An overview of Nissan OBD II, and why the CONSULT is superior when compared to generic scan tools for diagnosing problems on Nissan vehicles

Self-diagnostic systems are essential in today’s computer-controlled vehicles. It’s not enough for a computer to just respond to inputs; it must have the ability to determine whether it has succeeded or failed. Because no vehicle in the world is yet capable of self-repair, the ECU must also have the ability to communicate its findings and data to us, the technicians who can fix vehicles. In short, on-board diagnostics represent the ability to self-evaluate and communicate data. The more diagnostic work the ECU does, the less the technician needs to do to solve problems.

In the Days of the Posthumously-Named OBD I…

In the beginning of computerized engine management, every manufacturer developed its own form of self-testing and communication. It was entirely up to the manufacturer what should be tested, how it should be tested, and how the results of the tests should be communicated. Many early Nissan self-diagnostic systems used both a proprietary software/hardware interface such as the CONSULT, as well as a built-in self-diagnostic mode initiated without expensive tools that could be interpreted by counting LED flashes, then comparing this output to a diagnostic trouble code (DTC) chart. Thus, those who were serious about Nissan repair could invest in a Nissan scan tool, and more occasional technicians could still repair vehicles without Nissan-specific tools.

Not all vehicle manufacturers, however, were as concerned with providing an alternative method of diagnosis for non-dealership techs. In an effort to reduce emissions by making vehicles easier to repair, the California Air Resources Board (CARB) mandated that all cars sold in the state use the SAE’s OBD II standard, starting with the 1996 model year. OBD II then became a country-wide requirement, and now all vehicles sold in the US use OBD II-compliant testing and communication.

OBD II Changes Things by Making Them the Same

What is the OBD II standard? OBD II standardizes communication for the data-link connector shape and pinout, trouble codes, and communication protocols. OBD II allows any generic scan tool to connect and talk to any car. This is good news for non-specializing technicians. One inexpensive tool can read the standard trouble codes that mean the same thing on any car, regardless of make or model.

Nissan Goes Above and Beyond

On the other hand, generic OBD II is not the best choice for Nissan diagnosis because Nissan has not limited itself to just the minimum OBD II-required information. OBD II compatibility is mandatory and is always available, much like the built-in self-diagnostic capabilities on older Nissan vehicles. However, additional self-diagnostic information is available on the “OEM side†— Nissan-specific diagnostic information, bi-directional testing, and utilities tailored to Nissan systems. Accessing all of these additional capabilities usually requires using a Nissan scan tool – the CONSULT. If your shop repairs a lot of Nissan vehicles, a new CONSULT III plus is an excellent investment, because while you might be able to fix a Nissan without it, you’ll be able to fix it a whole lot faster with it.

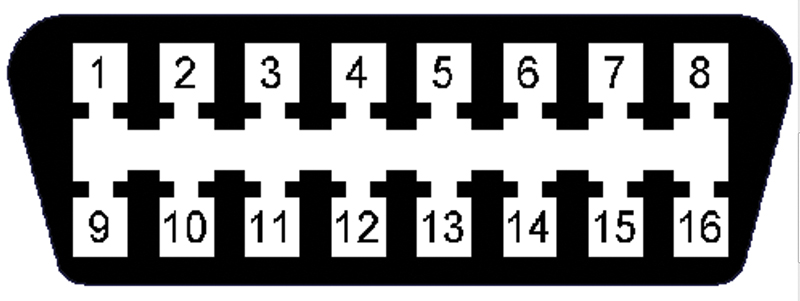

If you’re ever confused about the OBD II DLC pin numbering, just remember that the pins are numbered left to right, top to bottom, just like text in a book.

Jack In and Shake Hands

The OBD II diagnostic connector is always the same shape, and some of the pin locations and functions are standard across all implementations of OBD II. The OBD II Data Link Connector (DLC) should be within two feet of the steering wheel on the driver’s side. Adherence to the OBD II specs depends a bit on the year a vehicle was produced. A 1996 will probably lack full compliance, but by MY 2001, it’s usually safe to make some assumptions. Pins 7 and 15 should be ISO 9141 (if used). Pins 6 and 14 should be CAN (if used). Pin 4 will be chassis ground and pin 5 will be sensor ground. Pin 16 will be battery voltage. When in doubt, there will always be a DLC diagram in the service manual.

Nissan used a different style non-OBD II-compliant 14-pin connector for the CONSULT scan tool up until MY 2000, so between 1996 and 2000, you’ll find two different DLCs. If connecting a generic scan tool, use the OBD II connector. If connecting the CONSULT, use the Nissan connector. Even though the CONSULT is able to physically connect to the OBD II connector, there will be no access to the OEM side of the diagnostic system. After 2000, full access to the OEM side is available through the OBD II connector.

