Hot Rod Professional gets up close and personal with the movers and shakers in today’s diverse and technologically-advanced hot rod market.

By Glen Quagmire

Introduction

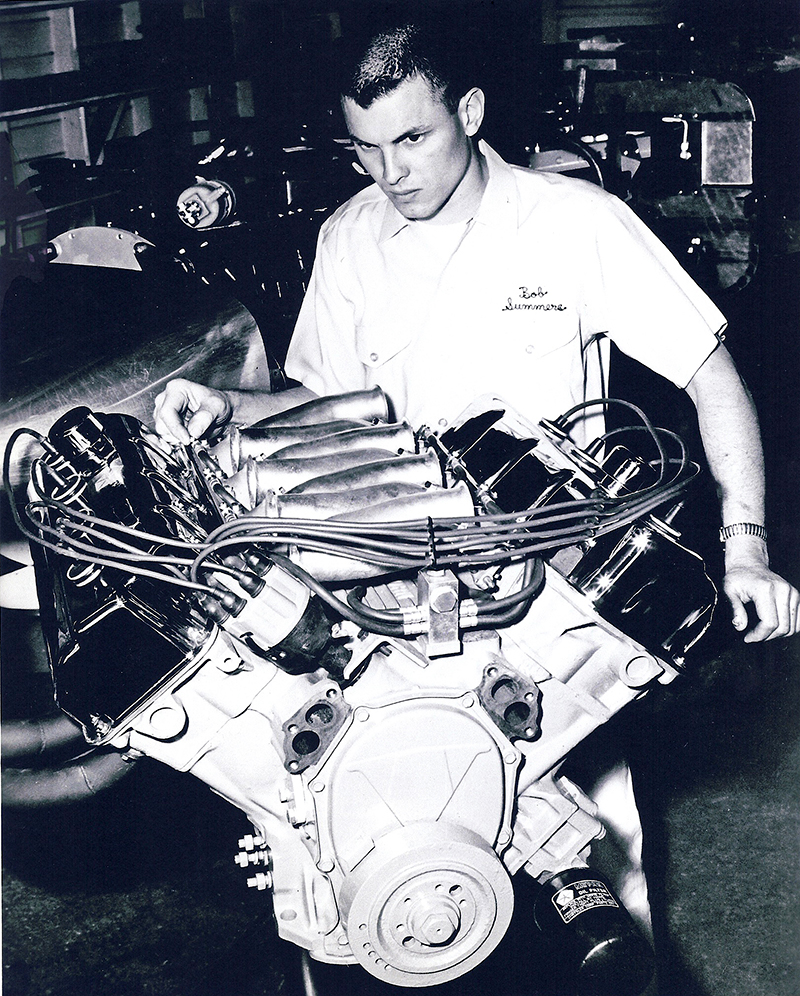

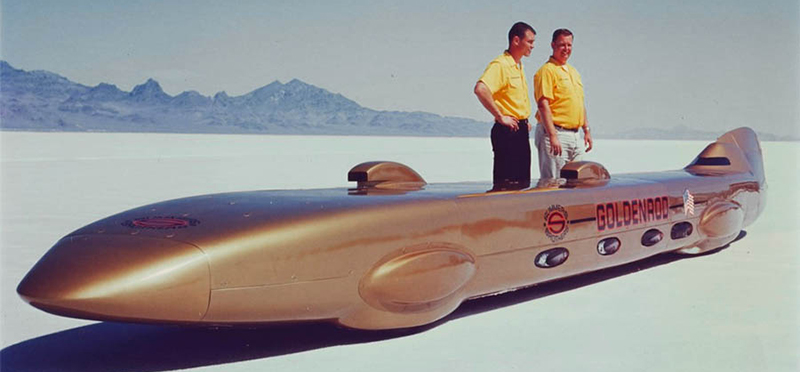

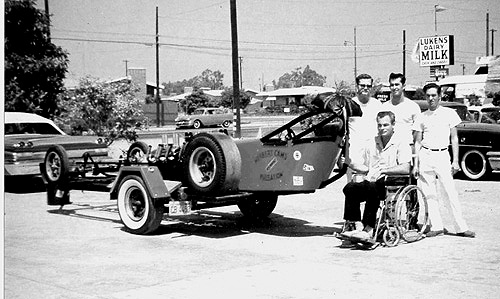

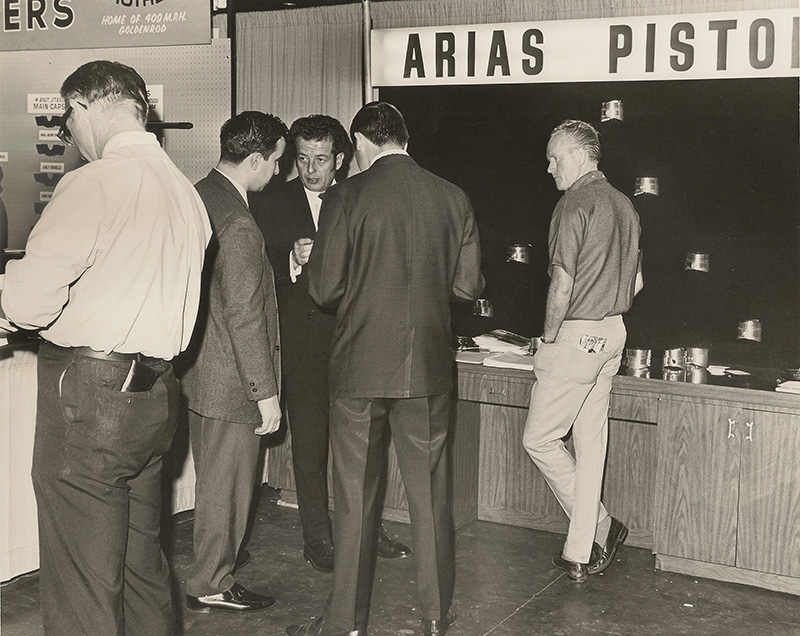

Hot rodding has come a long way since Ed Iskenderian first started experimenting with camshaft profiles and Joe Hrudka made his own sealing products that evolved into the company known as Mr. Gasket. These men and others were racers, innovators, and marketers whose creativity led them to develop solutions or improvements that allowed them to win races and customers.

You might think that, in the last half-century, all of the innovations in camshafts and gaskets and other hot rodding technology would have been explored, developed and marketed, and that there would be no room left for new innovations.

You would be wrong.

Hot rodding has changed dramatically since those days, on the track and on the street. We have new generations of cars, people, and technology that are ripe for the Isky’s and Hrudka’s of today to apply their genius to engine, chassis, and drive line systems.

Thanks to the competitive spirit inherent in hot rodding, there are many such people building innovative products and systems today. And it’s a great time for hot rodding, since there are so many different types of vehicles and so many different types of street and race performance.

The Time is Prime for Hot Rodding

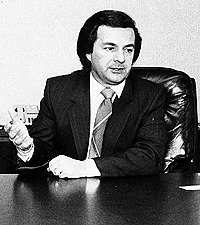

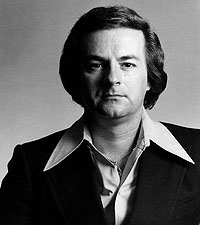

When folks hear the name Mr. Gasket, most associate that company with the name of its founder, Joe Hrudka. His rise to prominence was typical of other hot rodders in the 1950’s and 1960’s. He and his brother were successful drag racers, winning NHRA championships in 1961 and 1962. In the process, he and other racers