel, and have raised beads called embossings on their surface. These embossings surround the critical sealing areas: combustion chamber, coolant passages, and the high-pressure oil passage. You’ll sometimes hear these layers referred to as “Active Layers.†That’s because the spring steel embossed areas are compressed to get the seal, then relax as the cylinder head lifts off the block. When we compress these embossed areas, we have to have something to compress them against, so an MLS head gasket has a layer in the middle often referred to as the “passive layer.â€

In this close-up, you can see the concentric “Wavestopper†rings around the cylinder. Each ring is capable of acting independently of the others to maintain load on the gasket even during the hardware distortion caused by heavy loads.

Also, it’s important to remember we’re talking about compressing and releasing the gasket 200 million times throughout the life of the engine. As you’ve probably gathered by now, the quality of the stainless spring steel used in these active layers is critical to long gasket life!.

We know that the most difficult job of a head gasket, as far as sealing goes, is containing combustion pressure. We’ve got 1,200 psi plus of gas pressure compared to 18 psi for the coolant and maybe 60 psi for the oil. Gasket engineers usually add something to the passive layer of the MLS gasket to help get this accomplished. We call it a stopper. Sometimes it is just a doubling of the passive layer around the combustion chamber, but for higher output engines it gets more complex. Victor Reinz has its patented “Wavestopper” technology, and FelPro its LaserWeld technology to get good combustion sealing as cylinder pressure rises.

Retaining fluids

Here, you can see the active top and bottom layers, the stopper layer in the middle, the embossed beads in the active layers, and the Intellicoat polymer coating applied to selected areas of the gasket.

Extra load is required to seal fluids, too, so MLS gasket engineers also add embossments around coolant passages and oil passages. Because the load required is less than that for combustion, the embossments are not as rigid a design. The best way to think of this is as a “balancing act.†The gasket engineer has just a finite amount of bolt load and has to balance the job of sealing combustion pressure with the job of sealing fluids. Computer modeling along with years of engineering experience is what it takes.

Coatings

MLS head gaskets need more help to seal the coolant. If we just ran the bare stainless steel gaskets, there’d be a tendency for the coolant to seep or weep under the embossed area. Early MLS designs had the active layers coated with a polymer to help prevent this. Typically, this material was brown or black in color and covered the entire active layer. Even with this polymer coating, extremely smooth surfaces were required on the head and block to get good seal. Fast forward 20 years and now you see the polymer silkscreened just over the critical areas of the gasket. The advancements in polymers have made for more reliable, easier to seal designs that don’t require the ultra-smooth sealing surfaces of the past.

Long, long life

We can wind up this discussion by bringing the topic full circle. MLS gaskets, being steel-on-steel-on-steel, have nothing to delaminate, so work great on bi-metal engines. Hardened stainless steel beads can be compressed and relaxed millions of times and not fail, hence the 200,000-mile life expectancy we desire. So here we have the “perfect†head gasket in both design and materials for today’s engines.

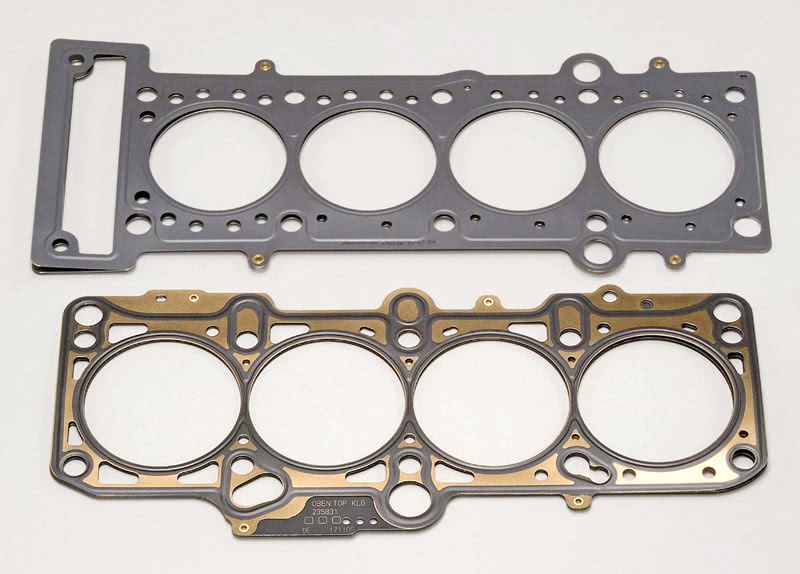

These examples, a BMW Mini (top), and a VW, both illustrate the precision with which MLS head gaskets are made.

Â

Victor-Reinz, FelPro and Cometic all make top quality MLS gaskets and they are available through the major racing parts suppliers like Summit, Jegs and Lane.

Where do you buy these head gaskets, i sure could use them for my race motors,becouse every week i teare down my motors and the copper ones are a little high,so i figure this is one way to help my buget on meterals. so if anyone knowes where i can get these head gaskets plese let me know. Thanks.