Similarities and Differences

OBD II and the Nissan OEM side share some similarities, but also have some differences. Let’s start by talking about how the generic side and OEM side are the same. First, both use self-testing to find faults. There are three basic types of diagnostic strategies:

- Normality testing

- Rationality testing

- Functionality testing

Normality testing is pretty simple; the ECM is asking the question, “Is what I am seeing normal?†An ECT sensor might be expected to report between 230 and 11,000 ohms. If the circuit resistance is 1 ohm, or 1,000,000 ohms, the ECM knows that it’s not normal and the test fails. Normality testing is used to find opens, shorts, shorts to power, sensor faults, and faults in the monitored system. In other words, normality testing can find any problem that leads to the circuit being out of known-good range.

Rationality testing is a little more complex, and it requires the ECM to know a lot more about its world. For instance, if engine speed is 700 rpm, AF ALPHA is 100%, and TPS is 75%, you and I know that there is likely a problem with the TPS. If the throttle is ¾ open, the engine speed should be well above 700 rpm. Using rational testing and more complex programming, the ECM knows this, too. Stated another way, even though the TPS resistance is normal (it’s normal for the throttle to be ¾ open sometimes, right?), the ECM is able to make judgments about the accuracy of the TPS report based on what it knows about the relationships between sensor readings. That’s rationality testing.

Functionality testing is used for actuators where the ECM is both controlling and monitoring the actuator. The ECM can be either directly monitoring the actuator via a position sensor, or it may be monitoring another sensor capable of observing the result of the actuator’s function. A system with an electronically-controlled EGR valve and an EGR temperature sensor is an example of this type of functionality testing.

The ECM Must be Tripping

Regardless of whether a Normality, Rationality, or Functionality test is used to find a fault, both the generic and OEM sides use “trips†to determine whether or not to turn on the MIL. A trip is not just driving from Point A to Point B. A trip is a set of enabling conditions that allow a self-diagnostic test to run. The enabling criteria may be continuous when the key is on or the engine is running, or it may be a very specific set of rpm, load, temperature, and speed conditions. Some trips may even require the car to be sitting with the key off.

DTCs can be one-trip or two-trip, meaning that the a DTC may be set as soon as the fault is detected (one-trip), or only set after a fault has been detected at least twice (two-trip). If a one-trip DTC is set, the MIL will turn on immediately. If a two-trip DTC fault is detected, a pending code will be stored, but the MIL will not illuminate unless the fault is detected on a second trip.

One-trip DTCs faults are typically problems that might cause symptoms for the driver, so the MIL is illuminated right away. Faults that may damage the catalytic converter are even higher priority and will cause the MIL to flash. Two-trip DTCs are lower priority faults, so they are verified before unduly worrying the driver.

What does the MIL Say?

Another way the generic and Nissan sides are similar is in the way the MIL is controlled to alert the driver of system malfunctions. The MIL has only two states: on and off (blinking being a combination). However, the MIL will tell us far more than two things if we know how to listen:

Key On Engine Off (Bulb check)

- Solid light confirms ECM’s ability to turn MIL on (all OBD II)

- Flashing light indicates System Readiness Tests (SRTs) are incomplete (2005 and newer Nissan only)