were experiencing problems with gasket failures, particularly exhaust gaskets. So, like any good hot rodder, he found a way to build a better gasket and started making them and selling them to others racers. When folks hear the name Mr. Gasket, most associate that company with the name of its founder, Joe Hrudka. His rise to prominence was typical of other hot rodders in the 1950’s and 1960’s. He and his brother were successful drag racers, winning NHRA championships in 1961 and 1962. In the process, he and other racers were experiencing problems with gasket failures, particularly exhaust gaskets. So, like any good hot rodder, he found a way to build a better gasket and started making them and selling them to others racers.

Initially doing business under the name Speed Specialties, he incorporated under the Mr. Gasket name in 1965 and went on to run the company for more than 30 years. The company greatly expanded its product offerings and went through a number of corporate ownerships, but Joe Hrudka will always be known as the guy who started Mr. Gasket. |

We’ve got today’s Camaro’s, Mustangs, and other domestic muscle cars. We have Asian sport compact cars like Hondas, Mitsubishi’s, and Nissans. We have rocket ship European models from BMW, Audi, and Porsche. And we even have specialty makes like Aston Martin and Lotus. Of course, we still have countless muscle cars from the 60s, 70s, and 80s in many states of preparation for street and track use. And there is a, perhaps surprising, resurgence in restoration and performance enhancement of vintage sports cars like MGs, Austin-Healeys, Triumphs, Alfa Romeos, BMWs, and many others.

We also have more choices for actual hot rodding than ever before. Sure there are many who just want to win the stop-light grand prix, and even those who are just looking for bragging rights. But there are many other hot rodding opportunities that have evolved since the days of Isky and Hrudka.

