A look at Nissan’s Electronic Throttle Control System and its components, including a discussion on the advantages of the design, as well as some diagnostic considerations that underscore the importance Nissan has given to reliability.

A look at Nissan’s Electronic Throttle Control System and its components, including a discussion on the advantages of the design, as well as some diagnostic considerations that underscore the importance Nissan has given to reliability.

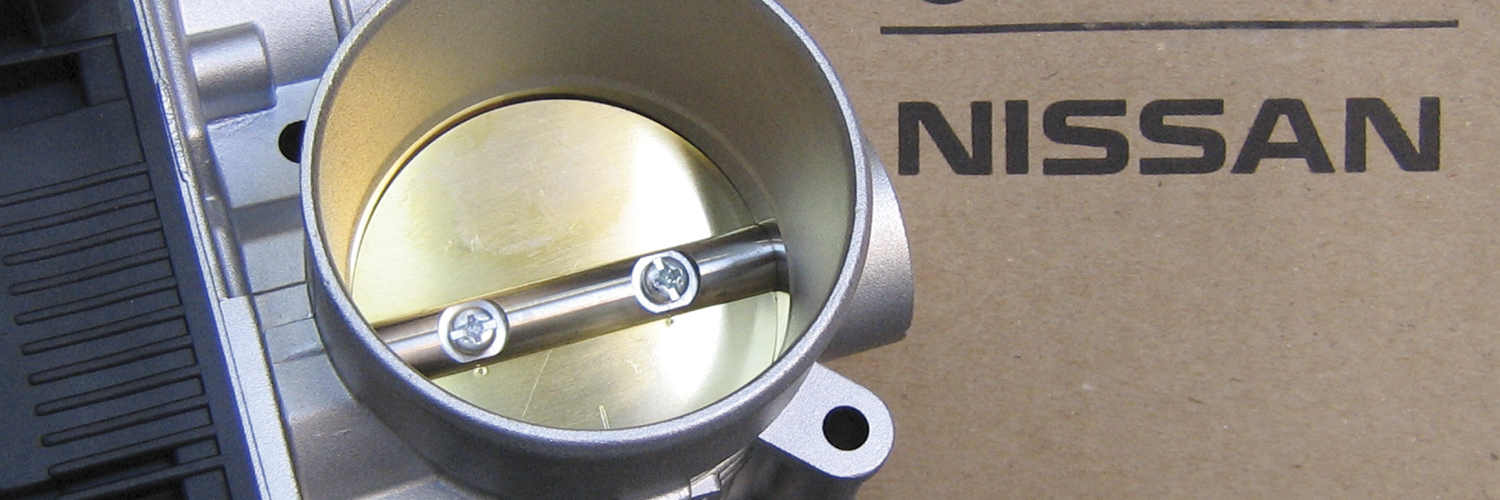

As we in the industry all know, there is no such thing as a “gas pedal,†but rather a pedal that controls air flow into the engine. Traditional designs connect the accelerator pedal directly to a valve within the throttle body using linkage or a cable. When the driver’s foot is off the pedal, the “butterfly” valve is closed against its stop. You will find an Idle Air Control Valve (IACV) or a similar auxiliary air-input path that the ECU can use to bypass the throttle plate. These days, all Nissan vehicles come equipped with fully electronic throttle control systems, and this article will introduce you to Nissan’s implementation of throttle-by-wire.