Key On Engine Running, MIL off

- No faults

- One failure on a two-trip DTC

- A current fault, but the SRT that would expose the fault hasn’t run yet

Key On Engine Running, MIL on

- Current fault

- Past fault, but has not completed three successful trips yet

- Past fault, but SRT that would confirm repair has not run yet

Key On Engine Running, MIL flashing

- There is a condition that is likely to cause damage to the catalyst

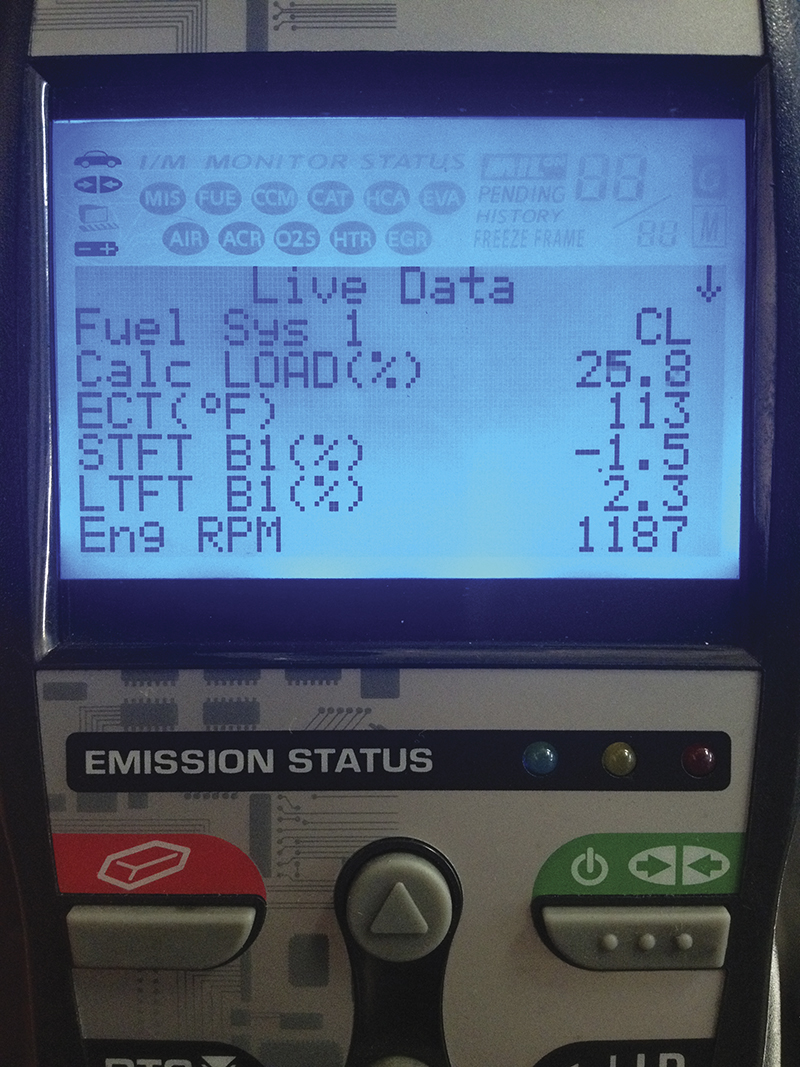

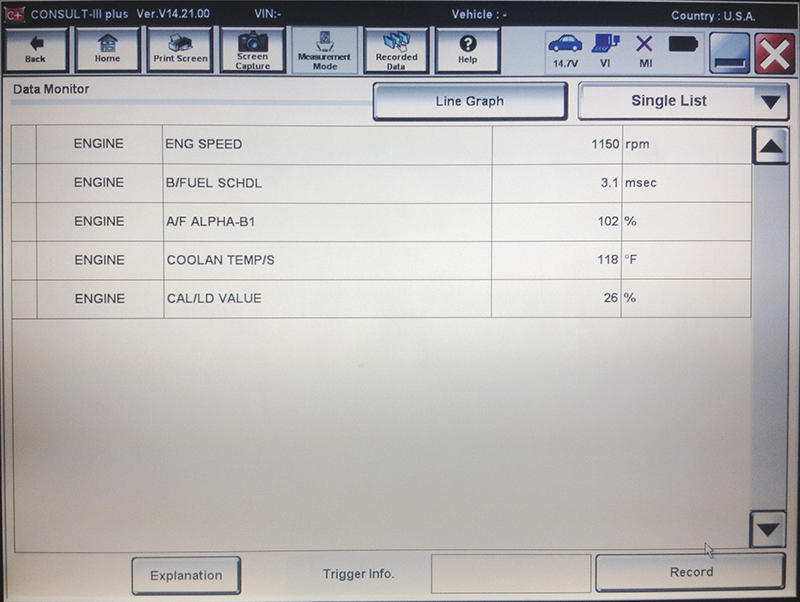

Live Monitor/Live Data (Mode 1 Generic)

Live data is just what it sounds like: actual sensor values displayed as they are being measured. When comparing the CONSULT Data Monitor to a generic scan tool’s live data, you’ll find a few differences. First, on the generic side, you’ll find data displayed only in the OBD II format. For instance, a generic tool might show a fuel trim PID as 3%+, whereas the CONSULT will display the PID as 103% ALPHA. Another major difference is that when the CONSULT is connected and reading live data, the vehicle enters a check mode where two-trip monitors become one-trip monitors, and pass/fail parameters are narrowed, making it easier to set trouble codes and easier to diagnosis marginal failures. The CONSULT can also automatically record frames before and after the fault if the fault occurs while viewing live data. These advantages make the CONSULT a much better test drive companion than a generic scan tool.