Conventional drag racing continues to be wildly popular. But import drag racing has evolved into a genre all its own. Drifting is growing in popularity, especially with younger folks. Off-roading is big. Oval track racing is doing fine, especially in certain geographic areas. Private road racing courses are popping up everywhere. And established race tracks are increasingly offering “track days,†where folks can take their cars with a modest level of preparation and safety equipment and drive at speed in a controlled environment.

Furthermore, we have a host of new technologies just waiting for the “Hot Rod†touch. Early evidence of this was apparent when aftermarket ECU/ECM chips were introduced when electronic engine management systems first came into vogue. But just look at all the systems and technologies in use on today’s cars that weren’t there in the early days.

We have front wheel drive systems. We have stability and traction control systems, supplementing ABS systems that have been around for quite some time. We have diesel-powered race cars winning at the highest levels of competition. We have a far greater choice of spark plug designs available than ever before, including a variety of exotic materials used in electrodes. We have new-generation fuel injectors with more precise spray patterns and fuel metering than ever before. And we have advanced oxygen sensors that continuously monitor exhaust content and report changes to the ECU/ECM instantaneously.

All of these systems and component parts are ripe for tweaking and improvement by those not constricted by the laws and rules that regulate what the OEs can do, making for a fertile field of cars and systems just waiting to be modified for enhancement, on the street or on the track..

Of course the issue is made more complicated by emissions requirements for street-driven cars, with California, as has become the custom, dictating most strictly what modifications are allowed and how vehicles must comply with their regulations. But the need to comply with such standards and do the responsible thing for the environment just makes for one more challenge for the creativity of today’s hot rodders and deep thinkers.

The People Behind the Speed

It’s clear that hot rodding is alive and well. And just like in the early days, so too is the hot rodding spirit. As a result, creative and competitive folks continue to explore the limits of technology in fuel and ignition systems, internal engine parts, chassis and suspension systems, transmission, axle, and transaxle setups, exhaust systems, and other vehicle components that enhance performance.

We all have our own special talents and areas of interest. Ed Iskenderian knew camshafts. Joe Hrudka understood engine sealing. Vic Edelbrock had a passion for carburetion and induction systems. Ed Hamburger specialized in oil pans.

It’s really not possible to overstate the impact on hot rodding of those who changed this hobby and sport forever. Smokey Yunick could legitimately be considered the best and most innovative engine builder of all time, having developed tricks and technologies that would power winning cars in the early days of NASCAR racing. Most likely some of his innovations skirted the rules and were so clever that they escaped the scrutiny of technical inspectors, but there’s no denying his genius in finding ways to squeeze every last horsepower and foot-pound of torque from the engines of the day.

And no discussion of hot rodding pioneers would be complete without mentioning the legendary Carroll Shelby. Racer, engine builder, chassis engineers, fabricator, car constructor, modifier, innovator and, certainly, huckster as well, Shelby epitomized all that is important about hot rodding.

Proof of that was to be found in his success on the race track, as well as in the design and construction of his fabulous Shelby Cobras that continue to represent all that is classic about hot rods. Even today, some fifty years after his cars were first produced, small-block Cobras typically fetch selling prices of a half-million dollars or more, with big-block cars usually in the seven-figure vicinity. And the handful of Cobra Daytona Coupes he built are so collectible today that they’re very nearly priceless.

Not only was Shelby a successful racer and car constructor, but a highly successful marketer as well, having established joint ventures with Ford Motor Company to produce and sell Shelby Mustangs, and later with Chrysler Corporation in the development and branding of the Shelby Chargers, Omni’s, and Daytona’s.

