It was 1991 . . . and my first stint in a dealership after years of working as an independent shop mechanic or manager. I went to work for a local Olds and GMC franchise as a service manager. It was a good year.

GMC came out with the Syclone pickup and we got just one in on allocation. A local street racer decided to relive his mis-spent youth and stopped in to buy the only one we had (fewer than 3,000 were built in 1991, and only about dozen in 1992.)

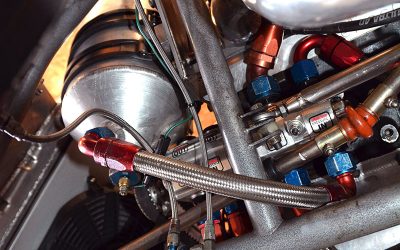

If you don’t remember those little rocket boxes, they were a job-shop-produced water intercooled turbocharged 4.3 V-6 powered all-wheel drive with great big sticky tires riding on a lowered S-10 pickup truck platform. The pistons, main caps, head gaskets, intakes, fuel system, and exhaust manifolds were unique to the application, and GMC borrowed the 350 throttle body and bolted her on the little race truck. It was rated at 280 horsepower and 360 foot pounds of torque, but they’d run the quarter at 13.6 at about a hundred miles an hour with zero to sixty times of 4.3 seconds at a rolling weight of 3,800 pounds (with a two hundred pound driver), so in truth they were probably making something like 325 horsepower and 400 foot pounds in stock trim.

Said reborn street racer bought the truck and promptly went out to lay waste to the other local street racers. He put the little rocket-powered country Cadillac in stealth mode by removing all the badging, and went hunting most Friday and Saturday nights for the first few weeks of the summer. He was doing pretty well . . . the truck was quick off the line, and since most street racing involves short distances he was making some pretty good beer money fooling the locals. Believe me, 400 foot pounds will move you along pretty smartly if you have AWD and no tire spin.

As he worked his way up the ladder, he got into some stiffer competition and his win/loss record looked like it might begin to suffer. So, he stopped in one day to see if there was anything I could do to get him a little more power.

Those were the dark days of electronic tuning. Performance chips were nearly unheard of and the few that were being produced mainly just advanced the hell out of the timing, over-fueled the engine, and shut off the detonation sensors. The results were sketchy at best. However, where there is a turbocharger there is a way . . .

I took a little time to study the plumbing and determined that the electronically-controlled waste gate valve was a simple spring-loaded shut/pressure opened solenoid-controlled bypass that dumped exhaust ahead of the turbine, thus regulating boost. And all it needed was a calibrated leak to delay opening the bypass to increase boost — after all, if some boost is good, more is better, right? One problem: GMC had figured out that this might be the case, so had installed tamper-resistant hose clamps to secure the control plumbing to the waste gate. If modifications were made, they’d be evident and warranty claims could be denied. Hmmm. Thwarted again? Not hardly . . .

Pretty smart of GMC, but tamper-resistant is NOT the same as tamper-proof, if you know what I mean, especially in the face of a determined and dedicated “performance-enhancement specialist.” I knew what I wanted to do: I was going to use a Holley main jet as the leak and just tee it in so I could tune right to the edge of the detonation sensor limits. My first guess wasn’t even close — that thing came up on boost, reared back and took off like a Saturn V launch vehicle . . . for about three seconds. Then it hit detonation, the det sensors grabbed it and the system shut down hard. I don’t know what all was shut off, but it felt like everything. I’ve never felt anything quite like it since — it was like you tossed out an anchor. It was so severe that it pinned you right up against the seat belt. I limped back for Round Two and began sneaking up on the limit. I trimmed the leak a couple more times (had a whole box of Holley jets, don’t you know) and got it just right for the 94 octane gas he was running. I don’t know how much more power it made, but it was a lot. It was significantly quicker and faster, and, as a side benefit, as it went to full boost the calibrated leak whistled like a tea pot at full boil under the hood. It was like more power and a warning system all in one!

Everything went swimmingly for nearly the entire summer. His winning record remained intact, and he stopped in on a regular basis to regale us with tales of terror. After one particularly-productive weekend, he shows up looking a little worried. Seems that over the course of the last evening spent on the asphalt the engine developed a persistent ticking sound, reminiscent of a lifter or valve guide. On closer exam it was determined that the noise was a little deeper, down in the crankcase, and the cadence was at crankshaft speed. Okay, this was officially “not good.â€Â With the customer’s permission, I removed the oil pan and was stunned to find one connecting rod that was twisted slightly and shortened just enough so that the crank counterweight was ticking the bottom of the piston pin boss! That’s about as close as you want to get! Just a little more and the counterweight would be serving double duty as a clearancing cutter.

A new rod and piston assembly was obtained and installed and the decision was made then and there to remove the calibrated leak since it was pretty obvious that GMC had done its homework in terms of reliability and distance from the edge of the proverbial cliff. Still, it was a summer to remember . . . and I’m sure there are those around here who still remember getting dusted by a middle-aged guy with a little black whistling pickup truck.

0 Comments