There is no such thing as a maintenance-free cooling system. It’s important to identify potential problems and catch them before a break-down situation. Let’s explore Nissan’s various engine cooling systems, the importance of proper fluids, and some best-practice inspection techniques.

The phrase “blew a head gasket†has made its way into the common vocabulary. How many folks truly know the literal meaning of that phrase, however, and likewise what causes the failure? Not many. At the very least, the customer knows something is definitely wrong when steam is coming from under the hood. This article should help your shop identify the distinctive components used in Nissan cooling systems, how to inspect them proficiently, when to service or repair them, and where to begin when the customer drives in.

What to Look for When a Customer Arrives

You can save yourself a lot of time by figuring out from the customer where to begin. In other words, do yourself the favor and find out why the car is on the tow truck in the first place. Did the customer see steam from under the hood? Did the warning indicator illuminate? Is there a coolant drip on the driveway? Or, none of the above: The customer is driving in for his or her yearly check-up. Ultimately, using the customer’s story to determine a jumping off point for diagnosis will keep you close to the initial problem. In most cases, the problem will lie within one of two straightforward issues: maintenance or repair.

The Cooling System Pressure Check

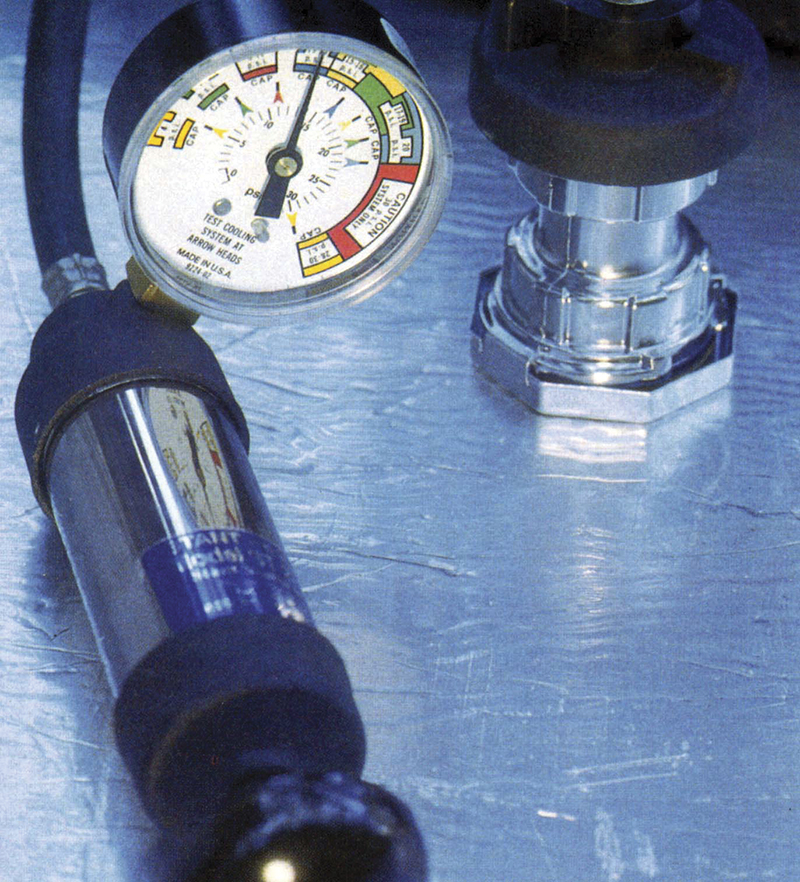

If your pressure tester doesn’t have the correct adapter, you can acquire the Nissan special service tool J-33984-A.

To start with, let’s discuss inspecting cooling systems in need of service. It’s best to develop a standardized cooling system inspection. In our experience, whenever a vehicle overheats, we want to determine whether or not the head gasket has failed because engine repair may push the vehicle “beyond repair†in the customer’s financial sensitivity. The most reliable way to determine whether the head gasket is compromised is to check for the presence of hydrocarbons (HCs) in the cooling system. Bring the vehicle up to operating temperature, stabilizing the cooling system if possible. Using your five-gas analyzer (be careful not to allow any liquid coolant into the probe), check for the presence of HCs in both the overflow bottle and the radiator — snap the throttle to see if the number increases. You can use this measurement to guide your repair discussion with your customer. In many instances, you cannot properly stabilize the cooling system and must therefore proceed with repairs before performing this test. In this case, prepare your customer for the worst and hope for the best.