Freeze Frame Data (Mode 2 Generic)

Freeze frame data is selected PIDs from the data stream during the time the fault was detected. Older vehicles store a single snapshot at the time the fault occurred (well, theoretically at least). Newer vehicles with CAN store five frames of data: three before the fault, one at the time of the fault, and one after the fault. OBD II specifies what data must be included in the freeze frame data (FFD). With a generic scan tool you’ll only have access to this OBD II-mandated data. However, with a CONSULT, you’ll be able to see all of the information Nissan engineers felt might be relevant to the fault.

Self-Diagnostic Results/Trouble Codes (Mode 3 Generic)

Nissan does not include Mode 6 data on the OEM side. If you want hex code, you’ll need a generic OBD II scan tool. Depending on the unit, you may have no access, raw hex code, or converted human-readable numbers.

Trouble codes fall into two categories: OBD II and manufacturer-specific. What’s the difference? An OBD II code will mean pretty much the same thing on any car. A manufacturer-specific code will only apply to one make. Why bother with manufacturer-specific codes? The reason is that these unique codes can describe faults in systems that are specific to Nissan vehicles. Or, they can describe problems in a more detailed way than what would comply with the OBD II specification. In other words: OBD II does not cover everything, nor does it cover everything in enough detail. OEM codes allow Nissan to provide more information to technicians, and more information is always better. Both the CONSULT and generic scan tools will display OBD II and OEM codes, but the CONSULT will also have OEM code descriptions whereas a generic may not.

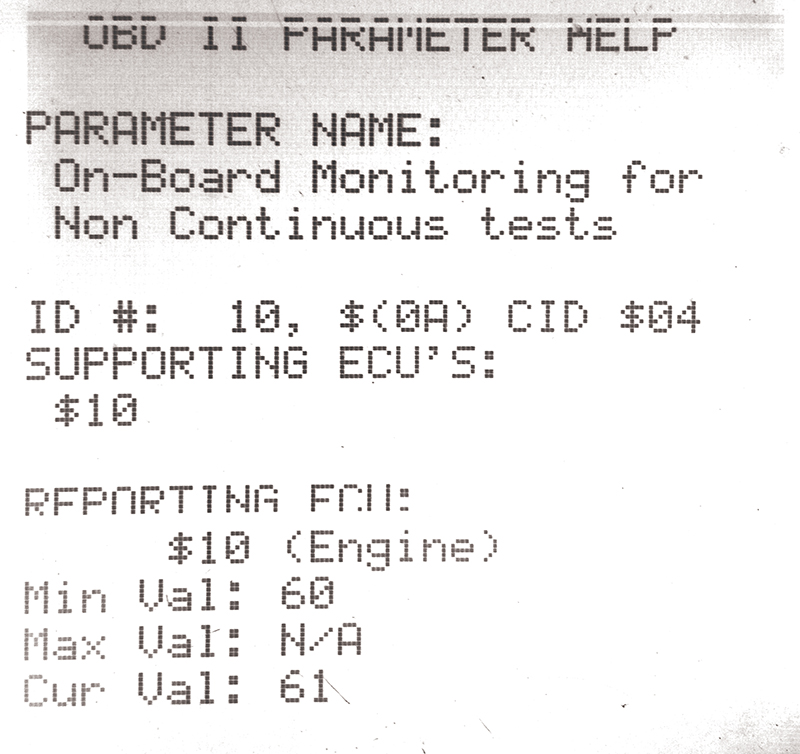

SRTs/Non-Continuous Monitors (Mode 6 Generic)

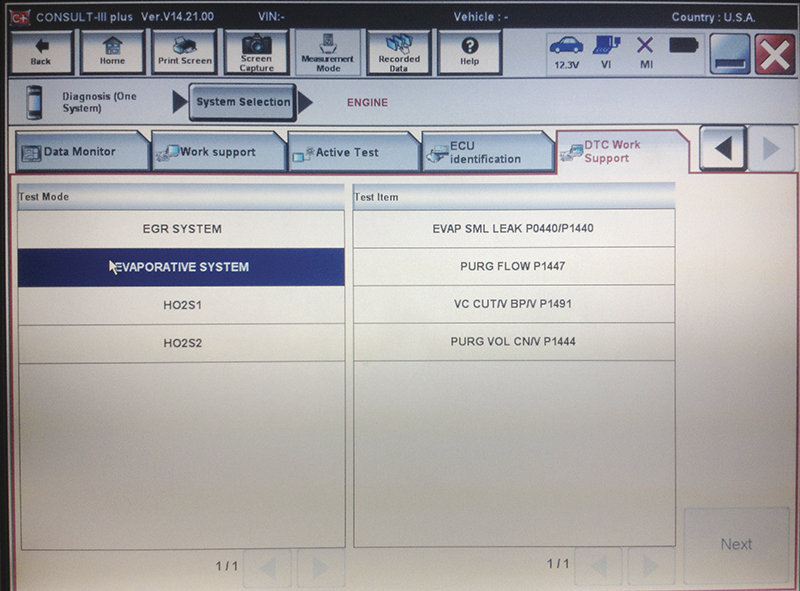

Use DTC Work Support to confirm the presence or absence of a problem. This utility can be used before starting diagnosis or after a repair.