How it Works

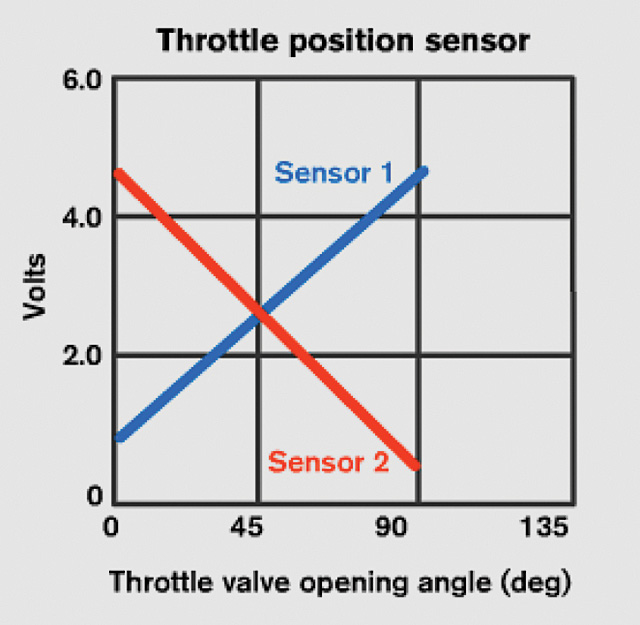

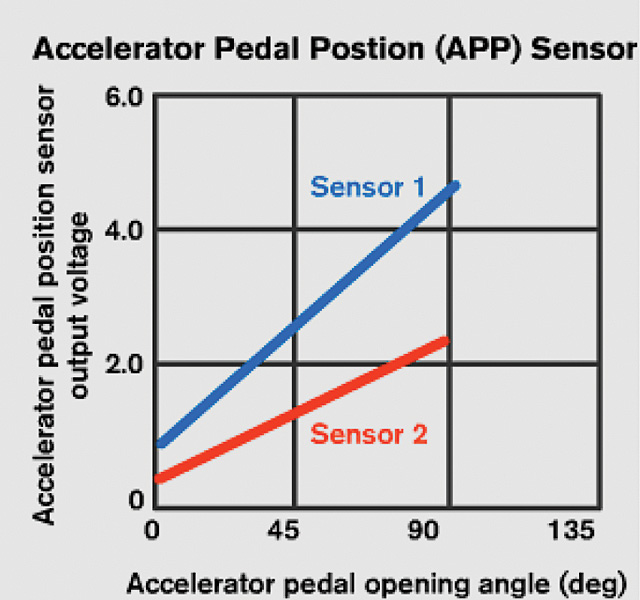

In the most common throttle-by-wire design from Nissan, instead of a cable there is an electronic throttle valve actuator that is commanded by the ECU and physically opens or closes the throttle valve. Because there is no cable tension, position sensors located on the accelerator pedal and on the throttle actuator give equivalent data to the ECU. When the driver moves the accelerator pedal, the Accelerator Pedal Position sensor (APP) reports the movement to the ECU, which then commands the throttle valve actuator to rotate the throttle plate open or closed. Instead of a secondary idle valve, the ECU can control the throttle plate as needed to regulate idle. The location of the throttle plate is reported by the Throttle Position Sensor (TPS) and is some percentage of a 5V reference.

The ECU learns over time what the throttle plate position should be at idle. This learning capability allows the ECU to accommodate unavoidable changes to air intake flow from carbon build-up or other restriction. There is no way for a technician to manipulate “base idle†on this system as you used to do with a traditional idle screw. The learned position can be lost when computer memory is lost, so be mindful of this fact when disconnecting the battery for repairs. CONSULT III Plus can be used to recalculate base idle using the WORK SUPPORT section.

Bulletproof Reliability

Throttle-by-wire is a phrase borrowed and changed from the aeronautical industry’s “fly-by-wire†concept. Modern airplanes replace hydraulic lines with computer-controlled localized servos, actuators, or motors. If it’s safe enough for airplanes, the technology is ready for vehicles.

Many people are concerned about the reliability of throttle-by-wire systems, especially if a failed TPS or APP means a loss of accelerator control. Nissan eliminates this fear by engineering these vital systems with duplicate sensors for error detection and fail-safe operation.

Nissan’s fail-safe includes two separate position sensors for both the accelerator pedal assembly and the throttle body valve. The TPS is made up of two separate sensors, each bringing down the 5V reference coming from the ECU. In the event that one position sensor malfunctions, the secondary position sensor will provide the data necessary for safe operation, as well as provide the rational baseline for comparison and error checking.

Likewise, the APP has two distinct sensors that report two different potential voltages for accelerator position. The ECU can monitor for logical malfunctions when one sensor reports outside of its capabilities.

Put simply, your customers are not going to have a reliability concern when it comes to throttle-by-wire. It would require two separate potentiometers within each sensor to fail simultaneously, or a wiring harness failure to create a drivability malfunction. The master warning indicator will illuminate if a problem is detected.

Advantages

Despite the complications involved with learning and understanding new technology, Nissan recognizes the importance of throttle-by-wire for current and future engine management. Let’s discuss some of the major advantages of a system that replaces the throttle cable and idle air control motor design.

First, there is no auxiliary idle control valve that can become restricted or malfunction. Likewise, there are no external moving parts like a cable or spring that could develop mechanical issues from weather or wear.