With the head gasket(s) confirmed intact, figure out why the vehicle overheated. The most common cause is a loss of coolant due to leakage, so let’s consider this first. Obviously, skip this step if there is no loss of fluid. Nissan recommends a commercially available tool for pressure-testing the radiator cap and the complete cooling system. You will need to acquire the appropriate tester adapters. Consult the service manual for the appropriate pressures to apply; this is usually around 23 psi for the radiator and engine, and around 13 psi at the cap. Using too much pressure can cause damage to the water pump or other internal seals, or force leaks that would not be caused under real-world circumstances.

Use common sense when looking for leaks under pressure. Search for existing coolant crust as evidence of prior leaks, or look for fresh fluid along cooling hose clamps, water pump seals, radiator seams, oil or transmission fluid coolers, and elsewhere. Some leaks cannot be seen, like those within the heater core. As many technicians already know, heater core leakage can be inferred from information through the customer’s complaint of residue on the inside of the windshield and a strong smell in the cabin. You can also inspect for coolant leakage through the evaporator drain if the leak is heavy enough.

Check the radiator cap for leakage using the pressure tester, but be mindful that over time a functional radiator cap will bed in to the neck of the radiator. Sometimes, the cap will seal properly and will vent pressure as necessary when on the vehicle, but may leak on the pressure tester. A good quick test is to forcefully grip the upper hose and see if coolant spills into the overflow bottle. If so, the cap is not likely sealing properly. Be certain that the fault lies with the cap rather than with a partially melted or defective radiator neck.

When a leak is found, proceed with repair following the appropriate Nissan manual. It is also best to replace older coolant hoses and clamps that are disturbed when doing coolant repairs within the same vicinity. Use Genuine Nissan parts to guarantee that the replacement component will have the best possible fitment and service life. We will discuss this later, but be certain to follow the Nissan service procedure for servicing engine coolant. Using incorrect fluid or incomplete service methods may result in additional cooling system problems.

Diagnosis of Coolant Flow Control

It may be tempting to use a generic screw clamp, but Genuine Nissan spring clamps will increase clamping force as the hose breaks in, reducing leaks and follow-up visits from the customer.

In some cases, the vehicle does not overheat because of a fluid leak, but rather due to a cooling system management malfunction. Your standardized cooling system check should also include inspection of the thermostat operation and fan cycling. Many modern Nissan vehicles have computer-monitored thermostat and fan operation, so you can expect a MIL with useful information available from the CONSULT. See below for examples.

While leaks may be straightforward, thermostat malfunction and erratic fan operation can create headaches when you are trying to pinpoint cooling system problems. Let’s discuss thermostat operation first. Because engines operate best at fairly high temperatures, coolant flow into the radiator is restricted by a physical valve called the thermostat, allowing heat to build up rapidly. You might find a vehicle that has no leaks, but overheats because the thermostat is stuck in the closed position, thus defeating the radiator. Verify a stuck thermostat without removing the unit by observing engine block temperature and comparing it to the service manual’s specification for thermostat opening temperature.