The ECM is always monitoring its sensors and outputs for problems. Some testing is continuous, and will set a code as soon as a problem occurs. Other testing is intermittent and requires certain conditions in order to start testing. These intermittent tests are known as System Readiness Tests (SRTs) in Nissan’s terms, or Mode 6 “monitors†in generic OBD II terms.

A generic scan tool will often show whether or not the system test is complete and if it has passed. In addition, some generic scan tools (GSTs) will also have the results of the tests as well as the test limits, or pass/fail criteria. This information may be in hex code or may be decoded by the scan tool. It depends on the GST, not the vehicle. The CONSULT will indicate test status and whether it passed or failed, but does not display test results and limits. Therefore, if you think raw Mode 6 data will be useful to you, a GST should be your tool of choice, at least for this one function.

DTC/SRT Confirmation (CONSULT II) DTC Work Support (CONSULT-III Plus)

The CONSULT may not have raw Mode 6 data, but it does have something even better: DTC/SRT confirmation. These are utilities that allow you to force a non-continuous test to run by starting the utility and following the prompts to create the necessary conditions to run the SRT. This is a great way to confirm a problem is current (happening right now) before embarking on further diagnostic checks. It’s also a great way to confirm repairs.

SRTs will also run while the car is in use, even without using the SRT confirmation mode. However, the car must be driven in a way that will trigger the SRT to run. Information on how to drive to enable an SRT to run can be found in the manual. Once again, it’s possible to fix a Nissan without a CONSULT, but a whole lot easier with a CONSULT.

Active Tests & Function Tests (Mode 8 Generic)

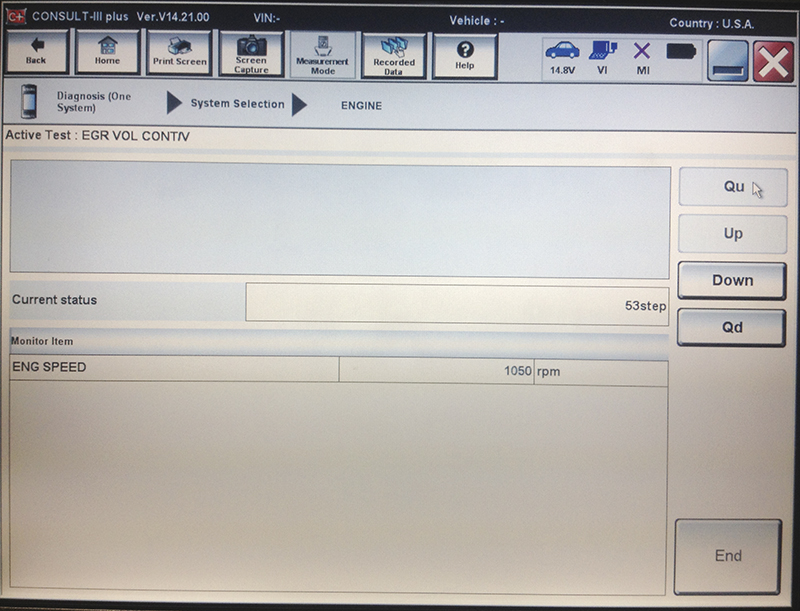

In this photo, an Active Test is being used to command the EGR full open at idle. The idle speed was not affected by the EGR activation, so we know that there is likely a problem with either the valve or the passage.

Active tests let you control the ECM’s output with the CONSULT. You can perform cylinder balance tests by disabling fuel injectors one at a time, command relays and solenoids on and off, force the fuel mixture rich or lean, change the ignition and cam timing, and a bunch more. Active tests are a real time saver.

The generic alternative to active tests is Mode 8. Typically, Mode 8 provides only very basic functions like commanding the canister close valve so you can perform EVAP testing.

Work Support (No Generic Equivalent)

Work support is what you might suspect. You’ll find scan tool-enabled shortcuts for setting the base idle, releasing the fuel pressure, adjusting the ignition timing, and other work-related functions. Nissan also provides a secondary method for accomplishing the same goals, but it’s invariably quicker to use the CONSULT than to use the manual procedure.

0 Comments