|

|

|

|

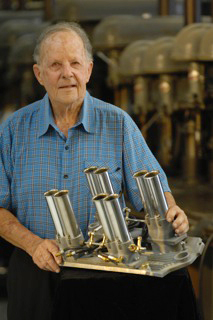

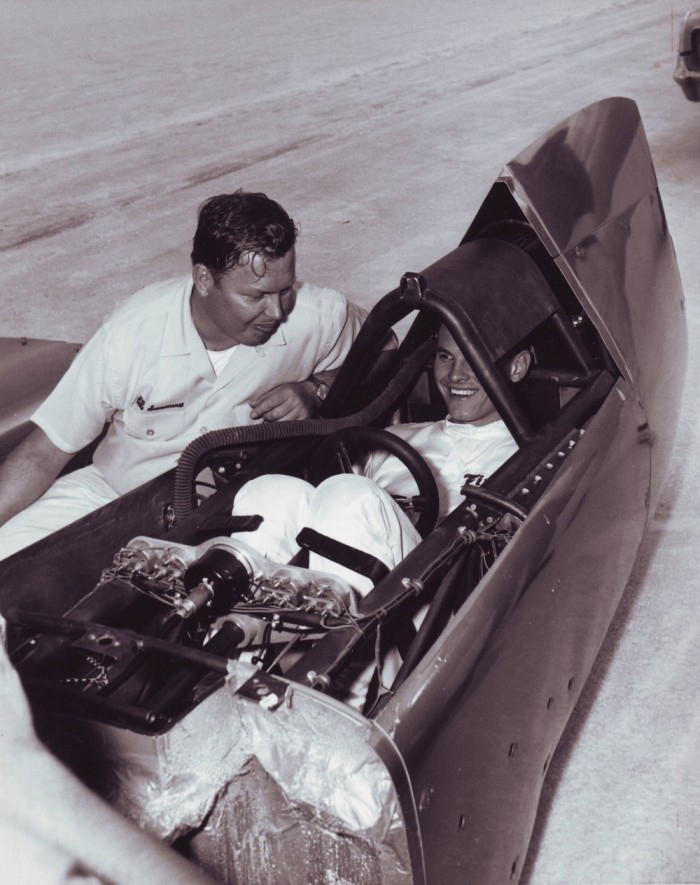

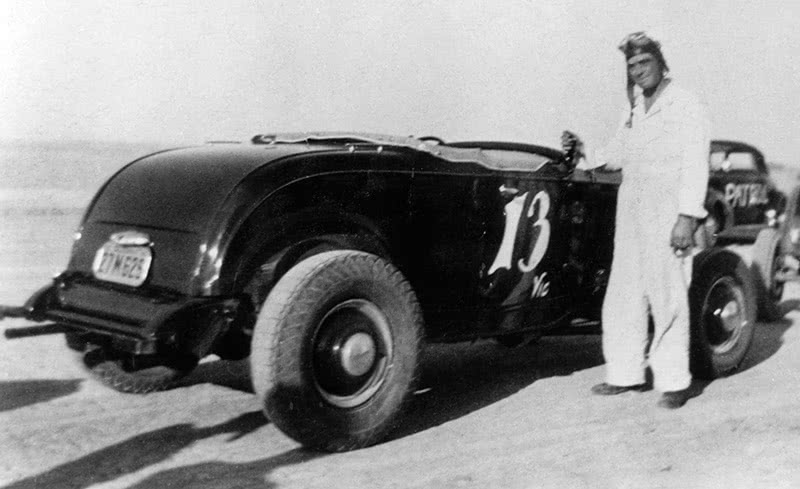

| Canadian-born Stuart Hilborn was fortunate enough to have his family move to Southern California where hot rodding was almost mandatory for a red-blooded youth. A flat-head Ford V-8 powered his first Model T, and he found early success as a dry lakes racer. He was also fortunate enough to have, as a neighbor and friend, former Indy 500 driver Eddie Miller. The two partnered on dry lakes competition until Uncle Sam called Hilborn to duty in World War II. After his service to his country, Hilborn fabricated his first fuel injection system, a pieced-together system using surplus aircraft hardware plus some home-built pieces. The system proved its value, powering Hilborn’s streamliner to a record-breaking 150+ miles per hour, the first car to do so on the dry lakes.

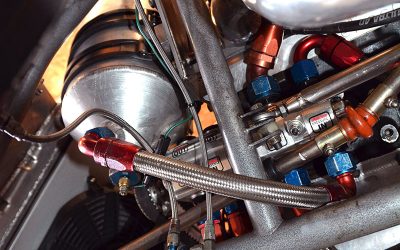

Hilborn continued the development of his legendary fuel injection systems for many forms of motorsports, and found tremendous success, particularly in Indycar racing, where Hilborn-equipped cars won some 34 Indy 500 races. Despite his passing last year at the age of 96, the company he founded in 1948 continues to be on the leading edge of fuel management system development. |

|

Hot Rodders of Today

Likewise, today’s hot rodding evolution has spawned a new generation of hot rodders who have developed new products and systems for all the various types of performance cars and are proving their ideas in the type of racing or performance in which they specialize. We have innovators in engine development, chassis systems, electronic chips and ECU’s, as well as specialized individual components like ignition systems, fuel injectors, and exhaust systems.

In this series we’ll have in-depth one-on-one conversations with many of these innovators of today, learning how they got their start, what moves them, which systems and technologies particularly interest them, and we’ll ask each of them to share secrets that will help HRP readers enhance the performance of theirs, and their customers’, hot rods.

We particularly invite your feedback on this series. We want to know which stories you find particularly helpful, we’d welcome your suggestions on successful hot rodders who would make for interesting profiles, and we’d love to have you tell us which areas of hot rodding are of particular interest to you.

0 Comments