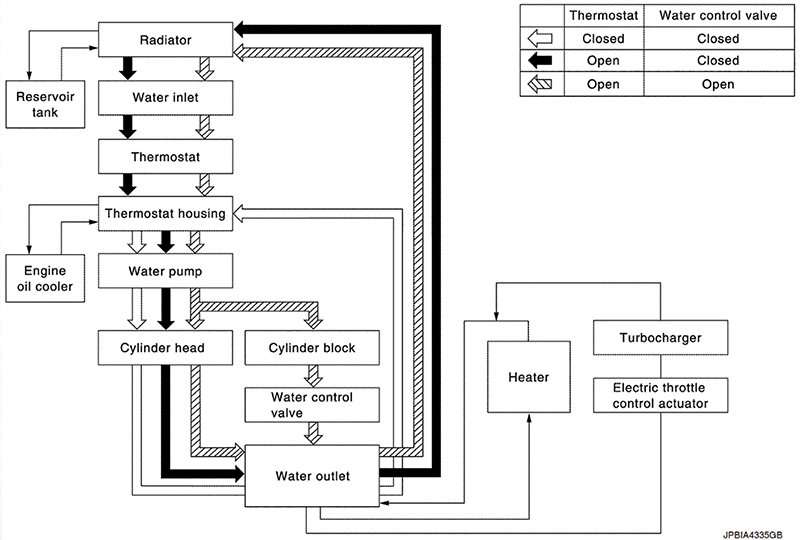

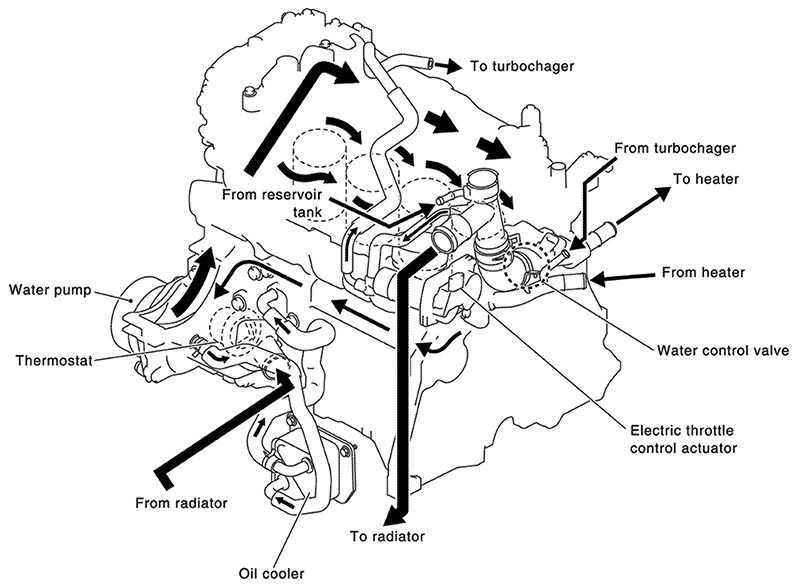

In some engine designs as found in the Altima and Juke, Nissan uses a secondary thermostat called the water control valve to further expedite engine warm up. In this two-stage design, the water control valve restricts coolant cycling to only the water pump and cylinder head. Once open, coolant is allowed into the engine block and is controlled by a traditional thermostat. It may be confusing, but getting the engine to operating temperature faster is better for both fuel economy and reduced emissions. Be sure to check the shop manual for this thermostat/water control valve design if you are unsure.

There is no official replacement recommendation for thermostat maintenance because a Genuine Nissan part is very reliable. However, it is typically best practice to replace a thermostat after an overheating event because the wax capsule inside may be damaged.

When a vehicle is cold, both the thermostat and water control valve are closed, and coolant remains within the cylinder head only. It can be bled off to the heater core when commanded.

Diagnosis of Radiator Fan Control

Your cooling system evaluation should include verification of fan operation. With the exception of most Nissan trucks (Pathfinder, Frontier, Armada, and Titan), all cooling fans are electronically controlled. Nissan trucks, for the most part, use a mechanical radiator fan driven off the crankshaft pulley by means of a serpentine belt. Inspect the drive belt for cracks and proper tension as part of your cooling system evaluation. You should also check for play and roughness in the water pump bearing itself.

An electric fan that does not spin, for whatever reason, will fail to provide the necessary supplemental airflow over the fins of the radiator when the vehicle is not traveling at highway speed, thus causing an overheat condition. Use the customer complaint to direct your diagnosis. If the vehicle overheats when the car is idling, going slowly in traffic, or under very heavy loads as when towing or driving uphill, then check to make sure the cooling fans are operational.

Like any electric system, problems can develop over time or after a collision. Let’s explore the way modern CAN-equipped Nissan vehicles control their electric cooling fans.