Also, engine performance is improved because the ECU can snap to 100% throttle faster than a pedal could pull the cable through its full travel. If the speed of the accelerator pedal is determined to be great enough, the computer can extrapolate that the user command is WOT and provide it more quickly than the driver’s foot ever could. Likewise, the ECU can normalize slight pedal travel variations and improve fuel economy by smoothing out acceleration. You will notice this normalization distinctly when feathering the throttle to engage the clutch of a manual transmission. In fact, the idle control behavior will raise throttle as the engine approaches stalling when engaging the clutch in first gear making that catch point throttle feathering technique obsolete.

Above all, throttle-by-wire enables the advanced cruise control and safety features of vehicle stability control. On Nissan vehicles equipped with Intelligent Cruise, the computer is capable of adjusting the throttle up and down to match speeds with another vehicle detected by its range-finding lasers. With Vehicle Dynamic Control, the throttle pedal will actually attempt to push up the accelerator if it detects an imminent threat, helping the driver move his foot from the gas pedal to the brake. ABS and vehicle stability control will override driver-requested throttle input when a slip is detected. Suffice it to say that each of these advanced systems have already been the sole subject of entire Nissan Tech News articles due to their complexity.

Diagnosis and Work Support

Like anything else on a car, it is possible for a throttle-by-wire component to require service. Diagnosis and adjustments are performed with the CONSULT III. While it is technically possible to do some repairs on some vehicles by following the Nissan repair manual and placing the vehicle into a diagnostic mode, this method is much more difficult and cannot be used for all repairs. It is best to get the proper scan tool for the job.

When intake air parameters are reset, either by ECU replacement or updating, it may be necessary to recalibrate the existing throttle-by-wire components. Follow the Nissan repair manual for ECU replacement on the particular vehicle you are servicing. For the 2011 Altima, the throttle-by-wire components will have to “relearn†their positions. Perform the following procedures in this order:

- Accelerator pedal released position learning

- Throttle valve closed position learning

- Idle air volume learning

These procedures are found in the repair manual. Accelerator pedal position is learned on this Altima by toggling the ignition switch ON for two seconds, followed by 10 seconds of OFF, then repeating the process. Throttle valve closed position is learned by using the CONSULT III, navigating to WORK SUPPORT, and choosing the CLSD THL POS LEARN button. This must be done with the engine cold (ECT < 77 deg. F.). Idle air volume relearn is the last step because it requires the engine to be at operating temperature. Turn off all accessories and allow the vehicle to idle. Using CONSULT III, navigate again to WORK SUPPORT and choose IDLE AIR VOL LEARN. Press start, and after about 20 seconds, the idle volume learn will be complete.

You may be required to perform some or all of the above procedures when replacing a particular component. For example, the same Altima requires #2 and #3 to be done after replacing the Electronic Throttle Control Actuator. Because the TPS is manufactured in conjunction with the throttle actuator, this is a common repair.

If the Service Engine Soon (MIL) light is on, and your scan tool indicates a malfunction with the TPS by showing DTC P0122 or P0123, follow the Nissan repair manual for diagnosis. Verify that appropriate grounds, harness integrity, and the throttle position sensor signals are out of specification before replacing the throttle actuator. It should be known that Nissan has an official remanufacturing program for its electronic throttle bodies guaranteeing both high quality and excellent reliability. Do not be tempted to replace the throttle position sensors with questionable salvaged parts or aftermarket knock-offs. Finish the job right using Genuine Nissan remanufactured parts.

High Performance Throttle-by-Wire

There is yet another important development for throttle-by-wire, but instead of electronically controlling throttle plate position, Nissan’s Variable Valve Event and Lift (VVEL) adjusts intake valve lift as needed. This is not the same as variable intake cam timing. With VVEL, the throttle plate is significantly more open at all times and makes greater air pressure available at the back of each intake valve. Then, when the accelerator is pressed, intake valve lift is increased to directly increase flow into the engine.

Engines without VVEL have limited air available in the plenum when the throttle plate is closed. Thus, when the throttle plate is opened, there is a delay while air rushes in to fill the plenum and finally becomes available for intake into the cylinder. Of course, wide open throttle is not often requested during initial acceleration, which means further restriction on intake air for non-VVEL engines.

The end result of VVEL design is better fuel economy from improved valve overlap control, better throttle response, decreased emissions, and less piston load from decreased intake vacuum. The precision capabilities of computer management and execution are the future of vehicle design. As usual, Nissan is pressing forward with reliable systems that improve its vehicles’ efficiency and effectiveness.

0 Comments