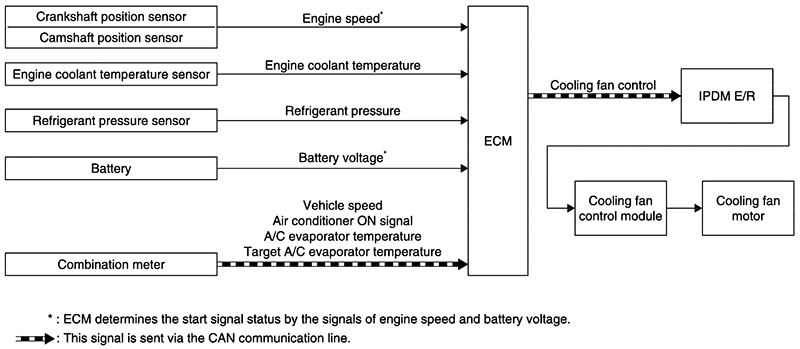

In simple of terms, the ECU determines whether the electric fans should be turned on using input from the Engine Coolant Temperature sensor (ECT), sensors for cam and crank position, and for vehicle speed, and the combination meter for A/C considerations. Once the ECU has decided that fans are necessary, it will transmit the cooling fan control signal over the CAN bus to the under-hood fuse box (Intelligent Power Distribution Module Engine Room – IPDM E/R), which then provides an ON/OFF duty cycle pulse to the cooling fan control module. With the duty cycle pulse, the control module creates a target speed for the fan using a percentage of duty cycle voltage. This control method effectively eliminates the need to distinguish between “primary and secondary†cooling fans.

A non-functional ECT will set a fault P0116 at full-cold start if its reading is not expected when compared to that of the Intake Air Temperature sensor (IAT) and other sensors. On the other hand, a fully functional ECT may set a fault P0118 when the system overheats to the point where the sensor thinks it cannot possibly be correct. One final consideration is that the ECT cannot provide useful information when it is not submerged in coolant. Verify that the system is full before chasing a phantom problem.

An always-open thermostat will extend the duration of the warm-up process long enough for the ECU to detect and set the MIL with P0128. However, it cannot determine whether the thermostat is stuck closed because it is not physically monitoring the valve. A stuck-closed thermostat may correlate with P0118, so be sure to check its operation whenever that fault is stored.

As touched on above, fan control is influenced by user-requested A/C performance. This includes passenger zone-controlled A/C or heat. When the A/C autoamp (control unit) reports a driver-requested target evaporator temperature, the ECU will command the electric fans as described above to help air flow over the condenser fins. In a similar fashion to how the ECU keeps track of idle position and driver-requested accelerator input for electronic throttle control, the ECU also records each incremental request for cooling fan operation to generate a final desired fan speed.

Sometimes it can be hard to determine coolant flow from a diagram like the one above. This layout of coolant flow for a 2011 Juke Turbo is an excellent diagnostic and repair aid.

Finishing the Repair: Proper Cooling System Service and Quality Control

The water control valve looks similar to a thermostat in almost every respect. This one opens at a slightly lower temperature, though (171 deg. F.).

Now that you’ve finished replacing a cooling system component that required draining the coolant, let’s discuss the official way of filling the coolant and stabilizing the system. First, figure out what the proper coolant is for this particular Nissan. The newest vehicles will utilize a factory-filled, pre-mixed Super Long Life coolant that is blue in color. Many older cars (except the GT-R) require the Nissan full-strength green coolant that must be diluted to 50% strength with water. Refer to the service manual.

Out with the old, in with the new! The Air Lift method uses shop air and a venture to establish a vacuum that removes old coolant and replaces it with new. No burping!

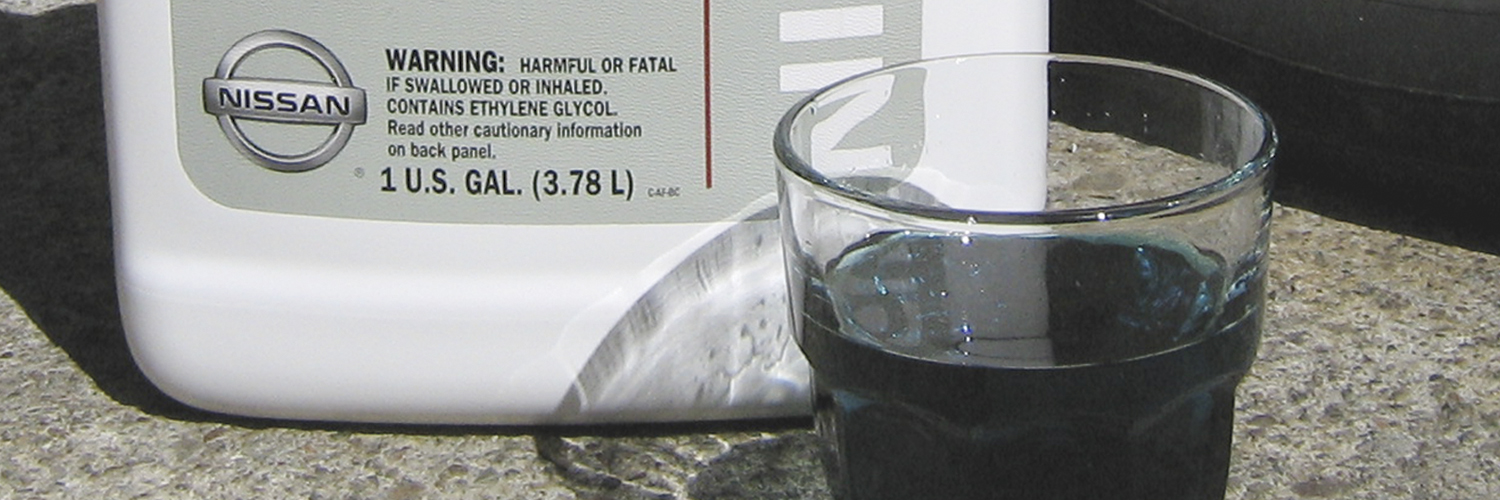

Nissan coolants are proprietary ethylene-glycol blends that are silicate-free and contain the appropriate lubricants formulated and tested specifically with Nissan engine materials. When a shop uses the generic green or gold coolants, the corrosion inhibiters are different and the formula is not tested for use specifically with the silicon, rubber, or aluminum found in Nissan engines. You may ultimately introduce more problems or accelerate internal wear when using a generic coolant, so don’t do it! You will find that your local Nissan dealership has Genuine Nissan antifreeze in stock at a very reasonable price considering the quality and peace-of-mind it provides.

Generic coolants are not designed for Nissan vehicles. The coolant test strip shows this antifreeze has a higher pH than Genuine Nissan coolant.

Nissan does not approve any third party antifreeze flush machines or additives for use with its cooling systems. If a cooling system truly should be flushed due to incorrect fluid or severe contamination, Nissan officially recommends filling the radiator completely with pure water. Run the vehicle up to normal operating temperature, rev the engine a few times with no load, then drain. Repeat until the fluid drains clear. Due to improvements in both materials and chemicals, it is rare to see significantly corroded cooling systems unless due to gross owner neglect. Typical draining and filling of the coolant should be sufficient to maintain vehicle longevity.

The radiator and auxiliary fan control on this 2011 370Z leverages the power of CAN communication to control supplemental air flow over the radiator.

Gone are the Days of the Yellow Coolant Funnel

The official method of servicing modern Nissan coolant systems is by means of a vacuum venturi Air Lift device. These devices are commercially available, but Nissan special tool #J-45695 can also be purchased to perform proper cooling system services. When properly using the Air Lift, you will be able to quickly and efficiently exchange nearly all of the old coolant and replace it without introducing air bubbles.

Non-Standard Cooling Systems

Don’t be afraid to try the Air Lift. Not only is it the device Nissan recommends for coolant service, but once you try it, you’ll never go back to slower drain and fill methods. This particular lift has wheel weights attached to the suction end for convenience.

Nissan hybrid vehicles and the Nissan LEAF have cooling systems that are in many ways different from what we discussed above. Because hybrid vehicles require cooling for both the internal combustion engine and the high-voltage inverter, an additional cooling system is necessary. Likewise, the Nissan LEAF must cool the inverter, but does not have to deal with high combustion chamber heat. We can only begin to scratch the surface in this article, but know that it’s important to follow the service manual procedures for these vehicles’ cooling designs.

As Nissan improves its engines, the cooling system must necessarily follow along with improved performance. Vehicle manufacturers must take care with the double-edged sword that is high engine temperatures. On one hand, higher heat means fewer emissions and greater efficiency, but on the other is mechanical failure!

0 Comments